Biomass assistant as well as preparation method and application thereof

A technology of biomass and auxiliaries, which is applied in dyeing, textiles and papermaking, and resistance to vector-borne diseases, etc. It can solve problems such as dyeing uniformity and poor color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

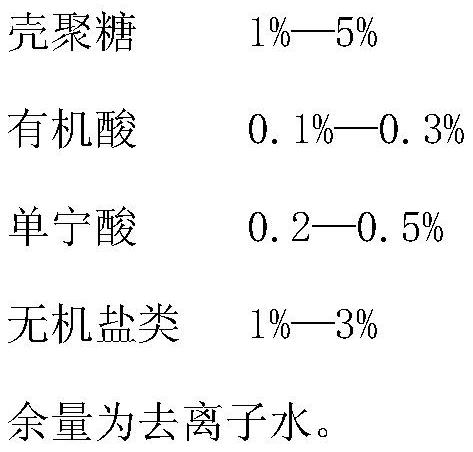

[0034] Biomido auxiliary formula is as follows (% by weight):

[0035] Chitosan 1%

[0036] 0.12% of acetic acid

[0037] Tea polyphenol 0.3%

[0038] 1% of sodium sulfate / water sodium sulfate (mass ratio 3: 1)

[0039] The remaining amount is deionized water.

[0040] The biological auxiliary method is as follows:

[0041] Step (1): Accurately weigh a certain amount of chitosan, and a solution containing 1% solids with a deionized water of 50 ° C;

[0042] Step (2): 0.12% of the acetic acid was added to the chitosan solution in step 1 to promote the dissolution of the chitosan solution and the viscosity was 12 MPa.s.

[0043] Step (3): 0.3% of the tea polyphenols, and 1% after potassium sulfate / sodium chloride were added to the magnetic stirrer and stir well.

