Patents

Literature

37results about How to "Push fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

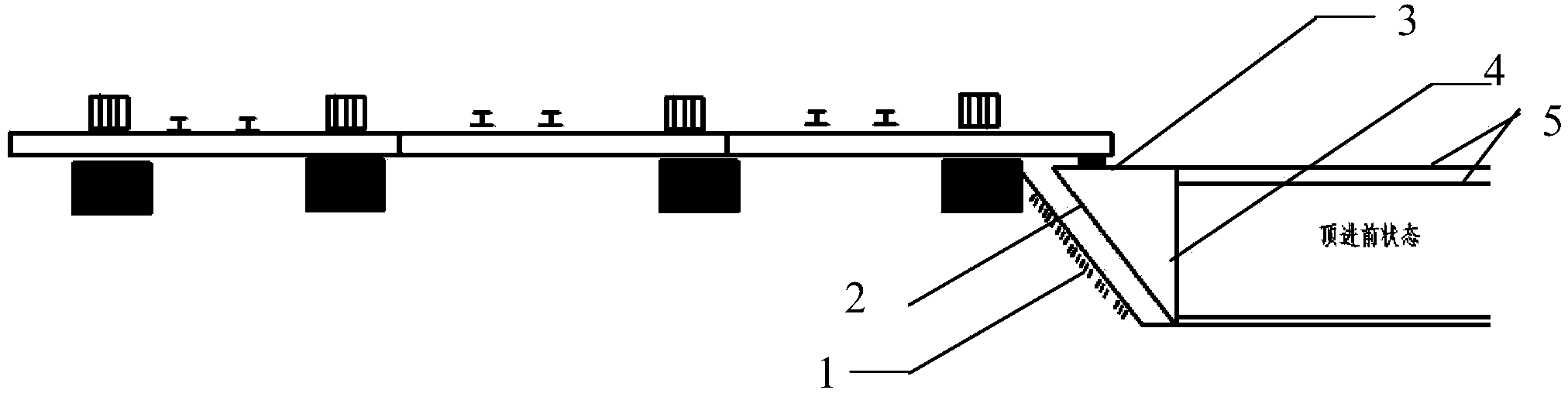

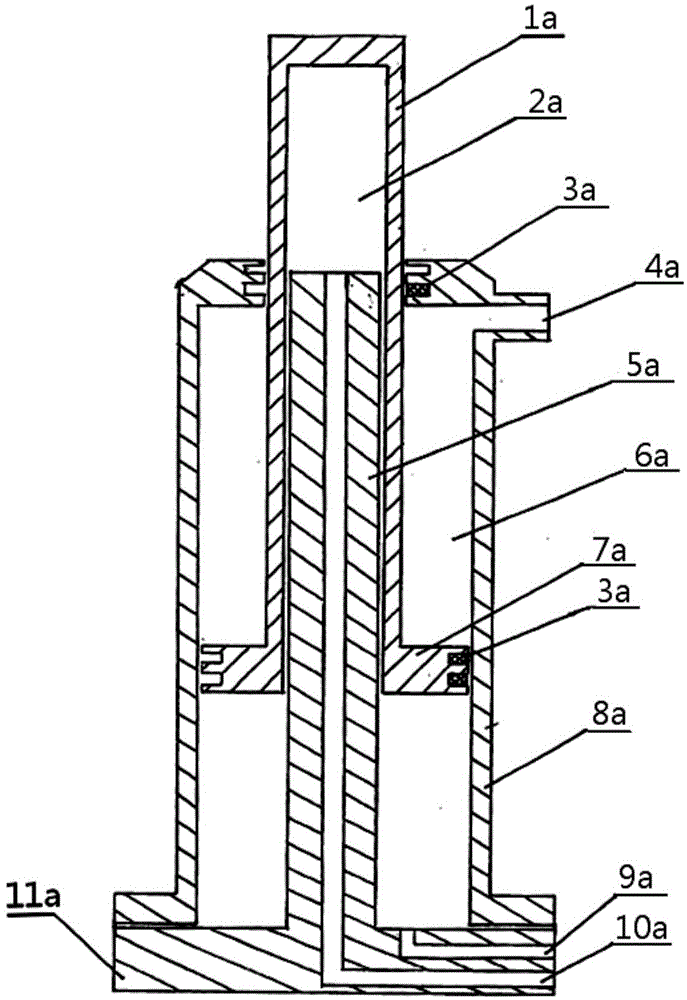

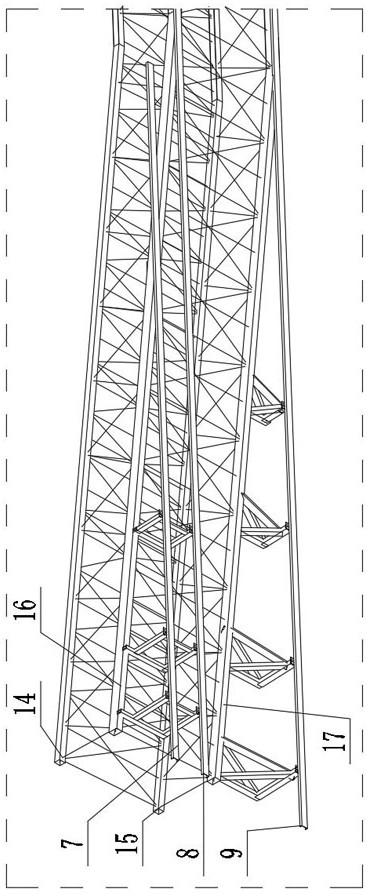

Deep water silt layer geological large-span multi-line reinforcing system and jacking culvert construction method

ActiveCN103866694APrevent lateral movementDoes not affect driving safetyBridge erection/assemblyInstabilitySlide plate

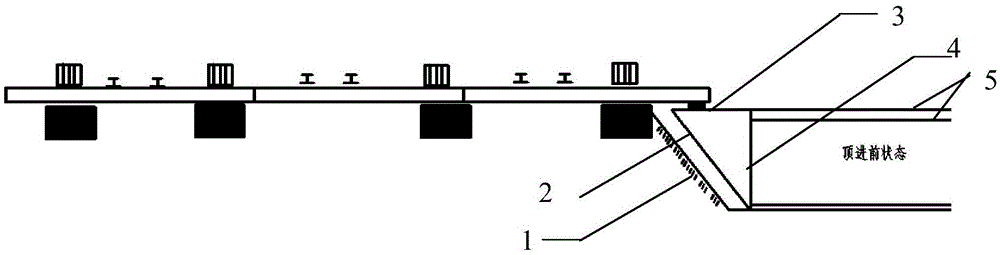

The invention relates to a deep water silt layer geological large-span multi-line reinforcing system and a jacking culvert construction method, and aims at providing a reinforcing system and a construction method for a high-water-level, long-jacking-stroke, large-span and high-tonnage jacking culvert to penetrate through multiple existing lines. The reinforcing system comprises a high-pressure jet grouting secant pile, a fender pile, an anti-traversing pile and a supporting pile. The jacking culvert construction method comprises the steps of starry well-point dewatering, foundation pit excavation and sliding plate fabrication, frame bridge prefabrication, line reinforcement, jacking equipment installation and process control. By adopting starry well-point dewatering, the problems of underground water burst and foundation instability during jacking are solved; since a frame bridge is integrally jacked after being prefabricated, the rigidity is high, the seismic performance is good and the influence by climate is smaller; compared with the traditional construction method, the reinforcement and the installation are convenient and easy to operate, the jacking speed is quick and the construction period is shortened; I-shaped steel, steel rails and sleepers used for engineering can be recycled; the overall economic benefits are remarkable, the practical value is greater and the application prospect is wide.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

