Patents

Literature

222results about How to "Reduce blemishes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

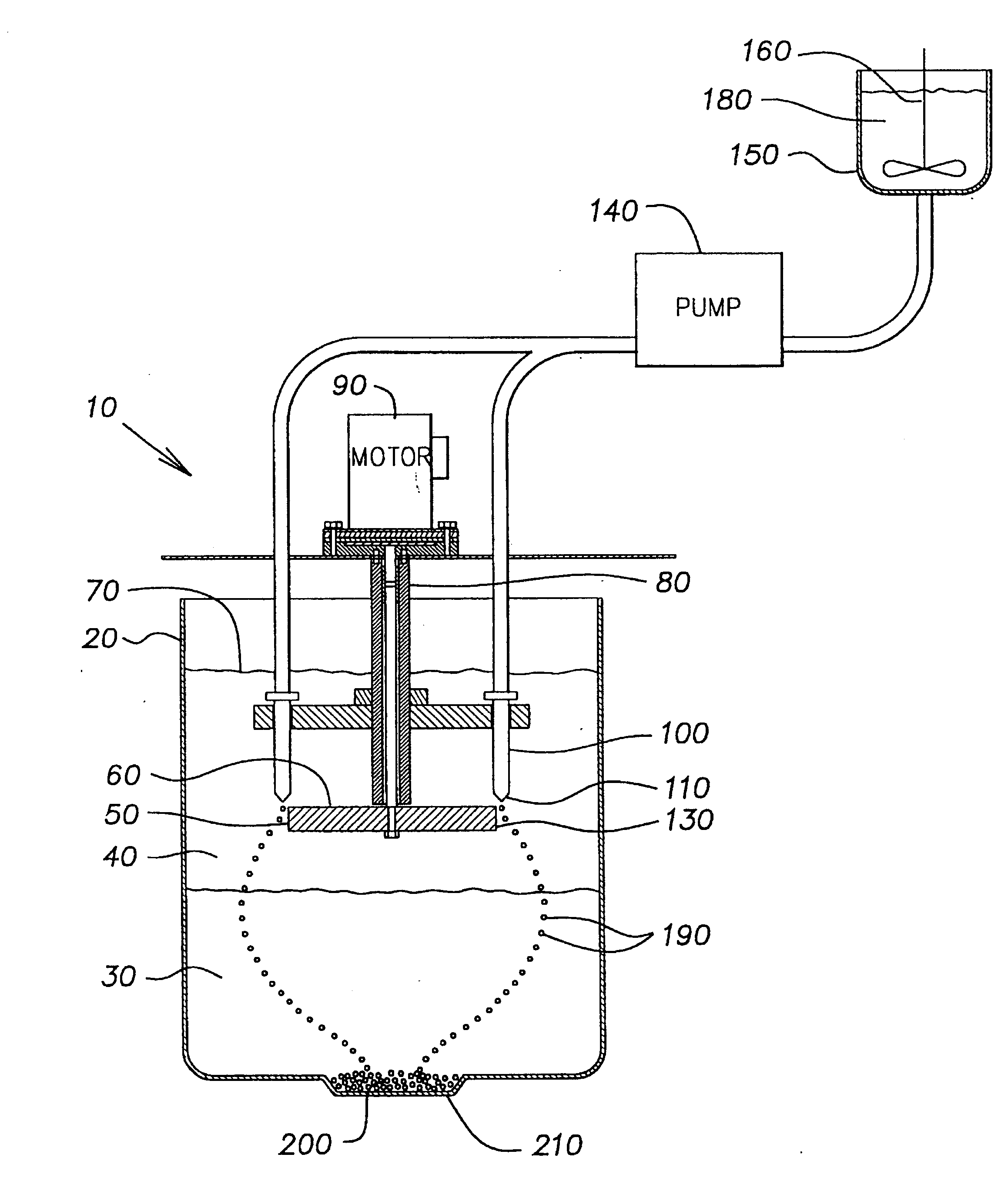

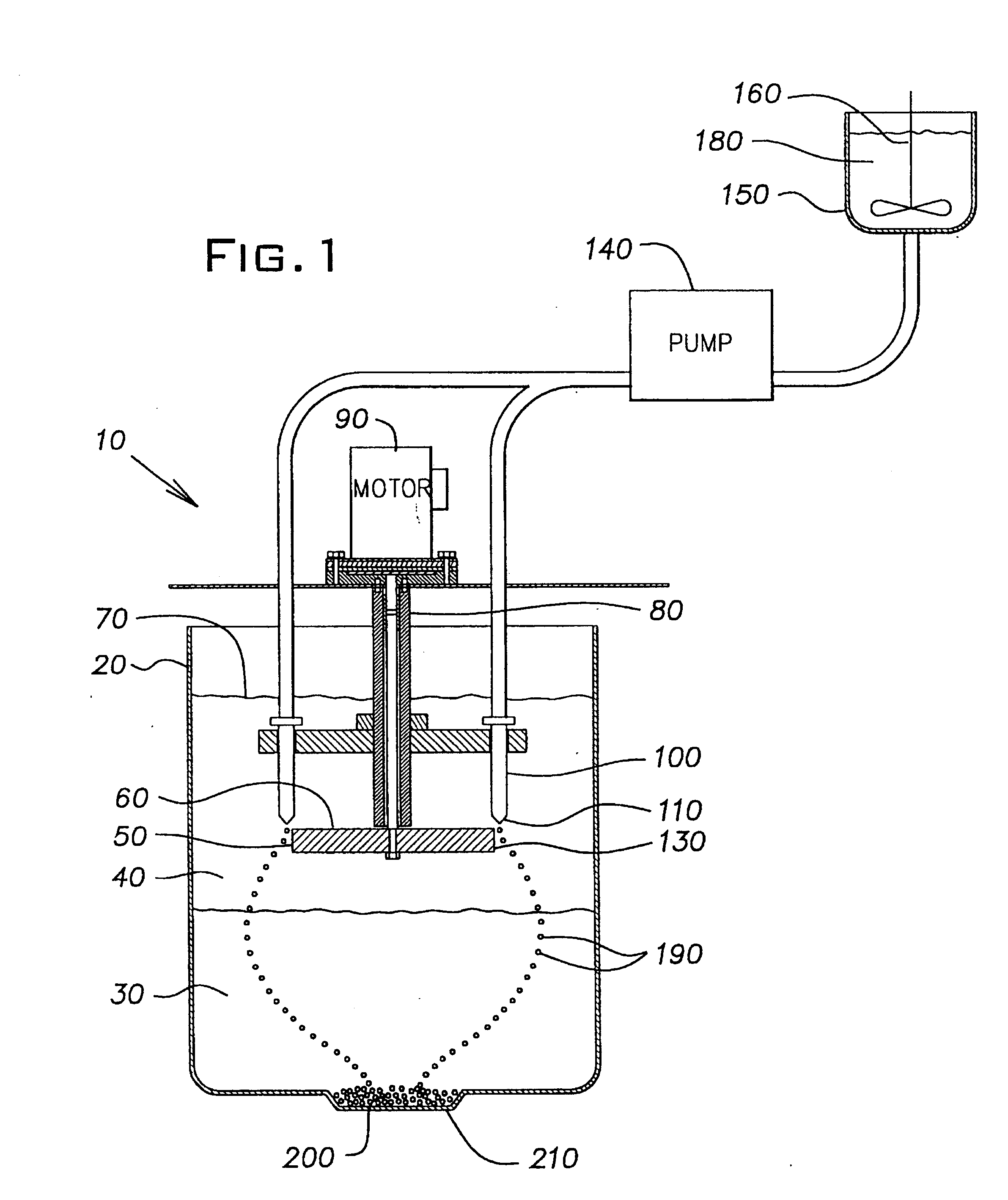

Method of forming ceramic beads

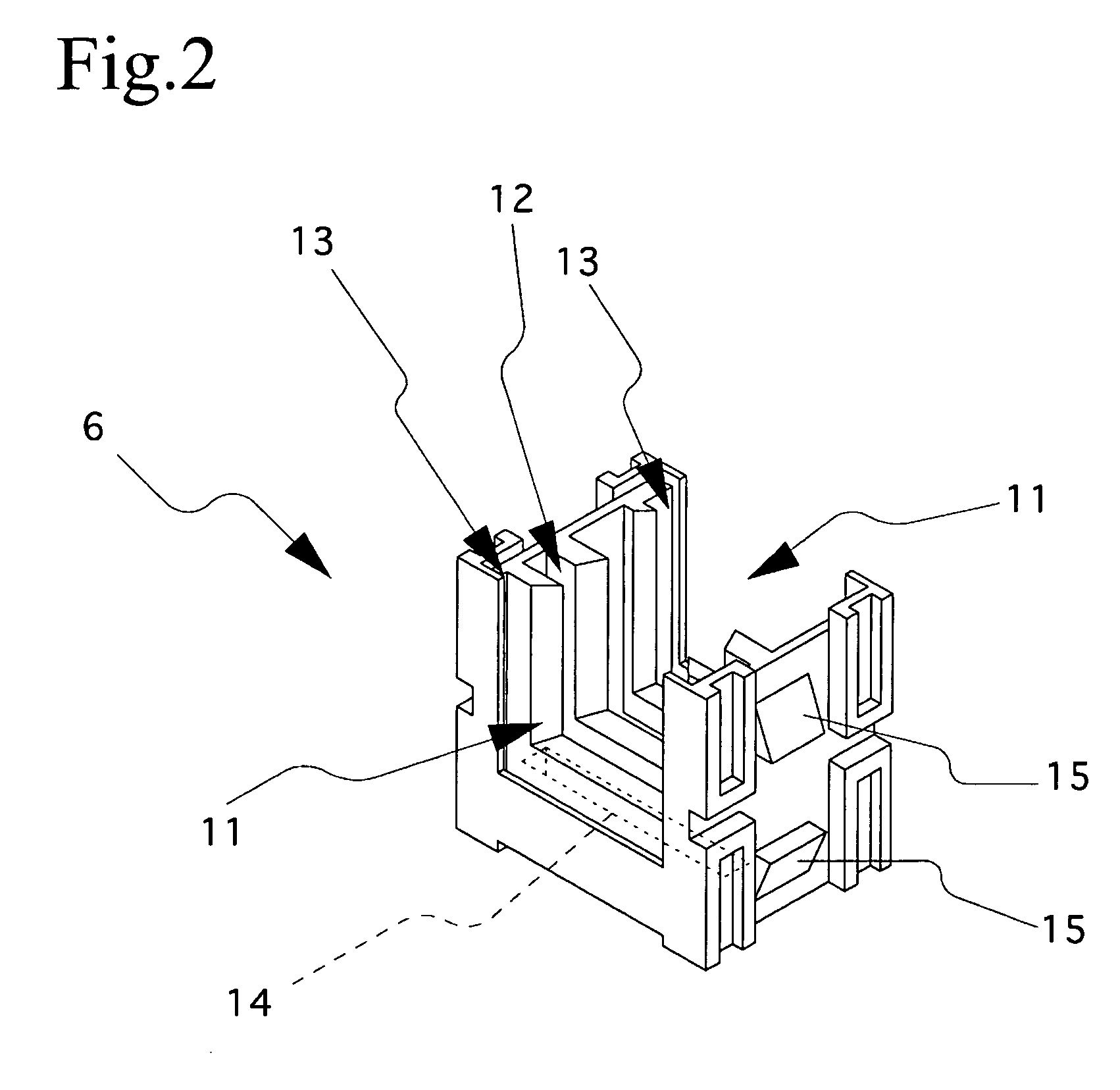

InactiveUS20040007789A1Reduce blemishesGood dispersionGranulation by liquid drop formationCeramic shaping apparatusMetallurgyFluid layer

