Yoga mat and manufacturing method thereof

A yoga mat and formula technology, which is applied in the direction of absorbing motion vibration mats, sports accessories, jumping equipment, etc., can solve the problems of yoga mats that do not have wear resistance, single texture, poor color fastness, etc., and achieve rich colors. , the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a kind of preparation method of above-mentioned yoga mat, comprises the steps:

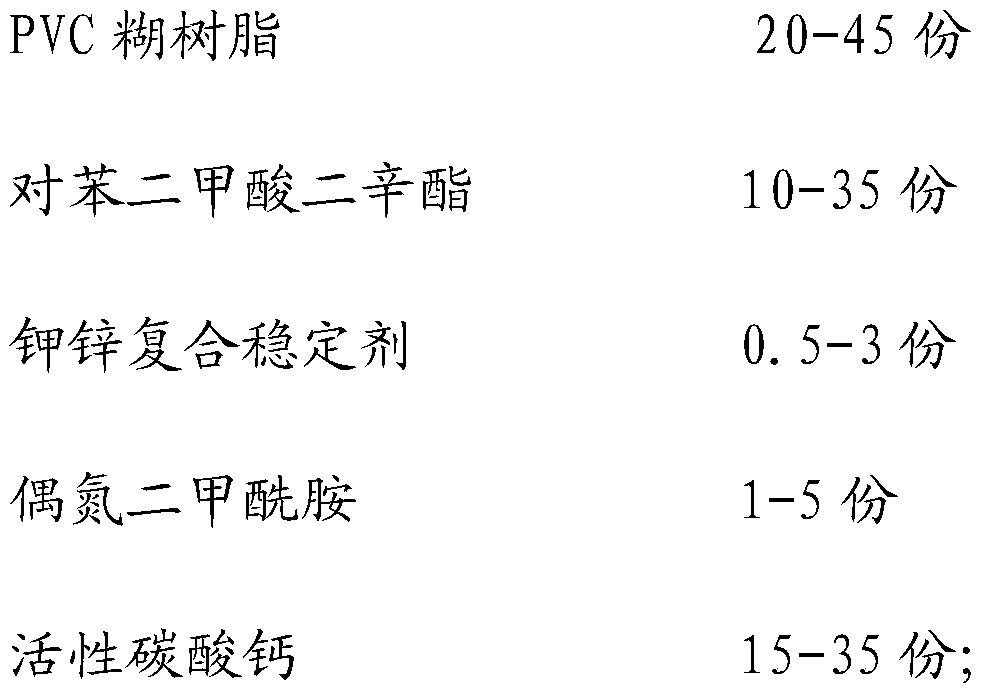

[0041] (1) Preparation of the foam layer: Stir and mix the PVC paste resin, dioctyl terephthalate, potassium-zinc composite stabilizer, azodicarbonamide, and active calcium carbonate in the prescribed amount, inject into the interlining layer , foam molding, to obtain a foam layer; the weight of the foam layer is 1100-1400g / m 2 ; The weight of the wear-resistant layer described in the step (2) is 100-400g / m 2 . The thickness of the foam layer is 4-10mm, and the thickness of the wear-resistant layer in step (2) is 0.5-1.5mm.

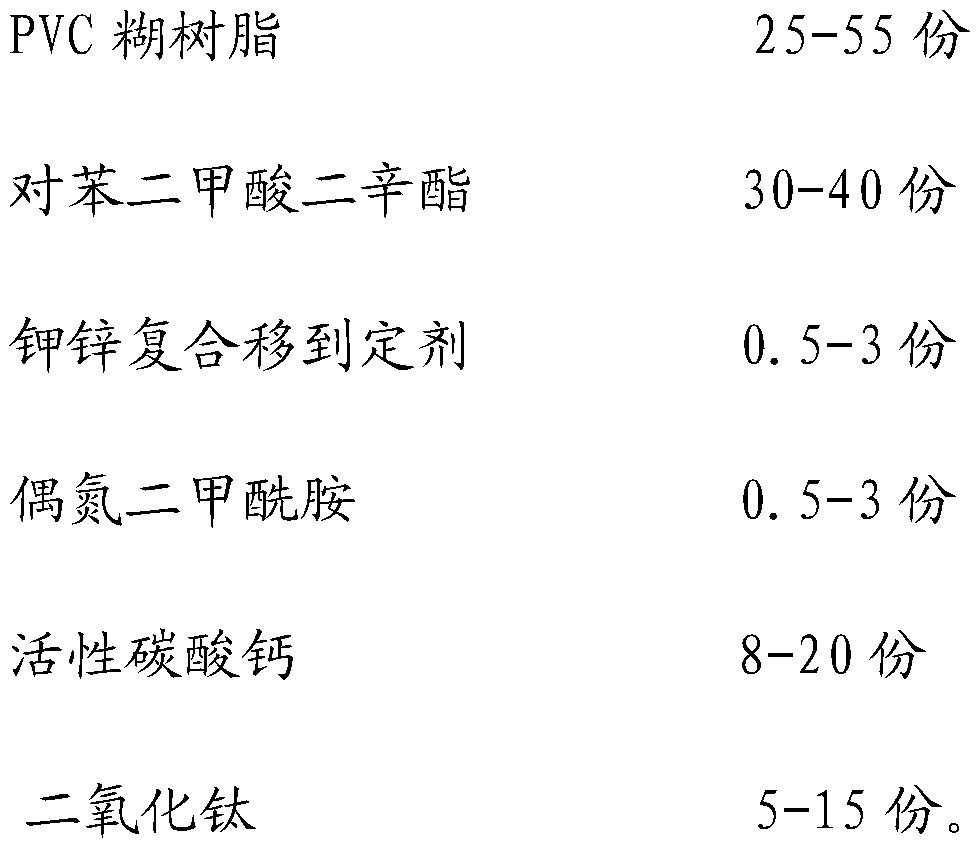

[0042] (2) Coating and scratching wear-resistant layer: Stir and mix the PVC paste resin, dioctyl terephthalate, potassium-zinc composite stabilizer, azodicarbonamide, activated calcium carbonate, and titanium dioxide in the prescribed amount, injection molding, and scraping On the foam layer obtained in the step (1), cooling is f...