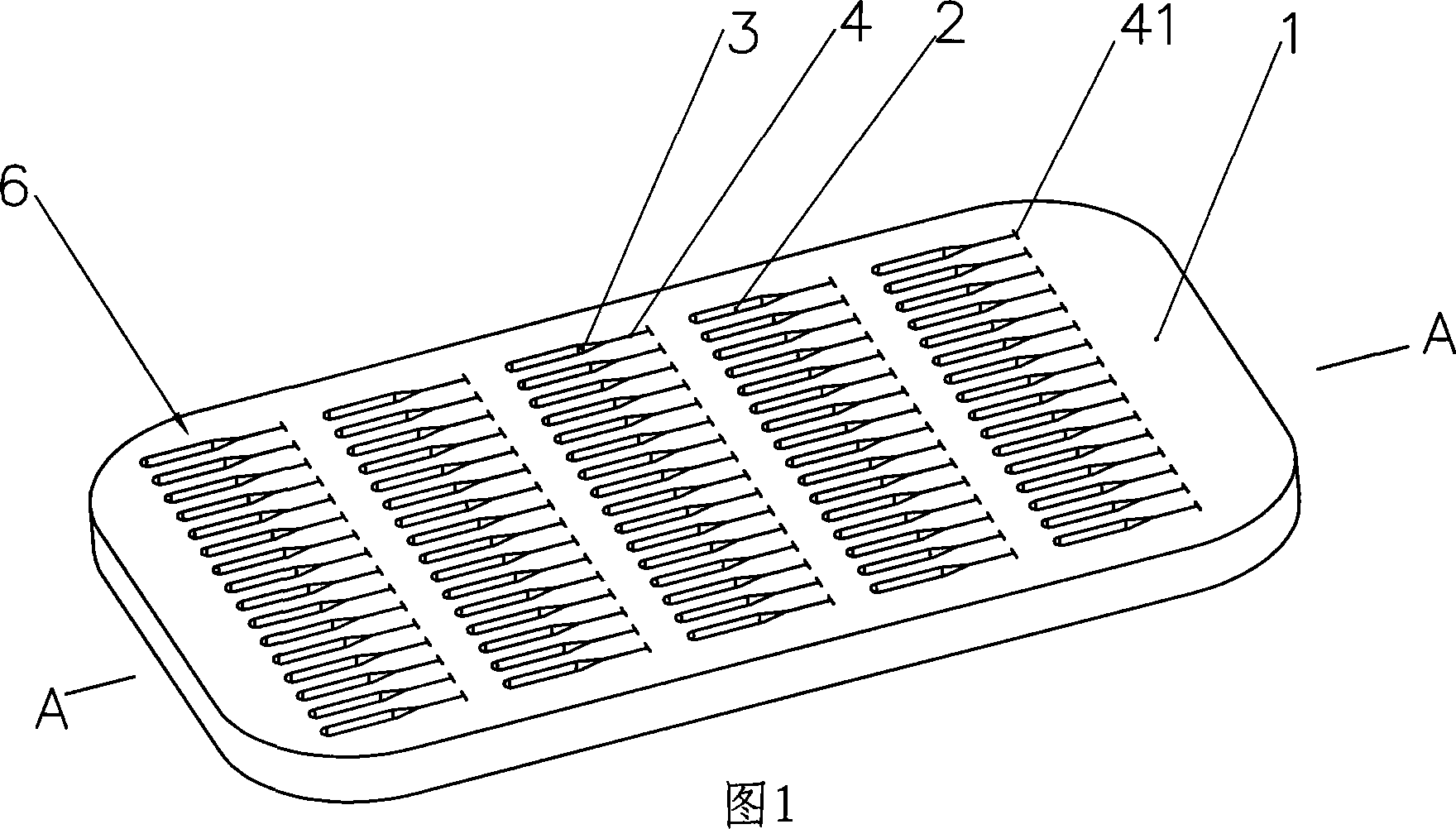

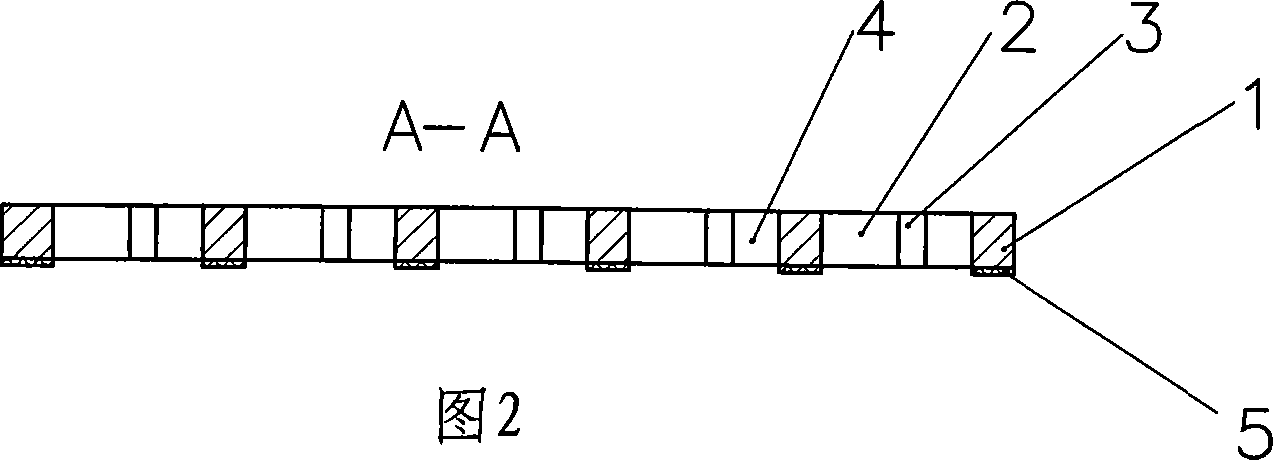

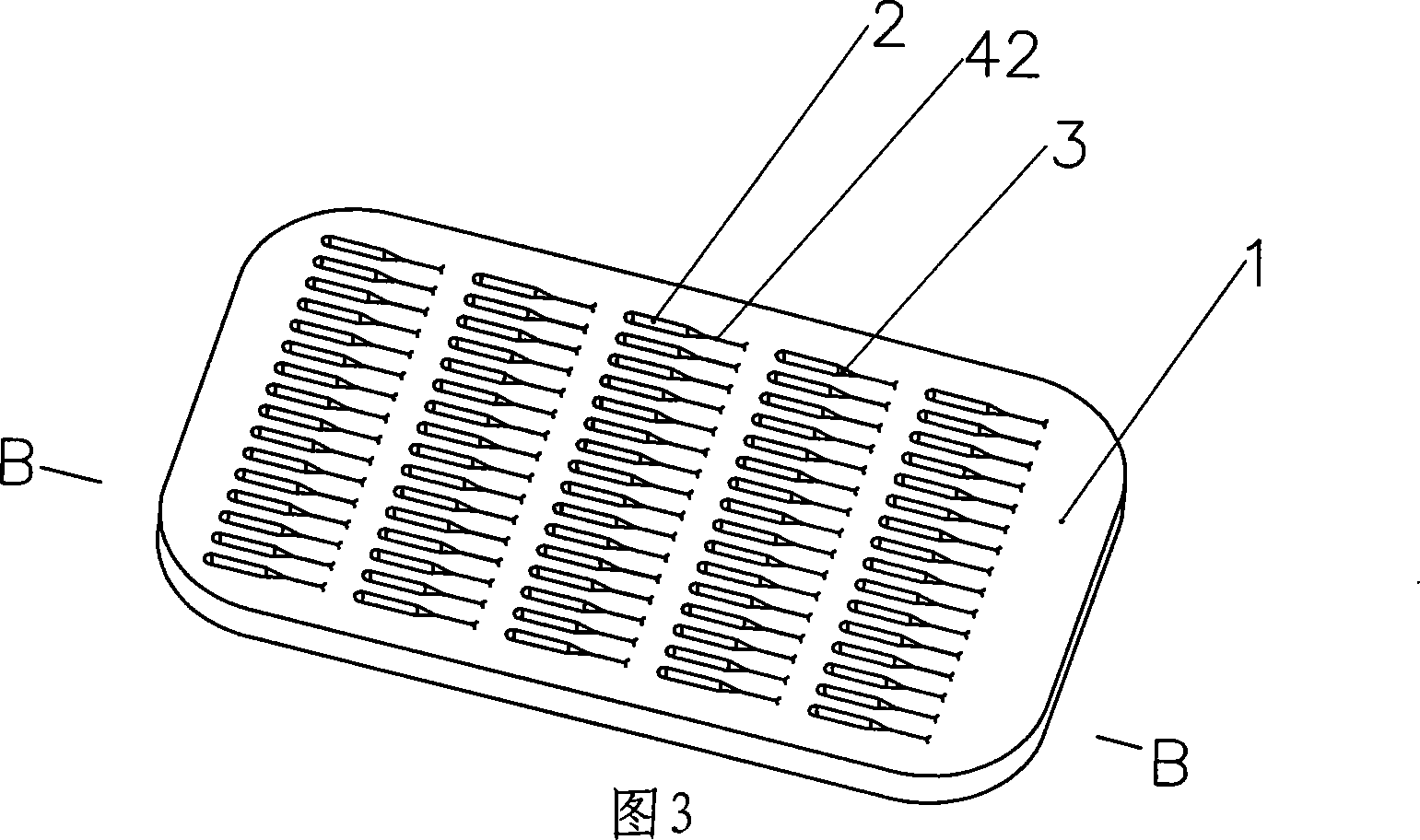

False bait fixing pad for fishing hook

InactiveCN101066048ALow costImprove general performanceOther angling devicesFishingBiomedical engineering

Owner:周志强

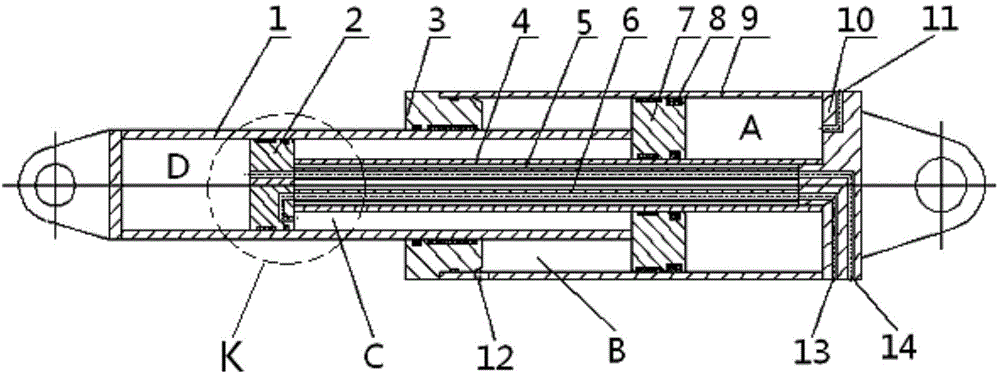

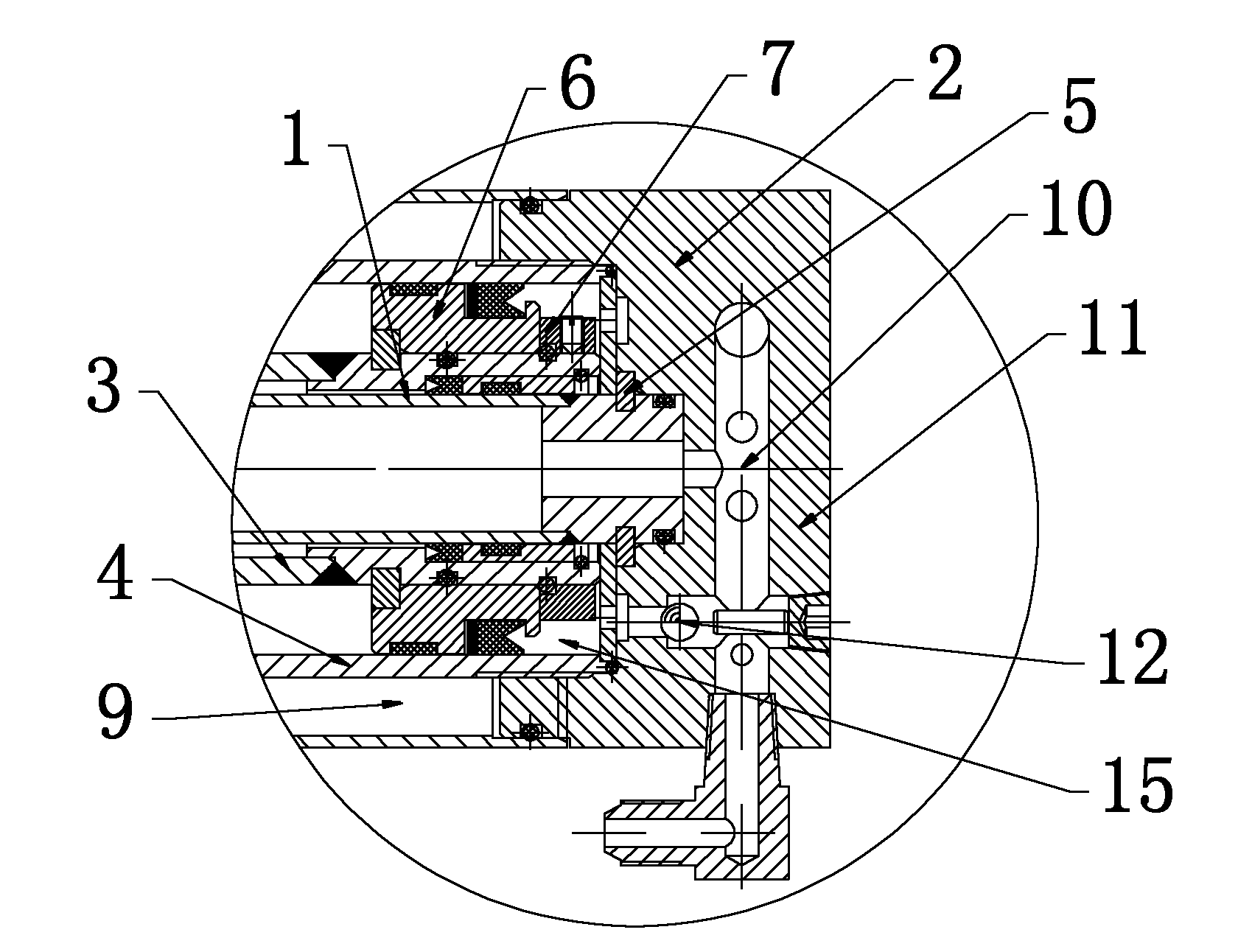

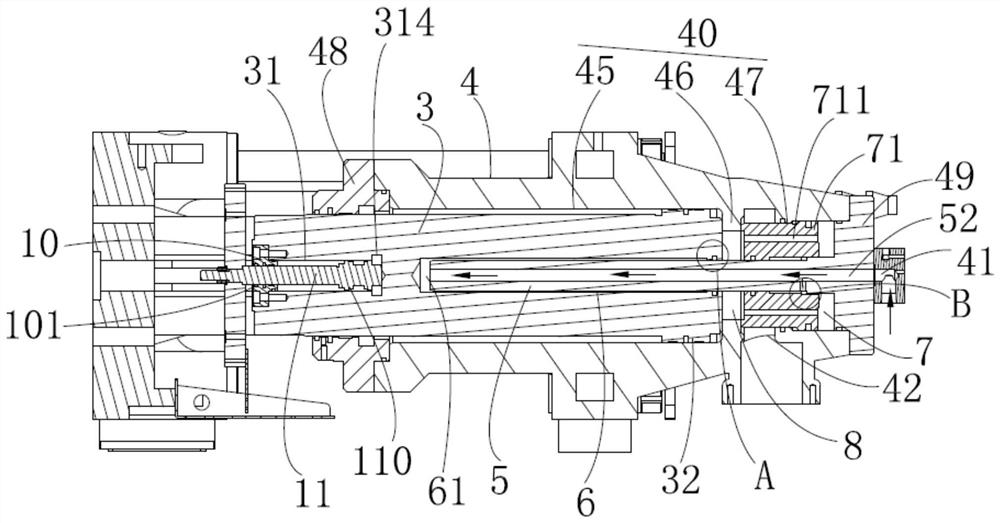

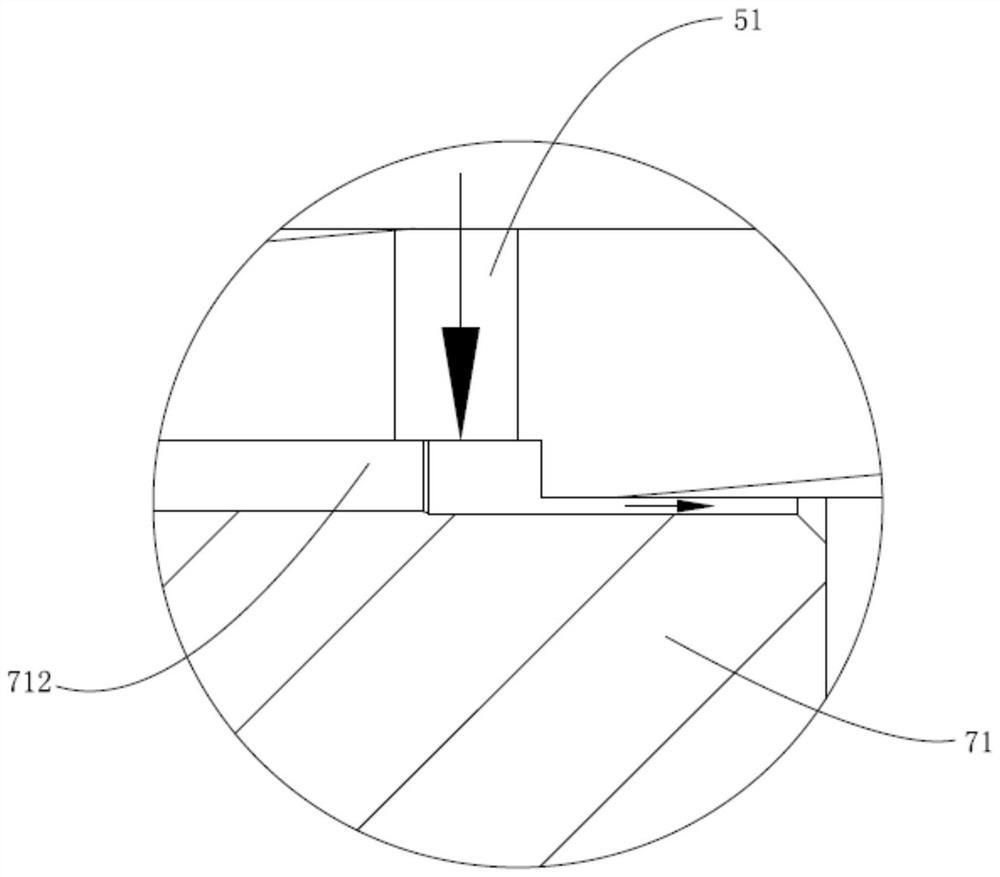

Variable-speed hydraulic cylinder

ActiveCN104806600APush fastImprove work efficiencyFluid-pressure actuatorsHydraulic cylinderCylinder block

The invention relates to a variable-speed hydraulic cylinder, which comprises a barrel, a first piston rod assembly and a second piston rod assembly, the first piston rod assembly comprises a piston rod and a first piston which are connected with each other, and the second piston rod assembly comprises a guide rod and a second piston which are connected with each other; the piston rod partially extends out of the barrel, the first piston is arranged in the barrel, and can slide along the inner wall of the body of the barrel, the piston rod is provided with a hollow structure, the guide rod partially extends out of the hollow structure and passes through the first piston to fixedly connect with the bottom of the barrel, and the second piston is arranged in the hollow structure, and can slide along the inner wall of the hollow structure; the variable-speed hydraulic cylinder is provided with a plurality of working oil ports, the working oil ports respectively communicate with four closed cavities defined in the variable-speed hydraulic cylinder, and by injecting hydraulic oil into the different closed cavities, the first piston rod assembly can extend and retract at different speeds. The variable-speed hydraulic cylinder disclosed by the invention can meet different requirements on extension and retraction speeds.