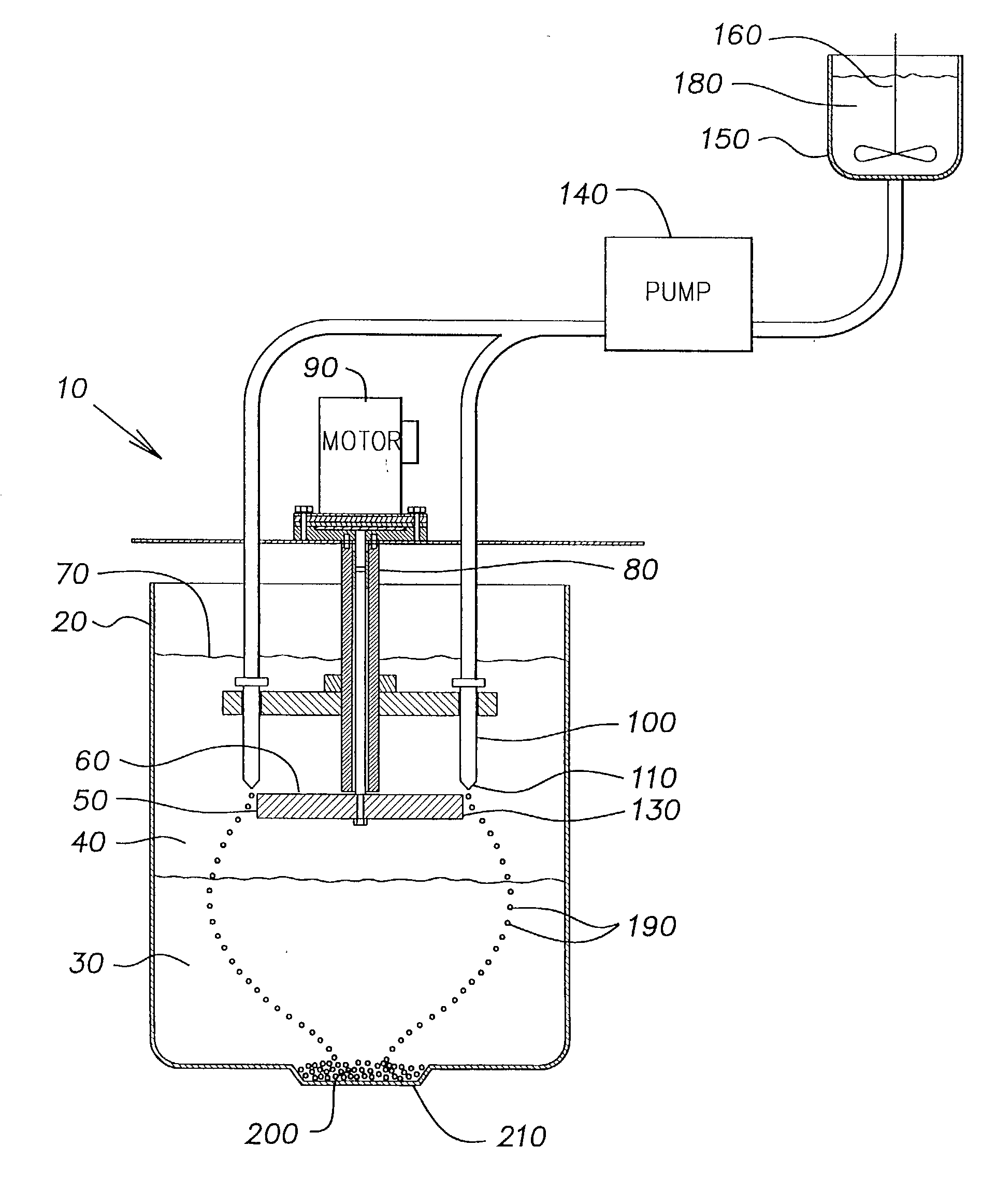

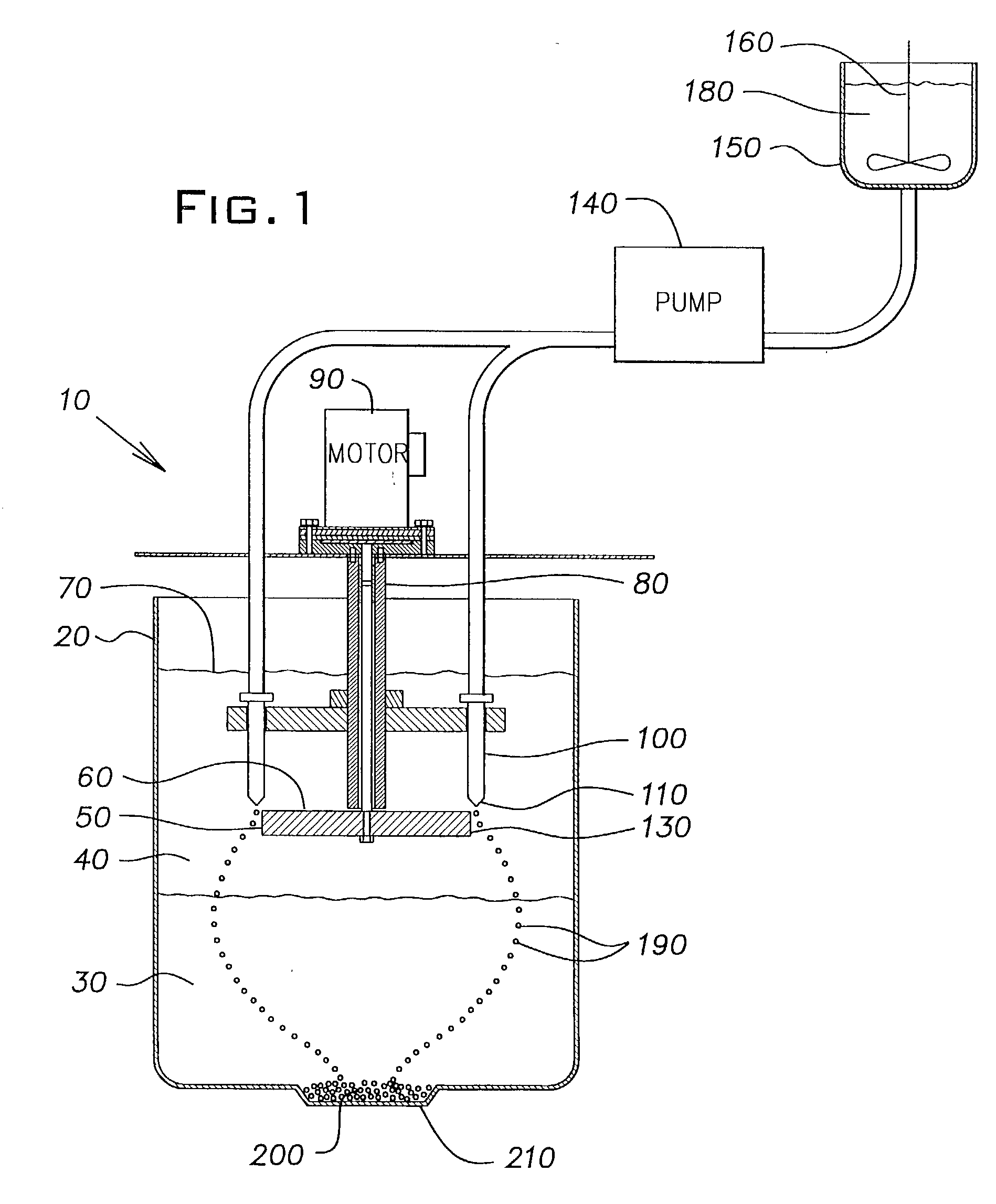

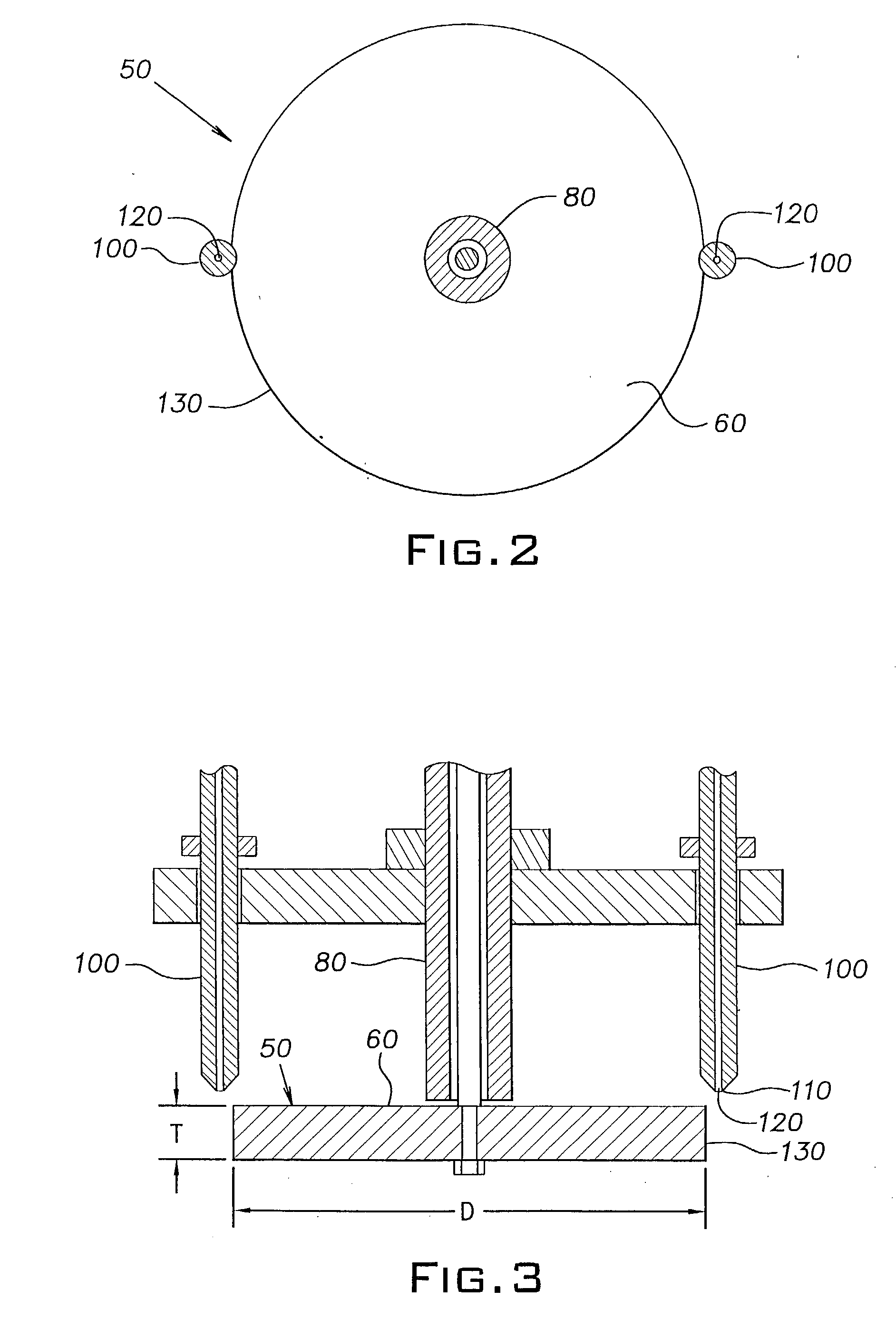

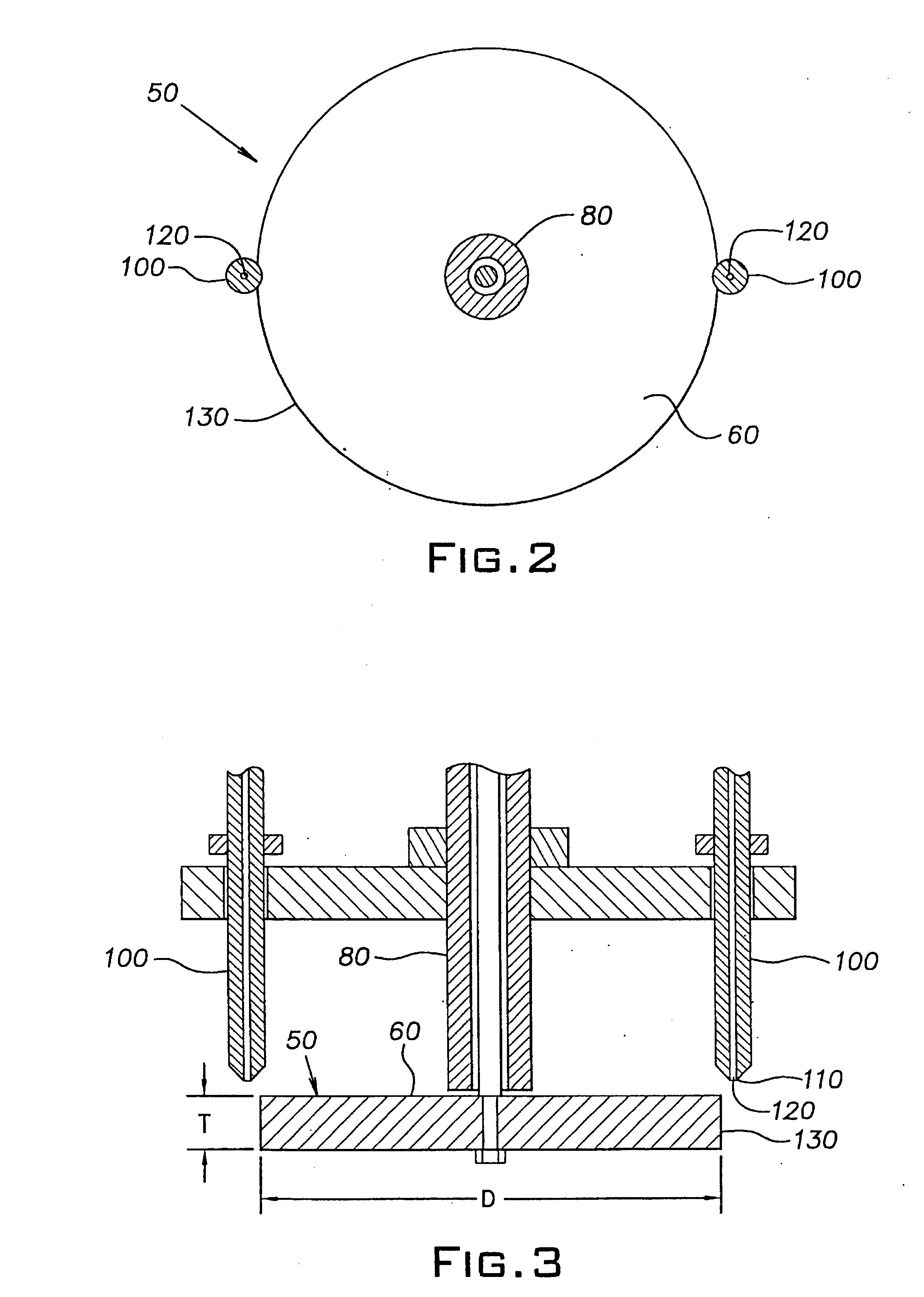

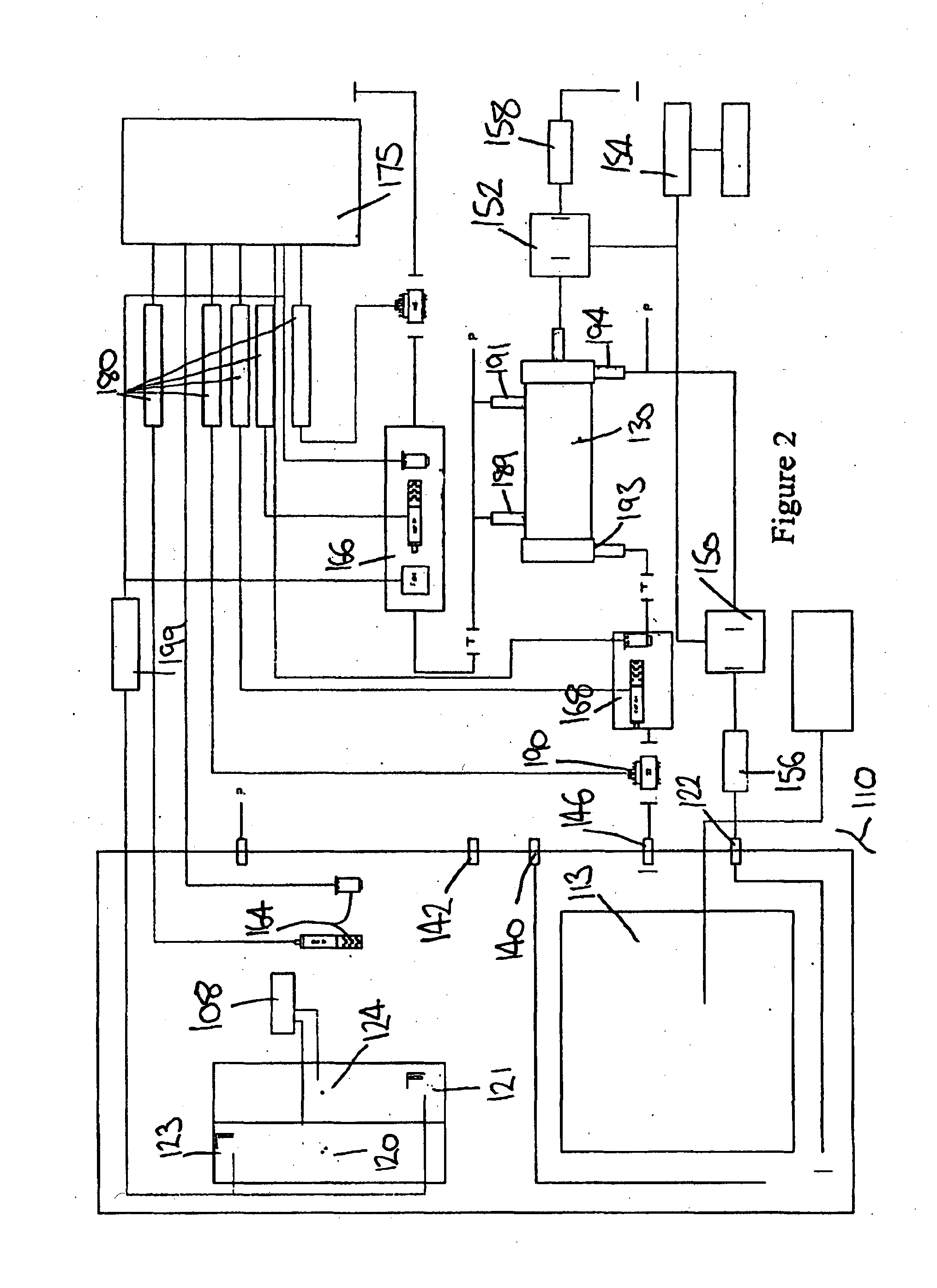

A method of forming substantially spherical ceramic beads that includes conveying an aqueous ceramic slurry to a nozzle tip that is immersed in an inert water-immiscible fluid layer. The nozzle tip is spaced a predetermined distance away from a rotating disk that is also immersed in the immiscible fluid layer. The rotating disk creates a shear force that at the nozzle tip that dislodges droplets of the aqueous ceramic slurry from the nozzle tip into the immiscible fluid layer. Once dislodged, the droplets assume a substantially spherical shape and a substantially mono-modal size distribution. The droplets are permitted to pass from the immiscible fluid layer into an aqueous gelling solution wherein the droplets are converted into rigid beads. In a preferred embodiment of the invention, the rigid beads are recovered from the gelling solution, washed, and then sintered to obtain a density of greater than about 98% of theoretical density and a sphericity of greater than about 0.95. The method can be used to fabricate substantially spherical zirconia-containing beads having a diameter within the range of from about 0.1 mm to about 2.0 mm that are useful, for example, as grinding media.

Owner:CERCO

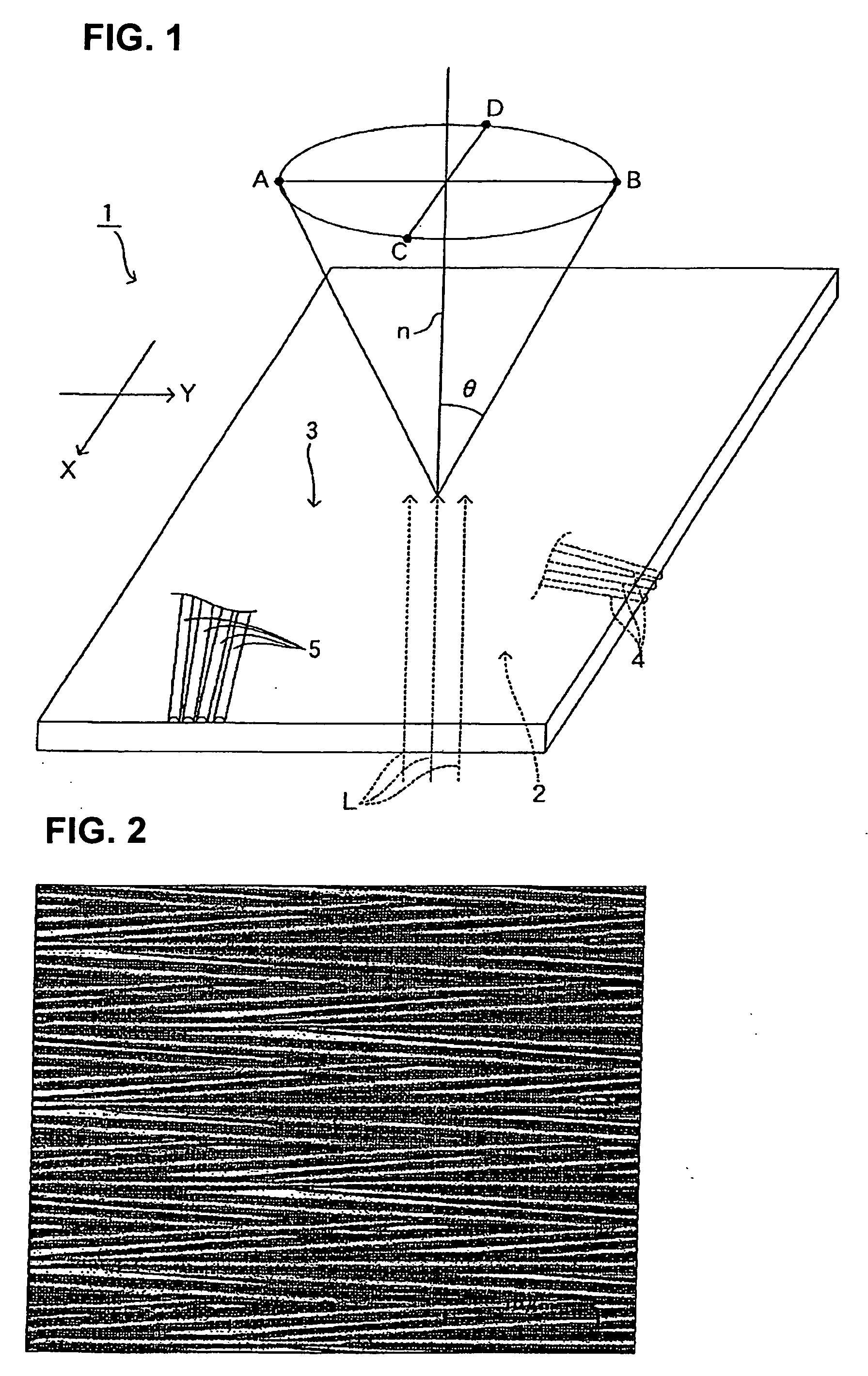

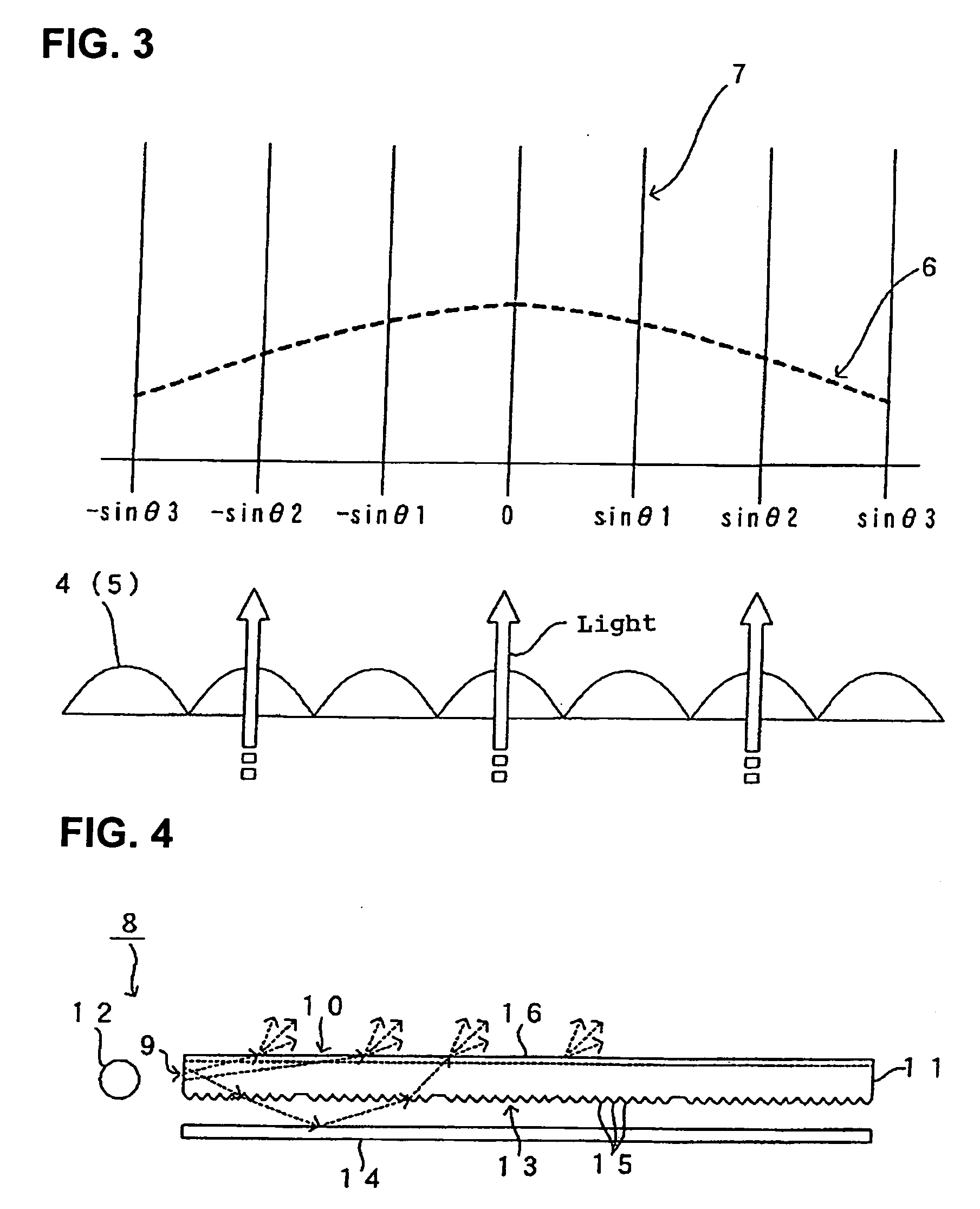

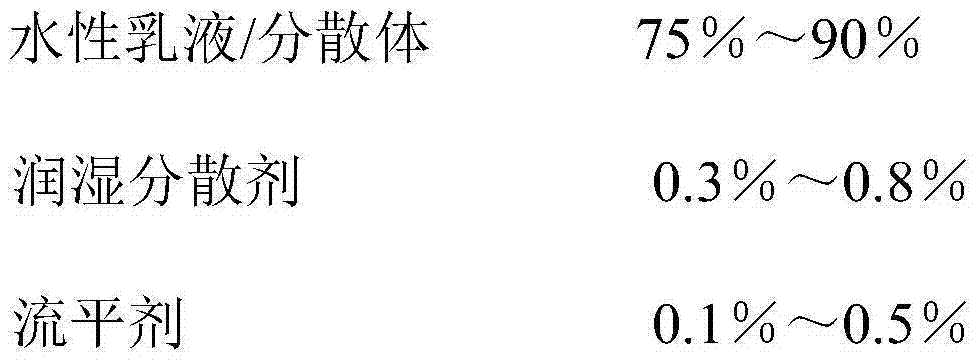

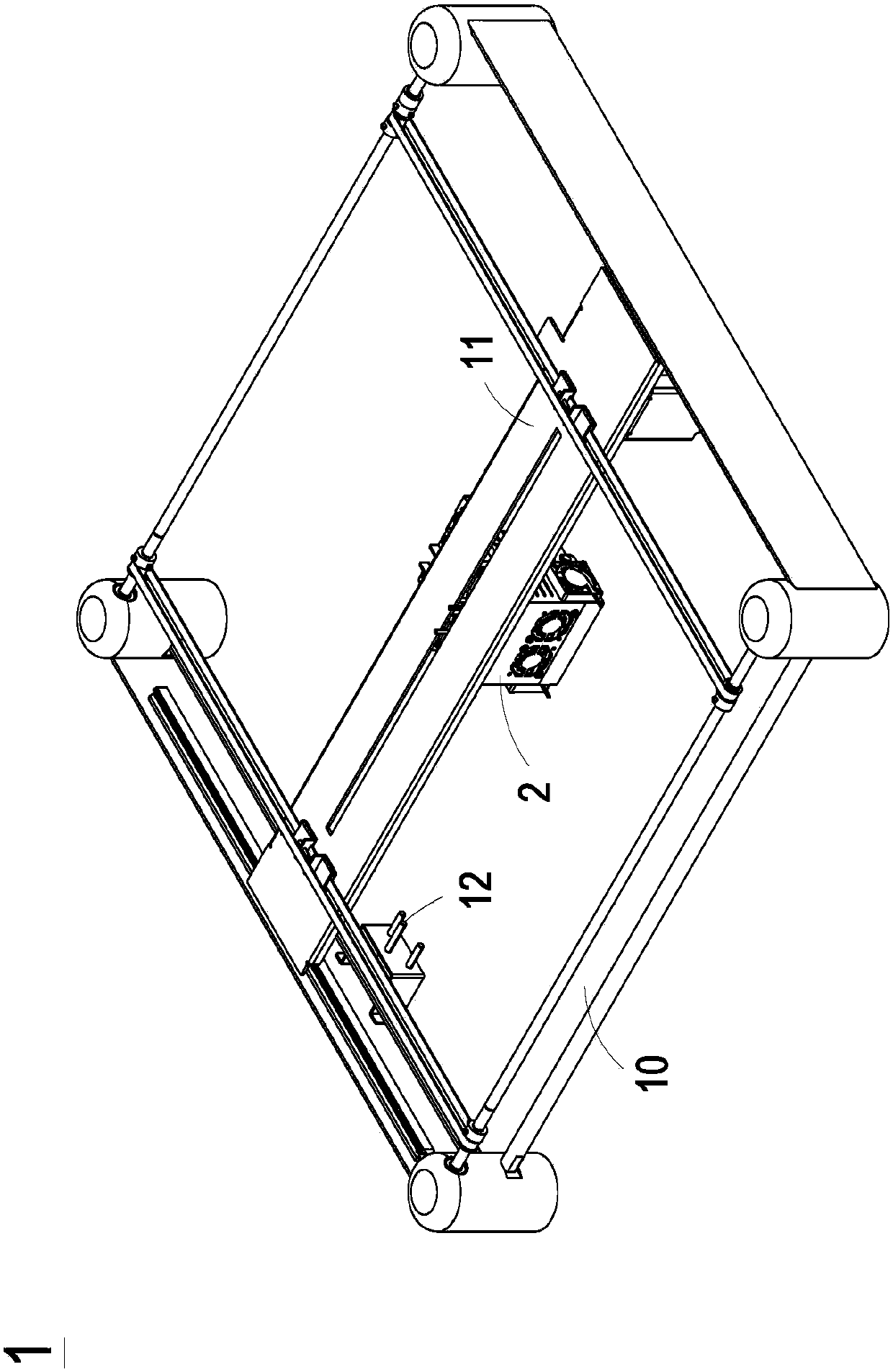

Optical Component and Backlight Unit Using the Optical Component

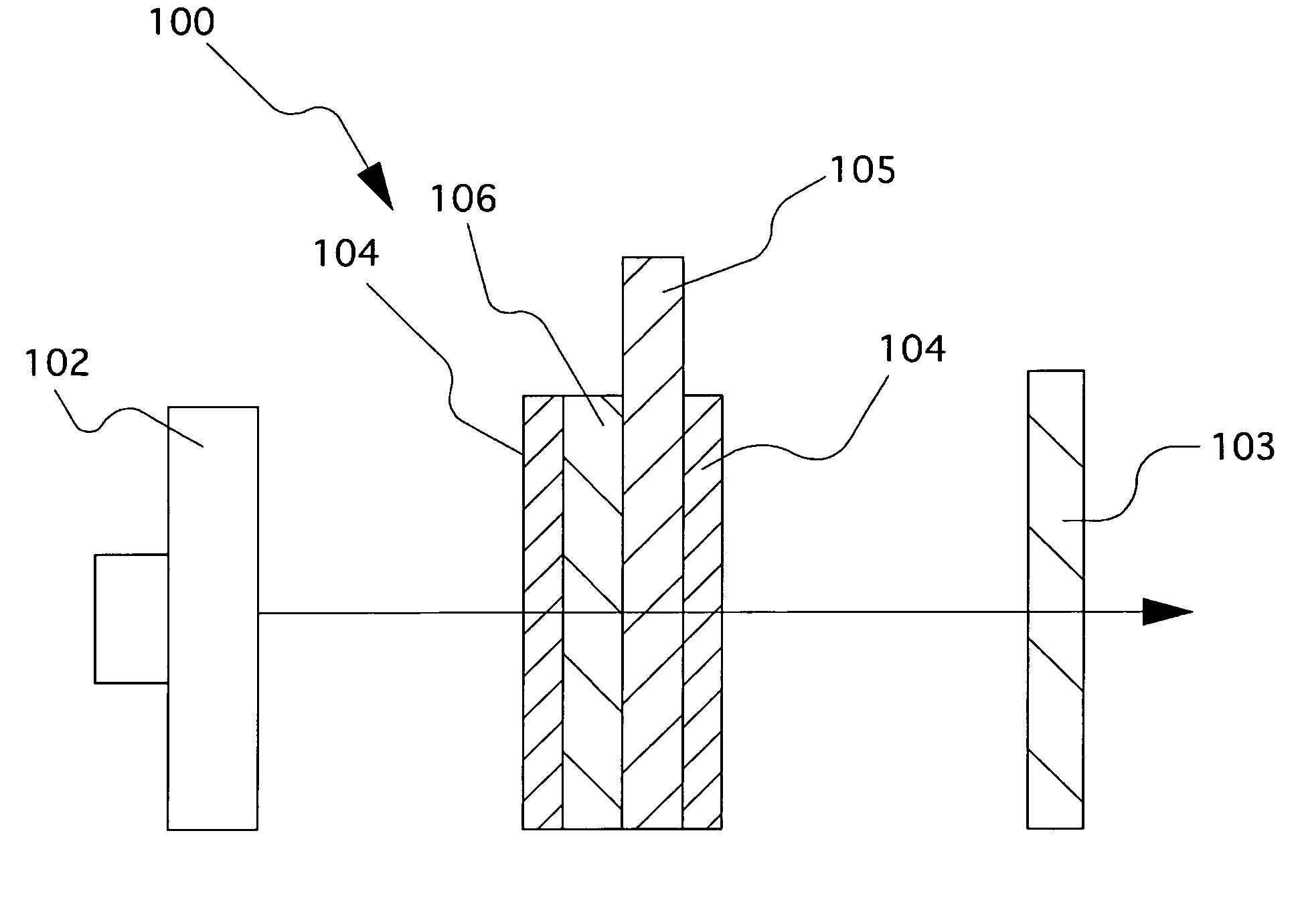

InactiveUS20070285941A1Wide viewing angleExcellent light diffusionPrismsMechanical apparatusHigh intensityPlane of incidence

