Reverse osmosis membrane production equipment and reverse osmosis membrane preparation method

A reverse osmosis membrane and production equipment technology, applied in the field of reverse osmosis membrane production equipment and reverse osmosis membrane preparation, can solve problems such as poor quality of reverse osmosis membrane, achieve quality improvement, improve quality, and ensure smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

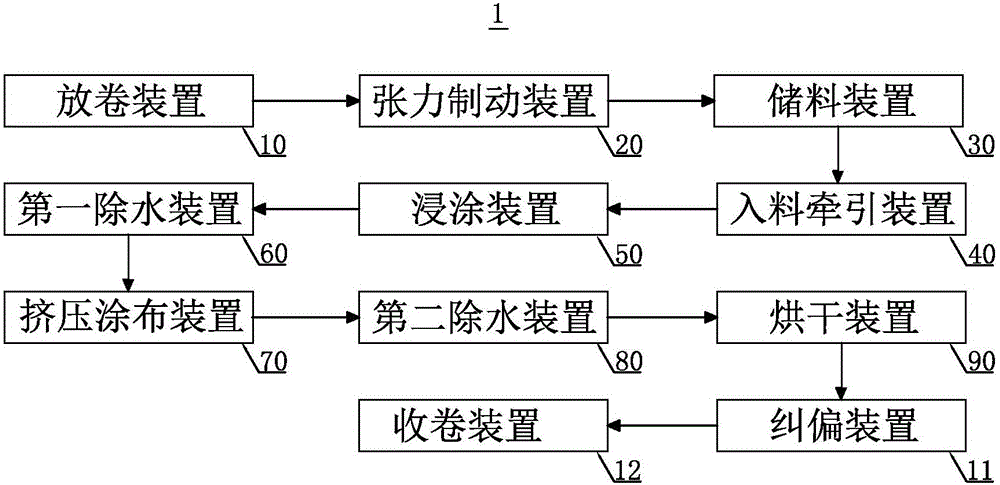

[0118] The method for preparing a reverse osmosis membrane according to the third embodiment of the present invention includes the following steps:

[0119] Step S1: providing a roll of base film;