Owner:XUZHOU HEAVY MASCH CO LTD

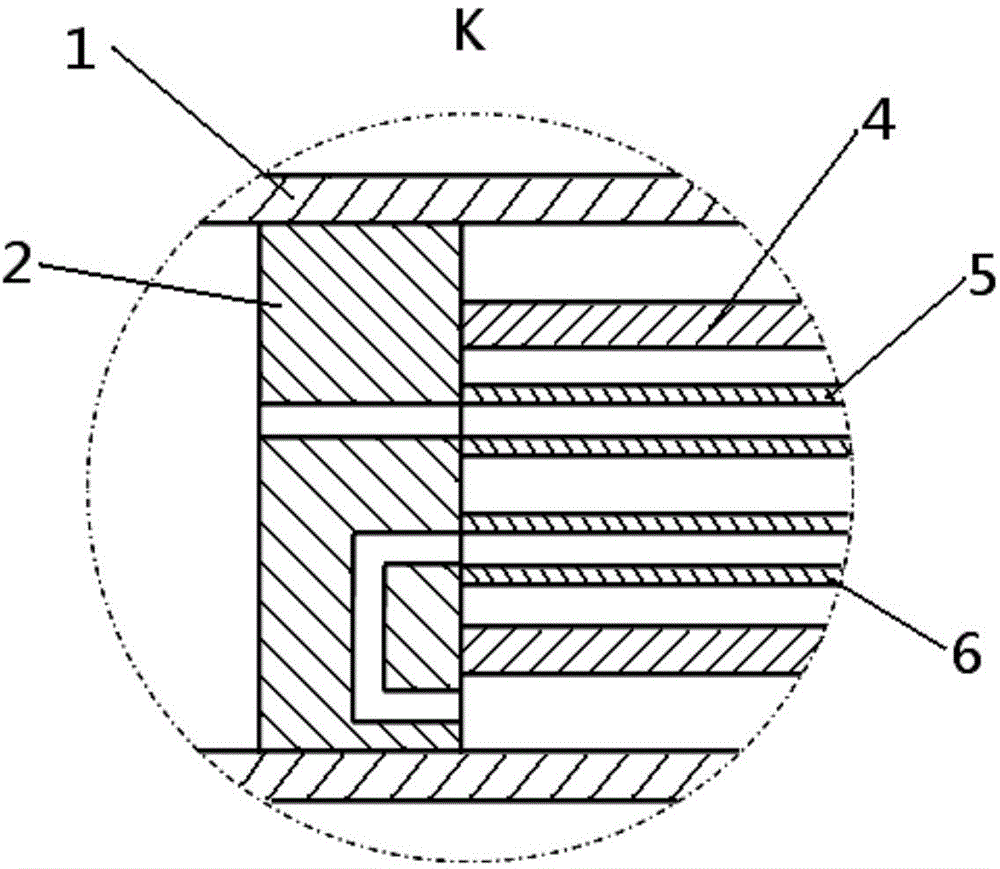

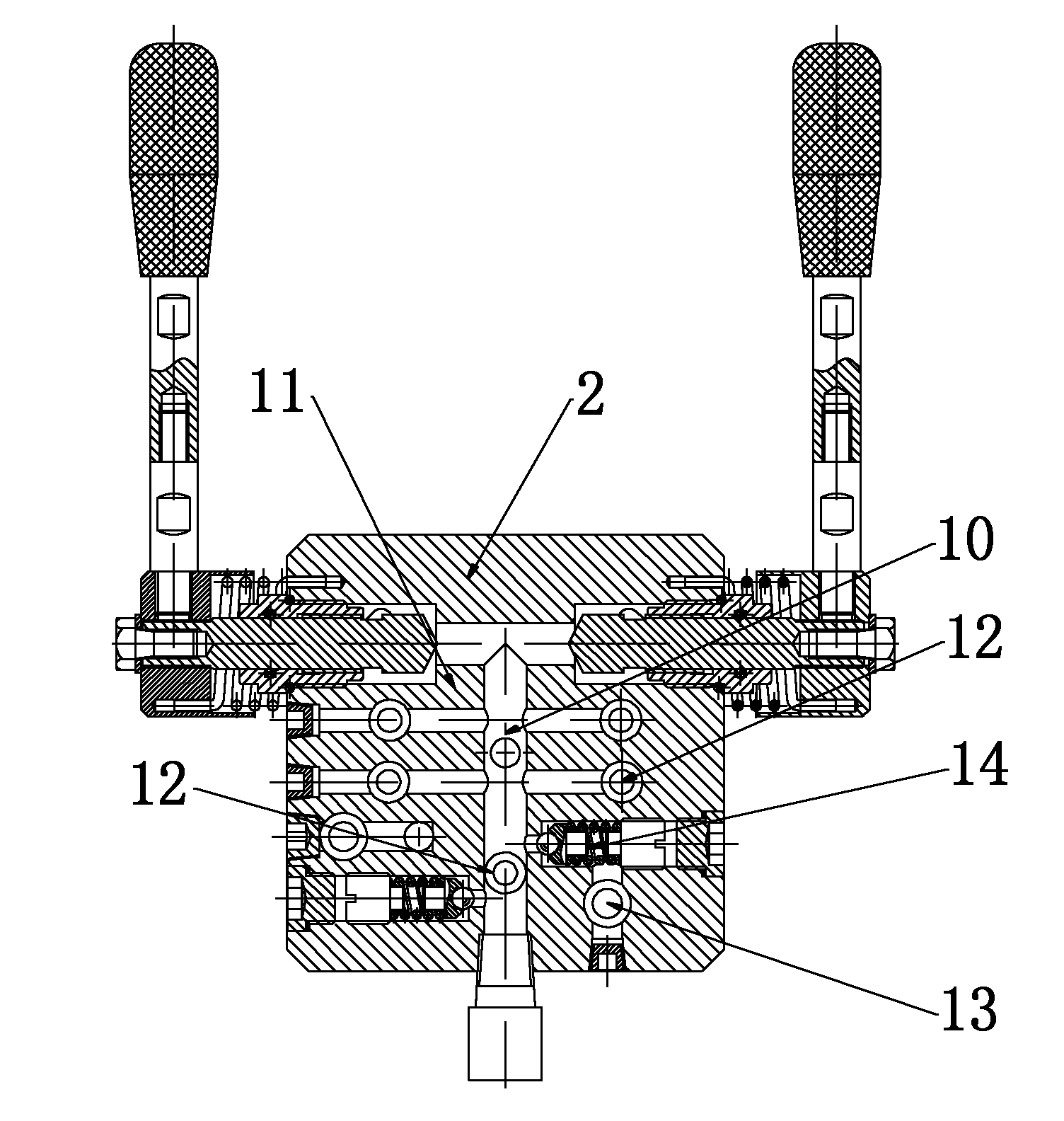

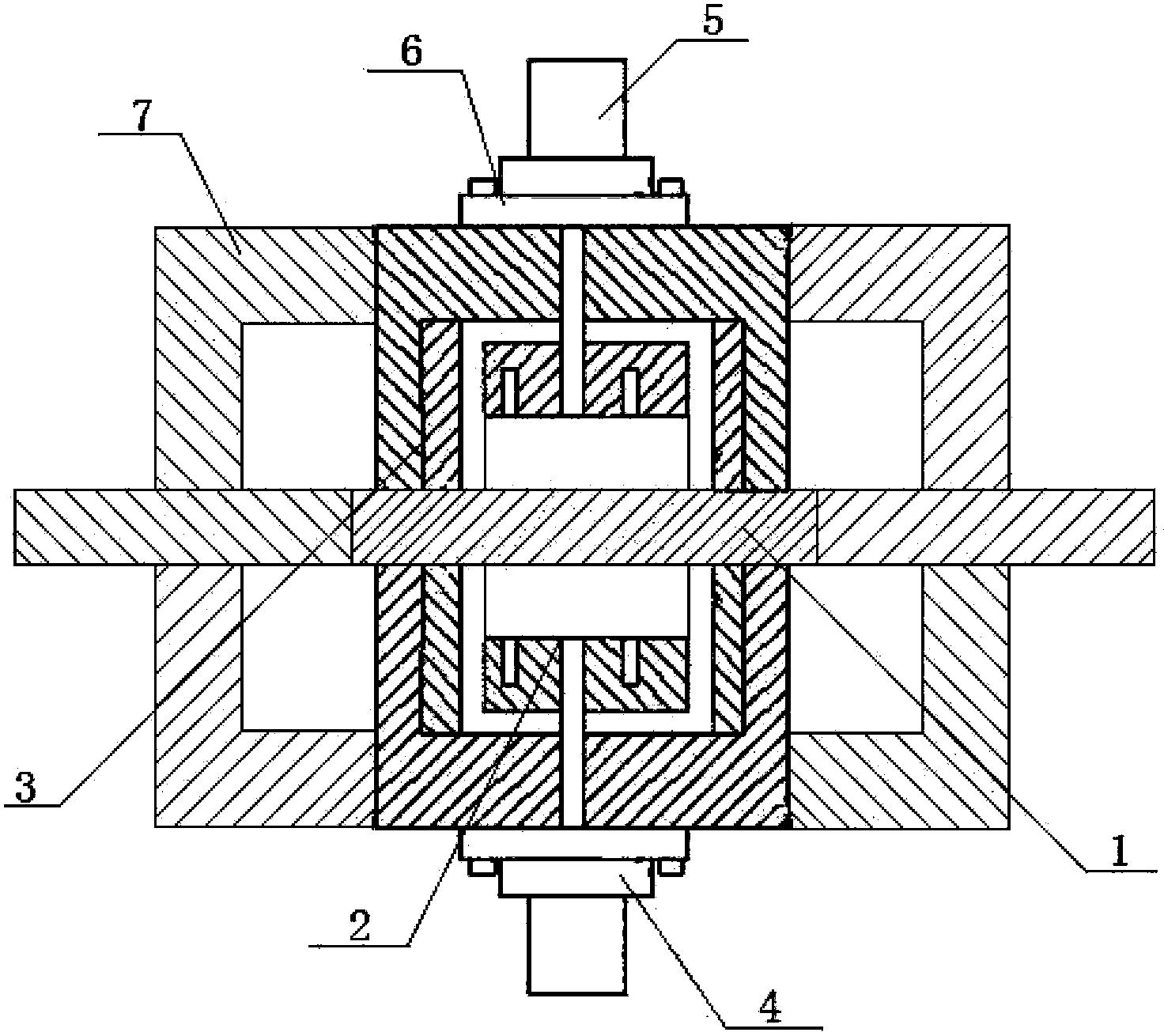

Double-speed oil cylinder

InactiveCN102182720ACompact structureReasonable designFluid-pressure actuatorsEngineeringCylinder block

The invention discloses a double-speed oil cylinder, mainly comprising a cylinder body, an oil cylinder front cover, an oil cylinder back cover, a large piston and a movable piston rod, wherein the other end of the cylinder body and the movable piston rod form a sealed space by the oil cylinder front cover, the large piston is arranged at one end of the movable piston rod, the movable piston rod is of a hollow structure, a fixed piston rod is arranged in the movable piston rod, the fixed piston rod is of a hollow structure, two ends of the fixed piston rod are communicated, one end of the fixed piston rod is connected with the oil cylinder back cover, one end of the movable piston rod in the cylinder body is sealed with the outer wall of the fixed piston rod by the large piston, and the large piston is glidingly connected onto the fixed piston rod. In the double-speed oil cylinder, a pushing force can be changed by means of the different compression areas of the movable piston rod and the large piston, synchronously the pushing speed and the retreating speed of the oil cylinder can be improved when the smaller compression area is used; therefore, the wood splitting speed can be greatly improved and the working efficiency is improved. A sequence adjusting valve is arranged so that the switching between the fast push and the large pushing force can be automatically realized aiming at requirements on the pushing force; and therefore, the operation is more simple and convenient.