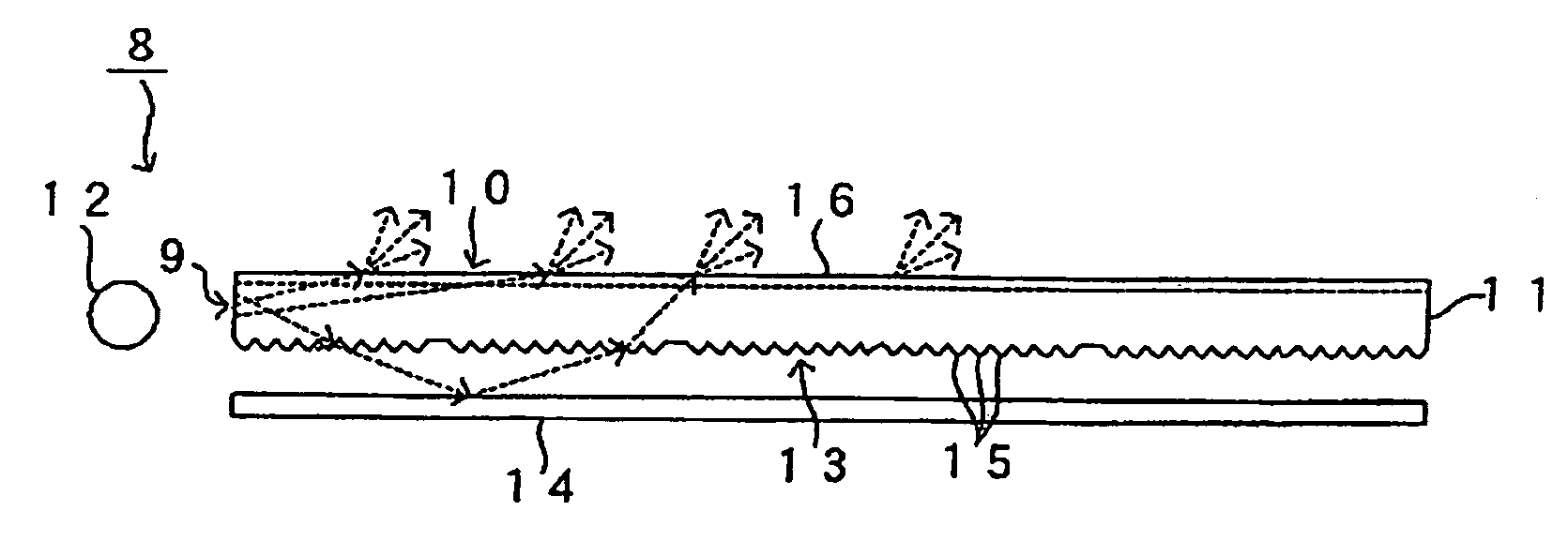

[PROBLEMS] An optical component in which the viewing angle can be widened while sustaining a high luminance and the defect of a display can be made inconspicuous, and a backlight employing the optical component. [MEANS FOR SOLVING PROBLEMS] When a substantially collimated light impinges on the plane of incidence (9), an outgoing light from the outgoing plane (10) exhibits anisotropy in its intensity along an azimuth of 30° to normal to the outgoing plane (10), the anisotropy being such that the ratio between a highest intensity and a lowest intensity in the intensity distribution of outgoing light intensity along the azimuth of 30° is set to not smaller than 1.2.

Owner:SAKARI +1

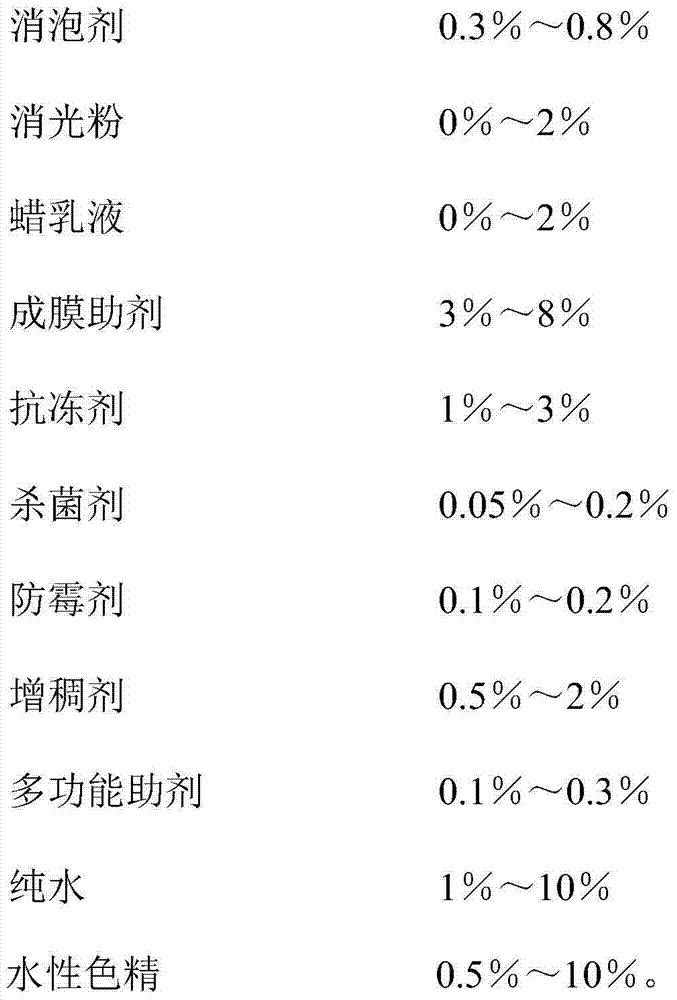

Water-based transparent colored paint for wooden ware and preparation method of paint

ActiveCN103881502AGood yellowing resistanceHigh gloss retentionAntifouling/underwater paintsPaints with biocidesWaxWater based

The invention discloses a water-based transparent colored paint for wooden ware and a preparation method of the paint. The water-based transparent colored paint is applied to decoration of the surface of a wood material (cabinets, tables, chairs, chair rails and the like). The water-based transparent colored paint comprises components including water-based emulsion / dispersoid, a water-based color concentrate, pure water, a film forming aid, a wetting dispersant, a foam killer, a flatting agent, a bactericide, a mildew preventive, an anti-freezing agent, a thickening agent, a multi-functional additive, a matting agent and wax emulsion. The water-based transparent colored paint for the wooden ware is bright in color and clear in texture and has the effects of greatly reducing the content of VOC, guaranteeing the application performance of the product and realizing the environmental protection characteristics of the product.

Owner:NIPPON PAINT YASHILI

Molding sand and preparation method thereof

InactiveCN103521681AGood collapsibilityImprove adhesionFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention discloses molding sand. The molding sand is characterized by being prepared from the following materials in parts by weight: 200-240 parts of quartz sand, 30-35 parts of sericite, 60-70 parts of kaolin, 30-40 parts of calcium carbonate, 10-15 parts of coke powder, 10-15 parts of clays, 2-4 parts of titanium dioxide, 4-5 parts of aluminum oxide powder, 20-30 parts of argil, 3-4 parts of asphalt, 10-15 parts of bentonite, 3-4 parts of ammonium dihydrogen phosphate, 4-5 parts of sodium metasilicate, 2-3 parts of sodium dodecyl benzene sulfonate and an appropriate amount of water. According to the invention, the quartz sand, the sericite and the kaolin are used and roasted to achieve abundant pores and good gas permeability, moreover, mobility is good, and grinding of added calcium carbonate, clay, titanium dioxide, asphalt, and the like is combined, so that the molding sand has excellent cohesiveness, plasticity and heat stability, and also has high collapsibility. The molding sand material disclosed by the invention is fine and uniform; a casting piece produced by the molding sand has a smooth surface and a few flaws.

Owner:HEFEI CITY TENVER PRECISION CASTING

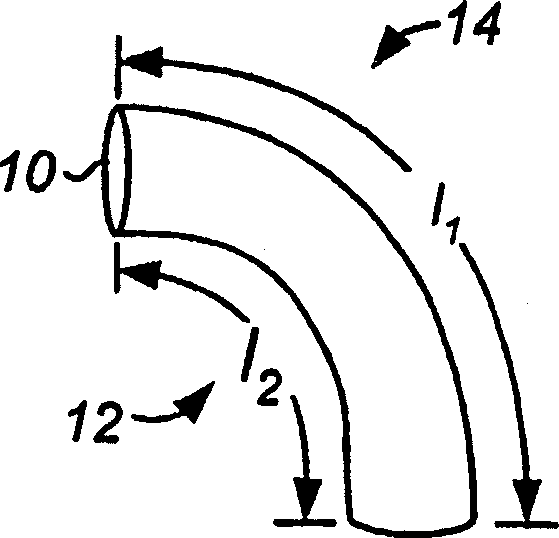

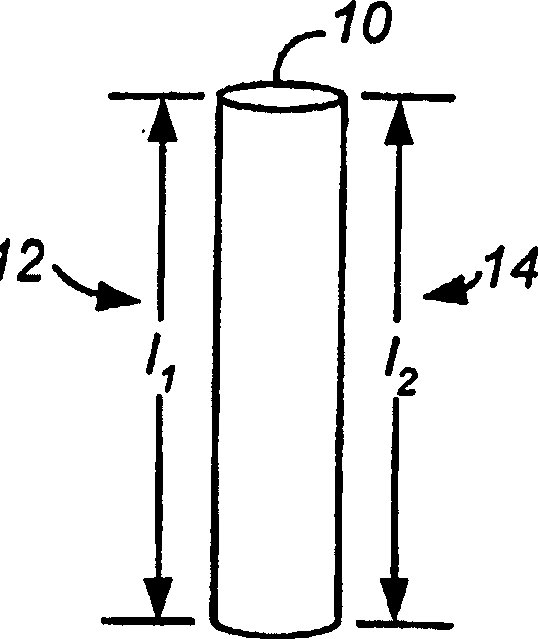

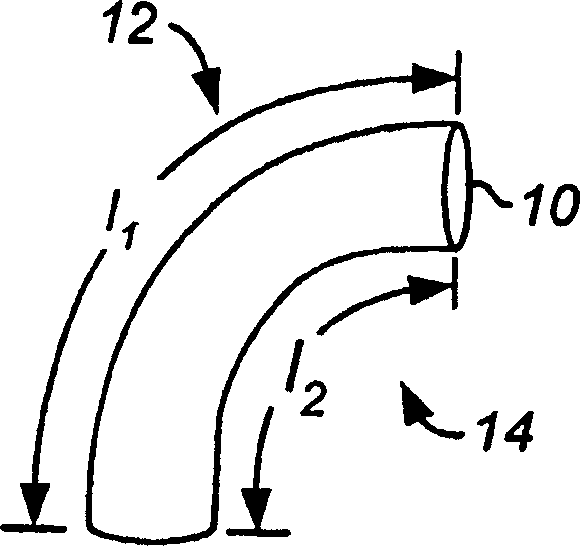

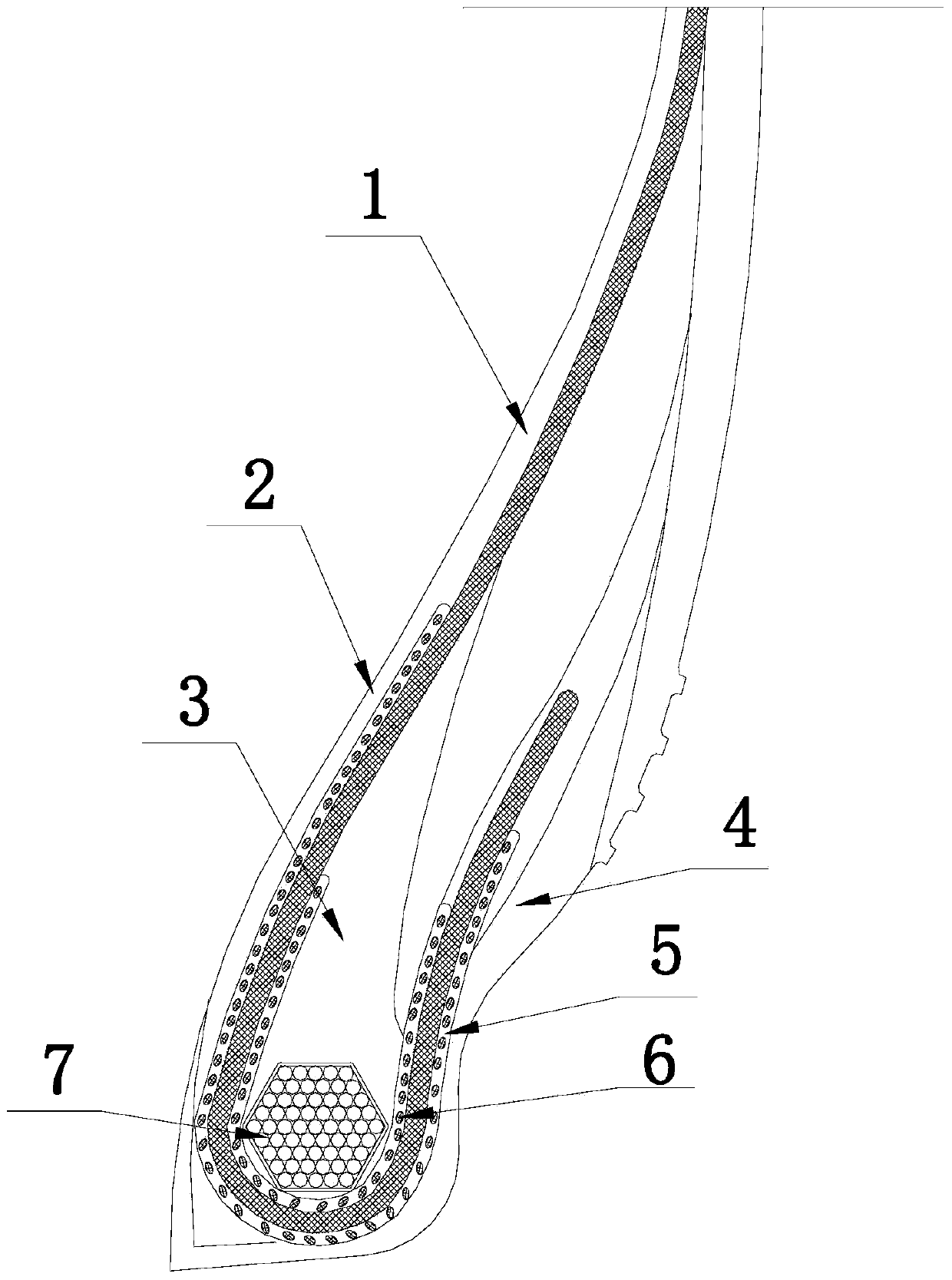

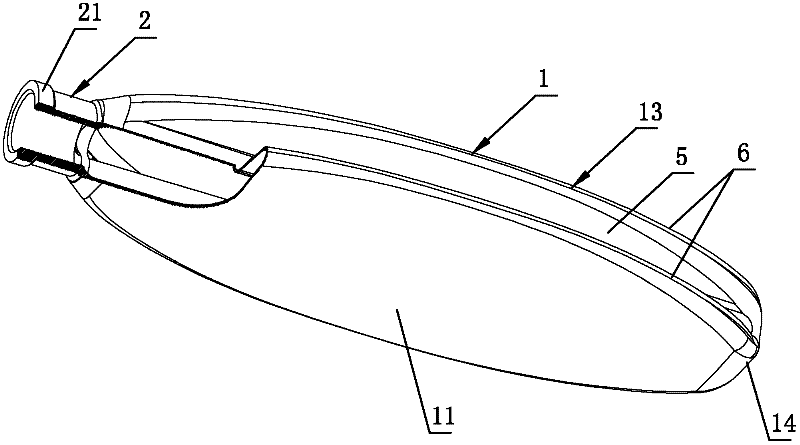

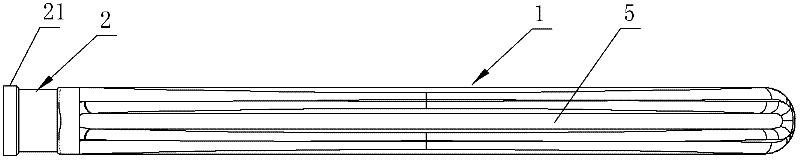

Activated polymer articulated instruments and methods of insertion

InactiveCN1870930AReduce blemishesReduce sensitivityEndoscopesRectum colonoscopesElectricityAutomatic control

An electro-polymeric articulated endoscope and method of insertion are described herein. A steerable endoscope having a segmented, elongated body with a manually or selectively steerable distal portion and an automatically controlled proximal portion can be articulated by electro-polymeric materials. These materials are configured to mechanically contract or expand in the presence of a stimulus, such as an electrical field. Adjacent segments of the endoscope can be articulated using the electro-polymeric material by inducing relative differences in size or length of the material when placed near or around the outer periphery along a portion of the endoscope.

