Novel processing device for manufacturing of fragrant soap

A processing equipment and a new type of technology, applied in the direction of molding soap, cutting soap, etc., can solve the problems of low automation, slow production speed, and defective product quality, so as to save the use of human resources, improve production efficiency, and reduce defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

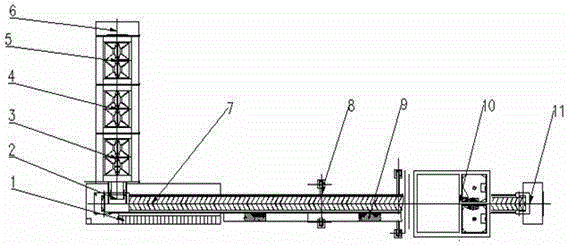

[0016] Such as Figure 1-Figure 2 As shown, a new type of processing equipment for making toilet soap includes a support platform 1, a forming chamber 3, a conveyor belt 7 and a packaging room 10. The support platform 1 can support the entire equipment to make the equipment stable and integrated. There is a soap outlet pipe 2, which can send out shaped scented soap. The forming chamber 3 is connected above the soap outlet pipe 2, and the soap can be shaped. The above forming chamber 3 is connected with a solidification chamber 4, which can mix materials To solidify, the top of the coagulation chamber 4 is connected with a mixing box 5, which can evenly mix the ingredients. The upper end of the mixing box 5 is provided with a feed pipe 6, which can be fed into the ingredients required for the soap. The above support platform 1 supports There is the conveyor belt 7, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com