Owner:JIASHAN SUPERPOWER TOOLS

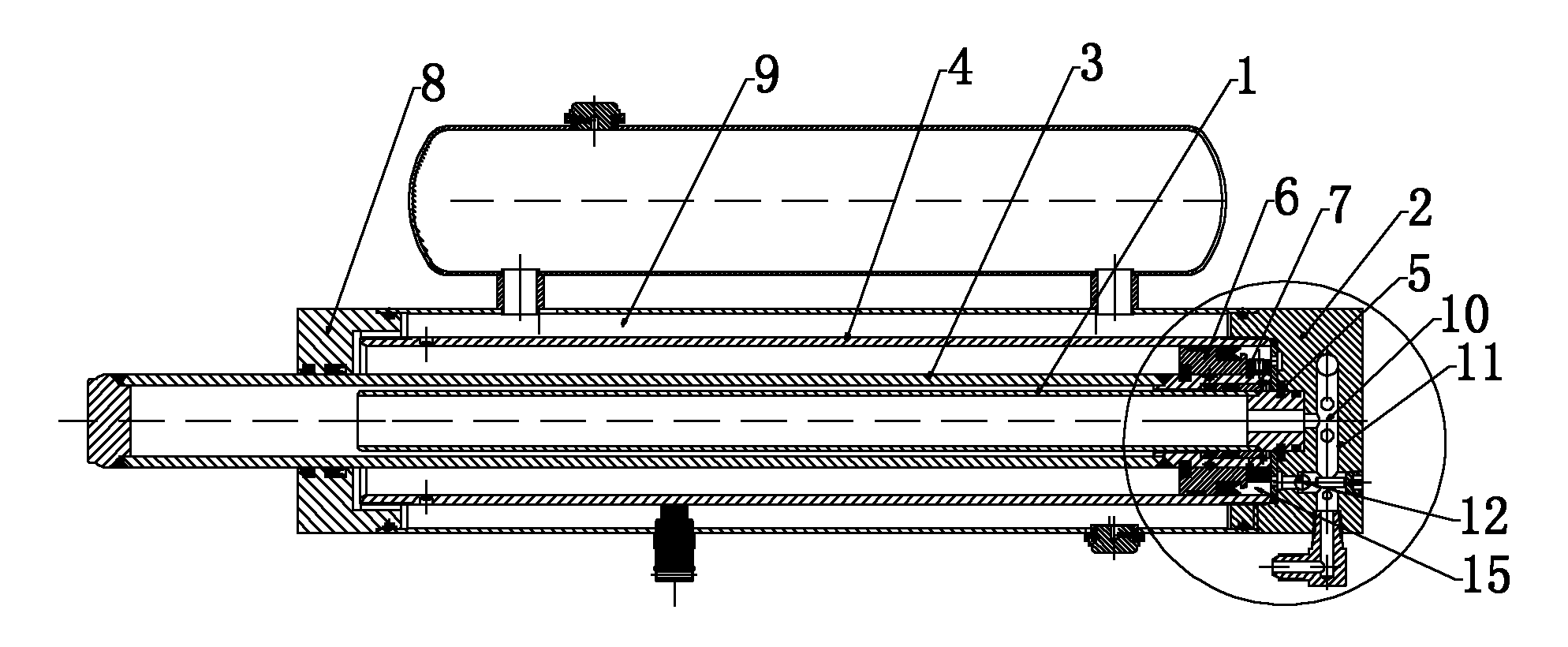

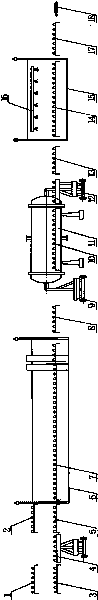

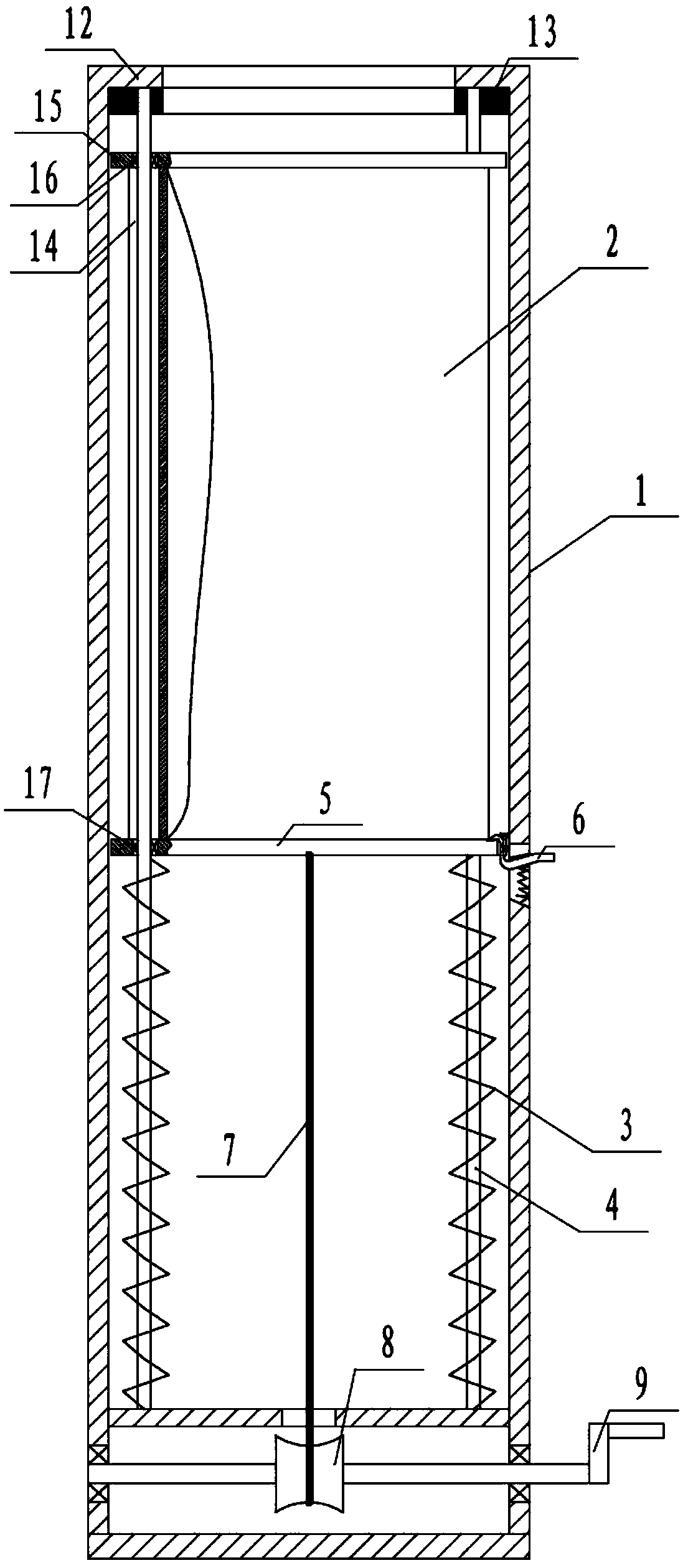

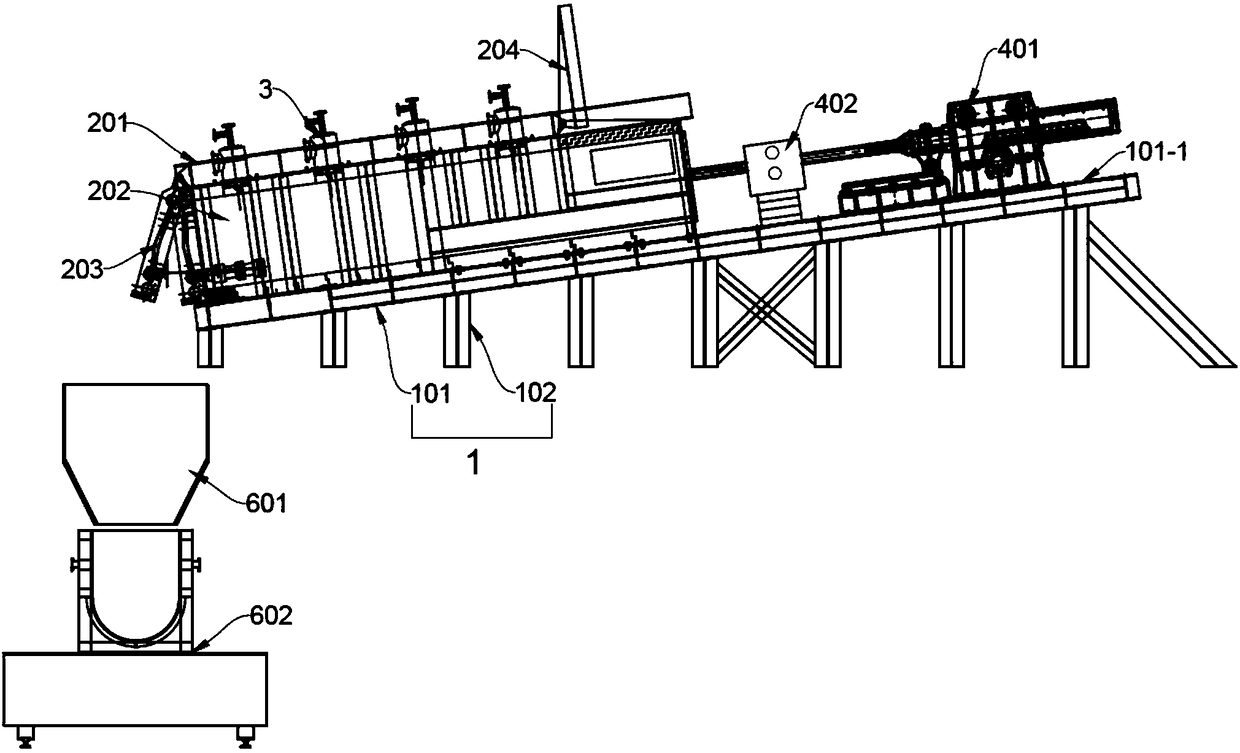

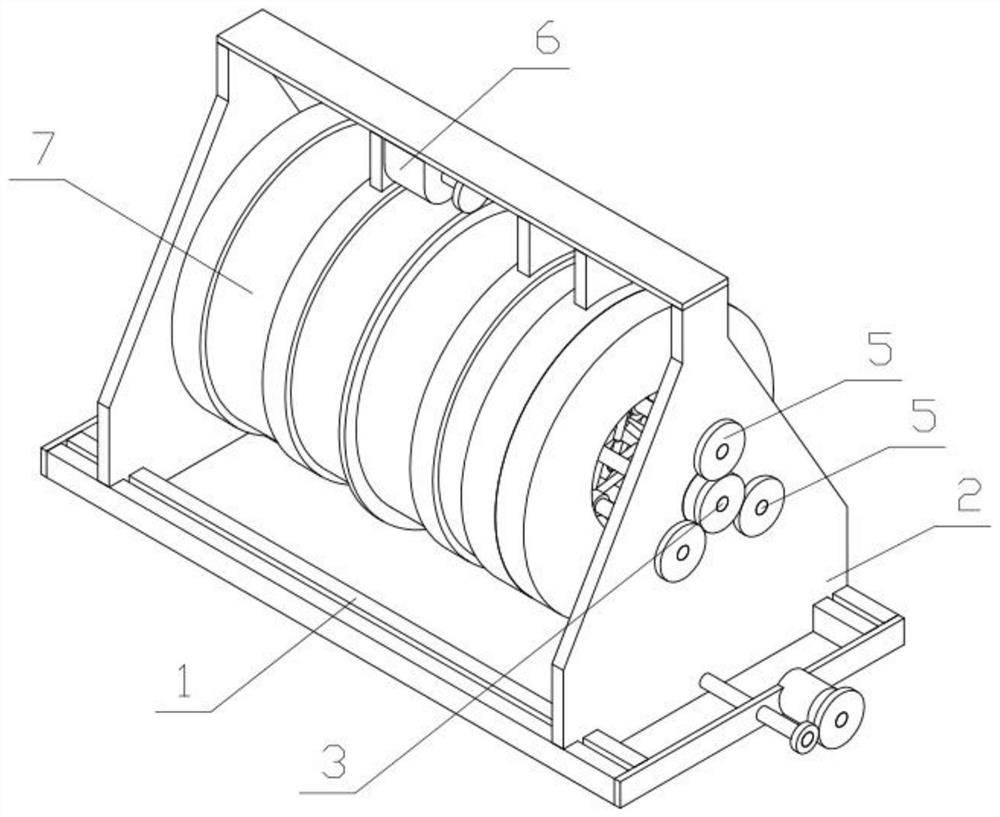

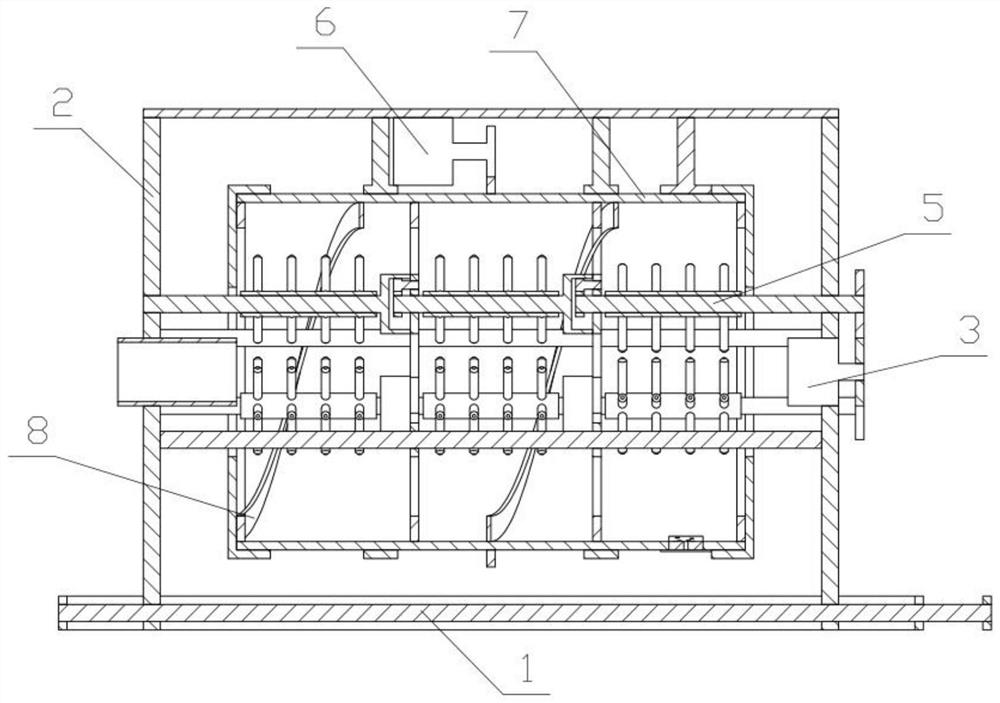

Continuous high pressure steeping device and method

ActiveCN101723703AEfficient use ofReduce labor intensityLiquid surface applicatorsCoatingsAutomatic controlCooling chamber

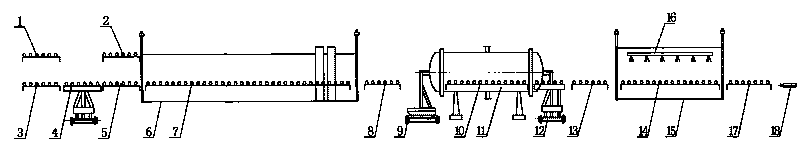

The invention discloses a continuous high pressure steeping device and a method, particularly to a continuous high pressure steeping device and a method suitable for industries of carbon, metallurgy and the like. A conveyer No. 4, a preheating chamber, a steeping tank, a cooling chamber, a conveyer No. 7 and a hooking and pulling machine are positioned on the same straight line and sequentially arranged in the continuous high pressure steeping device; trolleys No. 1, No. 2 and No. 3 are installed on a railway, and the trolleys No. 1, No. 2 and No. 3 and conveys, No. 1 No. 2, No. 3 and No. 4 are all provided with a pusher. The continuous high pressure steeping device and the method have the advantages and the effects that energy sources are effectively utilized, and the steeping efficiency is improved; the whole high pressure steeping process is continuously carried out, automated control is easy to realize, and the labor intensity of worker is lowered.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