Owner:NEOGUIDE SYST

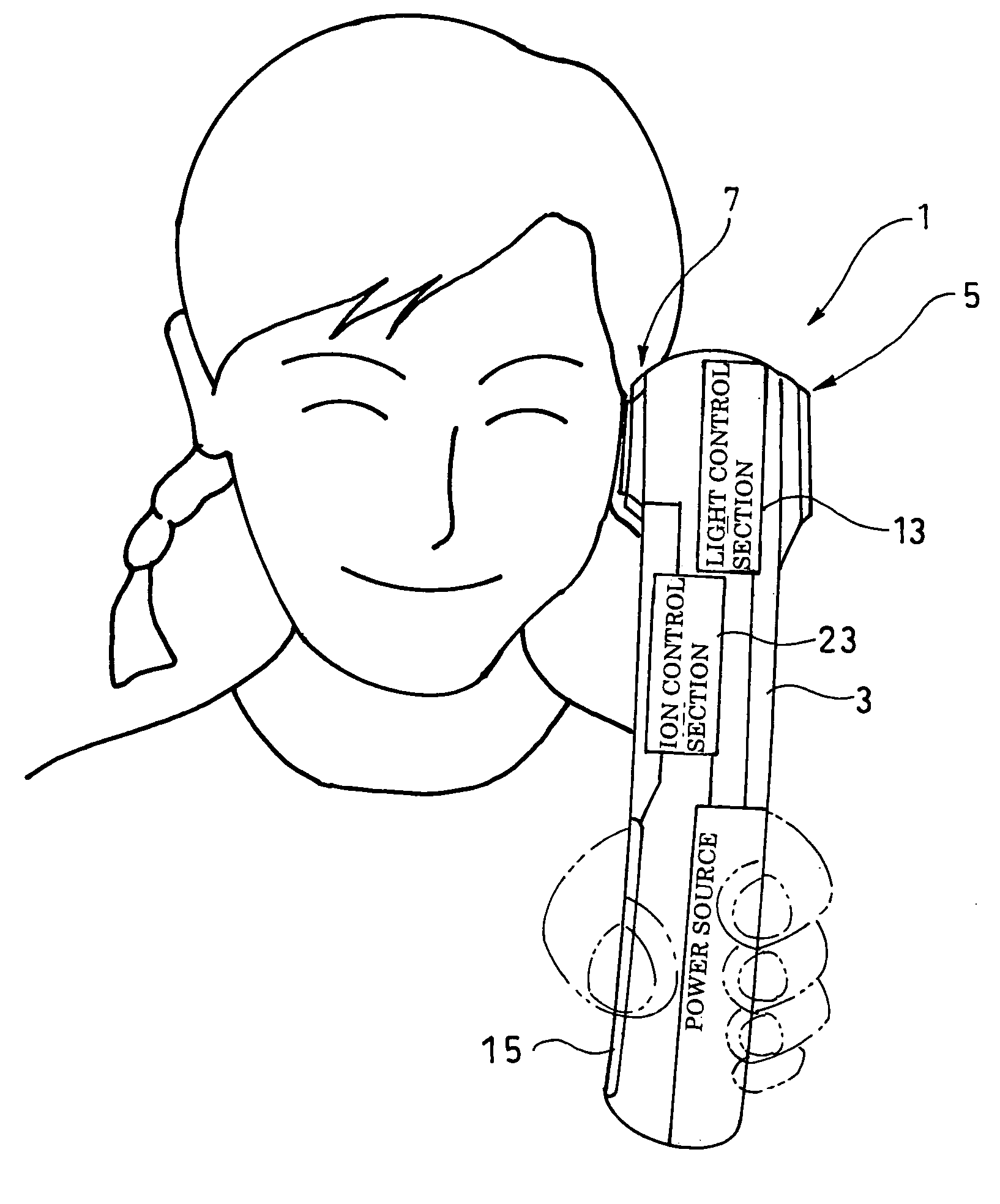

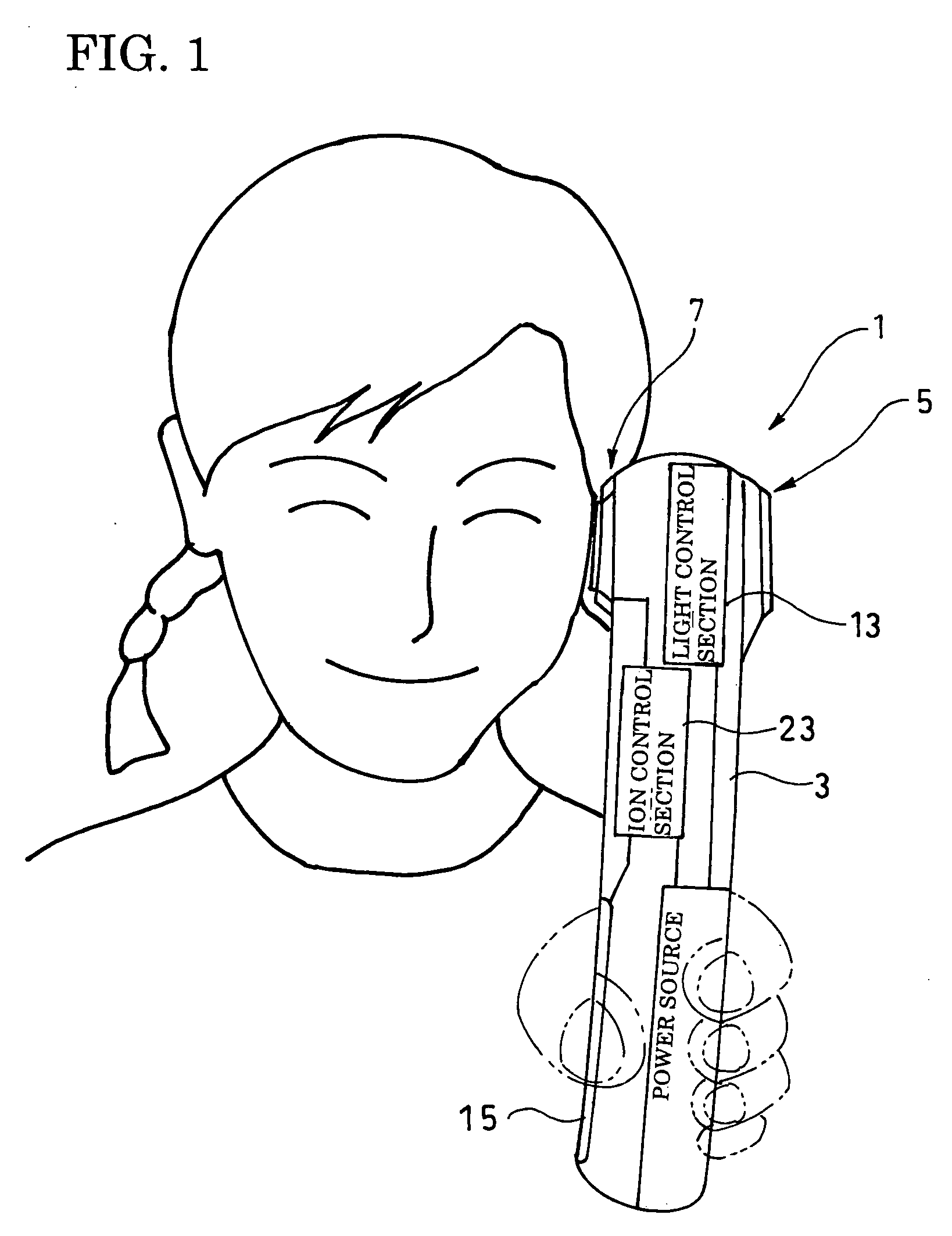

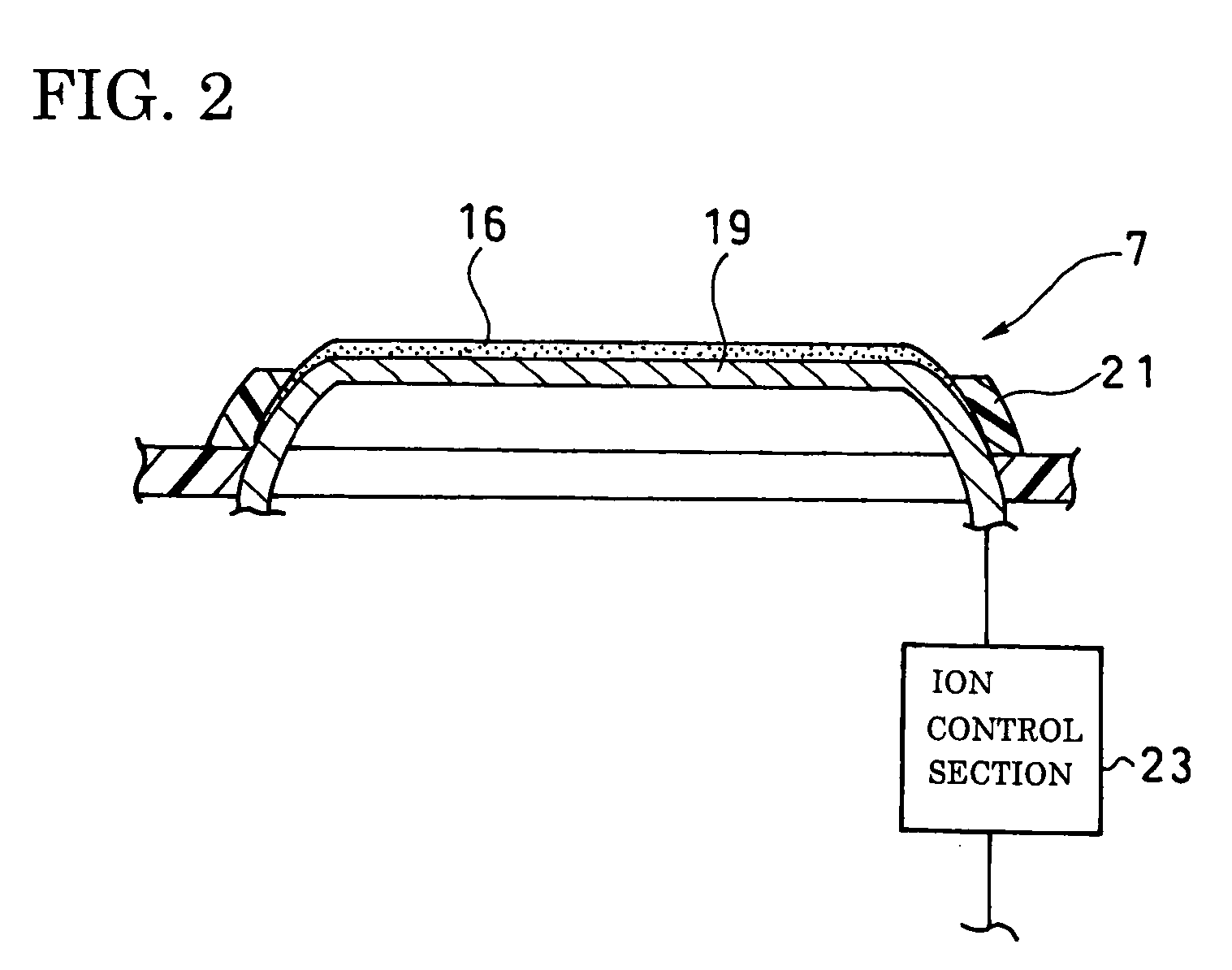

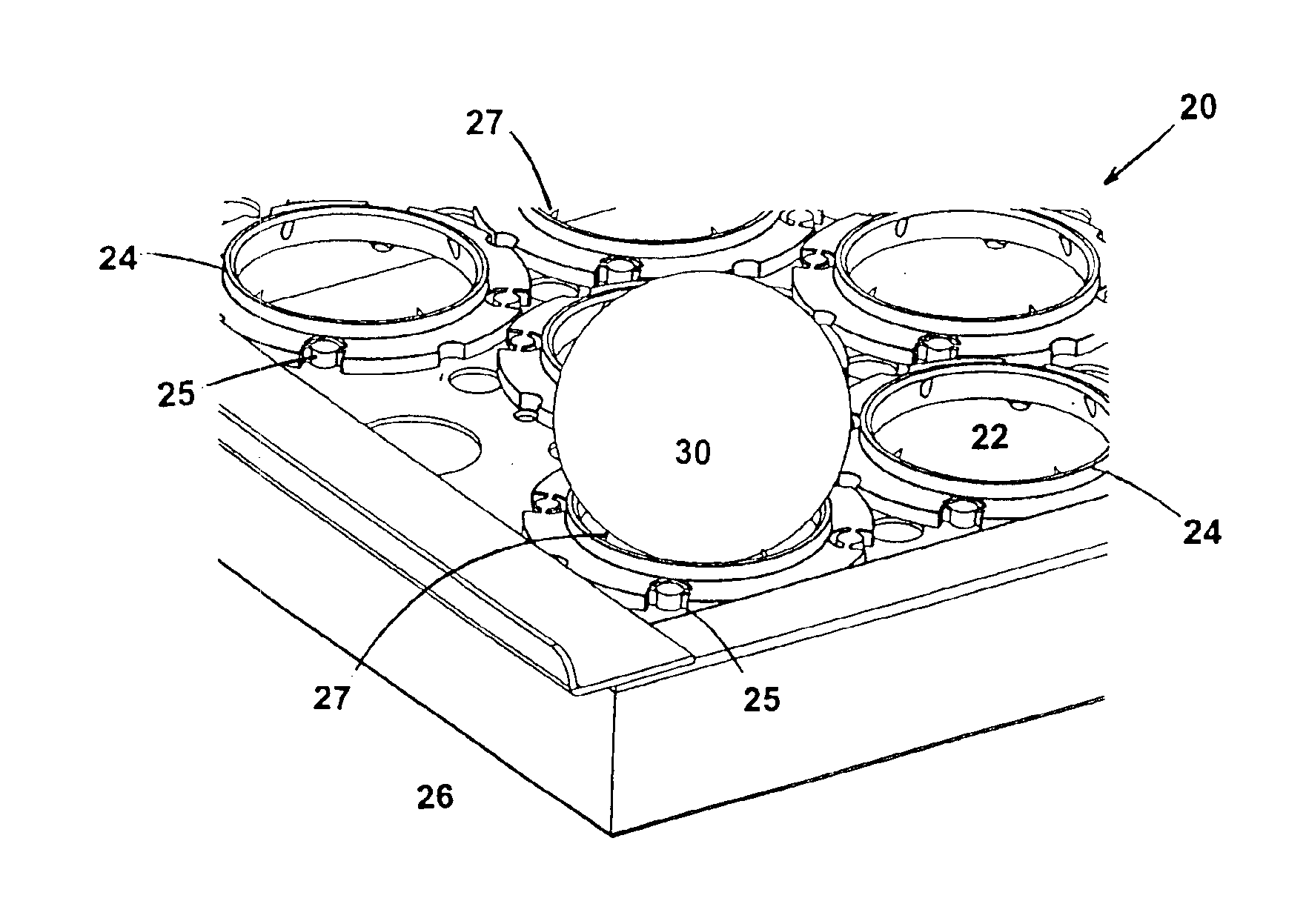

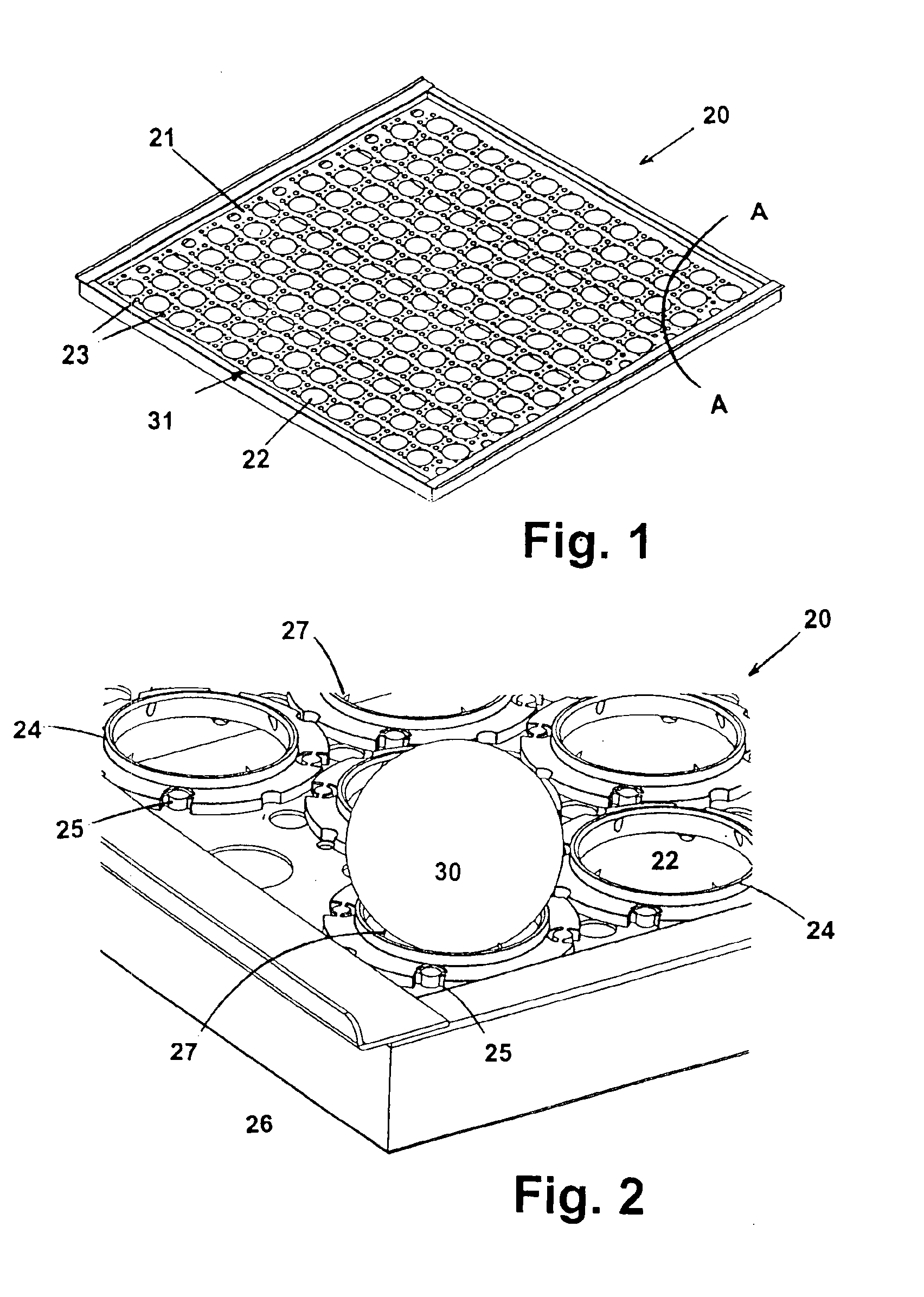

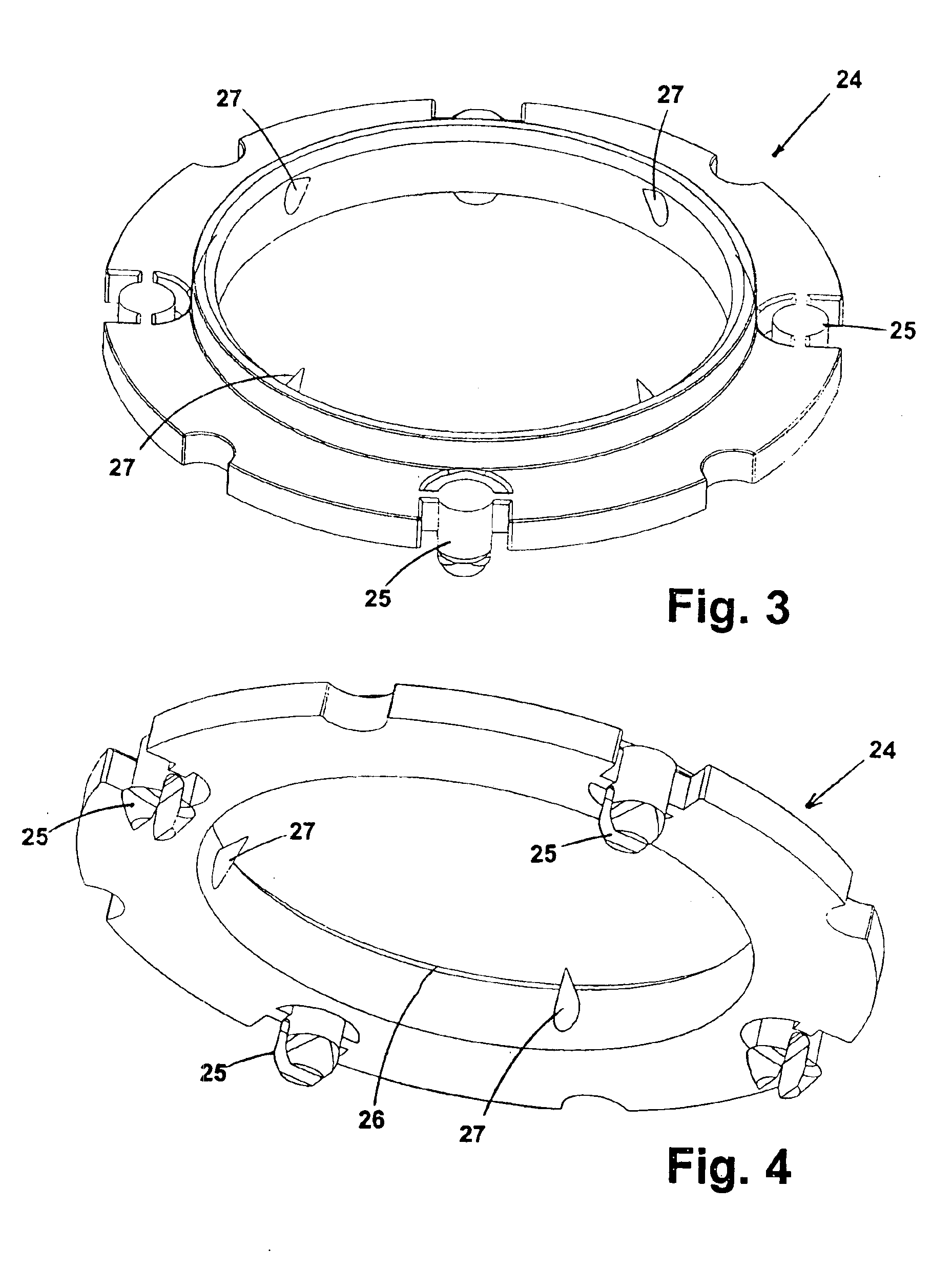

Beauty device

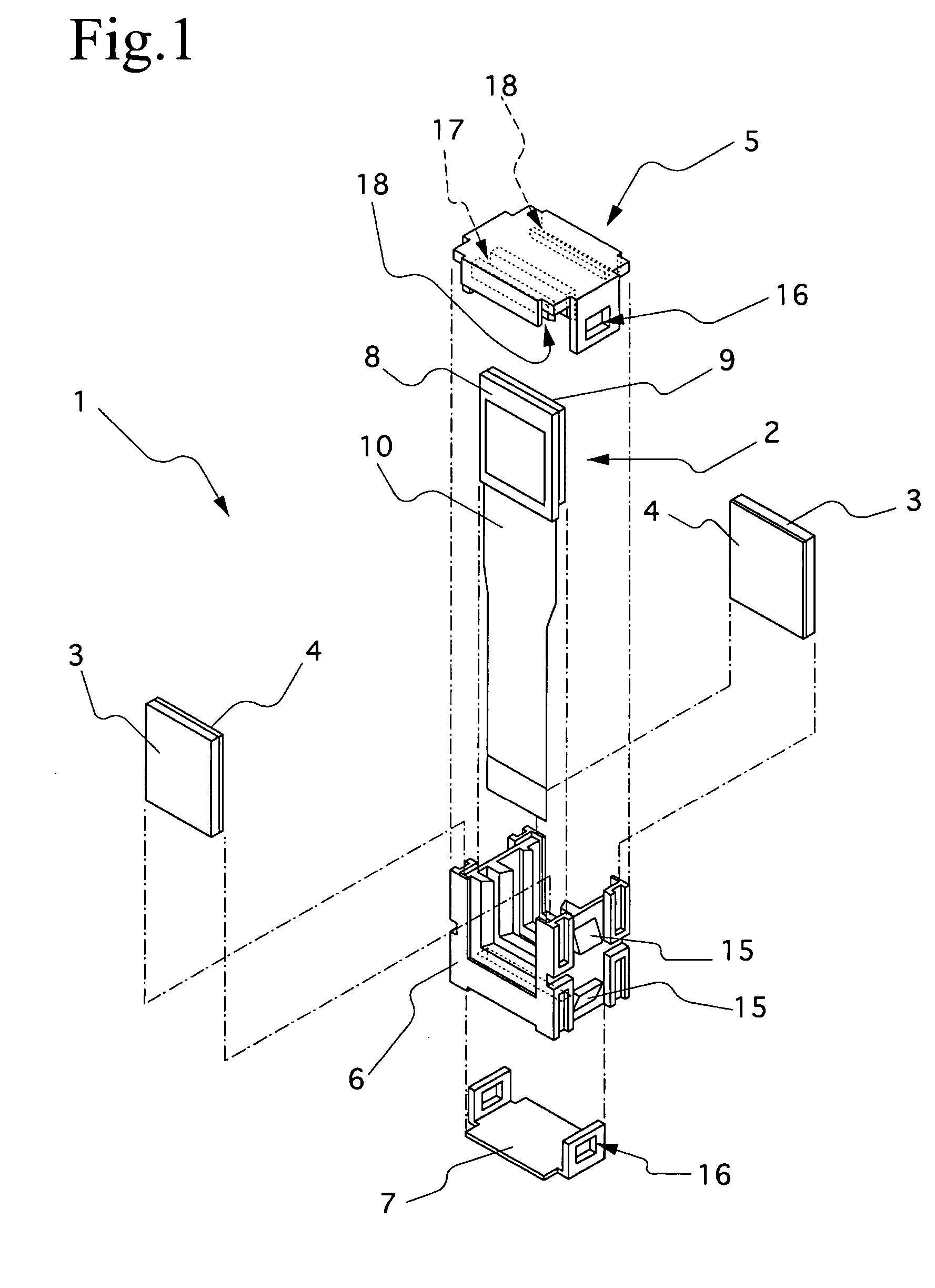

InactiveUS20050131497A1Improve absorption rateEasy to adjustElectrotherapySurgical instruments for heatingLight irradiationLength wave

A beauty device (1) includes a light irradiation section (5) that irradiates light of a predetermined wavelength; and an ion generating section (7) that generates an ion. The light irradiation section (5) is placed at one side surface of a main body and the ion generating section (7) is placed at the other side surface of the main body. The light irradiation section (5) includes a plurality of light source modules (25A, 25B) arranged in a predetermined array. Each light source module includes a plurality of light emitting diodes (20a, 20b, 20c, 20d) that are arranged in a predetermined array to emit light of two or more wavelengths.

Owner:FUTEC

Method of forming ceramic beads

InactiveUS6797203B2Reduce blemishesGood dispersionGranulation by liquid drop formationCeramic shaping apparatusMetallurgyFluid layer

A method of forming substantially spherical ceramic beads that includes conveying an aqueous ceramic slurry to a nozzle tip that is immersed in an inert water-immiscible fluid layer. The nozzle tip is spaced a predetermined distance away from a rotating disk that is also immersed in the immiscible fluid layer. The rotating disk creates a shear force that at the nozzle tip that dislodges droplets of the aqueous ceramic slurry from the nozzle tip into the immiscible fluid layer. Once dislodged, the droplets assume a substantially spherical shape and a substantially mono-modal size distribution. The droplets are permitted to pass from the immiscible fluid layer into an aqueous gelling solution wherein the droplets are converted into rigid beads. In a preferred embodiment of the invention, the rigid beads are recovered from the gelling solution, washed, and then sintered to obtain a density of greater than about 98% of theoretical density and a sphericity of greater than about 0.95. The method can be used to fabricate substantially spherical zirconia-containing beads having a diameter within the range of from about 0.1 mm to about 2.0 mm that are useful, for example, as grinding media.

Owner:CERCO

Anti-acne compositions and methods of use

InactiveUS6936267B2Narrow downPrevent regenerationCosmetic preparationsBiocideChlorine dioxideTreatment acne

The present invention relates to a composition for the treatment of acne comprising chlorine dioxide or chlorine dioxide generating compounds as acne reduction agents. The invention also relates to a method for treating acne by topically administering one of the compositions in an amount therapeutically effective to reduce the redness and blemishes associated with acne.

