Concrete early strength agent, early strength concrete and preparation method of early strength concrete

A technology for concrete and early strength agent, which is applied in the field of rapid improvement of early strength of concrete under low temperature environment, can solve the problems of precipitation, difficult control of process parameters, and cumbersome preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

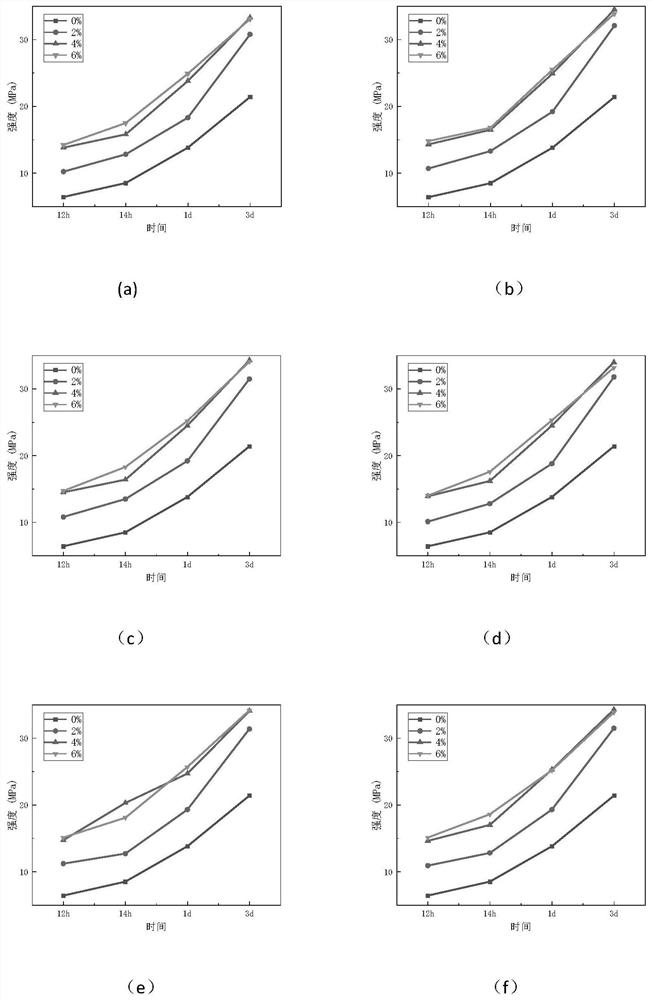

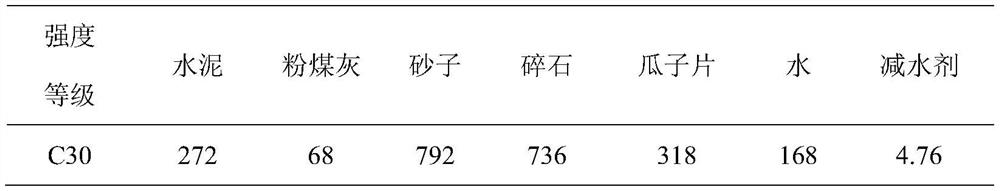

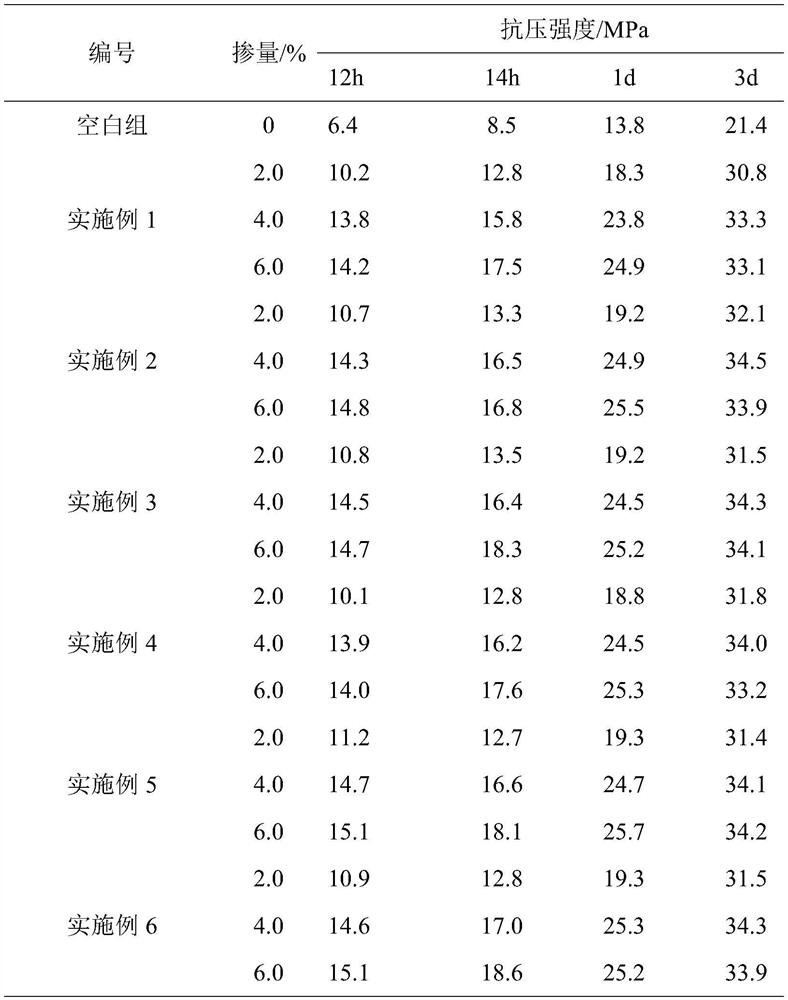

Examples

Embodiment 1

[0034] Component A of the concrete early strength agent in this embodiment includes the following ingredients in parts by weight: 170 g of silica sol dispersion, 130 g of siloxane emulsion, 30 g of surfactant, 110 g of soluble calcium salt, and 40 g of alcohol amines. The raw material composition of the silica sol dispersion liquid is: 1% sodium methylene bis-naphthalene sulfonate, 0.8% silane coupling agent, 60% nano-scale silicon dioxide, the balance is water, and the total amount is 100%. The raw material composition of component B is: 350g of metaaluminate, 250g of sodium silicate, 250g of lithium carbonate, 60g of calcium tartrate, and 7g of methyl cellulose ether. The mass ratio of component A to component B is 4:1.

[0035] The preparation method of concrete early strength agent component A in this embodiment is specifically as follows: weigh each component according to the formula, dissolve sodium methylene bis-naphthalene sulfonate and silane coupling agent in water, ...

