Casting iron pan and casting process thereof

A casting process and a technology for cast iron pots, which are applied in the field of cast iron pots and their casting processes, can solve the problems of long casting time and unstable properties of iron pots, and achieve the effects of reducing defects and defects, uniform properties and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

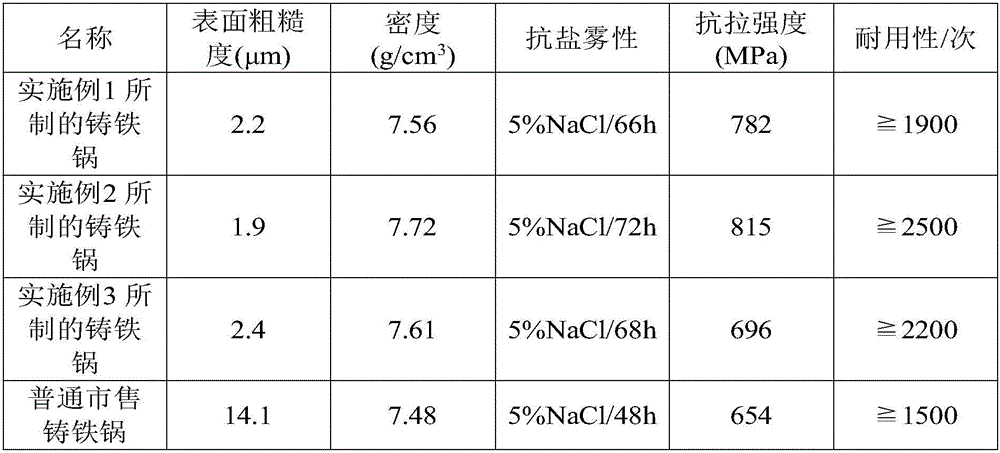

Examples

Embodiment 1

[0034] Casting process of a cast iron pot

[0035] Include the following steps:

[0036] Step S1, smelting molten iron: put cast pig iron broken into small pieces into the smelting furnace with metal elemental samarium and metal elemental neodymium in a mass ratio of 100:0.02:0.05, and continue heating to 1450°C. It is smelted into molten iron at high temperature, and at the same time, a mechanical stirring device is used to stir the molten iron at a speed of 100r / min, so that the molten iron is fully melted and even.

[0037] Step S2, pouring: Circulating air at 5°C is introduced into the sky above the smelting furnace, and the uniformly melted molten iron in it is slowly cooled to 1250°C, and then poured into a sand mold at a rate of 20L / s.

[0038] Step S3, preparation of nucleating seed crystal agent: quantitatively weigh raw materials, including 50 parts of ferric oxide, 20 parts of rutile, 10 parts of flake graphite, 10 parts of elemental silicon fine powder, pass throu...

Embodiment 2

[0044] Casting process of a cast iron pot

[0045] Include the following steps:

[0046] Step S1, smelting molten iron: Put cast iron broken into small pieces into the smelting furnace with metal elemental samarium and metal elemental neodymium in a mass ratio of 100:0.08:0.10, and heat up to 1500°C through continuous heating. It is smelted into molten iron at high temperature, and at the same time, a mechanical stirring device is used to stir the molten iron at a speed of 300r / min, so that the molten iron is fully melted and even.

[0047] Step S2, pouring: the circulating air of 15°C is introduced into the smelting furnace, and the uniformly melted molten iron in it is slowly cooled to 1350°C, and then poured into the sand mold at a rate of 50L / s.

[0048] Step S3, preparation of nucleating seed crystal agent: quantitatively weigh raw materials, including 150 parts of ferric oxide, 80 parts of rutile, 50 parts of flake graphite, 50 parts of elemental silicon fine powder, pa...

Embodiment 3

[0054] Casting process of a cast iron pot

[0055] Include the following steps:

[0056] Step S1, smelting molten iron: put cast pig iron broken into small pieces into the smelting furnace with metal elemental samarium and metal elemental neodymium according to the mass ratio of 100:0.05:0.07, and continue heating to 1475°C, It is smelted into molten iron at high temperature, and at the same time, a mechanical stirring device is used to stir the molten iron at a speed of 200r / min, so that the molten iron is fully melted and even.

[0057] Step S2, pouring: Ventilate circulating air at 10°C over the smelting furnace to slowly cool the evenly melted molten iron to 1300°C, then pour it into the sand mold at a rate of 35L / s.

[0058] Step S3, preparation of nucleating seed crystal agent: Quantitatively weigh raw materials, including 100 parts of ferric oxide, 50 parts of rutile, 30 parts of flake graphite, 30 parts of elemental silicon fine powder, pass through a 90-mesh sieve af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com