Owner:SWISS AMERICAN CDMO LLC

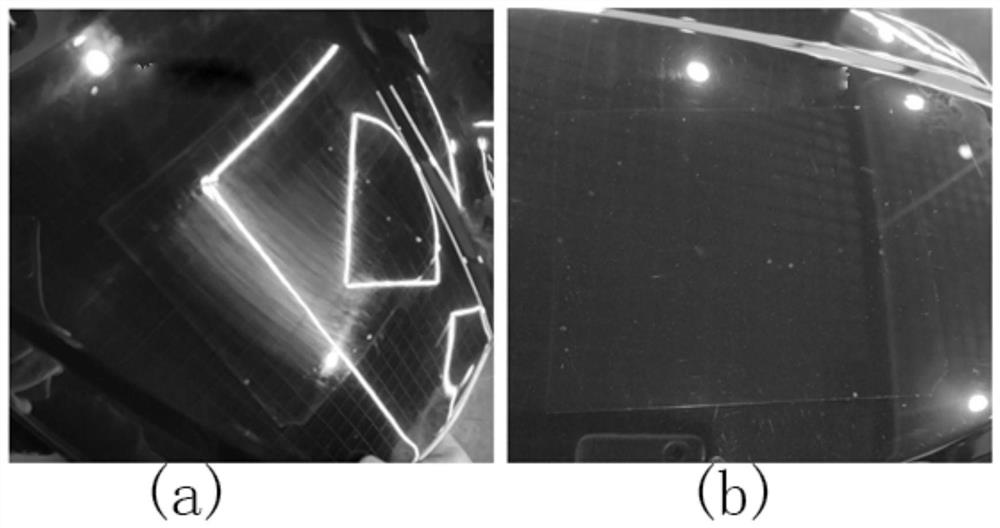

Liquid crystal display device and video camera

InactiveUS20050185116A1Avoid stickingSimplify workTelevision system detailsPolarising elementsLiquid-crystal displayFlexible circuits

A liquid crystal display device includes an EVF panel; polarizing plates stuck to a plastic substrate respectively disposed in an optical path of light incident on the EVF panel and in an optical path of light exiting from the EVF panel; a top frame section having openings respectively formed in an optical path area of light incident on the EVF panel and in an optical path area of light exiting from the EVF panel; a bottom frame section engaging with the top frame section; and a flexible-circuit-board holding section; wherein the polarizing plates are disposed so as to close the respective openings, and the EVF panel is disposed apart from the polarizing plates in an approximately hermetic space formed by the bottom frame section, the top frame section, the polarizing plates, and the flexible-circuit-board holding section.

Owner:SONY CORP

Heating of golf balls prior to painting

InactiveUS6872423B2Reduce trafficBlemish is further minimizedPretreated surfacesContainer/bottle contructionEvaporationEngineering

A method for preheating golf ball covers prior to painting. The process comprises forming a golf ball with a cover, then heating the cover from about 90° F. to about 150° F. for 1 to 3 hours in a heated enclosure prior to applying a coat of primer or paint to the ball. This is done to accelerate the evaporation of paint solvents, immediately after the paint is applied. The painted balls are subsequently dried in a heated enclosure at about 105° F. to 108° F. All additional coats of primer or paint are applied in a similar fashion, wherein the balls are painted while still in the heated state and not cooled down.

Owner:ACUSHNET CO

Yoga mat and manufacturing method thereof

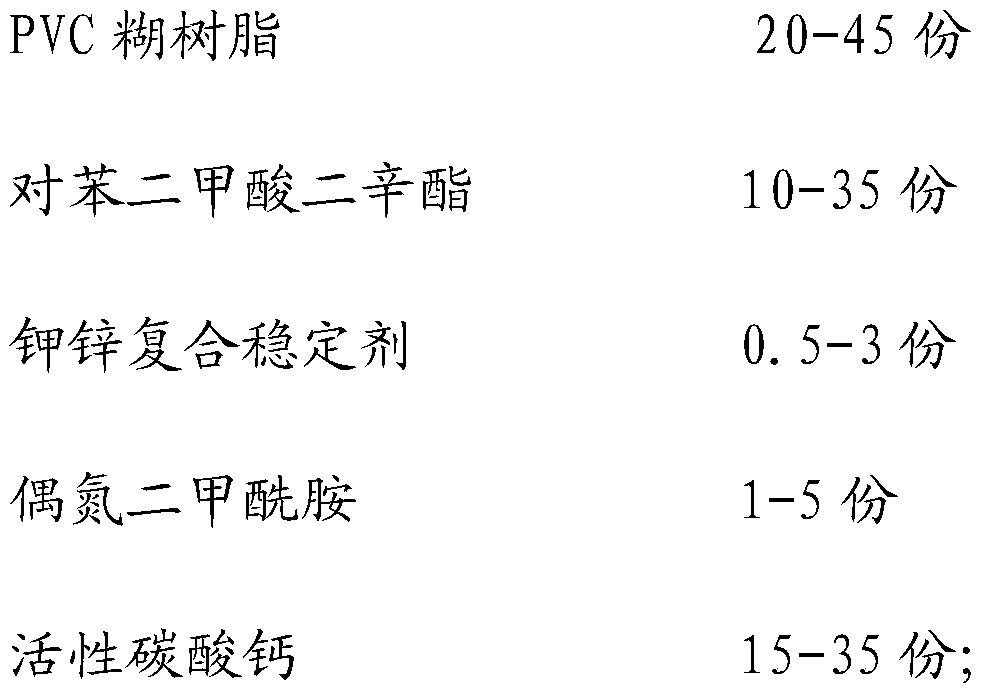

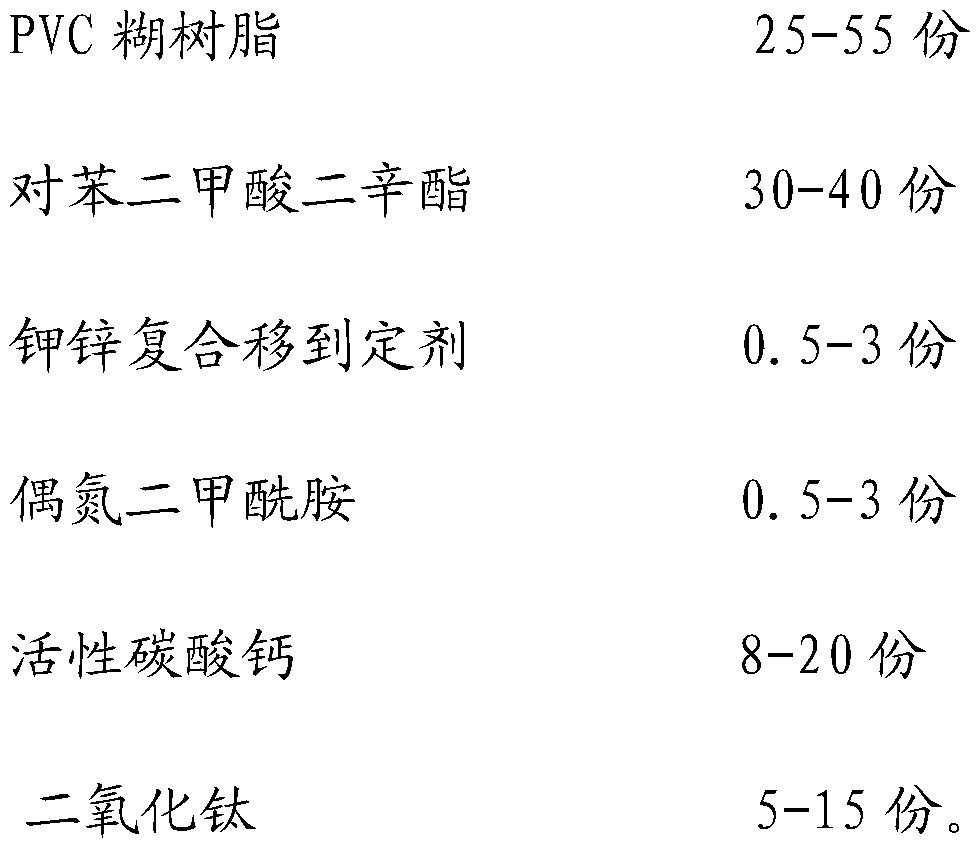

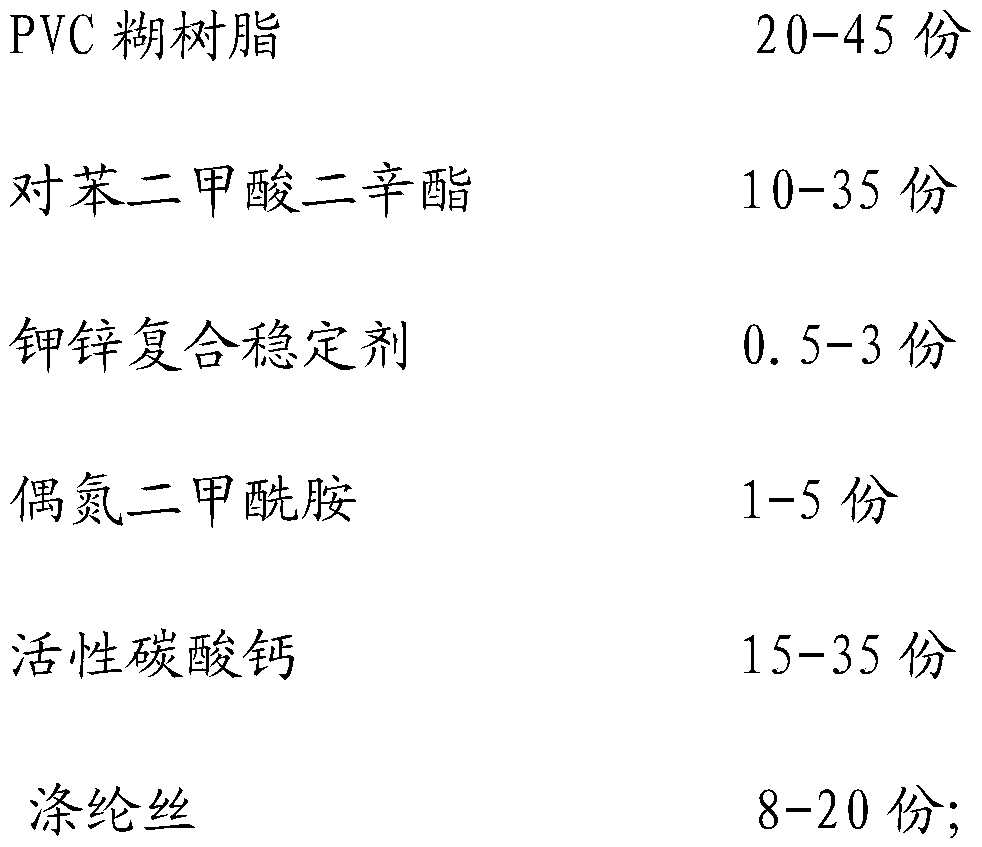

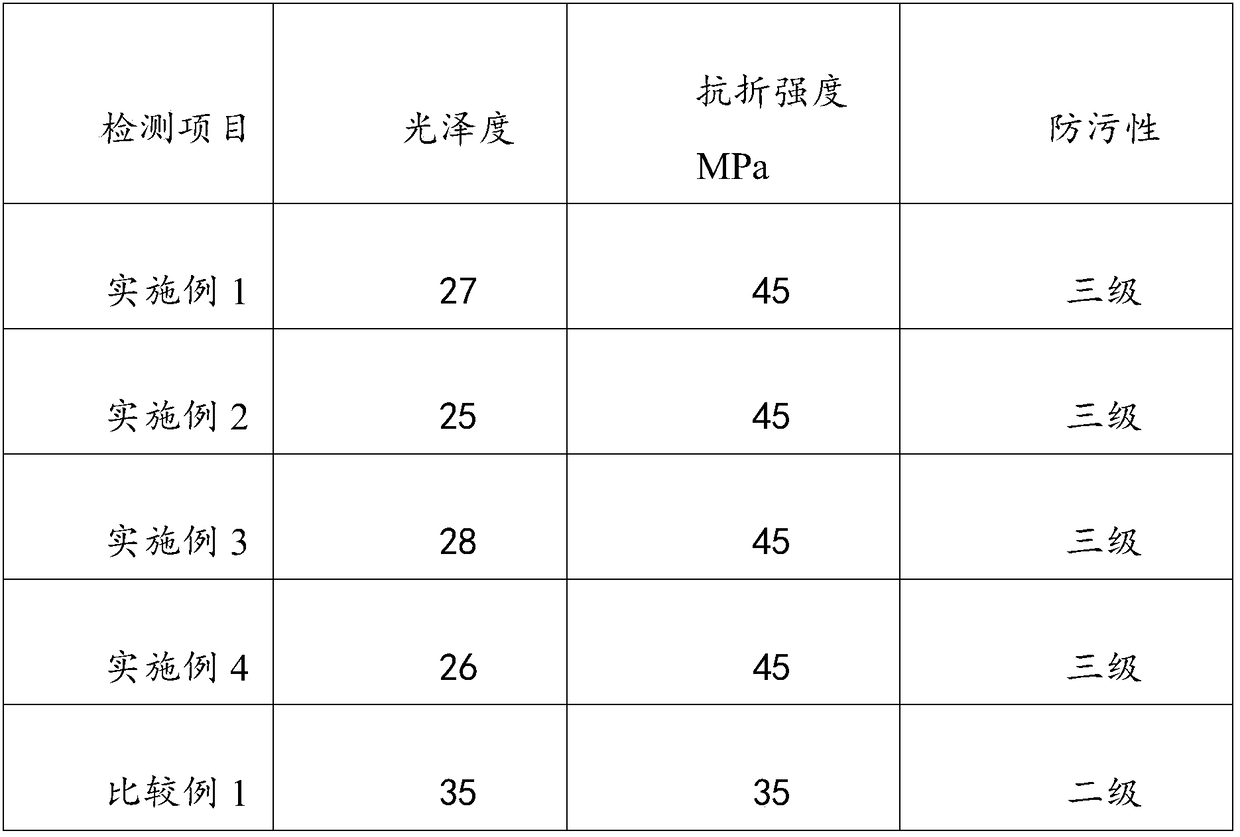

ActiveCN105498148AEnhanced Surface IndiaSolve the problem of poor color fastnessShock absorber matsPolyesterDioctyl terephthalate

The invention discloses a yoga mat and a manufacturing method thereof. The yoga mat comprises a lining cloth layer, a foaming layer compounded on the lining cloth layer, and a wearing layer compounded on the foaming layer, wherein the lining cloth layer is a layer of lining cloth, and the lining cloth is formed by weaving polyester silk; the foaming layer is prepared by foaming the following components in parts by weight: 20-45 parts of polyvinyl chloride (PVC) paste resin, 10-35 parts of dioctyl terephthalate, 0.5-3 parts of potassium-zinc complex stabilizer, 1-5 parts of azodicarbonamide and 15-35 parts of activated calcium carbonate; the wearing layer is prepared by foaming the following components in parts by weight: 25-55 parts of PVC paste resin, 30-40 parts of dioctyl terephthalate, 0.5-3 parts of potassium-zinc complex stabilizer, 0.5-3 parts of azodicarbonamide, 8-20 parts of activated calcium carbonate and 5-15 parts of titanium dioxide. According to the yoga mat, the wearing layer is additionally arranged, so that the problem that the color fastness of patterns on the surface of the conventional yoga mat is poor can be solved; furthermore, the traditional silk-screen method or intaglio printing method is replaced by a heat transfer method, so that the pattern content and colors on the surface of the product are richer.

Owner:广州市优伟家居用品有限公司

Method for preparing matte dry granular glazed brick

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

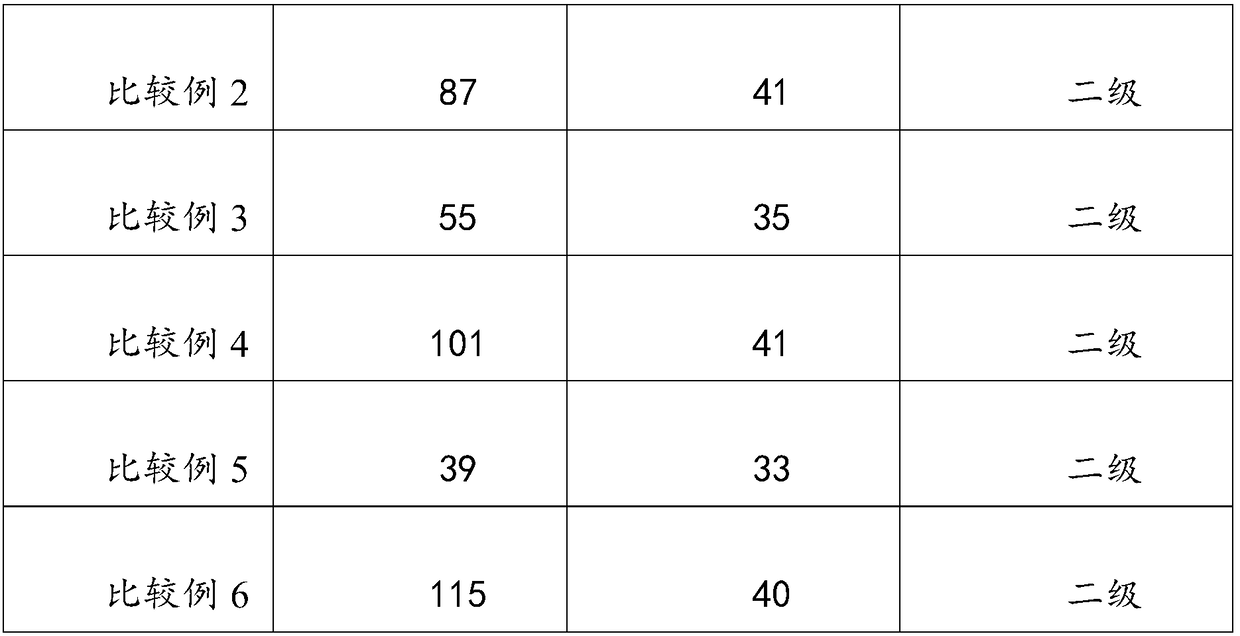

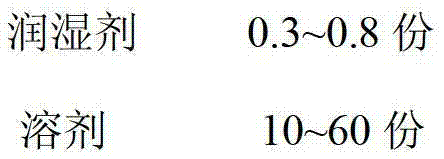

UV (Ultraviolet) gloss oil, high-gloss scrap-resisting decorative film prepared from same and preparation method of decorative film

The invention provides UV (Ultraviolet) gloss oil which comprises the following components in parts by weight: 20-40 parts of a monomer, 20-50 parts of an oligomer, 0.5-1.0 part of a flatting agent, 0.5-1.0 part of an antifoaming agent, 0.5-1.8 parts of an initiator, 0.3-0.8 part of a wetting agent and 10-60 parts of a solvent. The invention further provides a high-gloss scrap-resisting decorative film obtained by surface treatment with the UV gloss oil, and a preparation method of the high-gloss scrap-resisting decorative film. When the UV gloss oil provided by the invention is applied to surface treatment on an ordinary high-gloss decorative film, not only is the glossiness of the surface of a product improved, that is, the glossiness is greater than 115 degrees, but also the surface hardness of the product is improved, the pencil hardness of the surface is more than 1H; and the obtained high-gloss scrap-resisting decorative film has the capability of resisting the nail scrape and daily wiping.