Embodiment 2

[0037] Component A of the concrete early strength agent in this embodiment includes the following ingredients in parts by weight: 200 g of silica sol dispersion, 140 g of siloxane emulsion, 30 g of surfactant, 130 g of soluble calcium salt, and 45 g of alcohol amines. The raw material composition of the silica sol dispersion liquid is: 1% sodium methylene bis-naphthalene sulfonate, 0.8% silane coupling agent, 60% nano-scale silicon dioxide, the balance is water, and the total amount is 100%. The raw material composition of component B is: 350g of metaaluminate, 250g of sodium silicate, 250g of lithium carbonate, 60g of calcium tartrate, and 7g of methyl cellulose ether. The mass ratio of component A to component B is 3:1.

Embodiment 3

[0039] Component A of the concrete early strength agent in this embodiment includes the following ingredients in parts by weight: 230 g of silica sol dispersion, 150 g of siloxane emulsion, 30 g of surfactant, 150 g of soluble calcium salt, and 50 g of alcohol amines. The raw material composition of the silica sol dispersion liquid is: 1% sodium methylene bis-naphthalene sulfonate, 0.8% silane coupling agent, 60% nano-scale silicon dioxide, the balance is water, and the total amount is 100%. The raw material composition of component B is: 350g of metaaluminate, 250g of sodium silicate, 250g of lithium carbonate, 60g of calcium tartrate, and 7g of methyl cellulose ether. The mass ratio of component A to component B is 7:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com