Apparatus and methods for controlling atmospheric gas composition within a container

a technology of atmospheric gas composition and container, which is applied in the direction of separation process, transportation and packaging, packaging, etc., can solve the problems of difficult to provide desired environmental conditions for respiring produce, difficult to achieve the desired environmental conditions of respiration, and the loss of oxygen and nitrogen in the container, etc., to achieve the effect of less leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

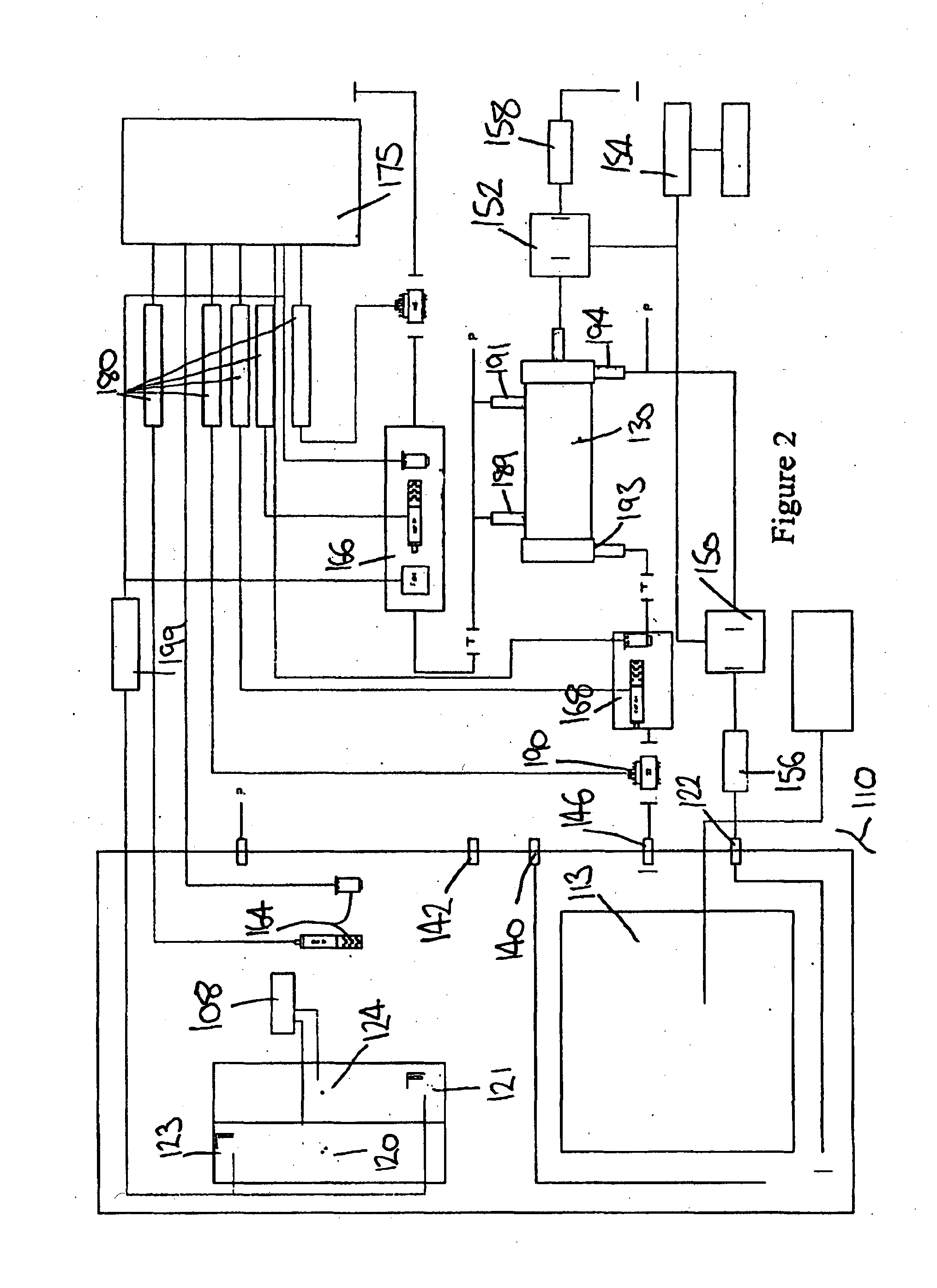

[0104]A test set up has been constructed to demonstrate the effectiveness of a preferred embodiment of the invention, in accordance with FIG. 2. It will be understood by persons skilled in the art that the test set up includes features which would not be required for the invention to function in a commercial embodiment, since certain measurements and functionalities useful for tests are not required in the commercial embodiment.

[0105]In this example, features like those described above are denoted with like numerals.

[0106]The test included a container 110 of 750 L volume, and a 153.1 kg load of bananas 113 disposed in the container 110. The container 110 was refrigerated at about 11° C. The container 110 was disposed in a test laboratory set at about 22° C.

[0107]A controller was provided at 108. The controller 108 was operatively connected to valves 120 and 122 and 124 in the walls of the container, and to a membrane unit 130. Fans 121 and 123 are also provided to force air from the...

example 2

[0127]The above test rig was improved by including a more rigid board to inhibit reduction in volume when a reduction in internal container pressure was experienced.

[0128]The sealing of the test rig was improved so that there was slightly lower leakage. Similar produce at similar stages of ripening were used—green bananas.

[0129]The results of various test runs are shown in FIGS. 15, 16, and 17. In FIG. 17 the earlier test runs were repeated and the results were shown to be repeatable, however, the CO2 level was reduced a lot further than was necessary, so other intermittency runs were conducted—15 / 75, 15 / 300 and the like, all shown in the Figures.

[0130]It should be stressed that although there are simple on-off runs made, this was only for convenience and the pump associated with the membrane unit could easily be run with a variac controller or the late which causes the pump to run at any level intermediate fully on or fully off, and the results will be similar and within the scope ...

example 3

[0131]The examples above have been scaled up and the results repeated for a mathematical model of a standard 40-foot container. The initial conditions were modelled to be a container volume of 67.4 cubic metres; volume of respiring goods 22.5 m5, mass of respiring goods 30 tonnes, selected leakage and respiration rates, and a temperature of 10 degrees Celsius. Further, the membrane constants were input, being selectivity, permeability, and the like. An inlet of atmospheric air was included in the model, of a certain flowrate.

[0132]On one run of the model, the membrane permeability constant was 3250 Barrer for CO2, thickness was 35 μm, membrane permeability constant for Nitrogen was 280 Barrer, membrane permeability constant for Oxygen was 600 Barrer, and for Water vapour it was 36000Barrer.

[0133]The results of the mathematical modelling showed that the system stabilised at generally the same gas composition for the tested model 750 L container when the same respiration rates, temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com