Owner:FOSHAN TIANJIN PLASTICS

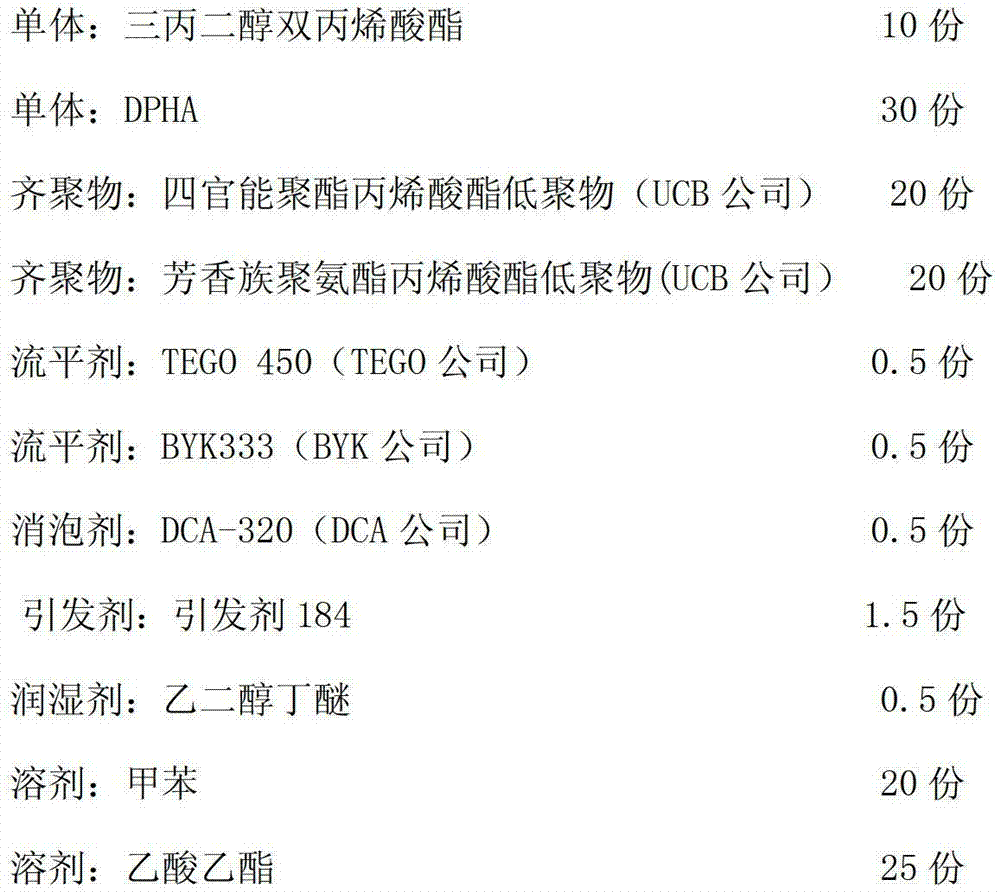

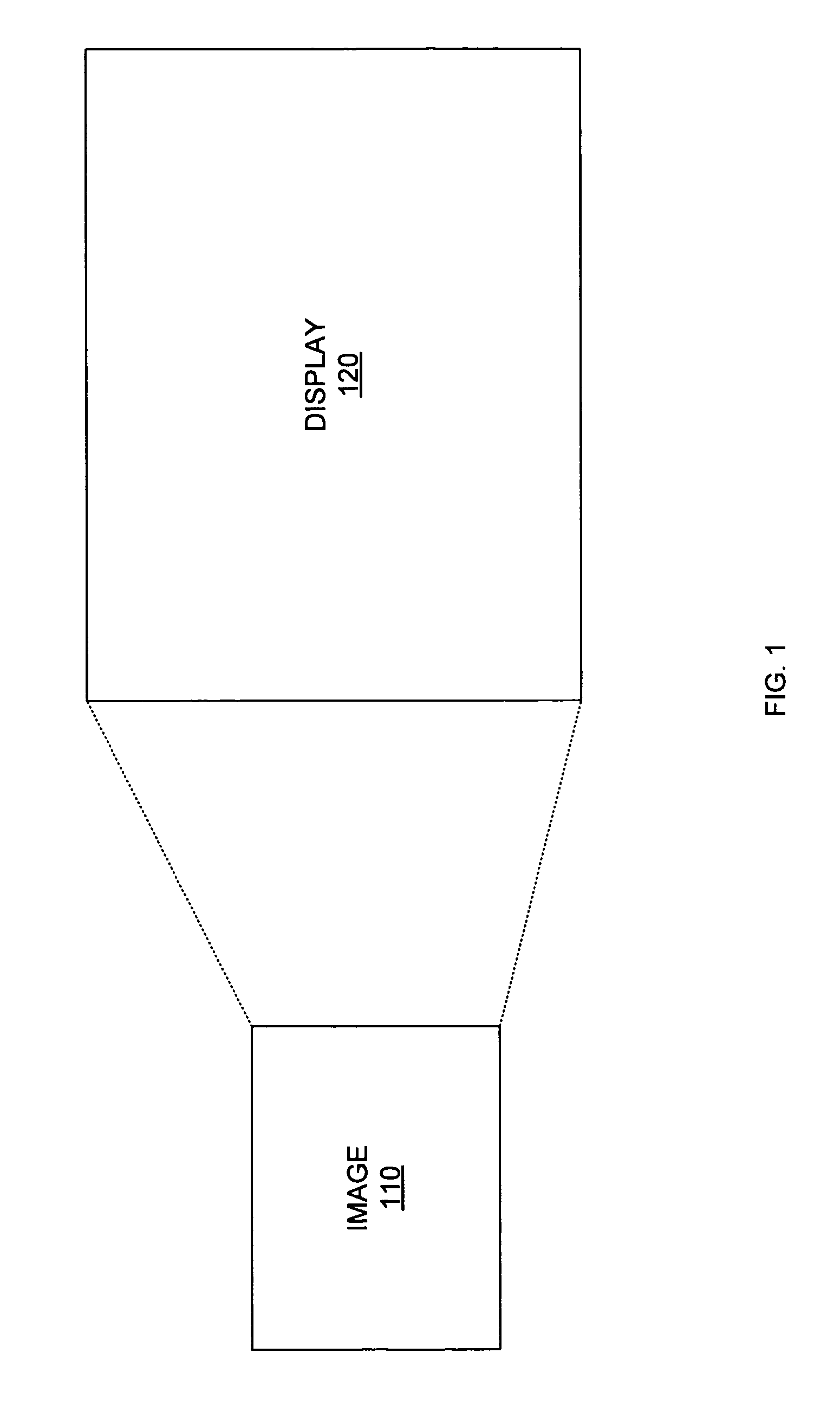

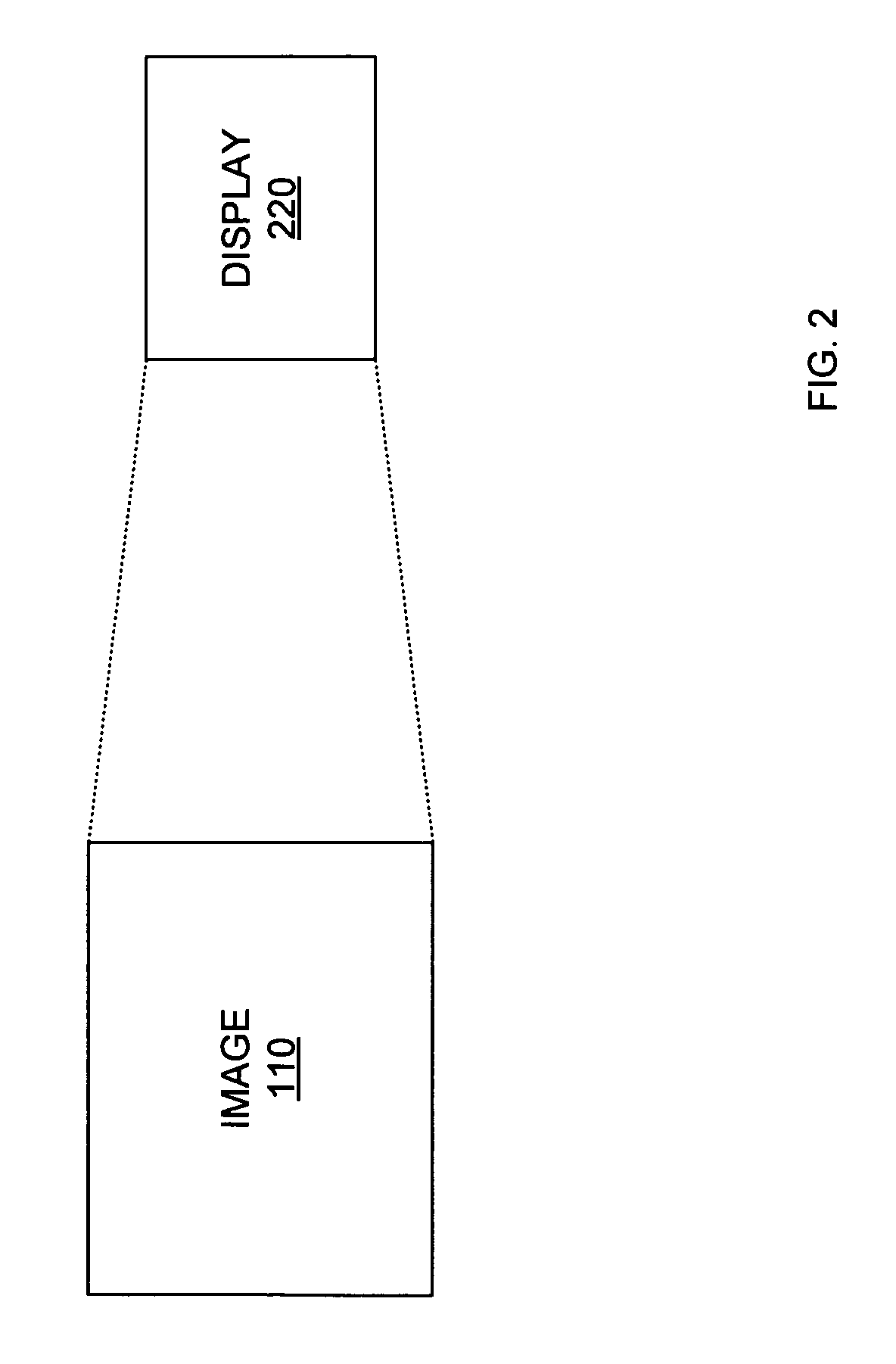

Image scaler with controllable sharpness

ActiveUS7957611B2Quality improvementReduce blemishesTelevision system detailsGeometric image transformationAcutanceImage quality

A method and system for scaling an original image into a scaled image is disclosed. Rather than using the corresponding position in the original image to generate the pixels values of a current pixel in the scaled image, image scalers in accordance with the present invention, calculate a high frequency adjusted position based on the high frequency components of pixels near the corresponding position. Pixel values based on the high frequency adjusted position provide better picture quality for the scaled image than pixel values based on the corresponding position. Furthermore, some embodiments of the present invention also use sharpness compensation to further improve the picture quality of the scaled image.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

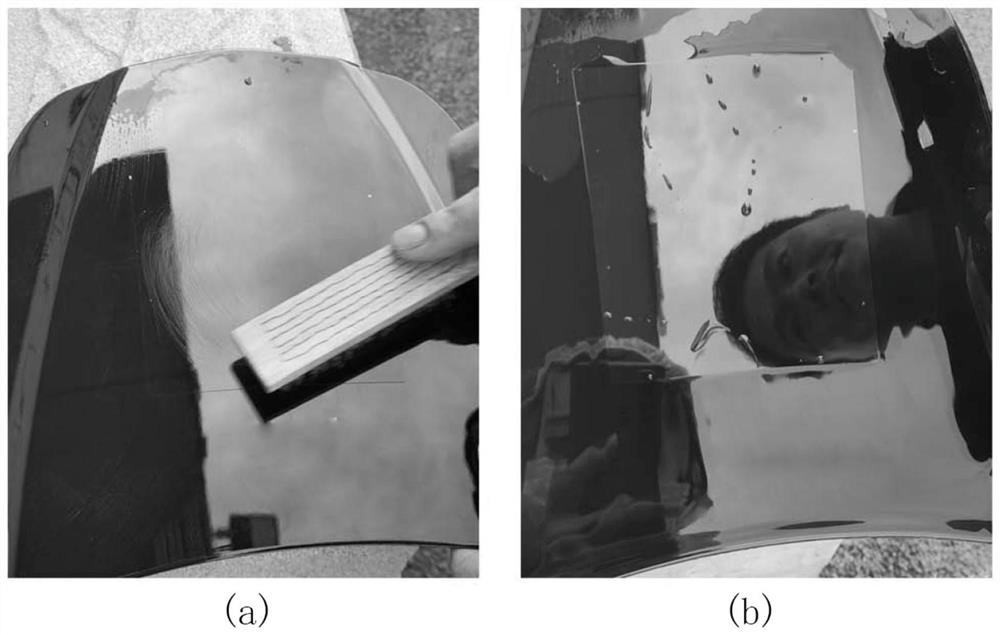

Self-repairing yellowing-resistant paint surface protective film and preparation method thereof

InactiveCN113072890AIncrease stickinessImprove protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceFunctional monomer

The invention discloses a self-repairing yellowing-resistant paint surface protective film and a preparation method thereof. The paint surface protective film is sequentially composed of a release film layer I, a pressure-sensitive adhesive layer, a TPU base material, a self-repairing coating and a release film layer II from bottom to top. The self-repairing coating is made of thermocuring functional polyurethane acrylate resin and comprises 20-50% of functional monomer modified acrylic resin, 10-30% of polymer polyol, 40-60% of a diluting solvent, 10-20% of a curing agent, 0.2-0.5% of a catalyst and 0.5-2% of an auxiliary agent, the TPU base material is optical-grade aliphatic TPU, the pressure-sensitive adhesive is an acrylate adhesive, and the release film layer is a PET silicone oil release film. The paint surface protective film prepared by the invention not only has excellent yellowing resistance and self-repairing performance, but also has high transparency, high glossiness, excellent scratch resistance, acid and alkali resistance, rain spot resistance and the like, so that the self-repairing yellowing-resistant paint surface protective film is suitable for the fields of automobile, furniture films and the like.

Owner:南阳金牛彩印集团有限公司 +1

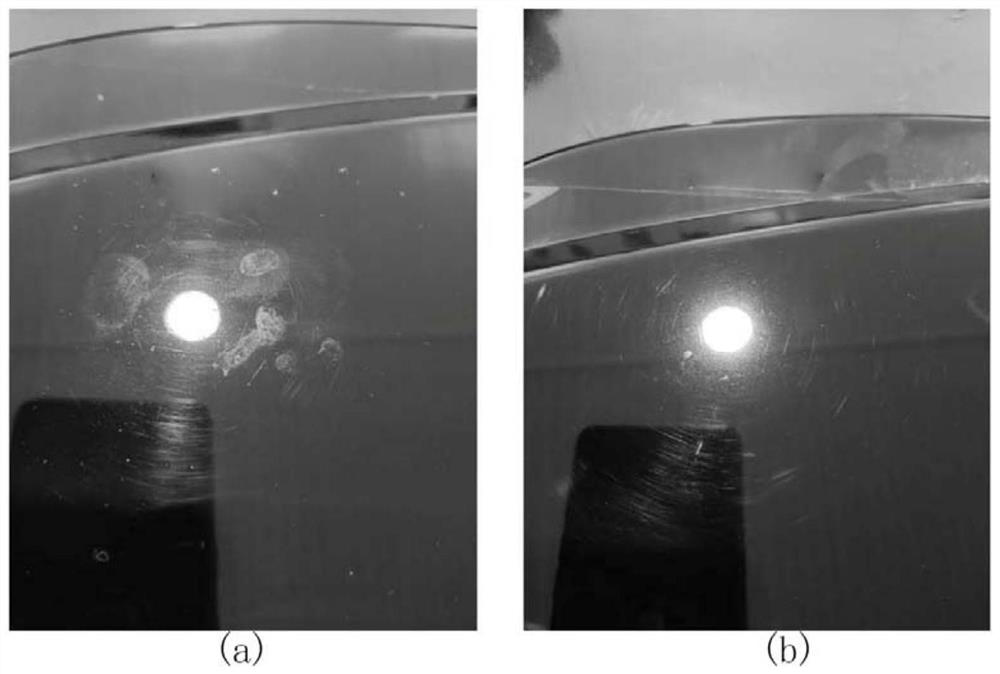

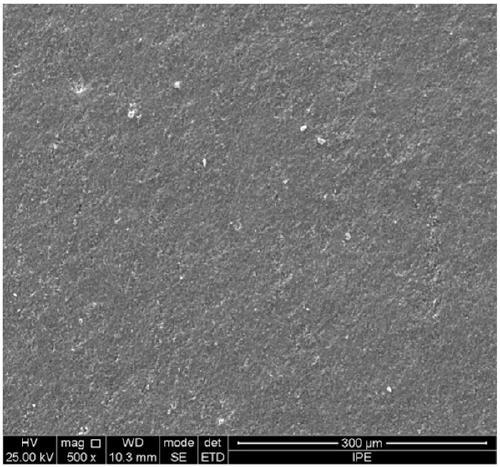

Cooling roller surface processing technology

The invention discloses a cooling roller surface processing technology comprising the steps of (1) cutting the surface of a roller sleeve of a cooling roller to remove an unsmooth part which can be observed through naked eyes; (2) fixing the roller sleeve on a rotating shaft, and enabling the roller sleeve to rotate; (3) carrying out shot blasting treatment on the surface of the rotating roller sleeve; (4) carrying out rolling treatment on the surface of the rotating roller sleeve in a mechanical rolling way; (5) carrying out ultrasonic treatment on the surface of the roller sleeve by using an ultrasonic vibration generator before the cooling roller is used. An amorphous strip obtained when an applicant prepares the amorphous strip by using the cooling roller treated by combining the three processes including shot blasting treatment, mechanical rolling and ultrasonic treatment in the process of processing the surface of the cooling roller is good in surface smoothness and continuity, few in product flaws as well as good in strip stability and strip thickness uniformity.

Owner:RIZHAO BOYUAN AMORPHOUS METAL MATERIALS

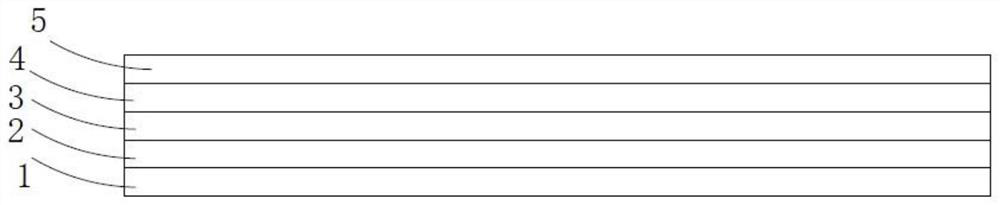

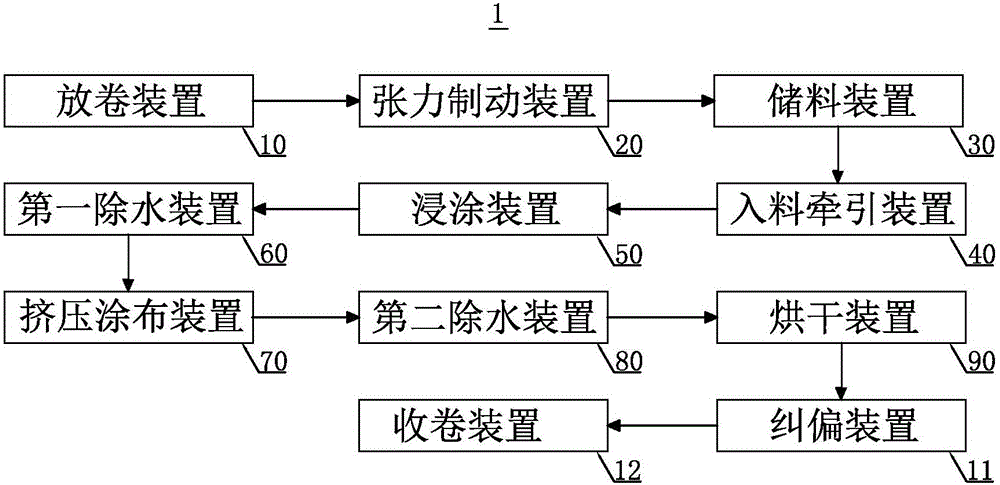

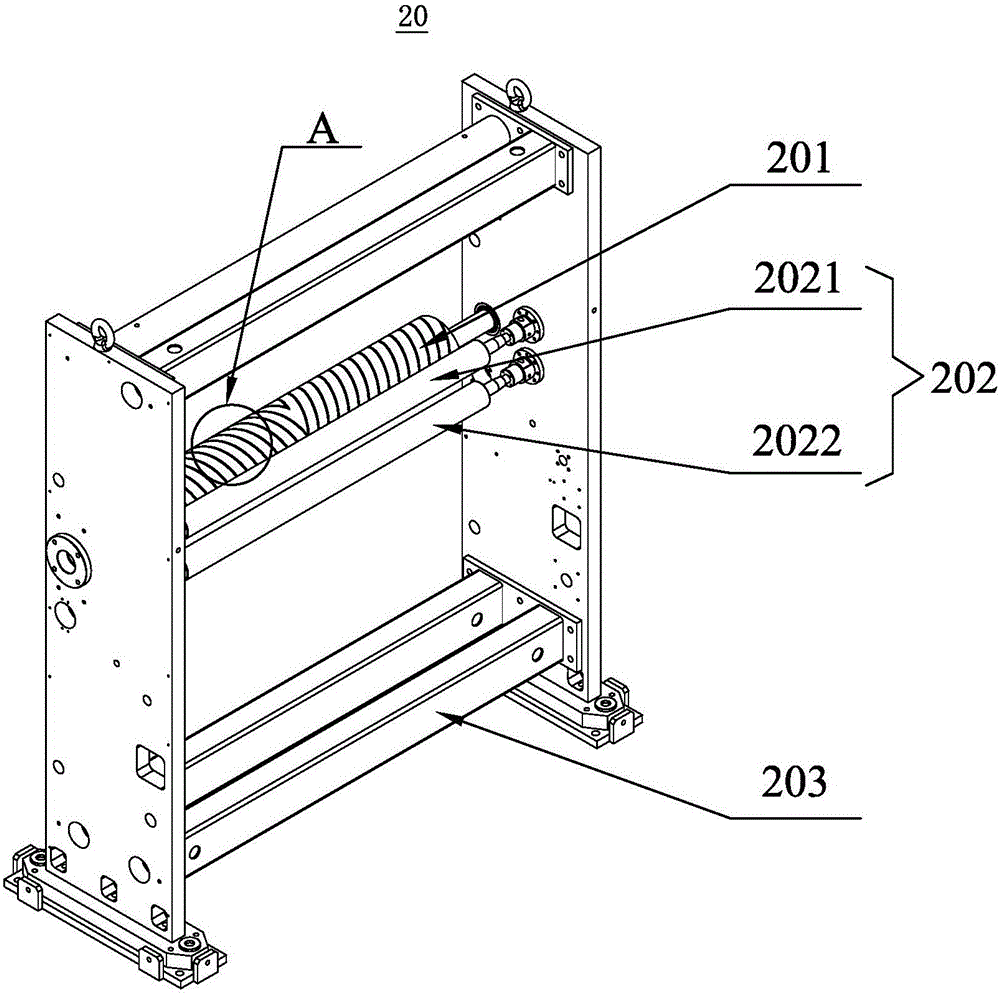

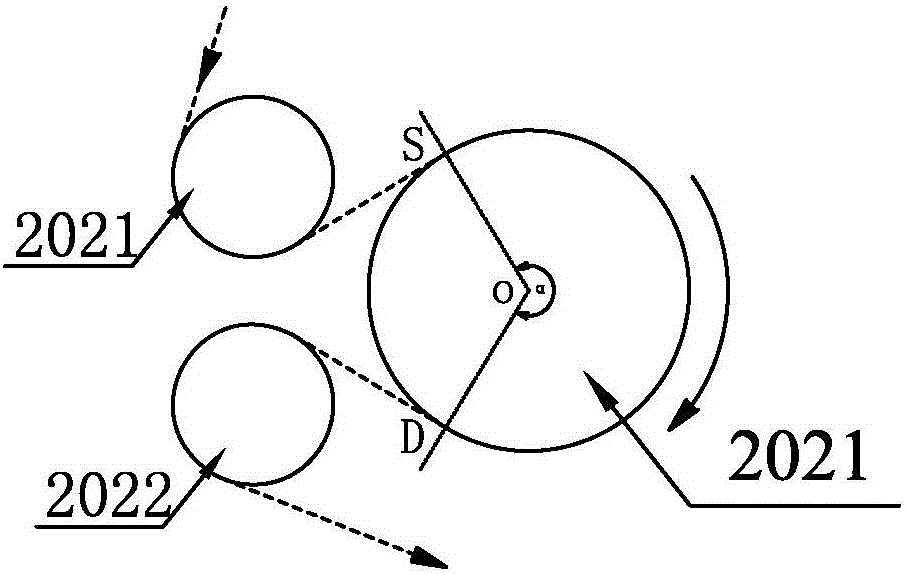

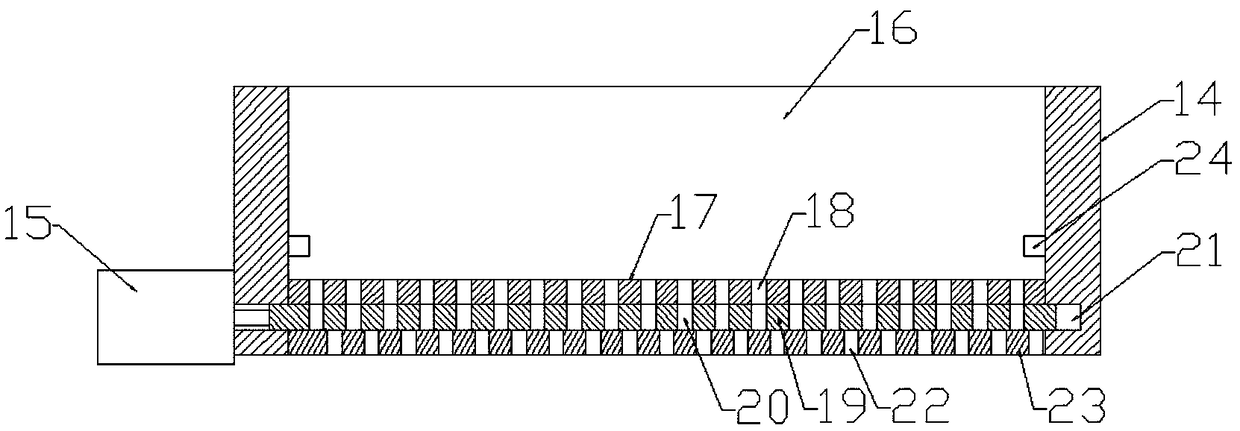

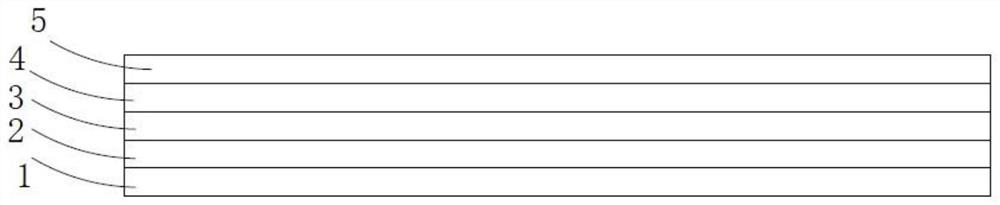

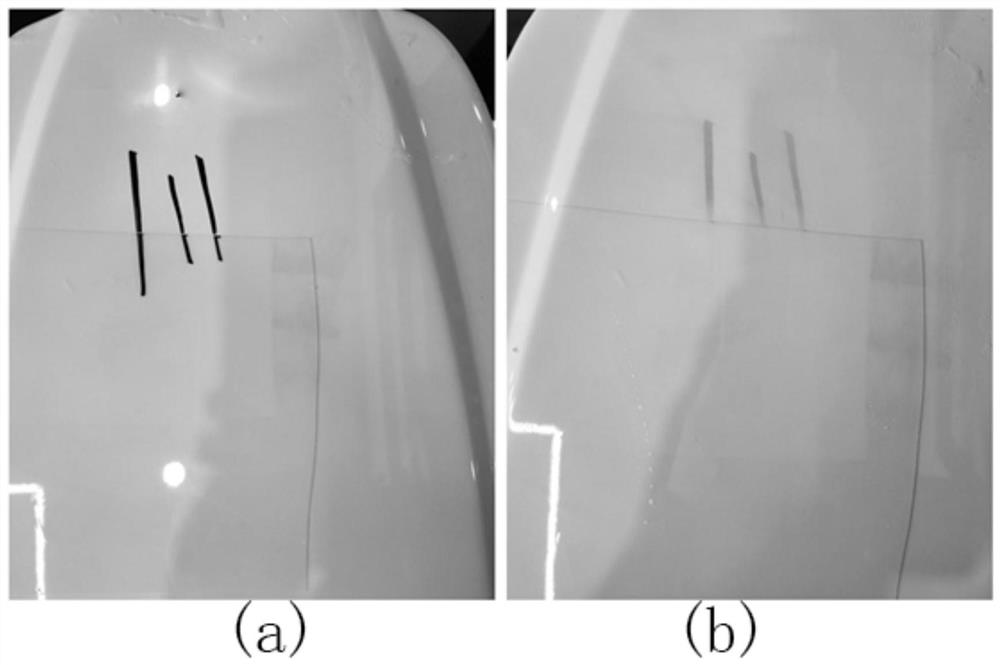

Reverse osmosis membrane production equipment and reverse osmosis membrane preparation method

InactiveCN106040010AGuaranteed flatnessReduce blemishesSemi-permeable membranesChemistryEquipment use

The invention provides reverse osmosis membrane production equipment used for forming a reverse osmosis membrane after technological treatment is carried out on a basement membrane. The reverse osmosis membrane production equipment comprises an unwinding device, a coating device, a drying device and a winding device, wherein a basement membrane provided by the unwinding device is coated by virtue of the coating device and then enters the drying device, and the basement membrane is suspended in the air, dried by the drying device and then wound by the winding device. The invention also provides a reverse osmosis membrane production method used for forming a reverse osmosis membrane after the technological treatment is carried out on the basement membrane. The production method comprises the following steps of: S1, providing a basement membrane roll; S2, coating the basement membrane; S3, suspending the basement membrane in the air and drying; and S4, winding the basement membrane. The reverse osmosis membrane produced by adopting the reverse osmosis membrane production equipment provided by the invention and the reverse osmosis membrane prepared by adopting the reverse osmosis membrane preparation method provided by the invention respectively have the advantages of good quality and the like.