Embodiment 1

[0049] A yoga mat is prepared according to the formula ingredients in Table 1, and is made according to the following preparation method, wherein the interlining layer is 14 stitches, and the specification is 75D glossy filaments.

[0050] Formulation of foam layer and wear-resistant layer in table 1 yoga mat

[0051]

[0052]

[0053] The preparation method of this yoga mat is as follows:

[0054] (1) Preparation of the foam layer: according to the formula ingredients in Table 1, the above-mentioned raw materials are stirred and mixed uniformly, injected into the interlining layer, and foamed to obtain the foam layer; the weight of the foam layer is 1300g / m 2 ; The weight of the wear-resistant layer described in the step (2) is 250g / m 2 . The thickness of the foam layer is 6 mm, and the thickness of the wear-resistant layer in step (2) is 1 mm.

[0055] (2) Coating and scraping wear-resistant layer: according to the formula ingredients in Table 1, stir and mix the ...

Embodiment 2

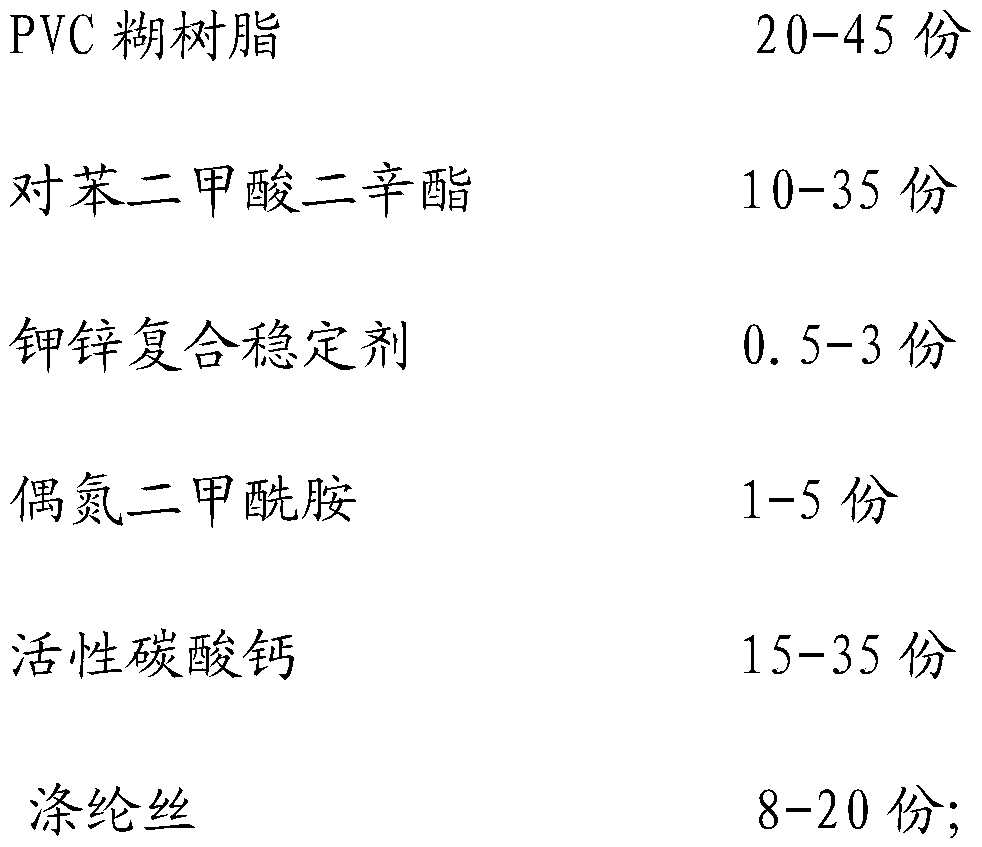

[0062] A kind of yoga mat, according to the formula ingredient in Table 2, and make according to following preparation method, wherein, interlining layer is to be 14 by stitching needle number, and the specification is 75D glossy filament to weave.

[0063] Formulation of foam layer and wear-resistant layer in table 2 yoga mat

[0064]

[0065] The preparation method of this yoga mat is as follows:

[0066] (1) Preparation of the foam layer: according to the formula ingredients in Table 2, the above-mentioned raw materials are stirred and mixed uniformly, injected into the interlining layer, and foamed to obtain the foam layer; the weight of the foam layer is 1300g / m 2 ; The weight of the wear-resistant layer described in the step (2) is 250g / m 2 . The thickness of the foam layer is 6 mm, and the thickness of the wear-resistant layer in step (2) is 1 mm.

[0067] (2) Coating and scraping wear-resistant layer: According to the formula ingredients in Table 2, the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com