Dyeable environment-friendly polyurethane elastomer and preparation method thereof

A polyurethane elastomer and environment-friendly technology, applied in the field of polyurethane materials, can solve the problems that polyurethane elastomers are not easy to dye, do not meet safety and environmental protection requirements, etc., and achieve the effects of bright color, environmental protection and safe production, and increased dyeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of dyeable environment-friendly polyurethane elastomer adopts twin-screw reaction extruder continuous production one-step synthesis process, comprising the following steps:

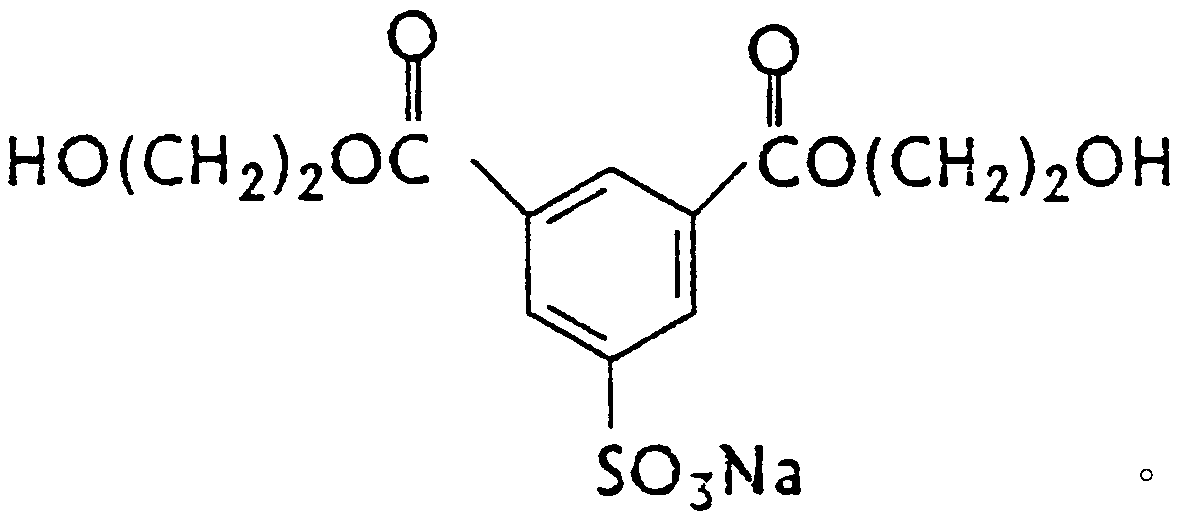

[0032] S1. Add polyhydric alcohol, 1,3-benzenedicarboxylic acid, 5-sulfonic acid-1,3-di(2-hydroxyethyl) ester sodium salt and antioxidant into feed tank A, stir well and heat evenly, and heat to After the material temperature is 100-120°C, continue to stir at a low speed below 50rpm and nitrogen blanket for later use;

[0033] S2. Melt the diisocyanate and add it to the trough B, heat it to the required temperature of 50-60°C, then continue to stir at a low speed of 50 rpm or less, pass nitrogen and seal it for later use;

[0034] S3. The materials in trough A and trough B are metered by the metering pump and sent to the mixing head. After stirring at a high speed of 2000rpm or more for uniform mixing, the mixed material is sent to the twin-screw reaction extruder for r...