Owner:SHENZHEN HAONENG TECH

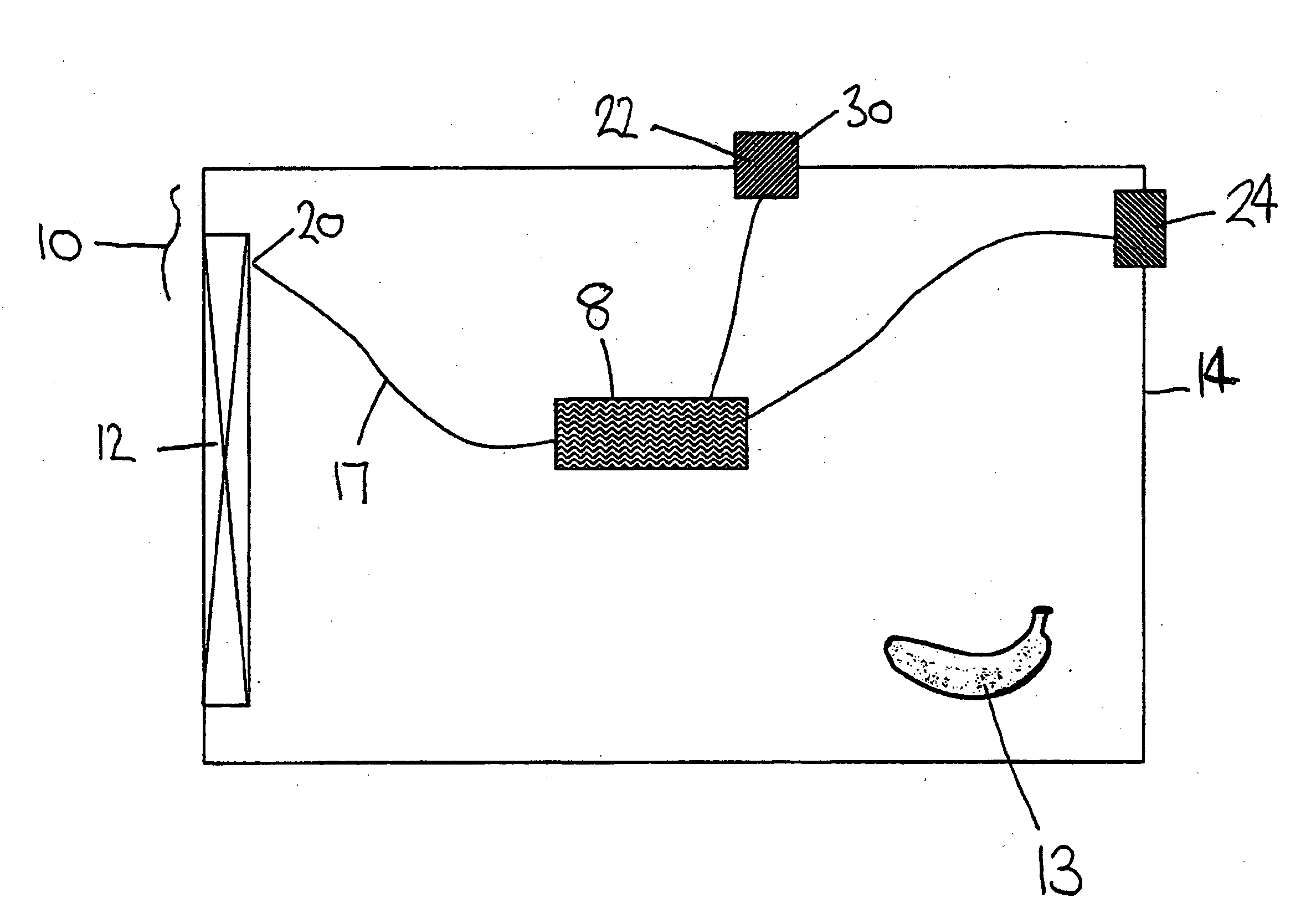

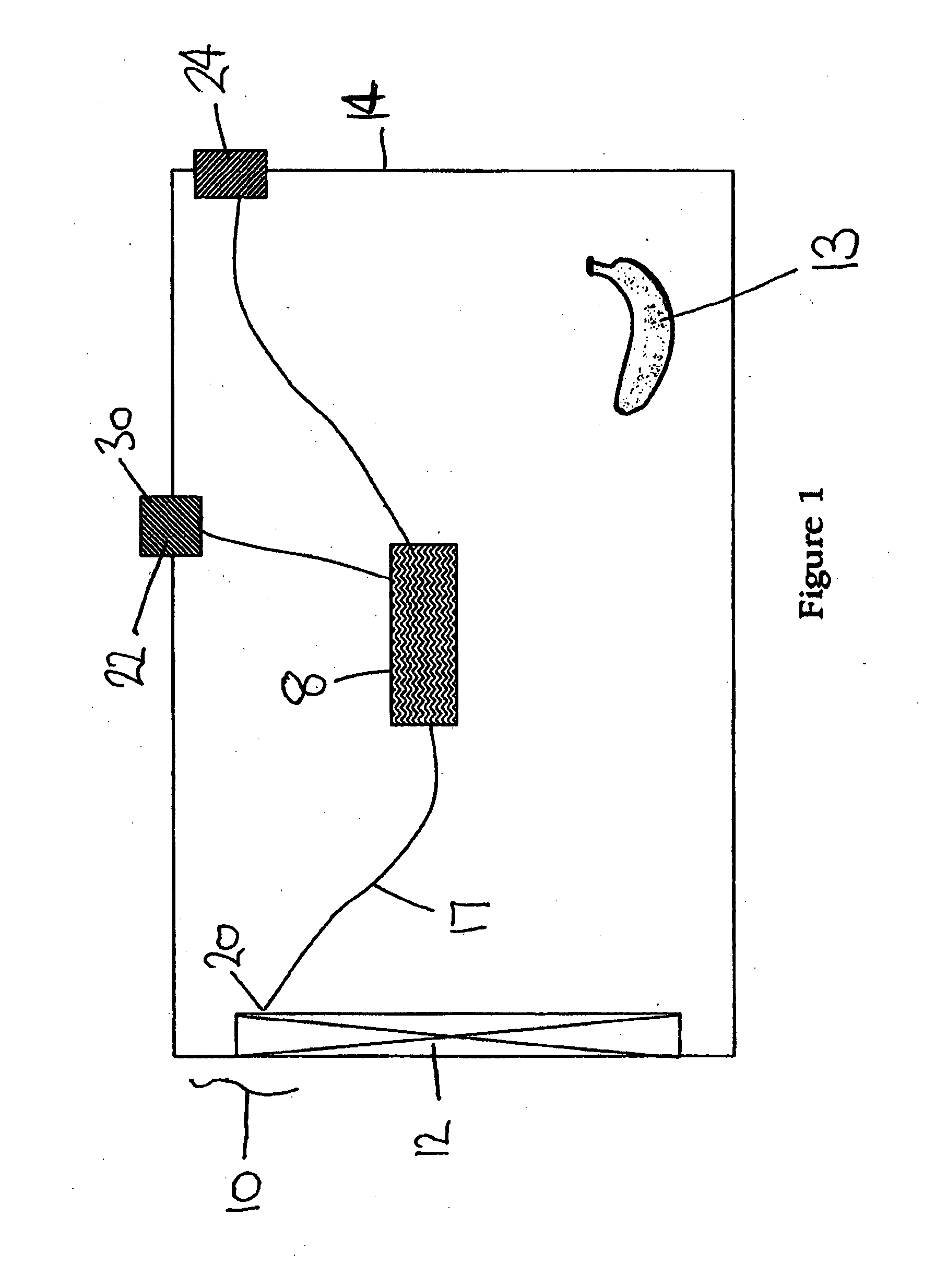

Apparatus and methods for controlling atmospheric gas composition within a container

InactiveUS20140308409A1Reduce leakageReducing unintentional reverse movementReady-for-oven doughsSemi-permeable membranesGas compositionProcess engineering

A method of controlling gas composition within a container containing respiring produce is described. The container includes at least one gas outlet and at least one gas inlet and the method includes the steps of: drawing gas from within the container through a selective membrane element under selected control conditions through the at least one gas outlet; introducing ambient air from outside die container into the container through the at least one gas inlet under selected control conditions to control the relative composition of gases inside the container. Apparatus for containing the goods and for controlling the atmosphere in the container according to the method are also described.

Owner:MITSUBISHI AUSTRALIA

Titanium suboxide electrode sheet and preparation method and application thereof

The invention provides a titanium suboxide electrode sheet and a preparation method and application thereof. The preparation method comprises the following steps: (1) vacuumizing titanium suboxide fine powder and applying pressure to carry out preforming to obtain a preformed product; and (2) performing discharge plasma sintering on the preformed product in step (1) to obtain the titanium suboxideelectrode sheet. According to the preparation method provided by the invention, the titanium suboxide with high Ti4O7 content is matched with the discharge plasma sintering, so that the conductivityand the corrosion resistance of the titanium suboxide electrode sheet are effectively improved, the service life of an electrode is prolonged, the compactness of the prepared titanium suboxide electrode sheet is improved, and the toughness and the post-processing property of the titanium dioxide electrode sheet are improved. According to the preparation method provided by the invention, a binder and the titanium dioxide fine powder are uniformly mixed, the defects of the electrode sheet can be reduced through pre-pressing forming, and the performance of the titanium suboxide electrode sheet isimproved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

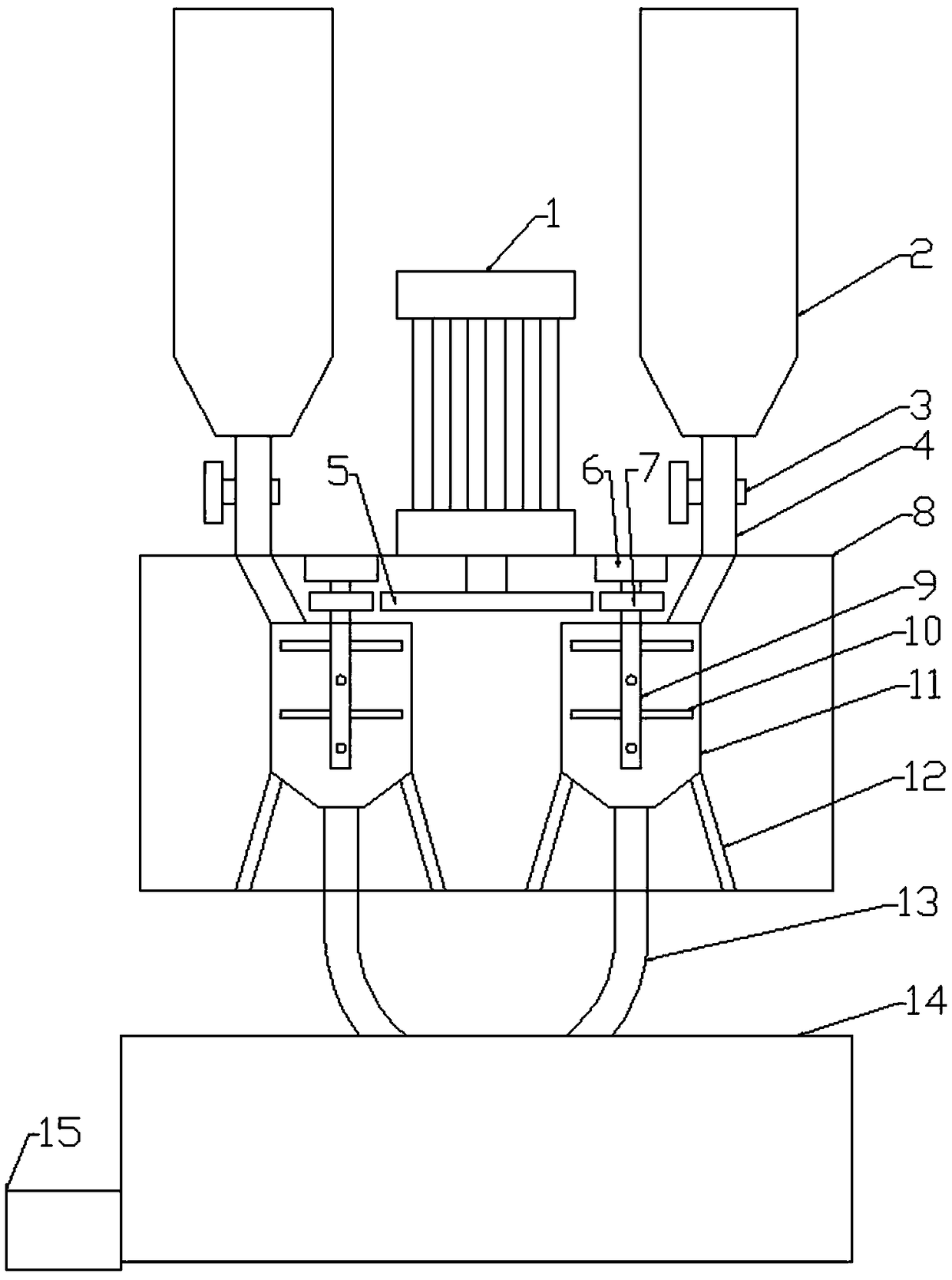

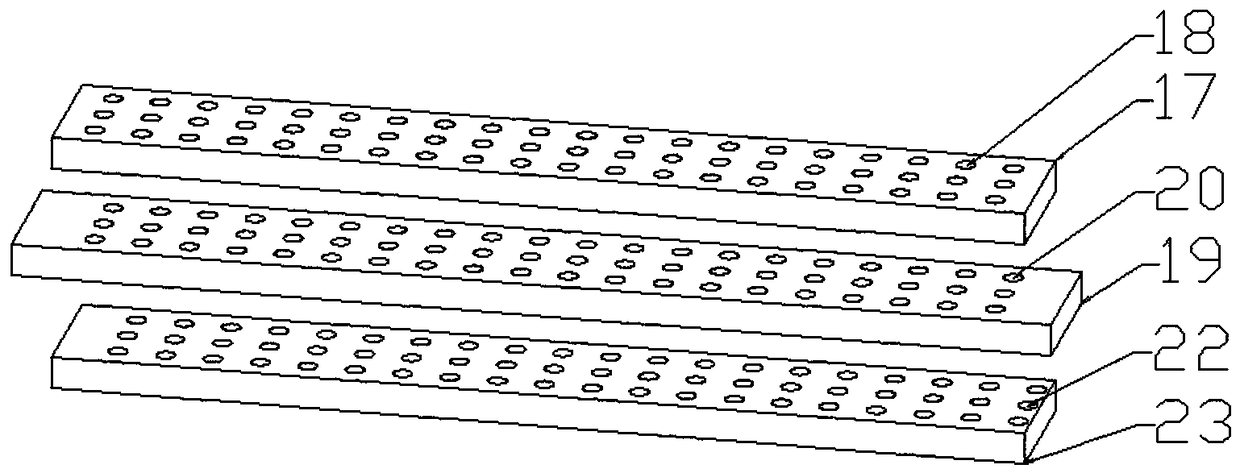

Powder falling device of 3D printer

InactiveCN108655393AAvoid mixingReduce blemishesAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringElectromagnetic valve

The invention discloses a powder falling device of a 3D printer. The device comprises stirring box and a powder falling box, wherein a servo motor is arranged at the upper end of the stirring box, a large gear is arranged at the upper end of a main shaft of the servo motor, feeding pipes are arranged at the two ends of the servo motor, and an electromagnetic valve is arranged on the feeding pipes;steel cylinders are arranged at the upper ends of the feeding pipes, supporting legs are arranged at the lower end inside the stirring box, a stirring tank is fixed at the upper end of the supportinglegs, a rotating shaft fixing base is arranged at the upper end of the interior of the stirring box, and the rotating shaft is arranged in the rotating shaft fixing base; a small gear is arranged onthe rotating shaft, a material falling pipe is connected to the lower end of a stirring pipe, a powder storage cavity is formed in the upper end of the interior of the powder falling box, and a powderinlet plate is fixed at the bottom of the powder storage cavity; a plurality of powder inlet holes are formed in the powder inlet plate in a array mode, a rectangular groove is formed in the lower end of the powder inlet plate, and a powder storage plate is arranged in the rectangular groove; and a plurality of powder storage holes are formed in the powder storage plate, a powder falling plate isfixed at the lower end of the powder storage plate, and a plurality of powder falling holes are formed in the powder falling plate. The powder falling device realizes a pre-dispersion treatment of the powder and the powder quantitative falling, the probability of flaws caused by pasting is reduced, and the powder utilization rate is improved.

Owner:安徽中健三维科技有限公司

Surface treatment paint of leather material

InactiveCN103980758ANatural appearanceGood lookingCoatingsLeather surface finishingAdditive ingredientMaterials science

The invention belongs to the technical field of surface treatment materials of leather, and particularly relates to surface treatment paint of a leather material. The invention aims at solving the technical problem: paint for treating the surface of the leather material can maintain the natural appearance of the leather, sufficiently soften the leather, reduce the abrasion of the leather and enhance the hand feeling. In order to solve the problem, the technical scheme is adopted as follows: the paint for treating the surface of the leather material comprises bottom paint and surface paint, wherein the bottom paint comprises the ingredients by weight percent: 25 to 35 percent of bottoming agent, 20 to 25 percent of fatting agent, 16 to 24 percent of matting and patching agent and 19 to 35 percent of deionized water; the surface paint comprises the ingredients by weight percent: 28 to 35 percent of resin, 5 to 12 percent of hand feeling agent, 8 to 15 percent of smoothening agent, 5 to 10 percent of water-borne brightening agent, 3 to 8 percent of permeating agent, 10 to 15 percent of softening agent and 8 to 38 percent of deionized water. The surface treatment paint has beneficial effects: 1, the natural appearance of the surface of the leather can be maintained; 2, the leather is softer, wear-resisting, smooth and good in hand feeling.

Owner:广东满天星皮具有限公司

Jade machining technology

ActiveCN106799915AReduce blemishesRound colorPolishing machinesFine working devicesNumerical controlHardness

The invention discloses a jade machining technology. The jade machining technology comprises the steps that S1, a working diagram is drawn according to the shape and structure of jade and then is input to a computer to generate data; S2, the jade is put into a numerically-controlled machine tool, peeling is conducted according to the generated data, and a rough blank is cut out; S3, offcut which is cut off in the step S2 is selected to perform hardness detection; S4, the rough blank in the step S2 is carved with the numerically-controlled machine tool according to the data generated in the step S1 so that a stone implement can be formed, carving includes repeated feed carving procedures, and the carving depths of the feed carving procedures are gradually decreased; S5, high-pressure water jet is adopted to form a microjet for accurate carving along traces carved on the stone implement in the step S4, and the pressure of the high-pressure water jet depends on the hardness detected in the step S3; and S6, the stone implement is polished after the step S5 is completed. By combining two cutting modes, the jade machining technology has the advantages of being high in machining precision and high in degree of automation.

Owner:浙江萌宠日记信息科技股份有限公司

Environmentally-friendly dry powder emulsion paint for inner wall and preparation method thereof

The invention relates to an environmentally-friendly dry powder emulsion paint for an inner wall and a preparation method thereof. The environmentally-friendly dry powder emulsion paint for the inner wall is prepared through the following raw materials in parts by weight: 20-35 parts of white cement, 20-35 parts of calcium carbonate powder, 8-18 parts of ash calcium powder, 30-40 parts of modified degreased soybean powder pulp, 5-10 parts of titanium dioxide, 10-20 parts of propolis powder, 6-8 parts of water soluble glucan, 4-6 parts of flatting agent, 2-3 parts of organobentonite, 1-3 parts of nanometer magnetic ordered mesoporous medium, 2-3 parts of antioxidant, and 1-3 parts of additive, wherein the additive is at least one of flame-retardant powder, nanometer negative ion powder and an antistatic agent; the flatting agent is a liquid acrylic flatting agent. The environmentally-friendly dry powder emulsion paint for the inner wall is reasonable in raw material selection, and proper in matching; compared with an existing emulsion paint, the prepared dry powder emulsion paint has the advantages of being outstanding in water resistance, outstanding in bonding performance, high in consistency in the drying process, and high in flatness; in addition, the emulsion paint is high in stability during the drying process, is influenced slightly by the outside condition, and is hard to discolor; in addition, the emulsion paint is outstanding in antibacterial capacity, high in static resistance and high in fire retardance.