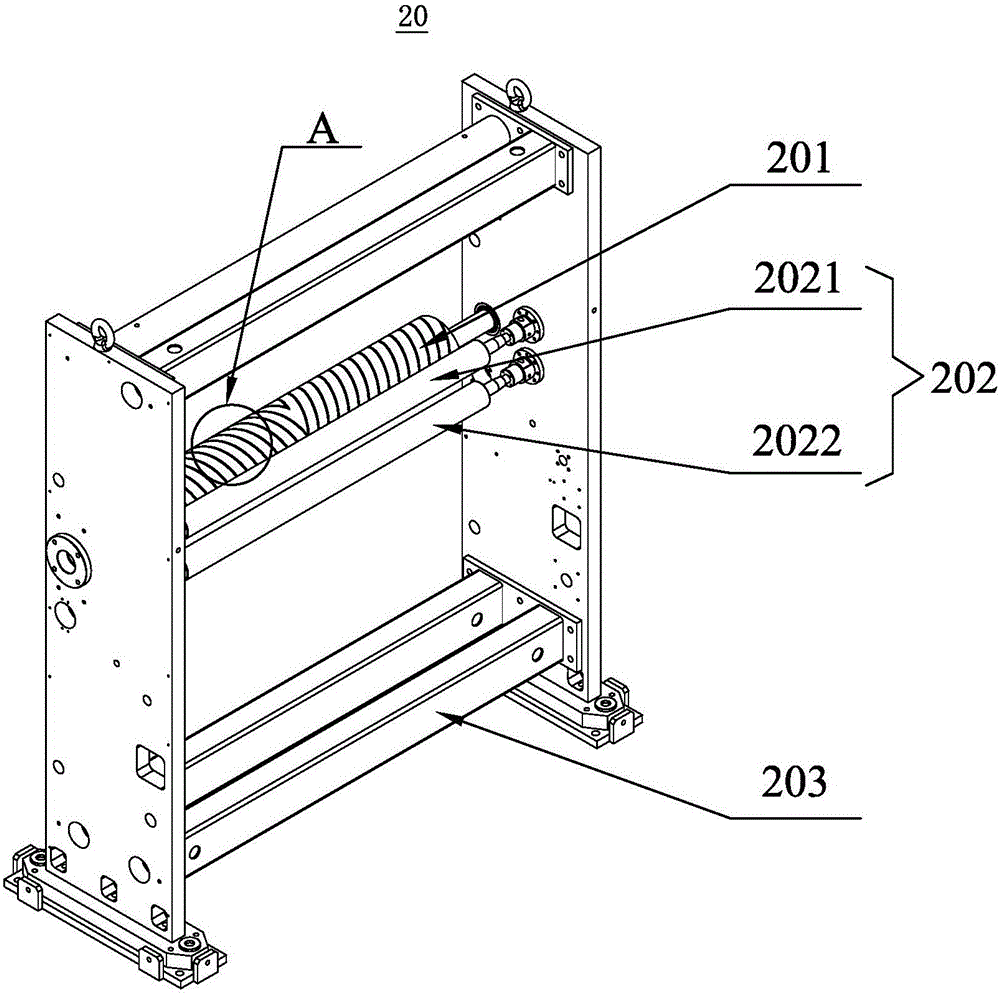

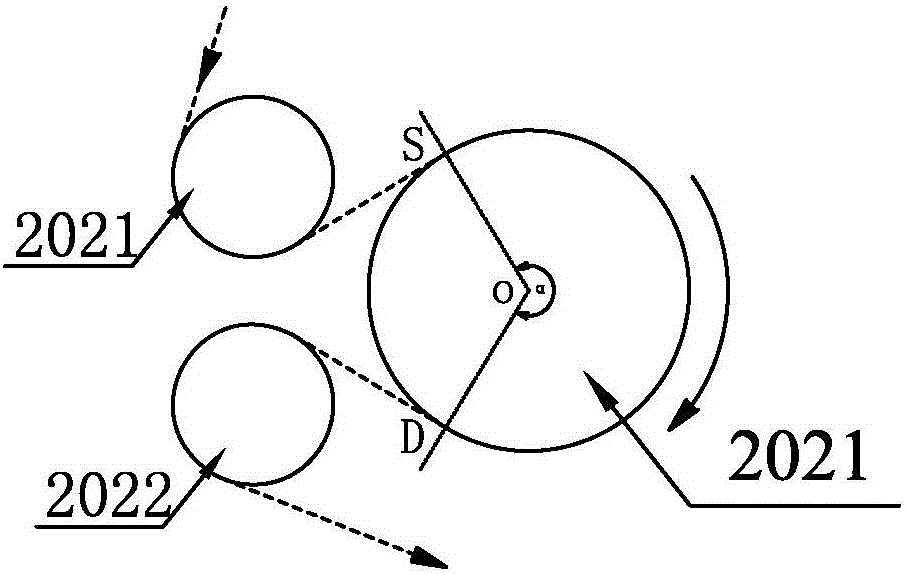

[0120] Step S2: making the basement membrane tense;

[0121] Step S3: pre-storing the unrolled base film;

[0122] Step S4: dragging the base film for dip coating;

[0123] Step S5: Dewatering the base film for the first time;

[0124] Step S6: extrusion coating the base film;

[0125] Step S7: Dewatering the base film for the second time;

[0126]Step S8: Dry the base film; specifically, provide hot air to the opposite sides of the base film at the same time, the hot air on the side of the base film away from the ground is provided by the first air nozzle, and the hot air on the side of the base film close to the ground Provided by the second air nozzle, the first air nozzle is a linear air outlet structure, and the second air nozzle is a planar air outlet structure;

[0127...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com