Cam connecting rod mechanism of soap dicer

A cam link and cam mechanism technology, applied in the direction of cutting soap, etc., can solve the problems of increasing the production cost of the enterprise, poor verticality, and the appearance of soap is not very neat, etc., and achieve the effect of accurate weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

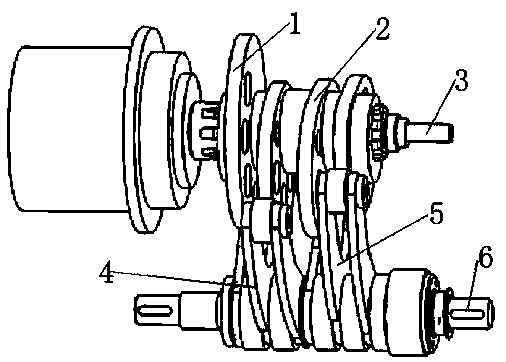

[0022] Such as figure 1 As shown, the cam mechanism is composed of: a driving cam 1, a driven cam 2, a camshaft 3, a driving swing link 4, a driven swing link 5 and a swing link shaft 6. The active cam 1 and the driven cam 2 are installed on the camshaft 3, and are fixed by spline connection. The spline connection can transmit large torque while the whole mechanism moves without gap, which can realize accurate transmission. The drive cam 1 and the driven cam 2 is a conjugate cam group, which means that the active cam 1 has a pair, and the driven cam 2 also has a pair. The conjugate cam structure is adopted, which can realize the precise movement of the mechanism, no gap, and no empty position, which ensures the gram of soap Heavy. The active fork 4 and the driven fork 5 are also fixed on the fork shaft 6 , the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com