Owner:陈浩谦

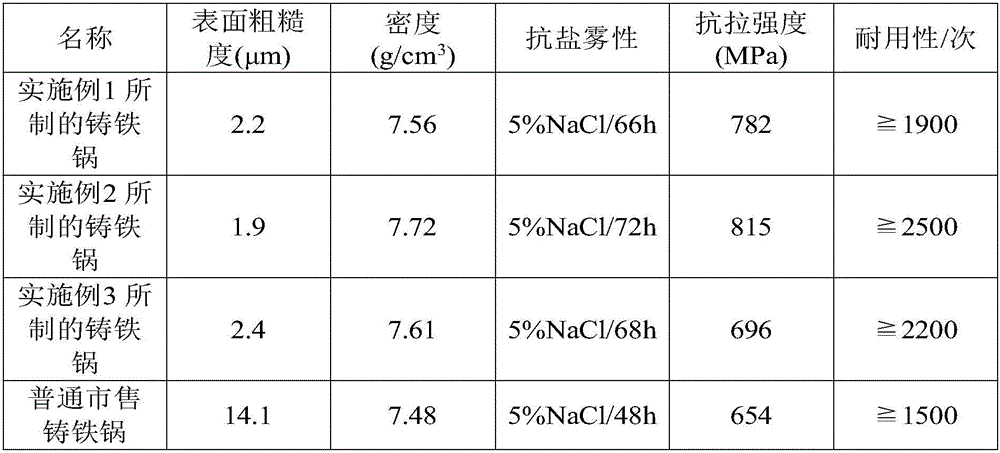

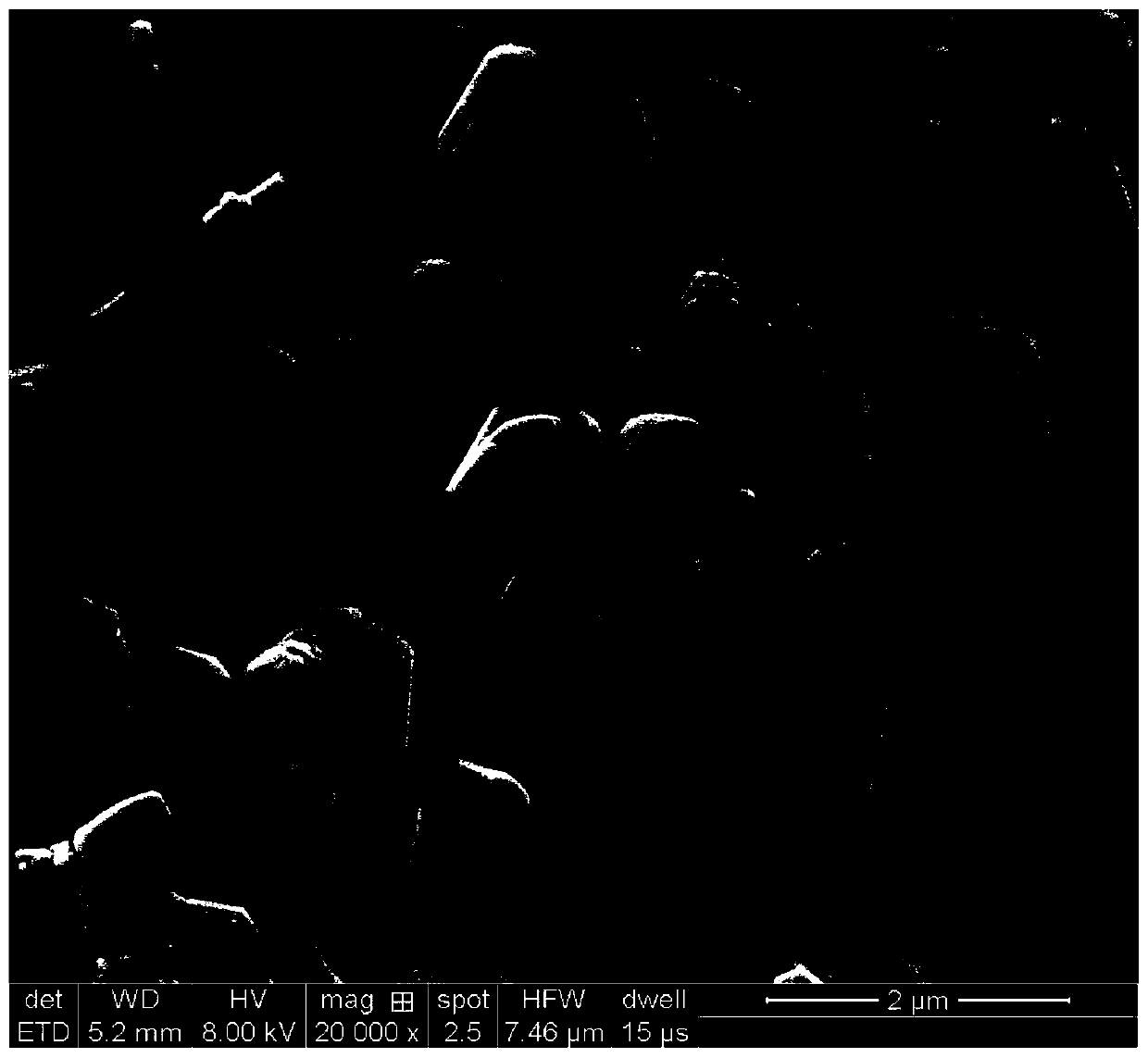

Casting iron pan and casting process thereof

InactiveCN105671235ALower nucleation barrierIncreased crystallization nucleation kineticsCooking-vessel materialsSeed crystalCast iron

The invention discloses a casting iron pan and a casting process thereof.The casting process includes the steps of smashing pig iron, adding samarium and neodymium pure metal into a smelting furnace to be smelted at a high temperature, lowering the temperature of molten iron to be 1250-1350 DEG C, casting the molten iron in a sand mold, preparing a nucleation seed crystal agent, instantly putting in the nucleation seed crystal agent, conducting stirring to evenly disperse the nucleation seed crystal agent in molten iron till small micro-crystals appear, cooling the molten iron containing small micro-crystals till the molten iron is solidified, conducting demolding to obtain a rough product, conducting tempering on the rough product, taking out the product, grinding a tempered casting iron pan till the surface is smooth and presents metal luster to obtain the casting iron pan finished product, putting the finished product in a closed package bag, and storing the casting iron pan in a dry, ventilated and cool place.The casting iron pan is high in strength, plasticity and durability, the problems that the casting iron pan is long in forming time and not stable in performance are solved, and the additional value of the casting iron pan is improved.

Owner:惠州市旲桥科技有限公司

Alumina ceramic and preparation method thereof

The invention provides an aluminum oxide ceramic. The aluminum oxide ceramic is prepared from aluminum oxide, calcined kaolin, bentonite, heavy magnesium carbonate, calcium carbonate, barium carbonate, glycerol, emulsified wax, titanium dioxide, zirconium dioxide and lanthanum oxide. The invention also provides a preparation method for the aluminum oxide ceramic. The preparation method comprises the following steps: mixing all the raw materials, adding water, carrying out ball milling, adding an aqueous polyvinyl alcohol solution with a mass fraction of 10%, continuing ball milling to obtain slurry, carrying out spray granulation to obtain a ceramic material, carrying out dry pressing molding, and performing roasting to obtain the aluminum oxide ceramic. According to the invention, Al2O3-SiO2-MgO-CaO composed of aluminum oxide, kaolin, bentonite, heavy magnesium carbonate and calcium carbonate is used as a basic system; barium carbonate, zirconium dioxide and lanthanum oxide are addedto serve as grain inhibitors; titanium dioxide serves as a solid solvent; glycerol and emulsified wax serve as dispersing agents; so the aluminum oxide ceramic with high bending strength is prepared.

Owner:陕西澳华瓷业科技有限公司

Sizing beam technological production method for linen yarn

InactiveCN103266436ARealize shaft sizing processReduce blemishesLiquid/gas/vapor removalVegetal fibresYarnWax

The invention relates to a sizing beam technological production method for linen yarn. The sizing beam technological production method is used for combined-beam sizing of the linen yarn, and includes the steps of (1) warping in batches: warping the linen yarn via a batch warping machine with a weaving beam range smaller than a conventional range; (2) preparing a sizing agent: forming the sizing agent by mixing 18Kg of starch, 5Kg of glue, 3Kg of wax slices, 1.5Kg of glycerin, 3Kg of antistatic agents and 3Kg of softening agents into 800 liters of water; (3) combined-beam sizing: sizing the linen yarn by enabling the linen yarn to enter a size groove filled with the sizing agent, and drying the sized linen yarn in a drying barrel after the sized linen yarn passes through a size squeezing roller; and (4) controlling moisture regaining rate: controlling the moisture regaining rate of the sized and dried linen yarn within a range between a yellow area and a red area by a moisture regaining rate control instrument. By the sizing beam technological production method which is easy to master, a combined-beam sizing technology for the linen yarn can be realized, flaws such as broken ends can be reduced, fabric woven subsequently is enabled to be smooth in surface, and quality of fabric products is improved.

Owner:CHANGSHU CHANGHONG TEXTILE

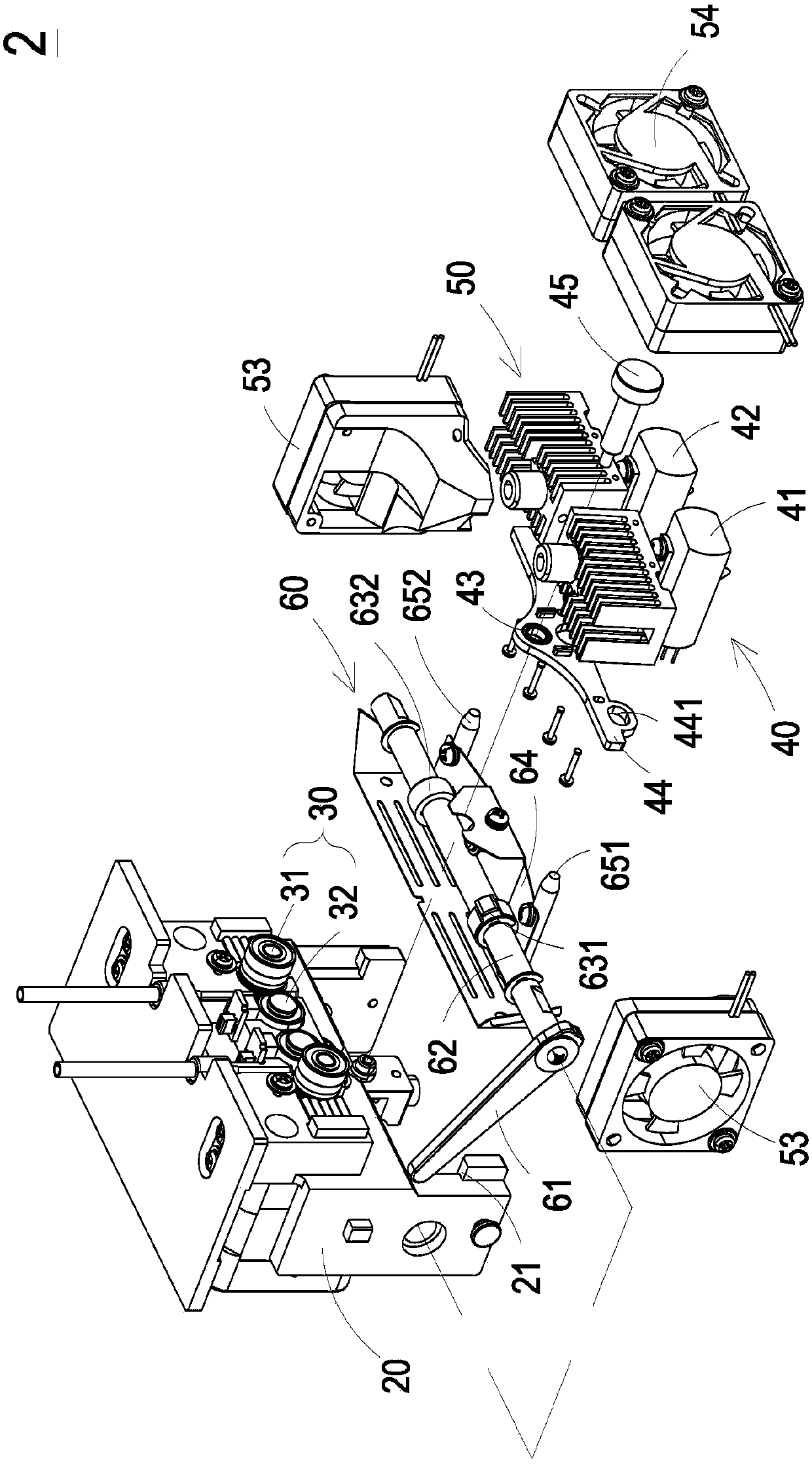

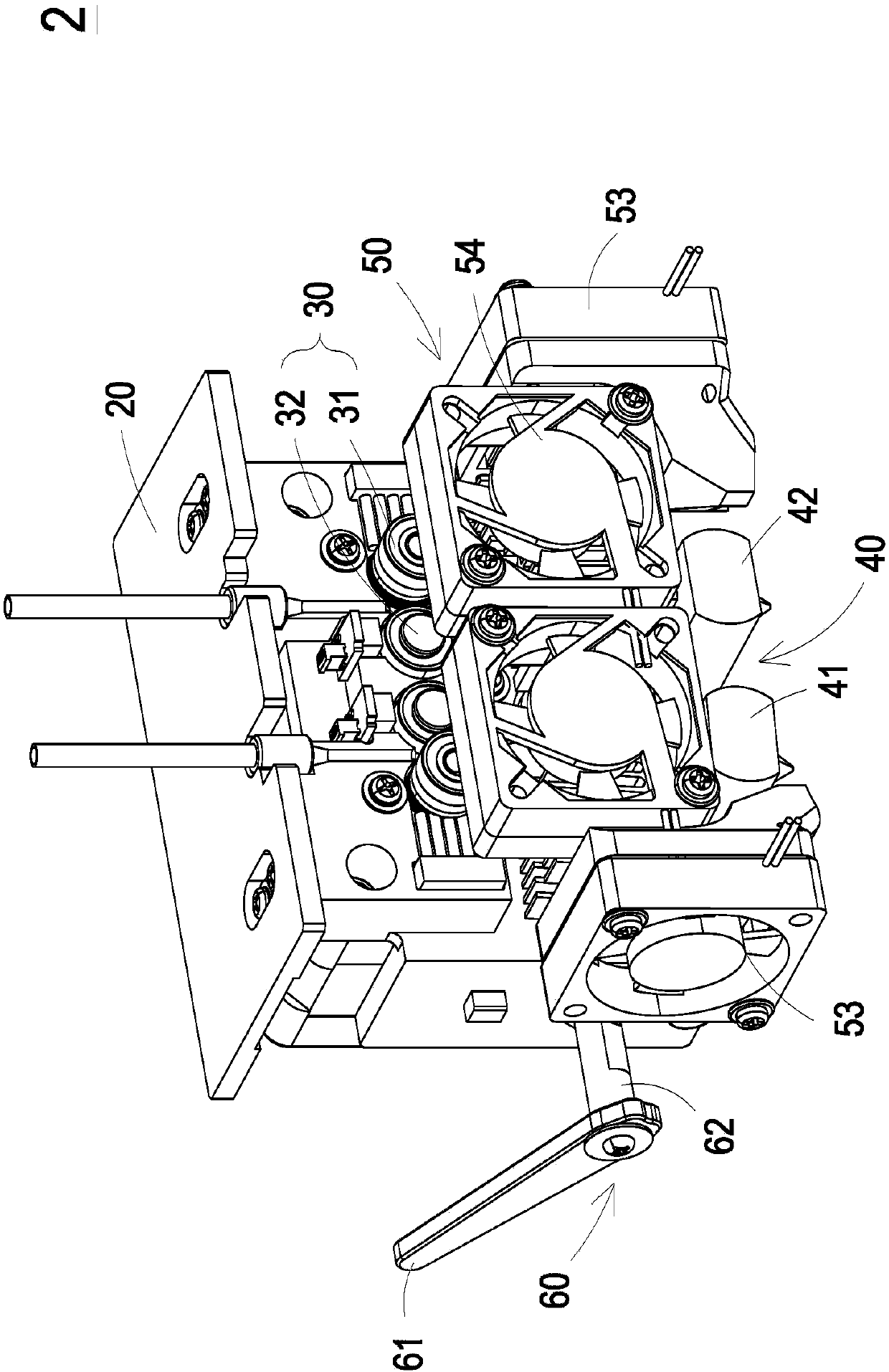

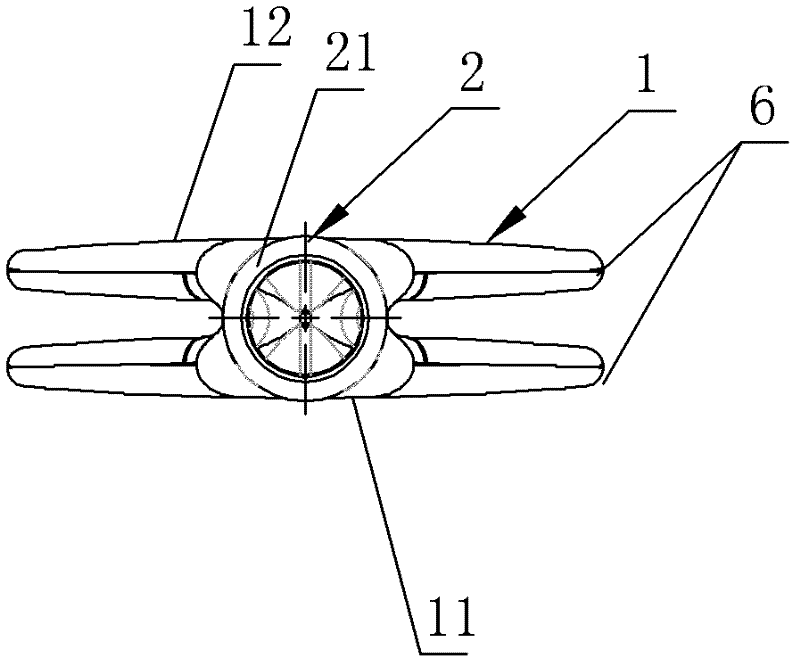

Double-nozzle assembly and three-dimensional printing device applying same

The invention relates to a double-nozzle assembly and a three-dimensional printing device applying the same. The double-nozzle assembly comprises a base, a nozzle module and a switching module; and abearing of the nozzle module is arranged in the middle of a positioning swing arm, a first nozzle unit and a second nozzle unit are fixed to the positioning swing arm and located at the two opposite lateral edges of the bearing correspondingly, and a fixing shaft piece erects the nozzle module on the base through the bearing. When a rotating shaft of the switching module switches a first cam or asecond cam on the rotating shaft to abut against one end or the other end of a force application elastic sheet in a pressing mode, a third connecting element or a fourth connecting element is driven to abut against one end or the other end of the positioning swing arm of the nozzle module in a pressing mode, so that the positioning swing arm swings with the bearing as the center, and the height difference between the first nozzle unit and the second nozzle unit is switched.

Owner:TECO IMAGE SYST

Thermocuring self-repairing paint surface protective film and preparation method thereof

PendingCN113072891AGood optical performanceStrong weather resistanceEster polymer adhesivesAnti-corrosive paintsPolymer sciencePtru catalyst

The invention provides a thermocuring self-repairing type paint surface protective film and a preparation method thereof. The paint surface protective film is sequentially composed of a release film layer A, a pressure-sensitive adhesive layer, a base material layer, a self-repairing coating and a release film layer B from bottom to top. The self-repairing coating is made of self-repairing thermocuring type modified polyurethane acrylate resin and comprises 10-18% of functionalized acrylic resin I, 10-18% of functionalized acrylic resin II, 12-35% of polymer polyol, 30-50% of a solvent, 15-30% of a curing agent, 0.05-0.2% of a catalyst and 0.3-1.0% of auxiliaries, and the base material is made of optical-grade aliphatic TPU, the pressure-sensitive adhesive is an acrylate adhesive, and the release film layer is a PET silicone oil release film. The paint surface protective film is simple in preparation process and easy for industrial batch production, the self-repairing coating has excellent scratch resistance, self-repairing performance, aging resistance, corrosion resistance, pollution resistance and the like after being thermally cured, and the self-repairing paint surface protective film can be widely applied to the fields of automobile and furniture paint surface protection, electronic equipment screen protection and the like.

Owner:南阳金牛彩印集团有限公司

All-steel radial tire with tire bead reinforced by two layers of U-shaped steel wires and preparation method of tire

The invention relates to an all-steel radial tire capable of adjusting the steel ladle structure of a tire bead and a preparation method of the tire, and in particular relates to the all-steel radial tire with the tire bead reinforced by two layers of U-shaped steel wires. The all-steel radial tire comprises a tire crown, a tire shoulder, a tire body cord fabric layer, an inner liner layer, a belt layer and the tire bead, wherein the tire bead comprises steel wire rings, bead filler and seam allowance protecting adhesive; the steel wire rings are reversely wrapped by the tire body cord fabric layer; a first steel wire cord fabric reinforcement layer and a second steel wire cord fabric reinforcement layer are respectively arranged on two sides of the tire body cord fabric layer; the first steel wire cord fabric reinforcement layer is boned between the tire body cord fabric layer and the inner liner layer; the second steel wire cord fabric reinforcement layer is arranged between the tire body cord fabric layer on the outer side of the tire bead and the bead filler. According to the all-steel radial tire with the designed tire bead, the flaws at the positions of seam allowances are effectively reduced, so that the tire rates of return and the compensate for checking tire wrong are decreased. Thus, the loss of an enterprise is reduced and the cyclic utilization rate of the tire is effectively improved. As a result, the all-steel radial tire provided by the invention conforms to the current enterprise philosophy of sustainable development and economy.

Owner:ZHONGCE RUBBER GRP CO LTD

Integral type respiratory bag and manufacturing method thereof

ActiveCN102553044APrevent air leakageSimplify the manufacturing processRespiratorsCoatingsAdhesiveEngineering

The invention discloses an integral type respiratory bag, comprising a hollow bag body and a joint which is arranged on a bag body connector, wherein a through hole on the joint is communicated with the inner part of the bag body. The integral type respiratory bag is characterized in that the bag body and the joint are integrally manufactured in a mould cavity by coating glue in a vibration manner, heating and molding. The invention further discloses a manufacturing method of the integral type respiratory bag. The bag body of the respiratory bag provided by the invention is manufactured in the glue vibration manner and thicker glue can be coated on a transition part between the side face and the bottom face of the bag body, so as to prevent fisheyes from being generated after the bag body is inflated. The respiratory bag provided by the invention is integrally molded and the joint does not need to be additionally arranged, so that the manufacturing procedure is simplified and the labor cost is reduced; viscose glue or adhesive does not need to be used for sticking so that the problem that the joint drops off due to poor sticking so as to cause air leakage is solved; and therefore, materials are saved and the production cost is reduced. With the adoption of the integral type respiratory bag provided by the invention, the phenomena of causing anaphylactic reaction of a human body and diffusing a pungent smell are avoided and no harm is caused to the human body.

Owner:广州晟威医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com