All-steel radial tire with tire bead reinforced by two layers of U-shaped steel wires and preparation method of tire

A technology of radial tires and bead rings, which is applied to tire parts, tires, tire edges, etc., can solve problems affecting tire performance and service life, and achieve the effects of improving cycle utilization, reducing losses, and reducing refund rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

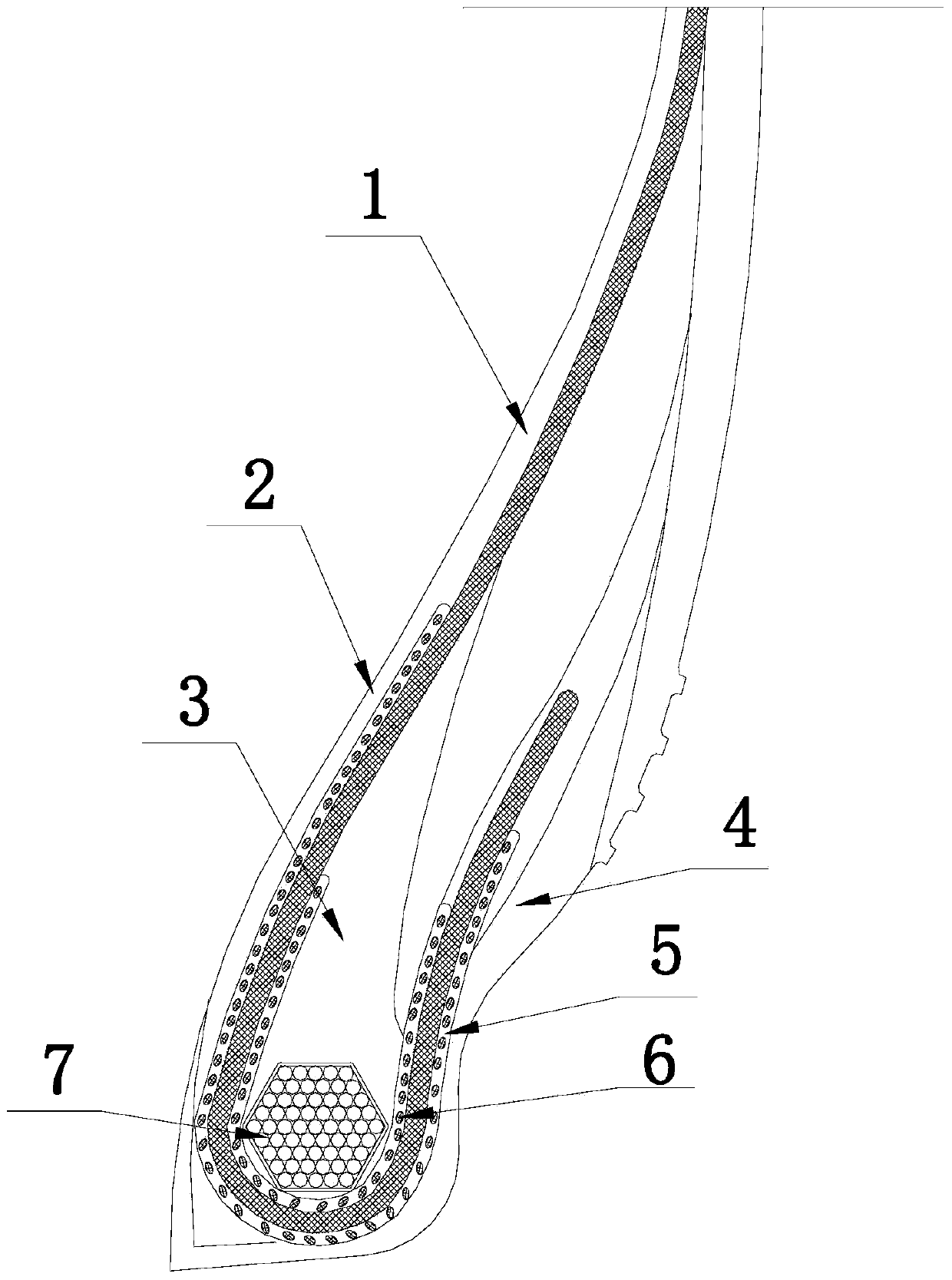

[0030] An all-steel radial tire with a two-layer U-shaped steel wire reinforced bead, the tire includes a tire crown, a tire shoulder, a carcass ply 1, an inner liner 2, a belt layer and a bead. Such as figure 1 As shown, the bead includes a bead 2, an apex 3 and a spigot protector 4, and the carcass ply 1 is turned up with the bead 2, and the two sides of the carcass ply 1 are respectively provided with first steel wires The cord reinforcement layer 5 and the second steel cord reinforcement layer 6 . The first steel cord reinforcement layer 5 is fitted between the carcass cord layer 1 and the inner liner layer 2, the cross section of the first steel cord reinforcement layer 5 bypassing the bead ring 7 is U-shaped, and the first steel cord reinforcement layer 5 The inner end point is higher than the turn-up end point of the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com