UV (Ultraviolet) gloss oil, high-gloss scrap-resisting decorative film prepared from same and preparation method of decorative film

A decorative film and high-gloss technology, which is applied in special decorative structures, decorative arts, coatings, etc., can solve the problems of difficult to know technical effects, complex composition, and many process steps, so as to achieve fewer defects, increase gloss, and improve durability. The effect of scraping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

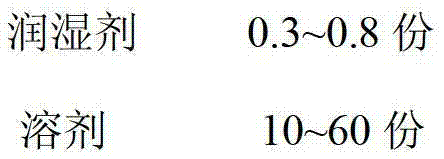

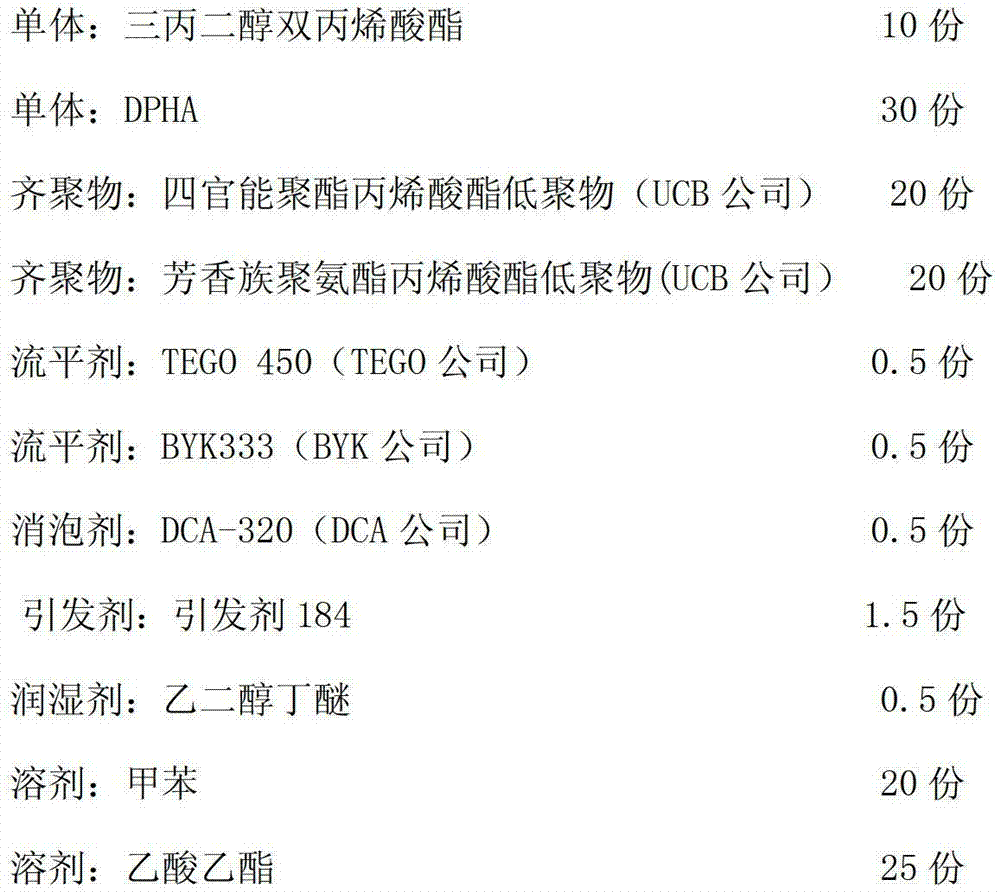

[0022] (1) To prepare UV varnish, weigh each component (by weight) according to the following formula:

[0023]

[0024] The preparation process of UV varnish has the following three steps: the first step, mix the monomer and oligomer uniformly according to the above formula, and slowly add the leveling agent and wetting agent; the second step, dissolve the initiator in part Solvent, and then added to the material in the first step, then add defoamer to it for defoaming; finally add solvent to adjust viscosity. The whole preparation process can be operated at room temperature.

[0025] (2) Coating and processing ordinary high-gloss decorative film by precision coating machine: apply the UV varnish prepared in step (1) on the surface of ordinary high-gloss decorative film, control the thickness of the coated wet film at 10-15 μm, and then carry out UV Drying and curing, wherein the drying temperature is controlled at 30-70 degrees Celsius, the line speed is controlled at 7-...

Embodiment 2

[0028] (1) To prepare UV varnish, weigh each component (by weight) according to the following formula:

[0029]

[0030]

[0031] The preparation process of UV varnish has the following three steps: the first step, mix the monomer and oligomer uniformly according to the above formula, and slowly add the leveling agent and wetting agent; the second step, dissolve the initiator in part Solvent, and then added to the material in the first step, then add defoamer to it for defoaming; finally add solvent to adjust viscosity. The whole preparation process can be operated at room temperature.

[0032] (2) Coating and processing ordinary high-gloss decorative film by precision coating machine: apply the UV varnish prepared in step (1) on the surface of ordinary high-gloss decorative film, control the thickness of the coated wet film at 10-15 μm, and then carry out UV Drying and curing, wherein the drying temperature is controlled at 30-70 degrees Celsius, the line speed is cont...

Embodiment 3

[0035] (1) To prepare UV varnish, weigh each component (by weight) according to the following formula:

[0036]

[0037] The preparation process of UV varnish has the following three steps: the first step, mix the monomer and oligomer uniformly according to the above formula, and slowly add the leveling agent and wetting agent; the second step, dissolve the initiator in part Solvent, and then added to the material in the first step, then add defoamer to it for defoaming; finally add solvent to adjust viscosity. The whole preparation process can be operated at room temperature.

[0038] (2) Coating and processing ordinary high-gloss decorative film by precision coating machine: apply the UV varnish prepared in step (1) on the surface of ordinary high-gloss decorative film, control the thickness of the coated wet film at 10-15 μm, and then carry out UV Drying and curing, wherein the drying temperature is controlled at 30-70 degrees Celsius, the line speed is controlled at 7-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com