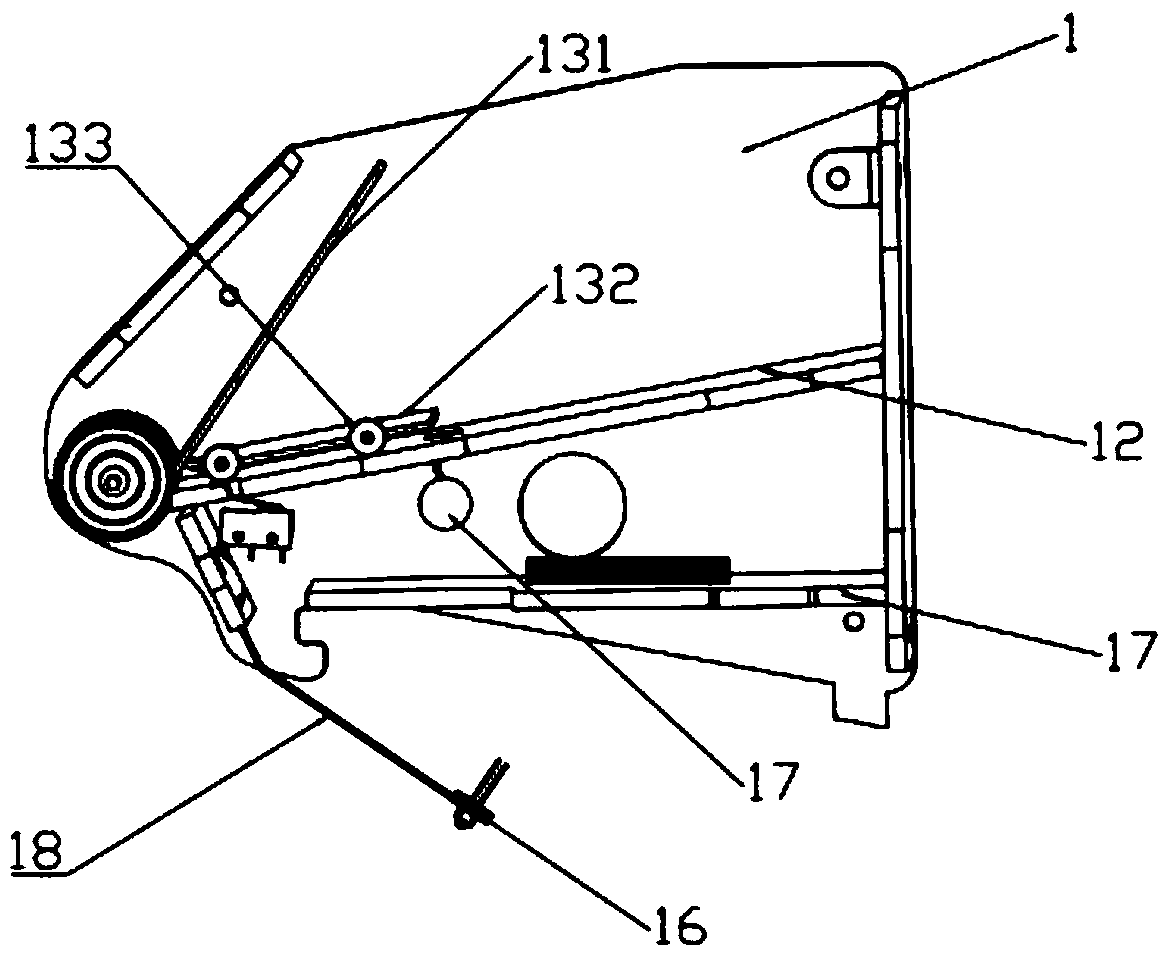

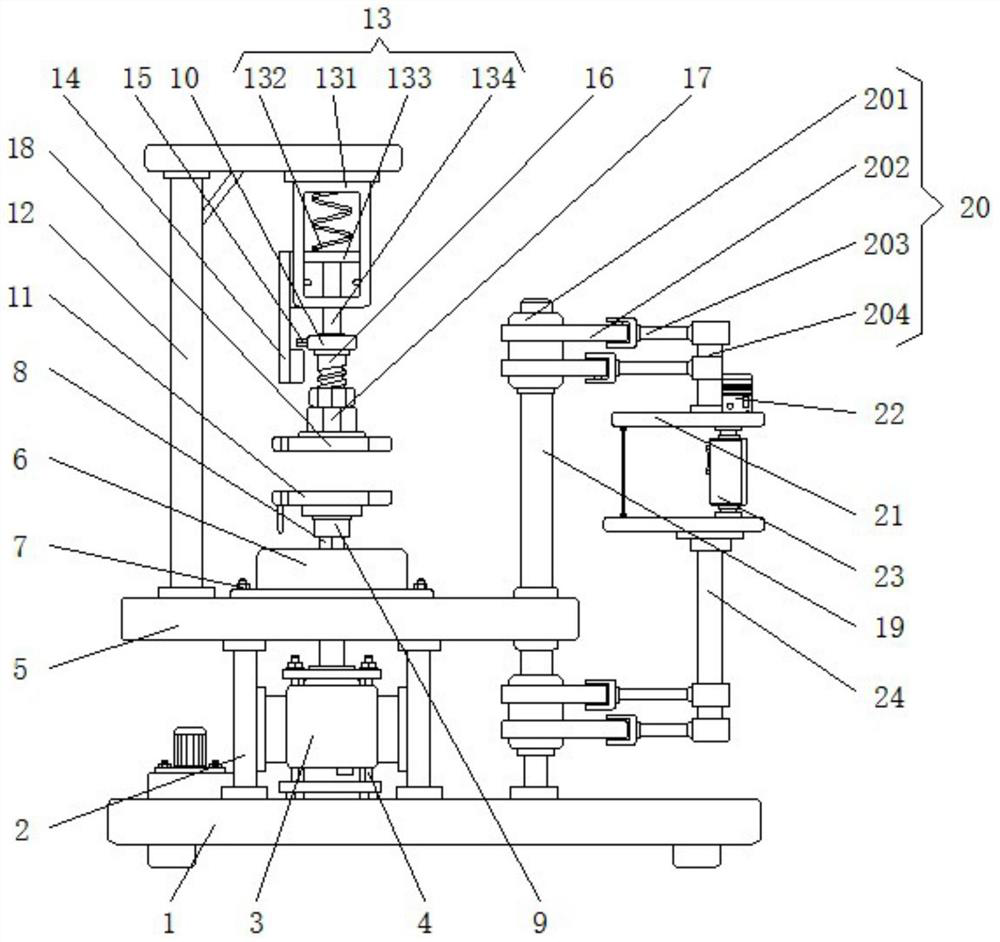

Ampoule bottle neck automatic opening system

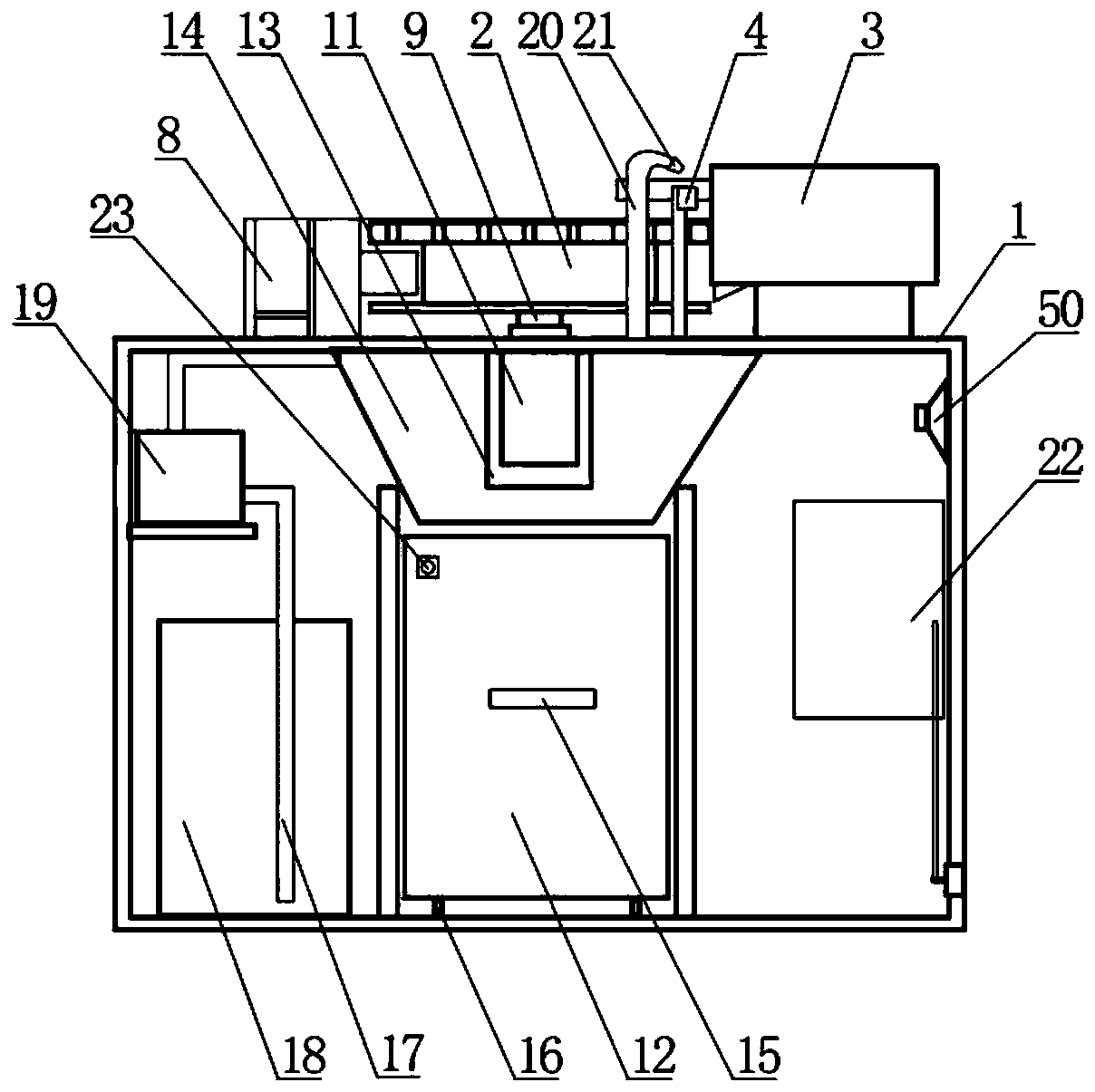

ActiveCN111422804AEasy to open automaticallyReduce workloadOpening closed containersBottle/container closureElectric machineryEngineering

The invention discloses an ampoule bottle neck automatic opening system. The system comprises a rack, an intermittent rotary disc, an ampoule bottle input device, an ampoule bottle label information detection device, an alcohol disinfection device, a grinding wheel assembly, a bottle neck breaking device, an ampoule bottle output device, a vertical shaft, a motor and a bottle neck collecting box.The ampoule bottle input device, the alcohol disinfection device, the grinding wheel assembly, the bottle neck breaking device and the ampoule bottle output device are distributed at the periphery ofthe intermittent rotary disc; and when the ampoule bottle rotates to a breaking station, the bottle neck breaking device breaks the bottle neck of the ampoule bottle, and the broken bottle neck fallsinto the bottle neck collecting box through a bottle neck through hole. By the adoption of the structure, full-automatic operation of automatic feeding, disinfection, scratch cutting, breaking and automatic output of the ampoule bottle is achieved, a batch of ampoule bottles can be conveniently and automatically opened, the workload of medical staff is greatly reduced, and the system is convenientto move and easy and convenient to operate and use. The system has the characteristics of high automation degree, streamlined operation and small and compact structure.

Owner:GUANGDONG NO 2 PROVINCIAL PEOPLES HOSPITAL

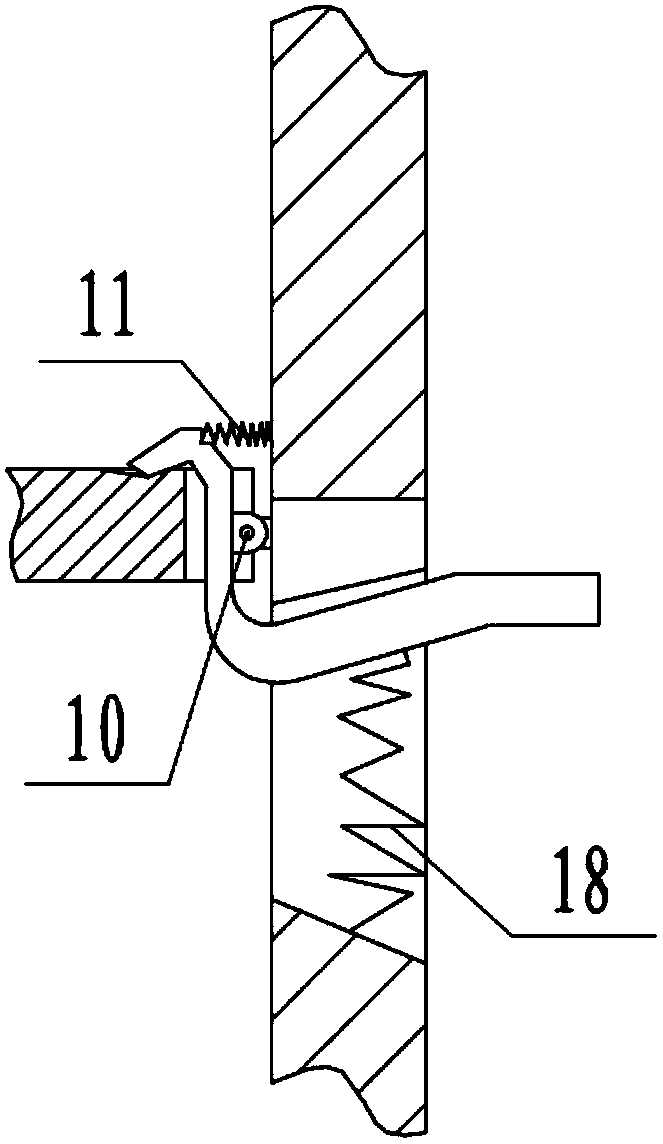

Electric power sand throwing fire extinguishing device

PendingCN108543249ARealize long-distance fire extinguishingImprove the safety of useFire rescueElectric power systemEngineering

The invention discloses an electric power sand throwing fire extinguishing device. The electric power sand throwing fire extinguishing device includes a launch cylinder and a sand loading cylinder, the upper end of the sand loading cylinder is open, the sand loading cylinder is placed in the launch cylinder with an open upper end and can movably axially move along the launch cylinder, and the bottom of the sand loading cylinder is connected to the launch cylinder through an ejection mechanism. The ejection mechanism comprises springs, guide rods and a push plate, the push plate is fixedly connected to the bottom of the launch cylinder and is connected to the multiple guide rods through through holes in a sleeving mode, and both ends of the multiple guide rods are fixedly connected into thelaunch cylinder and are arranged circumferentially and uniformly in the length direction of the launch cylinder. The guide rods are sleeved with the springs, one ends of the springs are fixedly connected to the push plate, and the other ends of the springs abut against the launch cylinder. A mechanical switch is arranged at the bottom of the launch cylinder, the mechanical switch can be clamped onto the push plate after the push plate retracts. According to the electric power sand throwing fire extinguishing device, long distance fire extinguishing is achieved, the service safety is improved,and the electric shock hazard is avoided.

