Soap printer

A technology for printers and soaps, applied in the directions of molding soaps, embossed/polished soaps, etc., can solve the problems of unreasonable structure and low working capacity, and achieve the effect of reasonable structure, powerful functions, and reduced installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

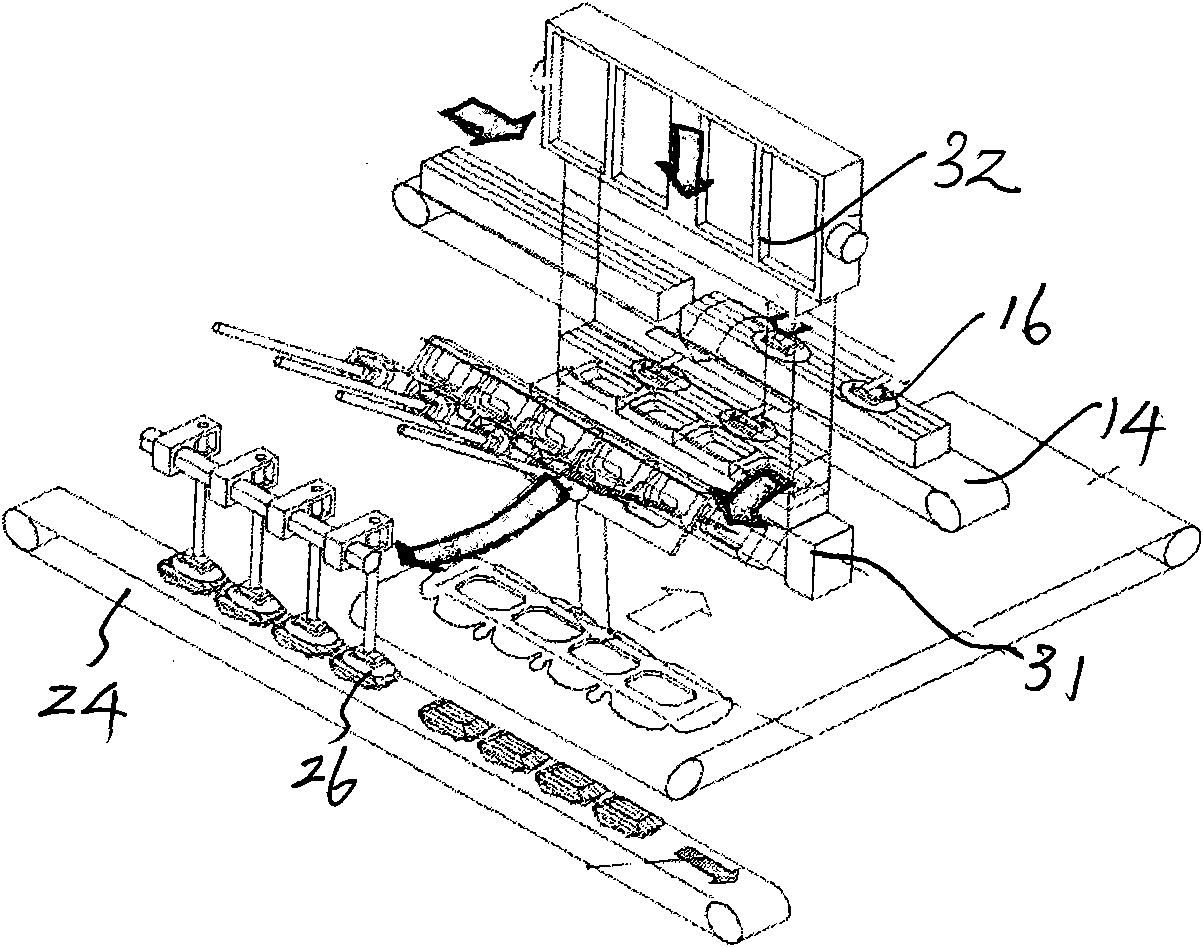

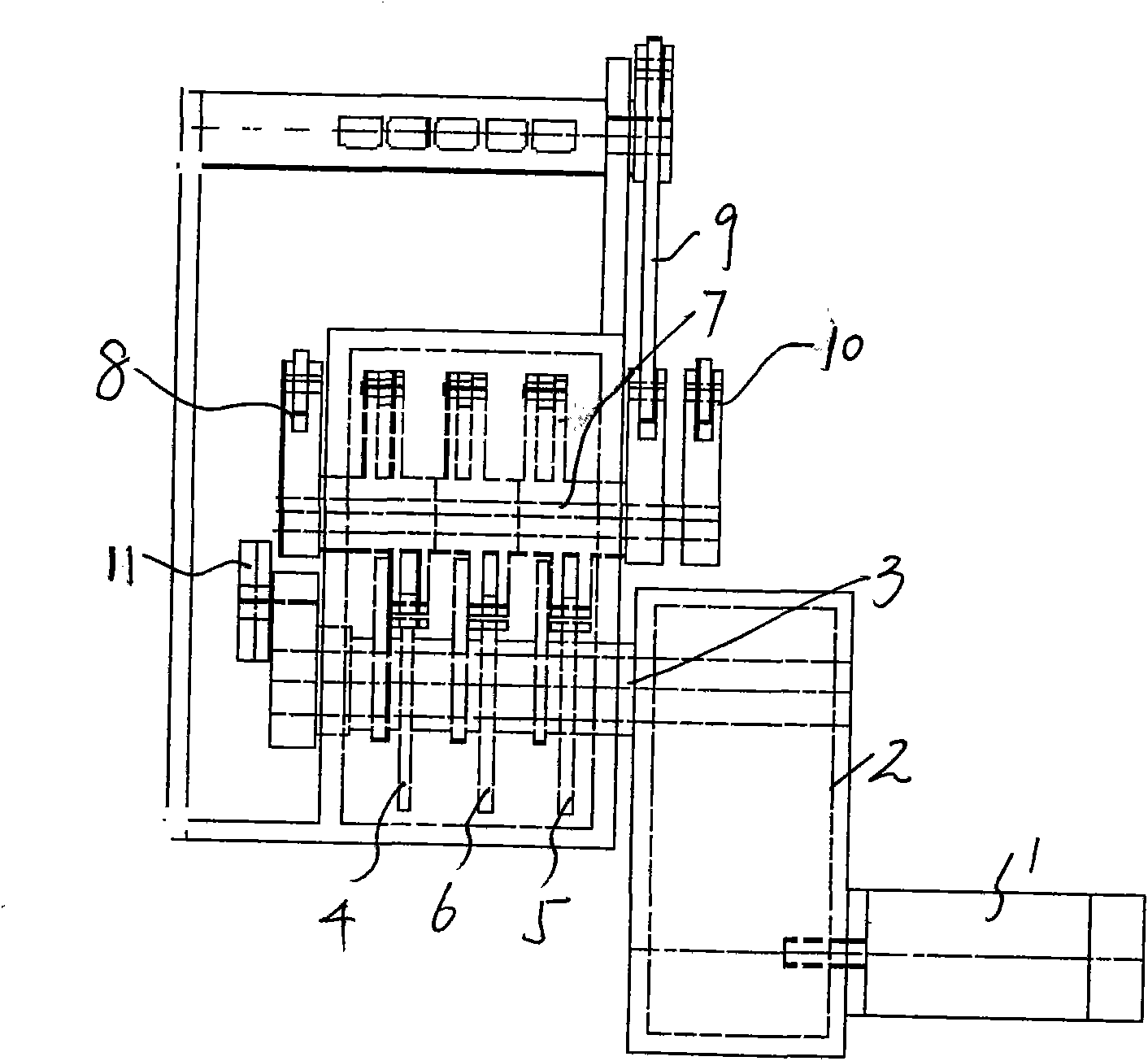

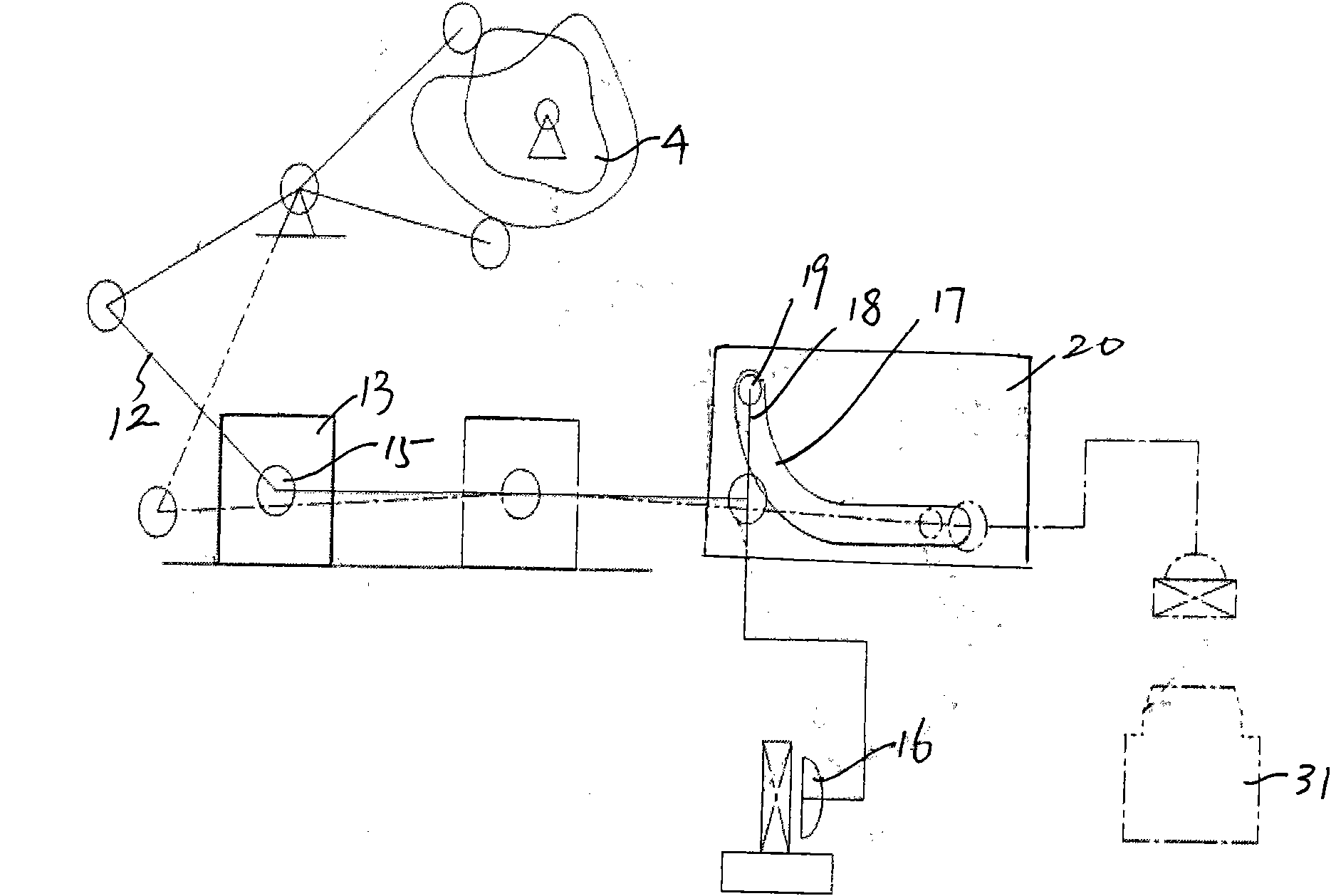

[0014] A soap printer, including a camshaft 3 driven by a motor 1 and a reducer 2. Three sets of conjugate cams are mounted on the camshaft: a soap bar cam 4, a lower die cam 5 and a soap bar cam 6. The soap bar cam passes through a swing bar 7 It is connected with the first crank slider mechanism 8 that drives the movement of the soap bar grabbing and turning mechanism, the lower die cam 5 is connected with the crank linkage mechanism 9 that drives the movement of the lower die turning mechanism through the swing rod, and the soap bar cam 6 is connected with the drive through the swing rod. The second slider crank mechanism 10 that the soap bar grabs and turns over is connected; the third slider crank mechanism 11 that drives the movement of the upper mold is mounted on the camshaft; the first slider crank mechanism includes the first crank connecting rod 12, the second A crank connecting rod is connected with the first sliding seat 13; the soap bar grasping and turning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com