Cutting device for post processing of handmade soap

A cutting device and handmade soap technology, applied in the direction of cutting soap, etc., can solve the problem of low cutting efficiency, achieve high cutting speed, large cutting volume, and improve cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

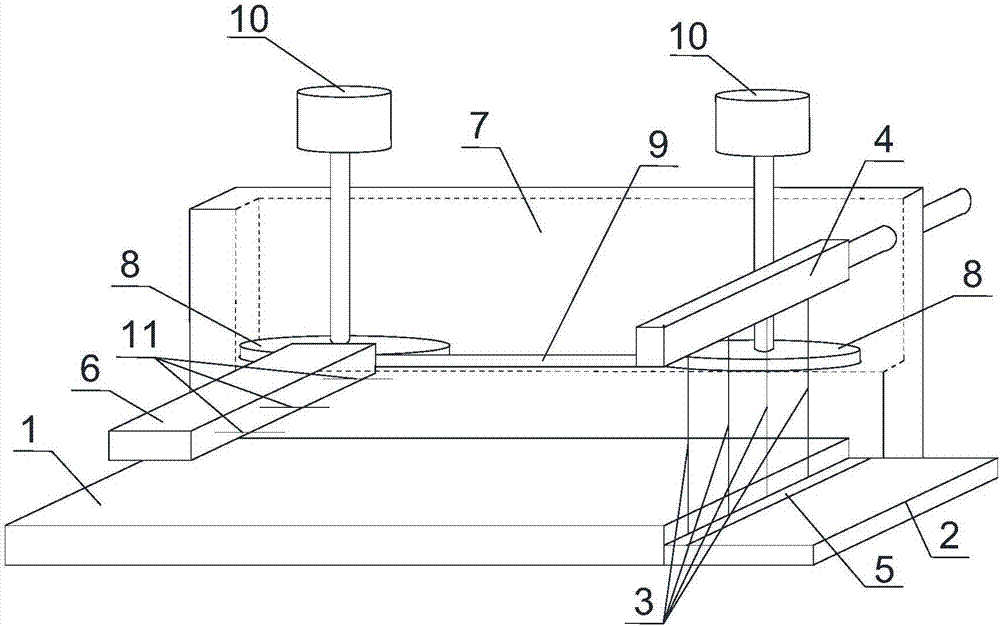

[0022] Such as figure 1 As shown, the cutting device for handmade soap post-processing of the present invention includes a horizontally placed cuboid workbench 1, and the side of the workbench 1 with width and height as sides is connected with a support plate 2 in parallel, and the support plate 2 There are at least three cutting wires 3 connected above, and all cutting wires 3 are equally spaced and parallel distributed along the width direction of the workbench 1, all cutting wires 3 are perpendicular to the support plate 2, and the upper ends of the cutting wires 3 are connected to the fixed block 4 , the lower ends of the cutting wires 3 are all connected to the slide plate 5 sliding along the width direction of the workbench 1, the slide plate 5 is slidably connected with the support plate 2, a push plate 6 is arranged above the workbench 1, and the push plate 6 is located on the working table The other side of the table 1 is opposite to the cutting wire 3, and the side s...

Embodiment 2

[0025] Based on Embodiment 1, the side of the workbench 1 with the length and height as the sides is connected and fixed with a panel 7, the height of the panel 7 is perpendicular to the table top of the workbench 1, two transmission wheels 8 are installed on the panel 7, and the two Two transmission wheels 8 are respectively located on both sides of the panel 7, and a conveyor belt 9 is sleeved between the two transmission wheels 8, and one end of the push plate 6 is fixed on the transmission surface of the conveyor belt 9 on one side of the workbench 1, and the conveyor belt 9 Convey along the long side of workbench 1. A motor 10 that controls the rotation of the transmission wheel 8 is connected above each transmission wheel 8 , and the motor 10 is located above the panel 7 .

[0026] The panel plays a role in supporting the transmission wheel. The transmission direction of the two transmission wheels is the same. The transmission wheel rotates and then conveys the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com