Owner:GUIZHOU POWER GRID CO LTD

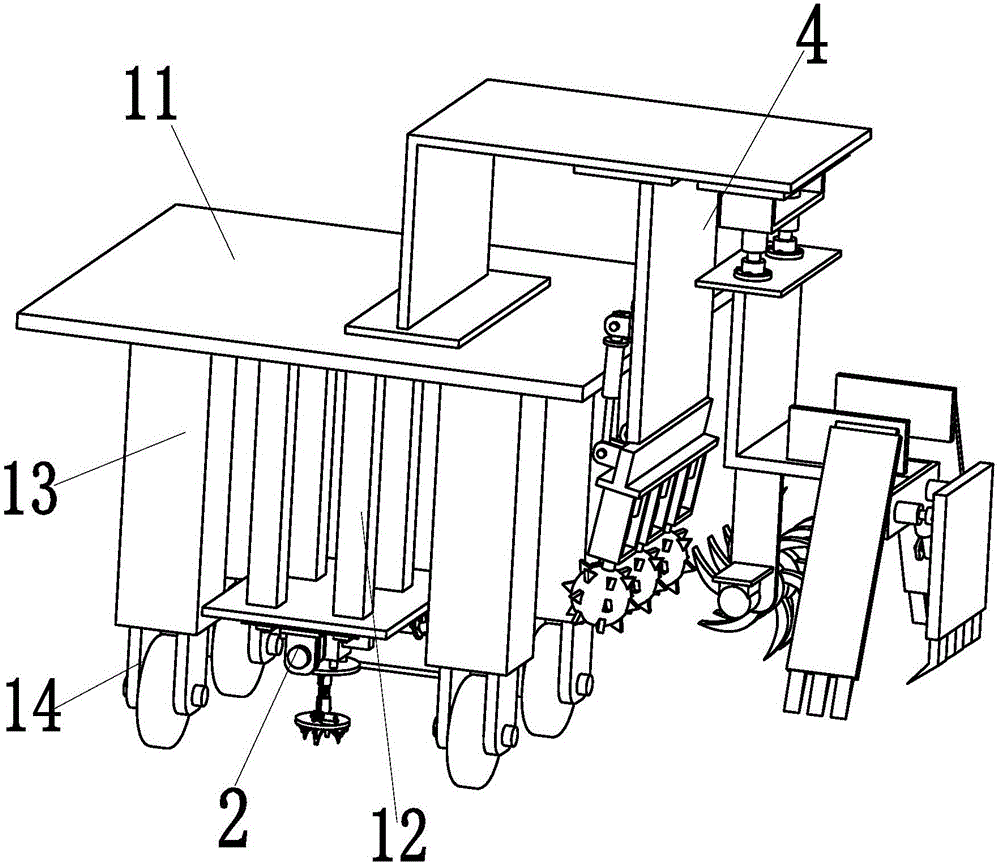

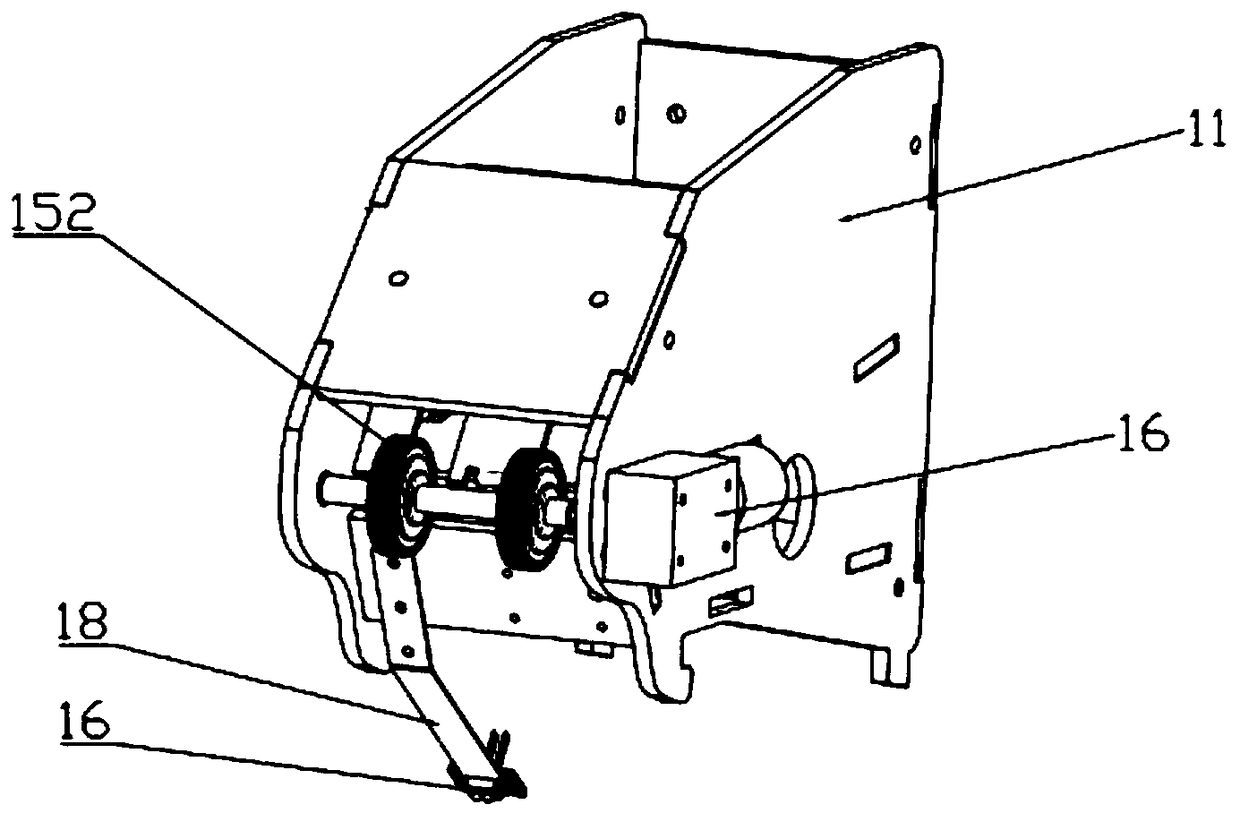

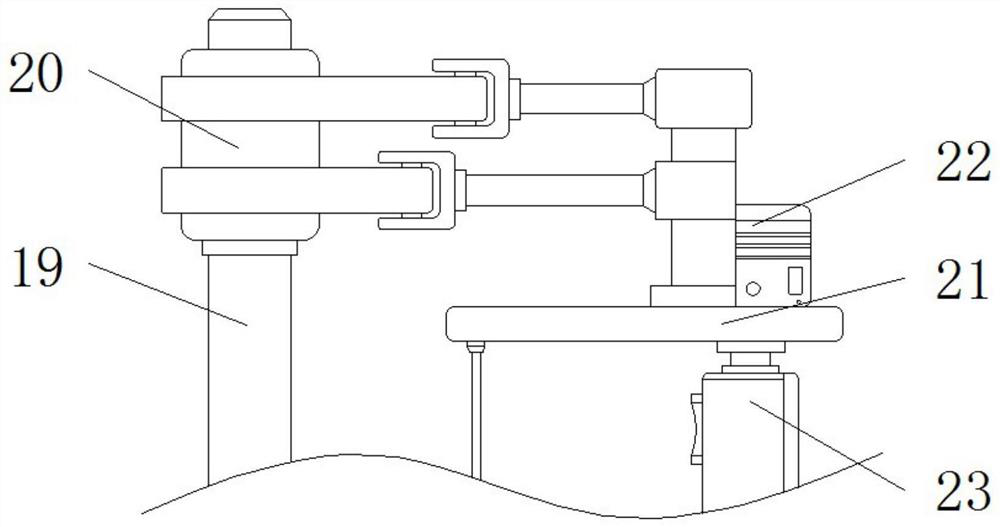

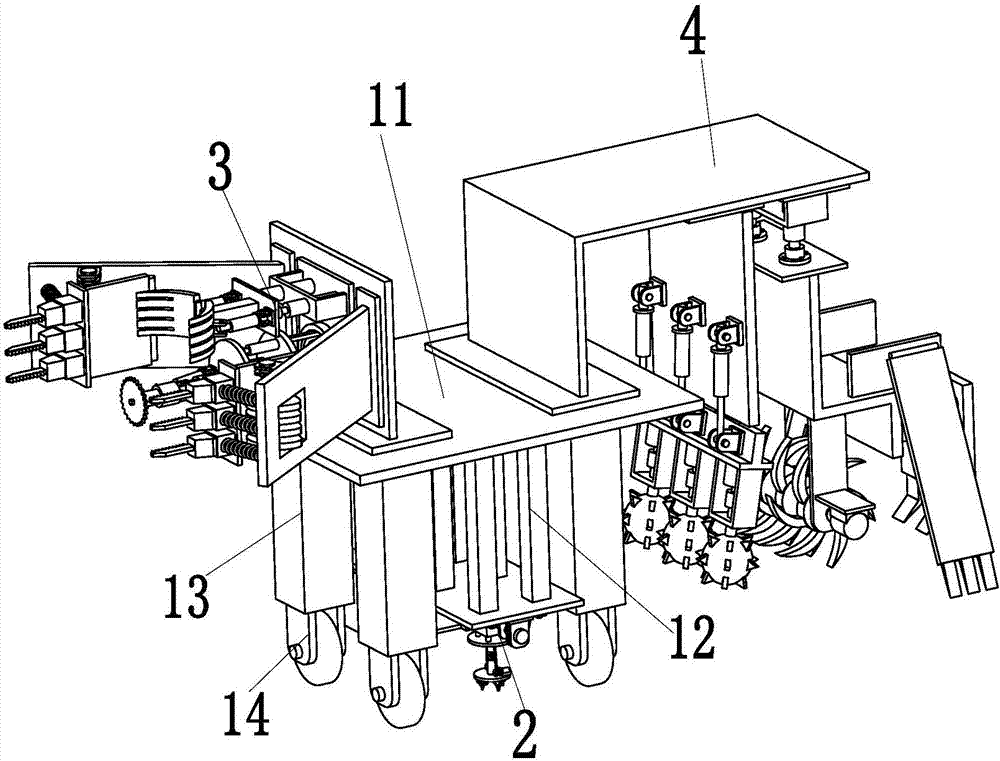

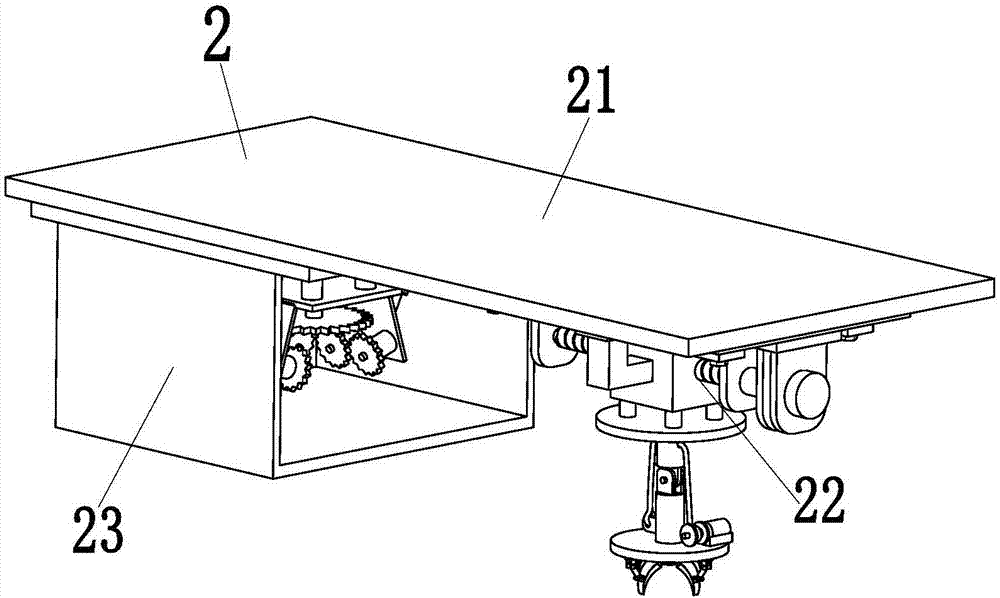

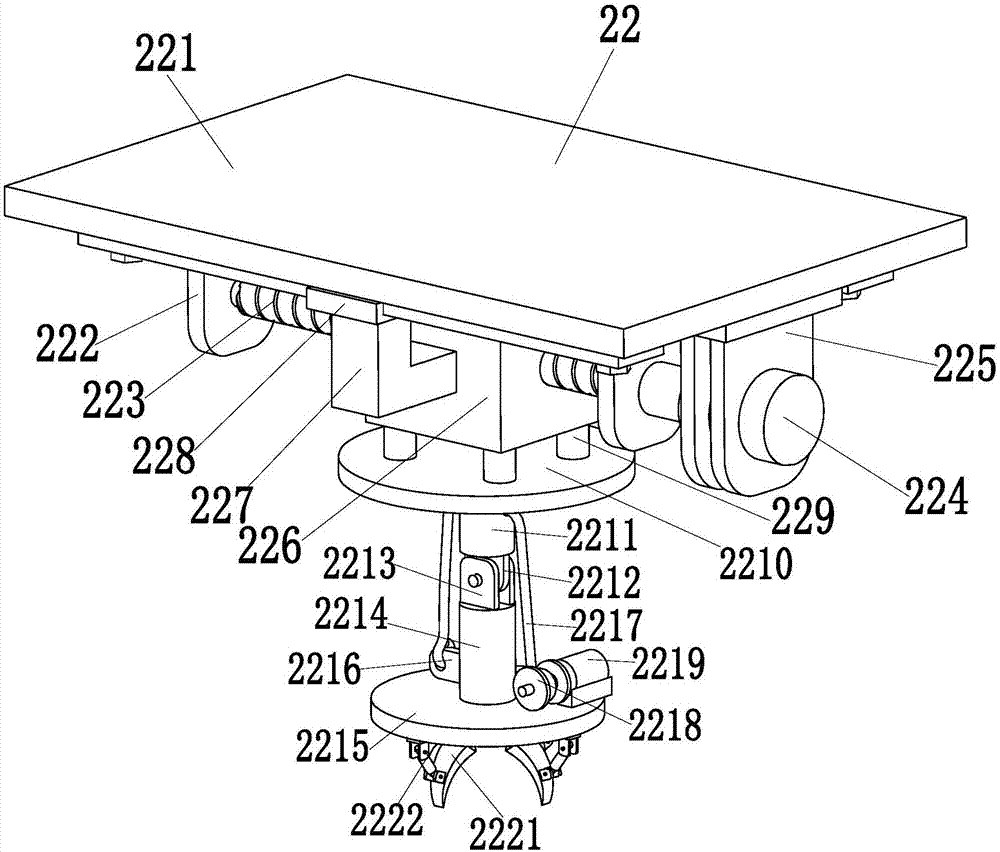

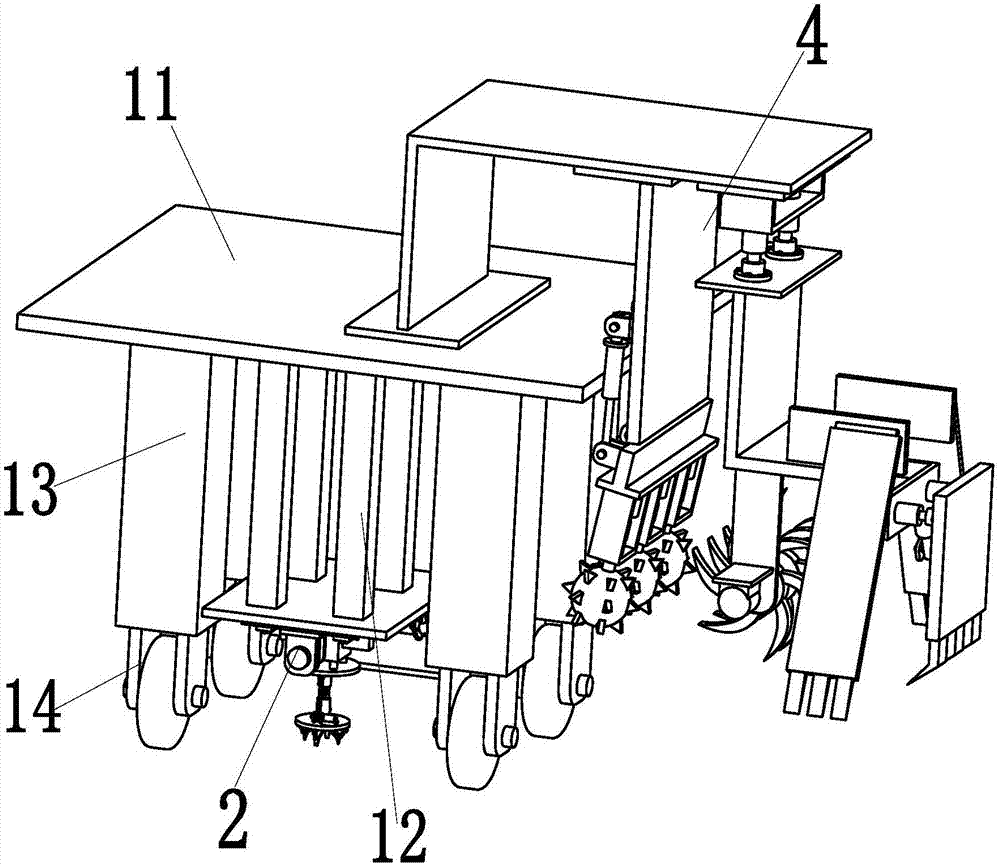

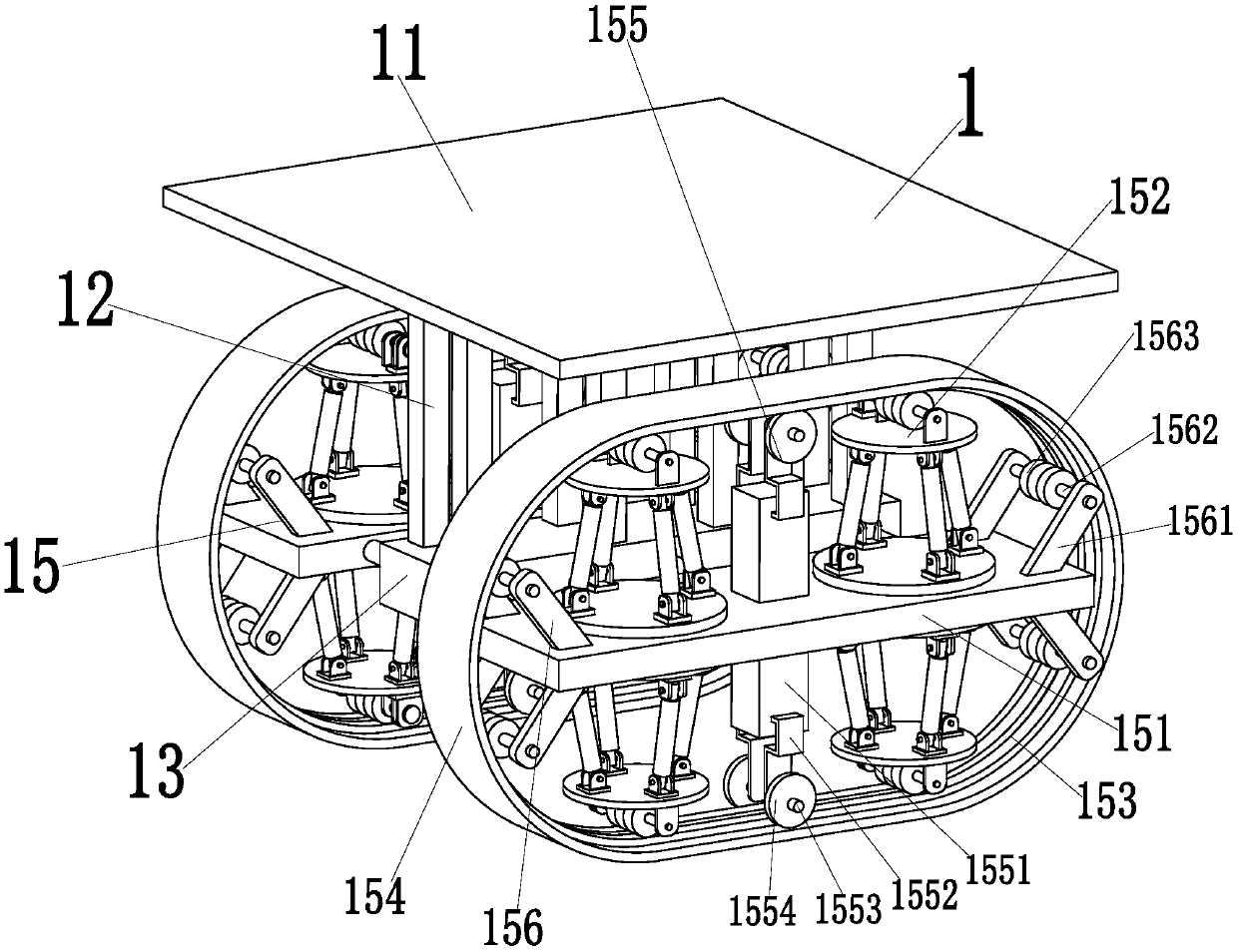

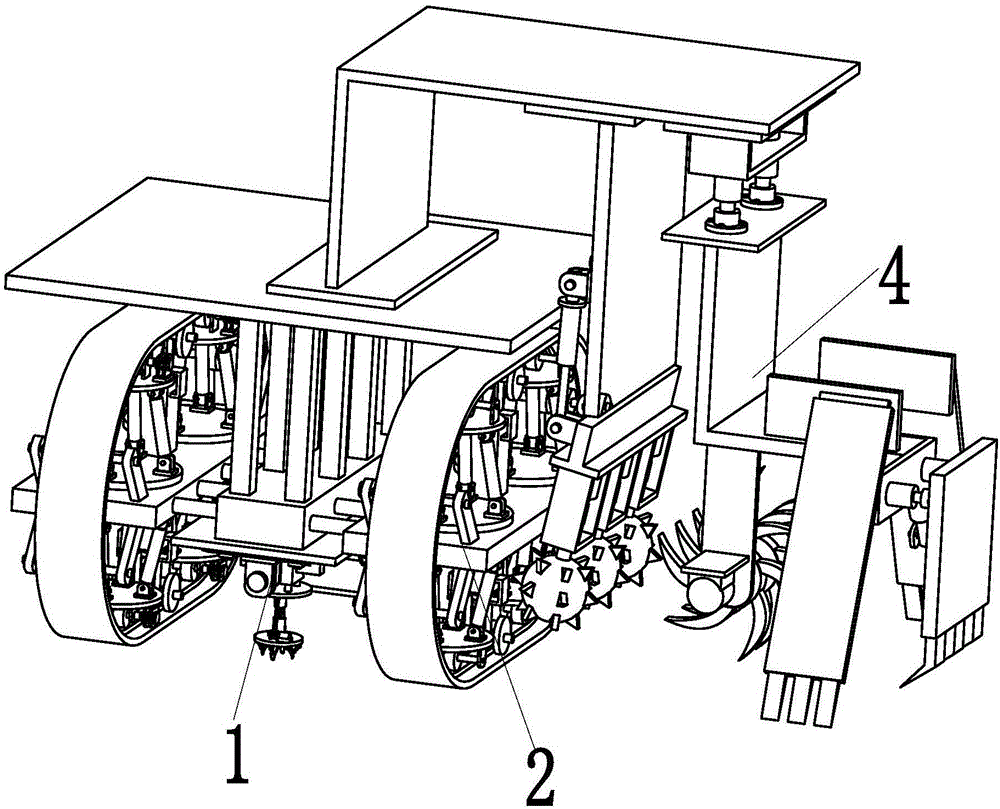

Automatic maintenance vehicle for subway rail

ActiveCN106120499ARealize automatic impurity removal functionRealize the automatic pruning functionRailway cleaningTrack maintainenceEngineering

Owner:临沂恒元城市建设运营有限公司

Deepwater silt layer geological large-span multi-line reinforcement system and jacking culvert construction method

ActiveCN103866694BUnstable solutionPrevent infiltrationBridge erection/assemblyInstabilityEconomic benefits

