Electrical control device and method of four-knife roll printing dicer

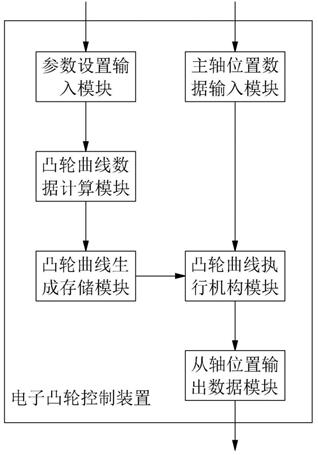

A technology of electrical control device and cutting machine, which is applied in the direction of electrical program control, digital control, program control, etc., can solve problems such as inability to meet product requirements, achieve stable cutting speed, small impact, and protect the mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

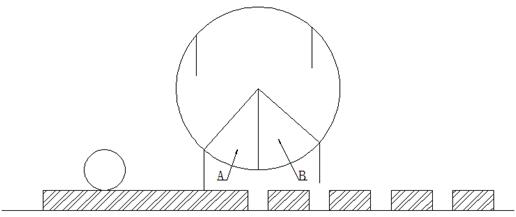

[0060] Establish the radius R=80 of cutter disc, cut the length L=100 of soap, the thickness H=20 of soap, calculate θ=arccos ((80-20) / 80)=0.723 according to the step in the above control method, Convert radians to degrees and round to 42°.

[0061] Figure 5 A total of 44 sets of data are calculated, Image 6 It is the cam curve position relationship diagram drawn based on the calculated 44 sets of data. Depend on Image 6 It can be seen that the curve formed by the densely packed points in the previous section is the curve of the synchronous interval, and the curve will be smoother after data optimization by the "cubic curve" of PLC; the straight line in the latter section is the evacuation zone curve, and the speed of the evacuation zone is obviously faster The speed in the synchronous area, so that the cutting knife will not block the movement of the material, which meets the working requirements of the four-knife roller printing and cutting machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com