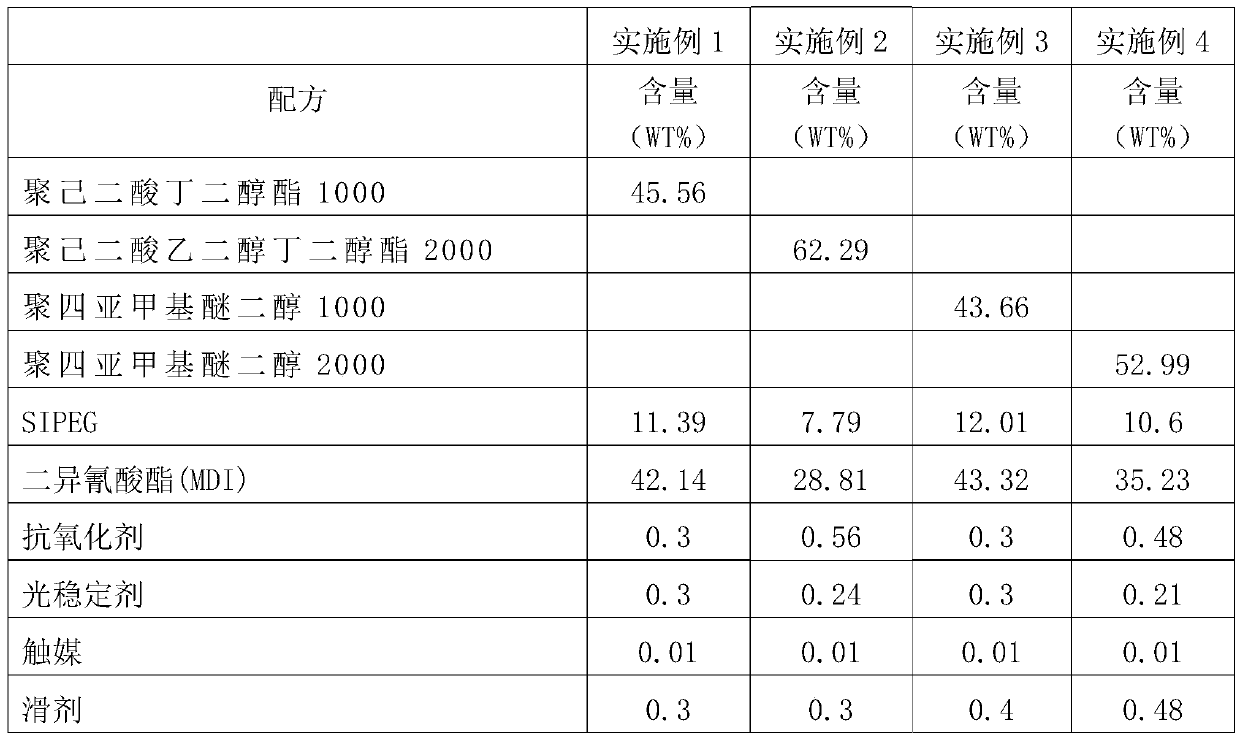

Embodiment 1

[0047] A kind of preparation method of dyeable environment-friendly polyurethane elastomer adopts twin-screw reaction extruder continuous production one-step synthesis process, comprising the following steps:

[0048] S1, based on the total weight of the polyurethane elastomer, 45.56wt% of polybutylene adipate 1000, 11.39wt% of 1,3-phthalic acid, 5-sulfonic acid-1,3-bis(2 -Hydroxyethyl) ester sodium salt and 0.3wt% antioxidant are added in feed tank A, fully stirred and evenly heated, heated to a material temperature of 100-120°C and then continuously stirred at a low speed and nitrogen sealed for later use;

[0049] S2. Based on the total weight of the polyurethane elastomer, melt 42.14wt% of diisocyanate and add it to the feed tank B, heat it to the required temperature of 50-60° C., then continue to stir at a low speed and ventilate it with nitrogen and seal it for later use;

[0050] S3. The materials in trough A and trough B are metered by the metering pump and then sent ...

Embodiment 2

[0053] A kind of preparation method of dyeable environment-friendly polyurethane elastomer adopts twin-screw reaction extruder continuous production one-step synthesis process, comprising the following steps:

[0054] S1. Based on the total weight of the polyurethane elastomer, 62.29wt% of polyethylene adipate butylene glycol ester 2000, 7.79wt% of 1,3-phthalic acid, 5-sulfonic acid-1,3- Bis(2-hydroxyethyl) ester sodium salt and 0.56wt% antioxidant are added in feed tank A, fully stirred and evenly heated, after being heated to 100-120° C. of feed temperature, continue to stir at a low speed and nitrogen seal for standby;

[0055] S2. Based on the total weight of the polyurethane elastomer, melt 28.81wt% of diisocyanate and add it to the feed tank B, heat it to the required temperature of 50-60°C, and then continue to stir at a low speed and pass nitrogen nitrogen seal before use;

[0056] S3. The materials in trough A and trough B are metered by the metering pump and then sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com