A kind of biomass auxiliary agent and its preparation method and application

A technology of biomass and auxiliaries, used in dyeing methods, textile and paper making, resistance to vector-borne diseases, etc., can solve problems such as dyeing uniformity and poor color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

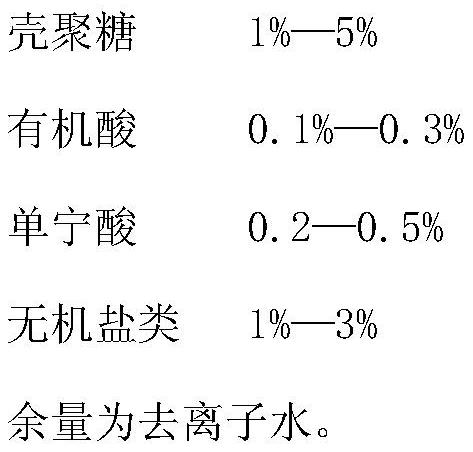

[0034] Biomass additive formula is as follows (by weight percentage):

[0035] Chitosan 1%

[0036] Acetic acid 0.12%

[0037] Tea polyphenols 0.3%

[0038] Potassium aluminum sulfate / anhydrous sodium chloride (mass ratio 3:1) 1%

[0039] The balance is deionized water.

[0040] The preparation method of biomass additives is as follows:

[0041] Step (1): Accurately weigh a certain amount of chitosan, and make a solution with a solid content of 1% with 50°C deionized water;

[0042] Step (2): Add 0.12% acetic acid in proportion to the chitosan solution prepared in step 1 to promote the dissolution of the chitosan solution, and the viscosity is 12 Mpa.s.

[0043] Step (3): After adding 0.3% tea polyphenols and 1% aluminum potassium sulfate / sodium chloride on the basis of step 2, place it on a magnetic stirrer and stir evenly for later use.

Embodiment 2

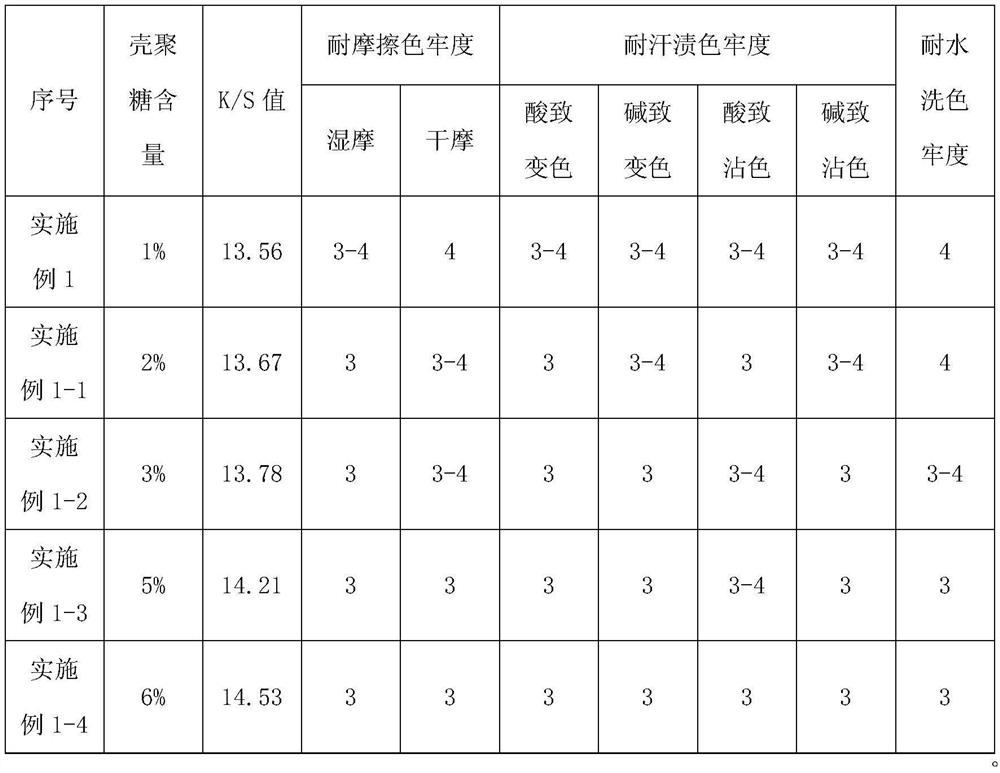

[0070] Biomass additives are prepared as in Example 1, the difference is that the proportion of chitosan in the biomass additives is adjusted as shown in Table 2, and the method of Application Example 1 is used to dye cotton / Hisel blended fabrics, To study the effect of chitosan content on the dyeing effect of fabrics, according to the national standard GB31701-2015, the color fastness and K / S value were tested respectively, and Table 2 was obtained.

[0071] Table 2, the impact of the content of chitosan on the dyeing effect

[0072]

[0073] Table 2 analysis: as can be seen from the data in Table 2, as the chitosan content increases from 1% to 6%, the K / S value of the fabric increases thereupon; and the color fastness to rubbing is lower than 2% at the chitosan content When the content of chitosan exceeds 2%, it shows a downward trend; the color fastness to perspiration, especially when the color fastness to acid and alkali changes exceeds 2%, the color difference is obvi...

Embodiment 3

[0075] Biomass additives are prepared as in Example 1, the difference is that the organic acid and its proportion in the biomass additives are adjusted as shown in Table 3, and the method of Application Example 1 is used to dye the cotton / Hisel blended fabric, According to the national standard GB31701-2015, the effect of organic acid content on the dyeing effect of fabrics was tested from color fastness and K / S value, etc., and Table 3 was obtained.

[0076] Table 3. Effect of selection and content of organic acid on dyeing effect

[0077]

[0078]

[0079] Table 3 analysis: as can be seen from the data in table 3, embodiment 1 is compared with embodiment 2-1 to 2-4 as preferred process, and along with the raising of acetic acid content, the K / S value of fabric is rising trend, and the fabric's The color fastness to rubbing increases gradually with the increase of the acetic acid content, and the color fastness to perspiration of the fabric is around level 3, and the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com