Embodiment 2

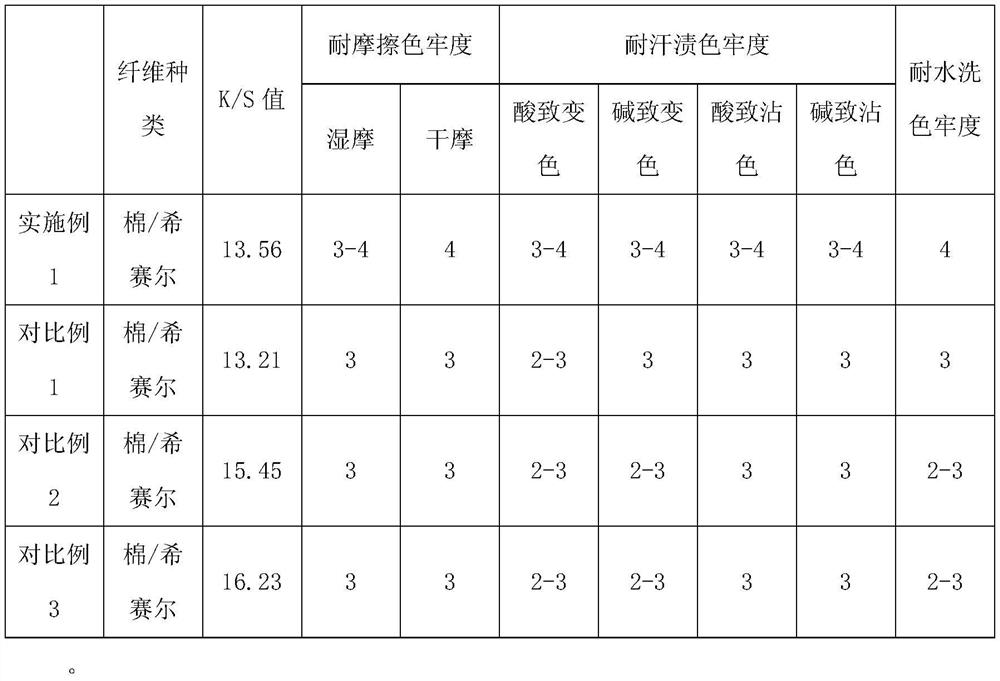

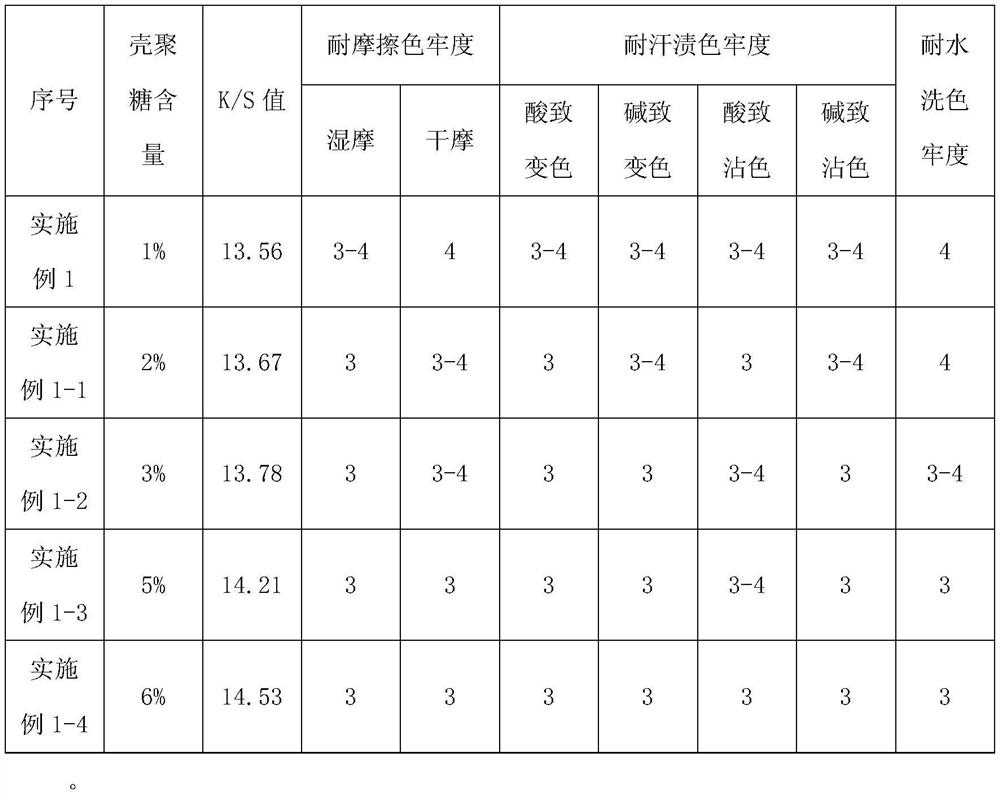

[0070] Biomass Auxiliary Auxiliary Anti-Embodiment 1, distinguishing between: Adjusting the proportion of the chitosan in the biomido auxiliary agent, as shown in Table 2, using the method of applying Example 1 to staining cotton / Hyr blend fabric, The effects of chitosan content on fabric dyeing effects were studied. According to national standards GB31701-2015, the color fastness, k / s value, etc. were detected, and Table 2 was obtained.

[0071] Table 2, the effect of chitosan on dyeing effect

[0072]

[0073] Table 2 Analysis: According to Table 2, as the chitosan content increases from 1% to 6%, the K / S value of the fabric follows it; and the resistance of resistance is less than 2% in the chitosan content of less than 2%. When the performance is good, more than 2%, the decline will be decreased; the fastness of the sweat, especially when the anti-sweet acid alkali discoloration is more than 2%, the color difference is obvious; when the chitosan content is less than 2%...

Embodiment 3

[0075] Biomass Auxiliary Anti-Bioplasmic Auxiliary Auxiliary Example 1 differs to: Adjusting organic acid and its proportion in the biomidic aid, as shown in Table 3, using the method of applying Example 1 to staining cotton / Hyr blend fabric, The effects of organic acid content on the dyeing effect of fabric were studied. According to national standards GB31701-2015, it was detected from color fastness, k / s value, and the like, respectively.

[0076] Table 3, the choice of organic acid and the effect of content on dyeing effect

[0077]

[0078]

[0079] Table 3 Analysis: It is known from Table 3, and Example 1 is a preferred process, and the control is performed with Examples 2-1 to 2-4. As the acetic acid content is increased, the K / S value of the fabric is elevated, the fabric The fast-resistant fastness is improved with the increase of the acetic acid content, gradually increases, the weakness of the fabric is near the 3 stage, and the change is not obvious. After re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com