Soap uniform sectioning equipment for production and processing

A technology of cutting and soaping, which is applied in metal processing, cutting soap, etc., can solve problems such as reducing work efficiency, and achieve the effect of increasing moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

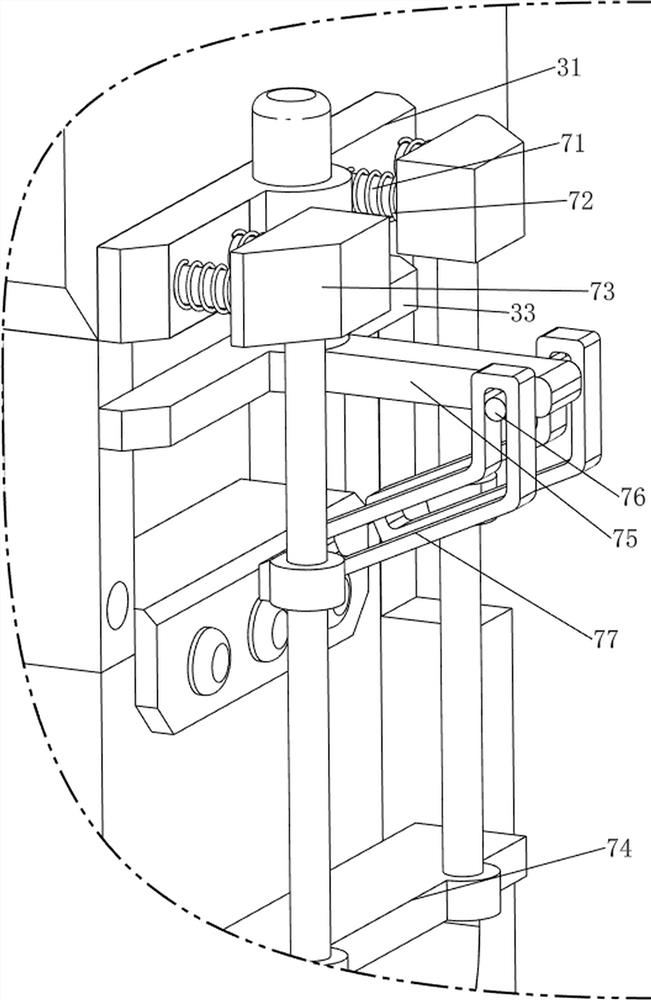

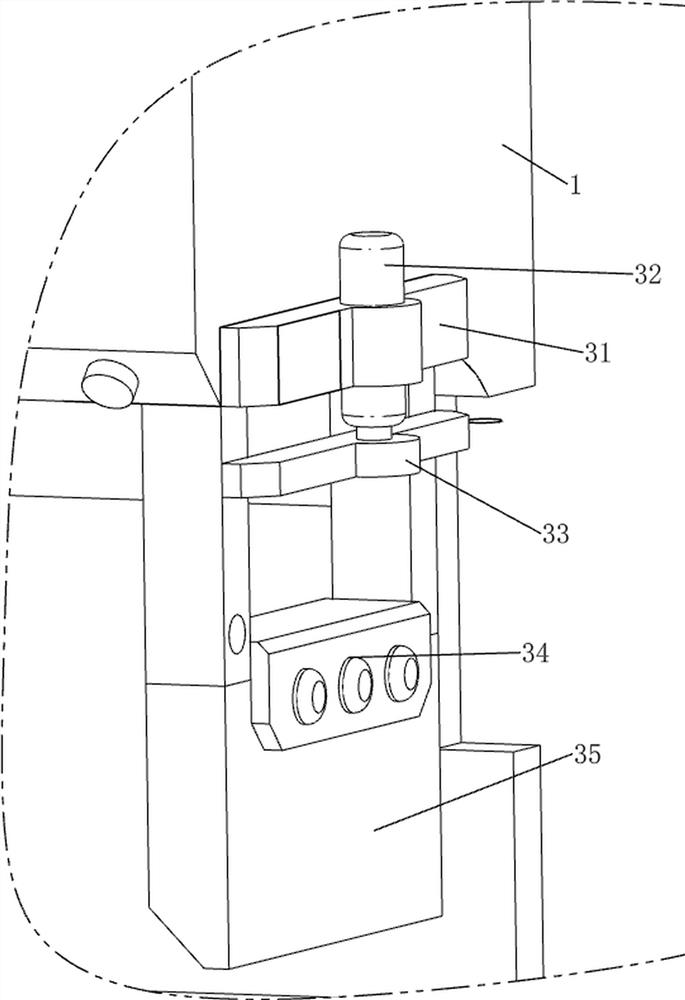

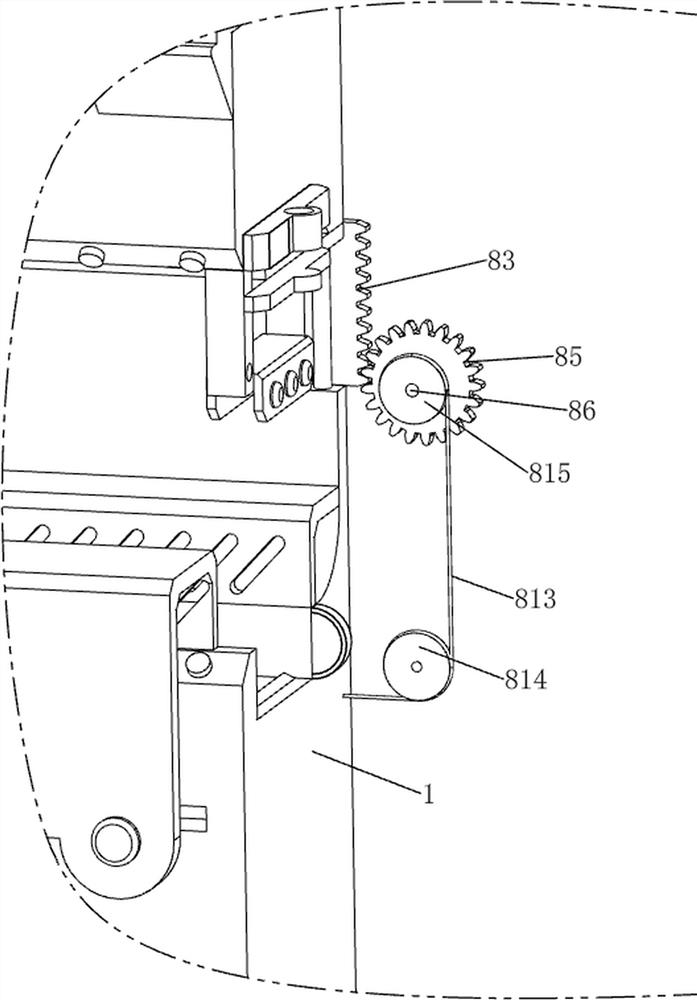

[0033] A device for uniformly cutting soap for production and processing, such as Figure 1-5 As shown, it includes an outer casing 1, a card seat 2, a cutting mechanism 3 and a transmission mechanism 4. The lower right side of the outer casing 1 is provided with a clamping seat 2 through bolts, the outer casing 1 is provided with a cutting mechanism 3, and the outer casing 1 is provided with a transmission mechanism 4 , the conveying mechanism 4 is used for conveying soap. The cutting mechanism 3 includes a first fixing block 31, an electric push rod 32, a push frame 33, a tool holder 34 and a cutter 35. The upper right side of the housing 1 is provided with a first fixing block 31 through bolts, and the middle of the first fixing block 31 is provided with The electric push rod 32, the bottom of the telescopic rod of the electric push rod 32 is welded with a push frame 33, the telescopic rod of the electric push rod 32 can drive the push frame 33 to move up and down, the push...

Embodiment 2

[0037] On the basis of Example 1, as figure 1 , figure 2 and Image 6 As shown, a collection mechanism 5 is also included. The collection mechanism 5 includes a mounting plate 51, a first motorized roller 52, a second motorized roller 53 and a collection frame 54. A collection frame 54 is placed on the right side of the card holder 2. The collection frame 54 uses For collecting soap, a mounting plate 51 is provided between the right side of the housing 1 and the left side of the collecting frame 54. The mounting plate 51 is inclined at a high left and a low right, so that the soap after being cut off slides to the right to the collecting frame 54. Before the mounting plate 51 There are 9 first electric rollers 52 connected evenly at the back of the mounting plate 51, the first electric rollers 52 are arranged in the direction of the right rear, and the rear part of the mounting plate 51 is evenly connected with three second electric rollers 53, the second electric rollers 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com