Titanium suboxide electrode sheet and preparation method and application thereof

A technology of titanium dioxide and electrode sheets, which is applied in the field of ceramic electrodes, can solve the problems of high conductivity, corrosion resistance, poor processability, and difficult compactness of titanium dioxide electrodes, so as to improve the overall quality, improve compactness, The effect of enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

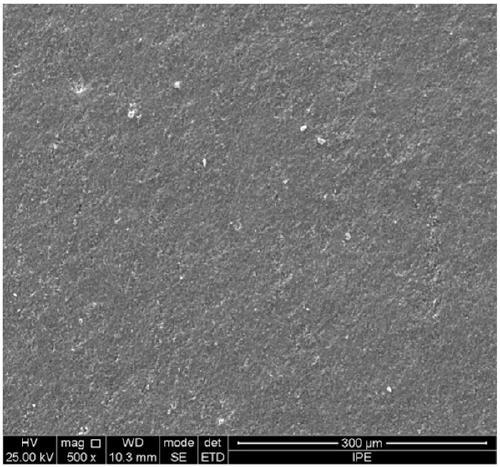

Image

Examples

Embodiment 1

[0057] This embodiment prepares titanium oxide electrode sheet according to the following method:

[0058] (1) Ball milling: Ti 4 o 7 Titanium suboxide powder with a content of 90% is ball milled under an argon atmosphere, and then sieved to obtain a titanium suboxide fine powder with a particle size not greater than 40 microns;

[0059] (2) Preforming: the above titanium oxide fine powder (Ti 4 o 7 Content is 90%) and binder PI is mixed evenly and loaded into graphite mould, the add-on of described binder PI is 2wt% of titanium oxide weight, then graphite mold is placed in spark plasma sintering furnace, vacuumizes to The vacuum degree is 9.5Pa and the pressure of 10MPa is applied to preform the mixed powder;

[0060] (3) Sintering: heat up to a sintering temperature of 900°C under the condition of maintaining argon, perform constant temperature and constant pressure discharge plasma sintering for 30 minutes, then turn off the heating power supply, and take out the titani...

Embodiment 2

[0065] This embodiment prepares titanium oxide electrode sheet according to the following method:

[0066] (1) Ball milling: Ti 4 o 7 Titanium oxide powder with a content of 99% is ball milled under vacuum conditions, and then sieved to obtain titanium oxide fine powder with a particle size not greater than 38 microns;

[0067] (2) Preforming: the above titanium oxide fine powder (Ti 4 o 7 content is 99%) mixed with binder PE+PP and loaded into graphite mold evenly, the addition of the binder PE+PP is 20wt% of the weight of titanium dioxide, the ratio of PE and PP is 1:1, Then place the graphite mold in a spark plasma sintering furnace, evacuate to a vacuum of 8Pa and apply a pressure of 60MPa to preform the mixed powder;

[0068] (3) Sintering: heat up to the sintering temperature of 1600°C under the condition of maintaining argon, conduct constant temperature and constant pressure discharge plasma sintering for 15 minutes, then turn off the heating power supply, and take...

Embodiment 3

[0073] This embodiment prepares titanium oxide electrode sheet according to the following method:

[0074] (1) Ball milling: Ti 4 o 7 Titanium suboxide powder with a content of 93% is ball milled under an argon atmosphere, and then sieved to obtain a titanium suboxide fine powder with a particle size not greater than 30 microns;

[0075] (2) Preforming: the above titanium oxide fine powder (Ti 4 o 7 Content is 93%) and binder PVB is mixed uniformly and packed into graphite mould, and the add-on of described binder PVB is 5wt% of titanium oxide weight, then graphite mold is placed in spark plasma sintering furnace, vacuumizes to The vacuum degree is 9Pa and the pressure of 100MPa is applied to preform the mixed powder;

[0076] (3) Sintering: heat up to a sintering temperature of 1200°C under the condition of maintaining argon, perform constant temperature and constant voltage discharge plasma sintering for 5 minutes, then turn off the heating power supply, and take out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com