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

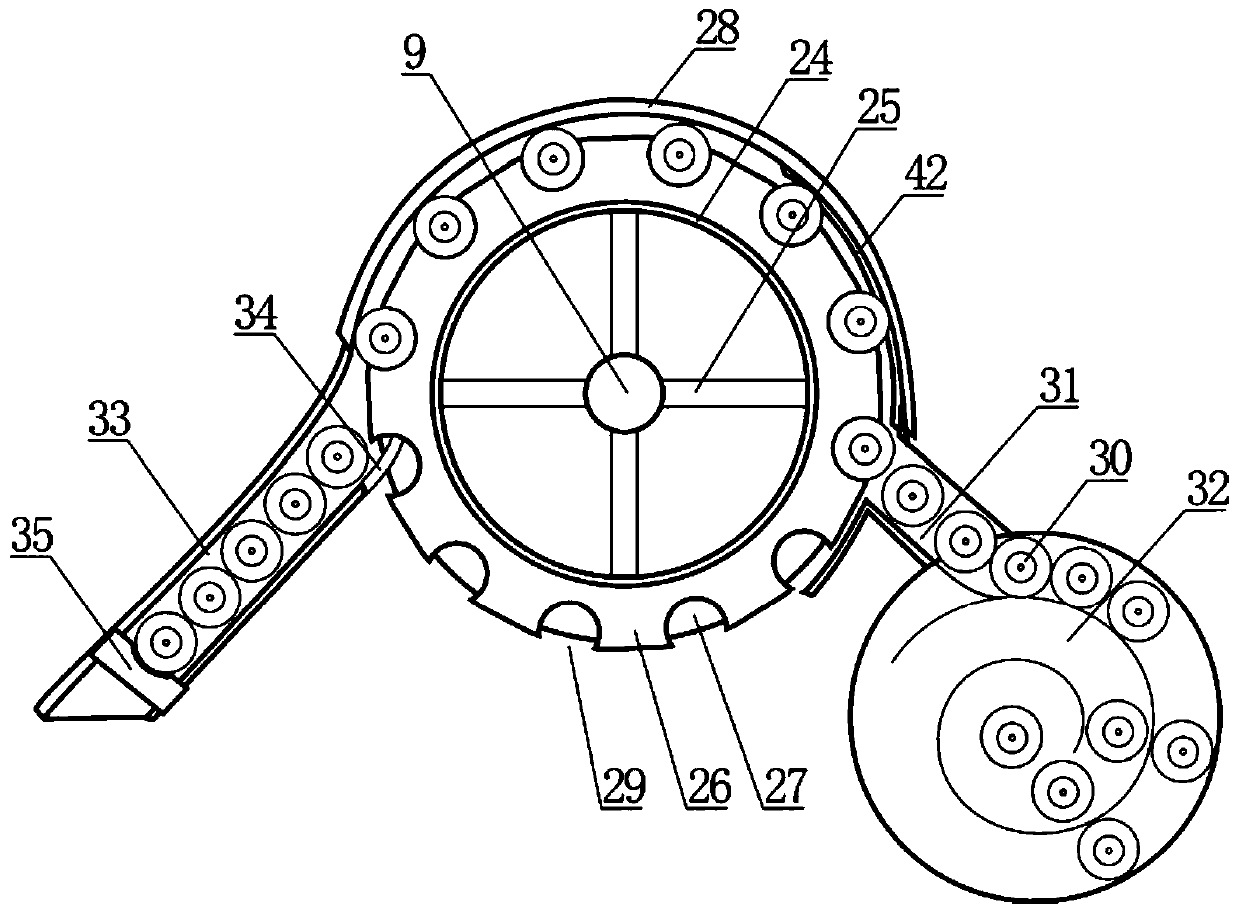

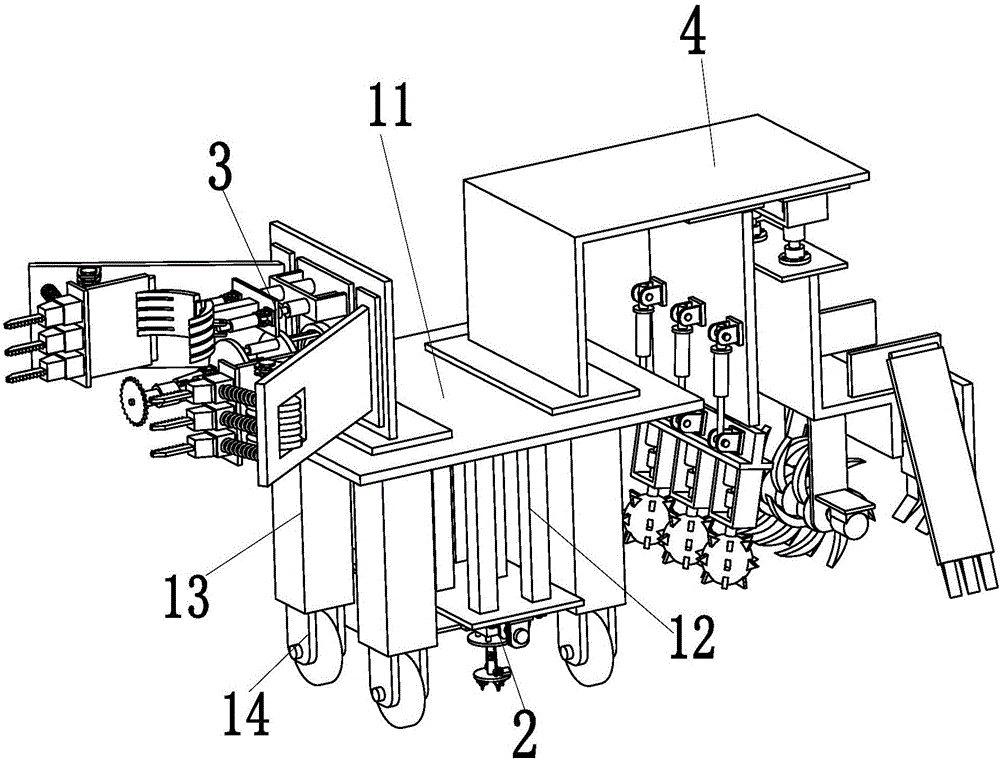

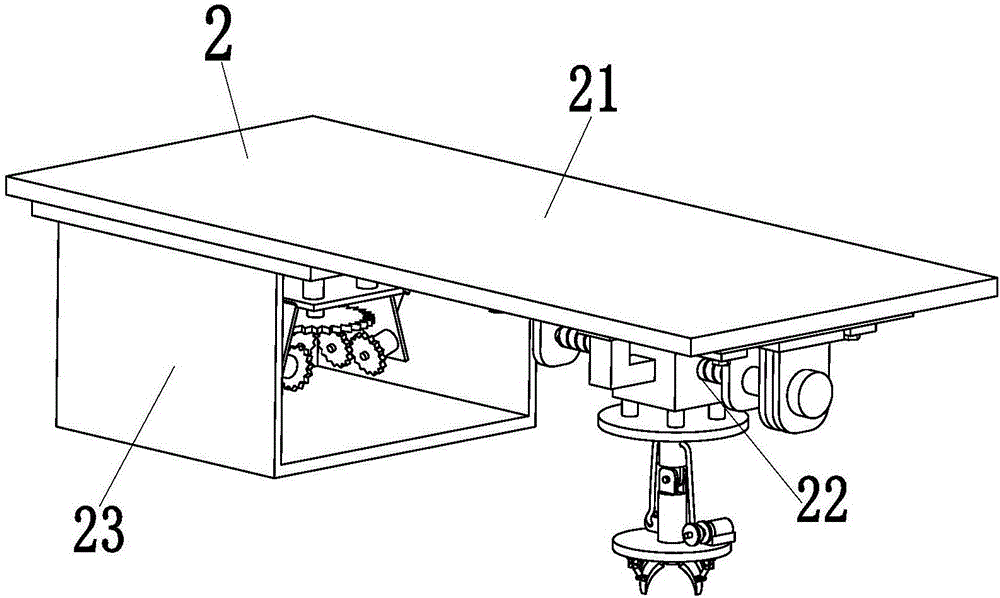

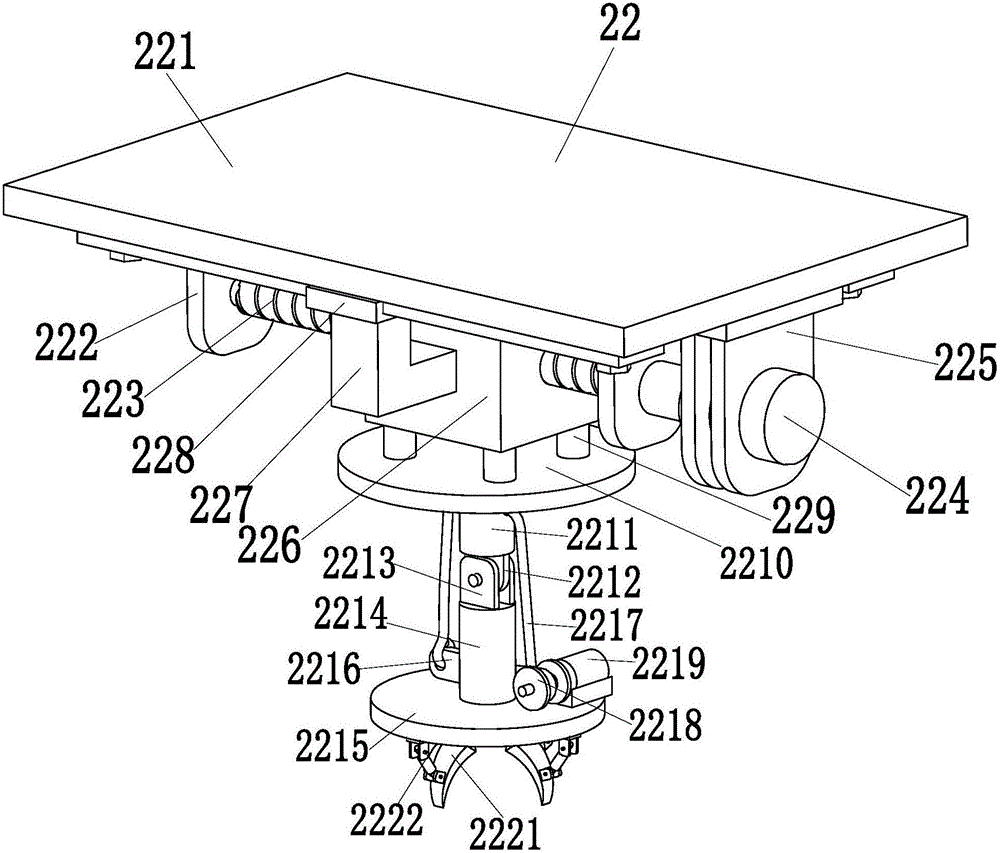

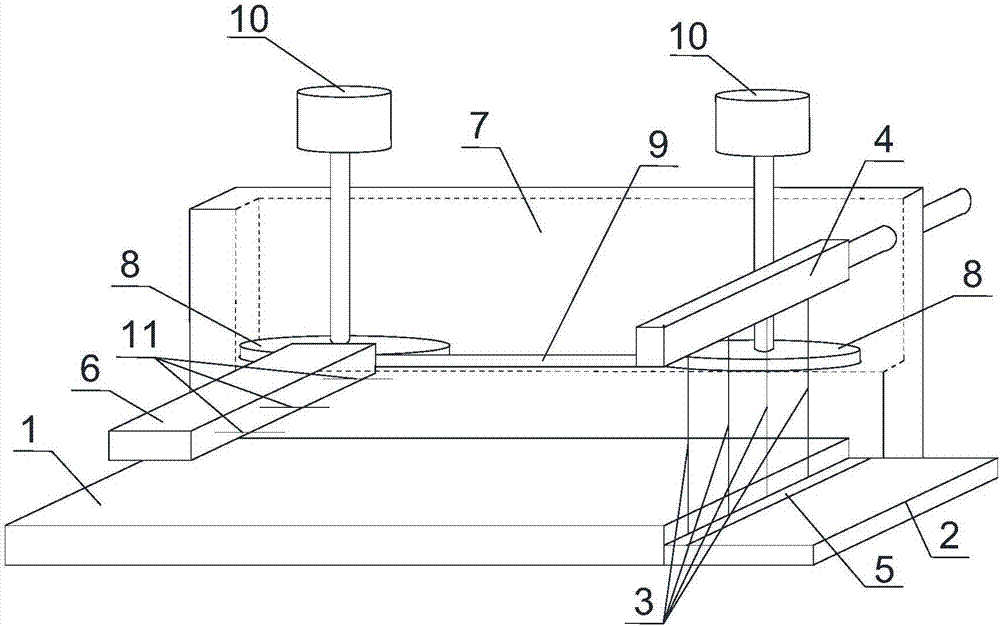

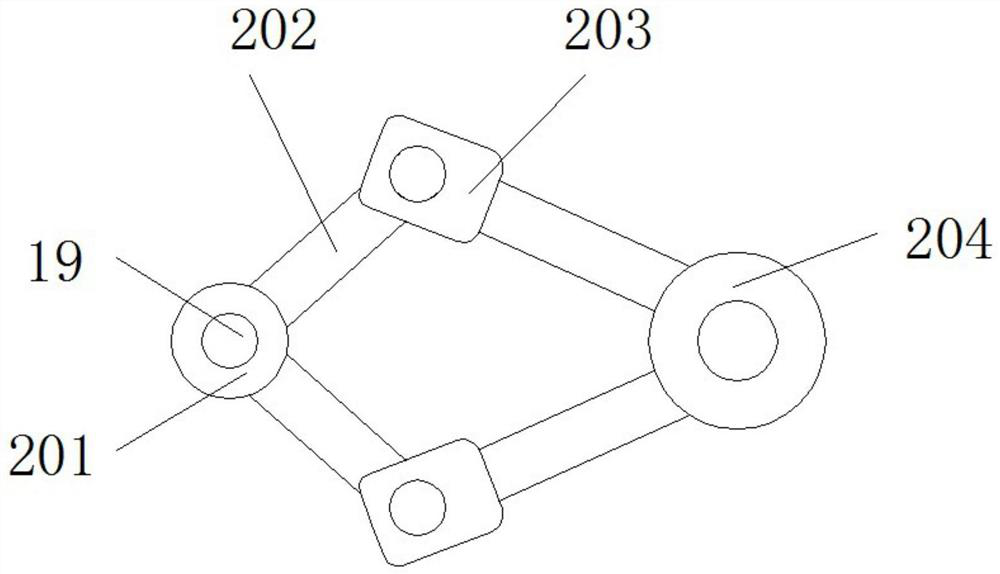

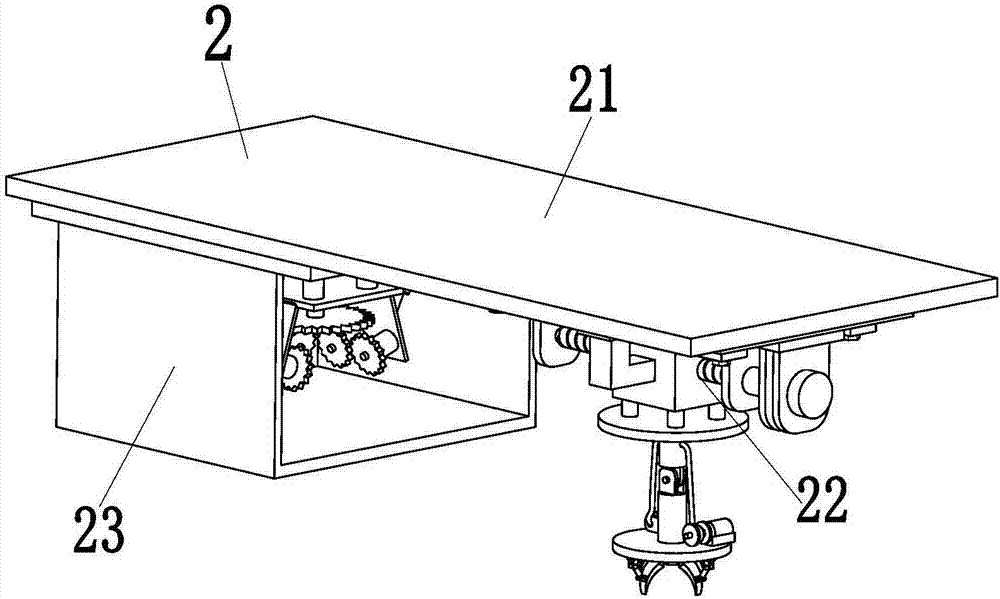

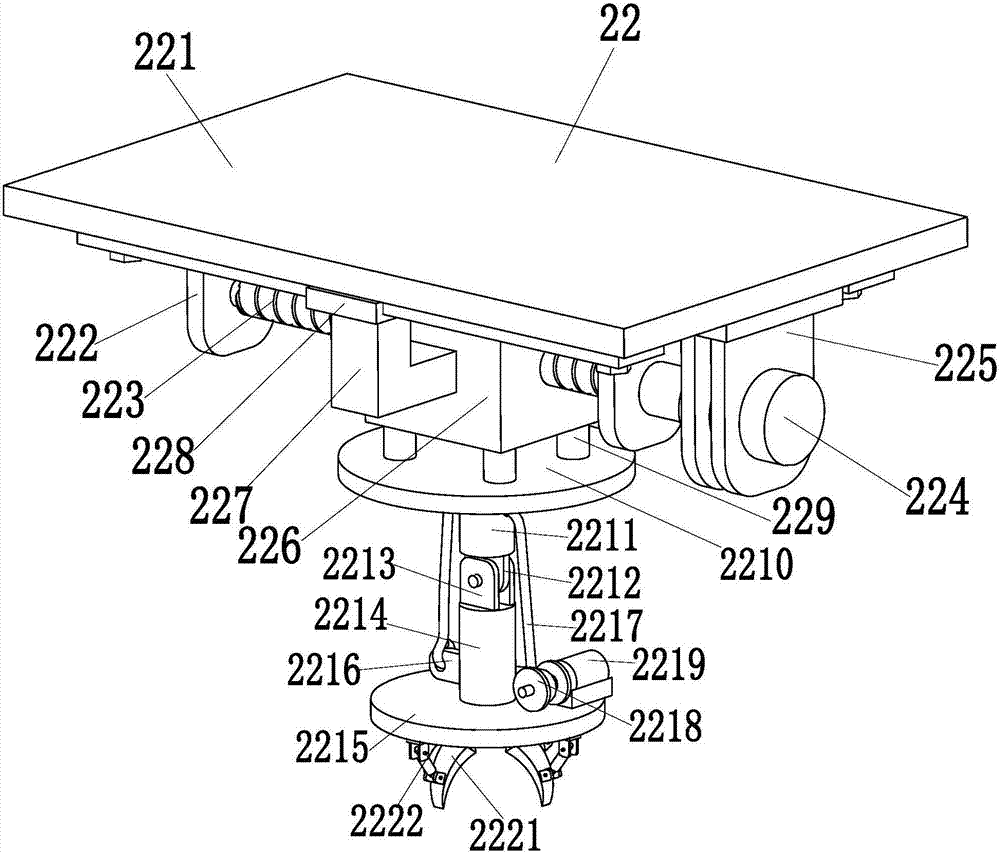

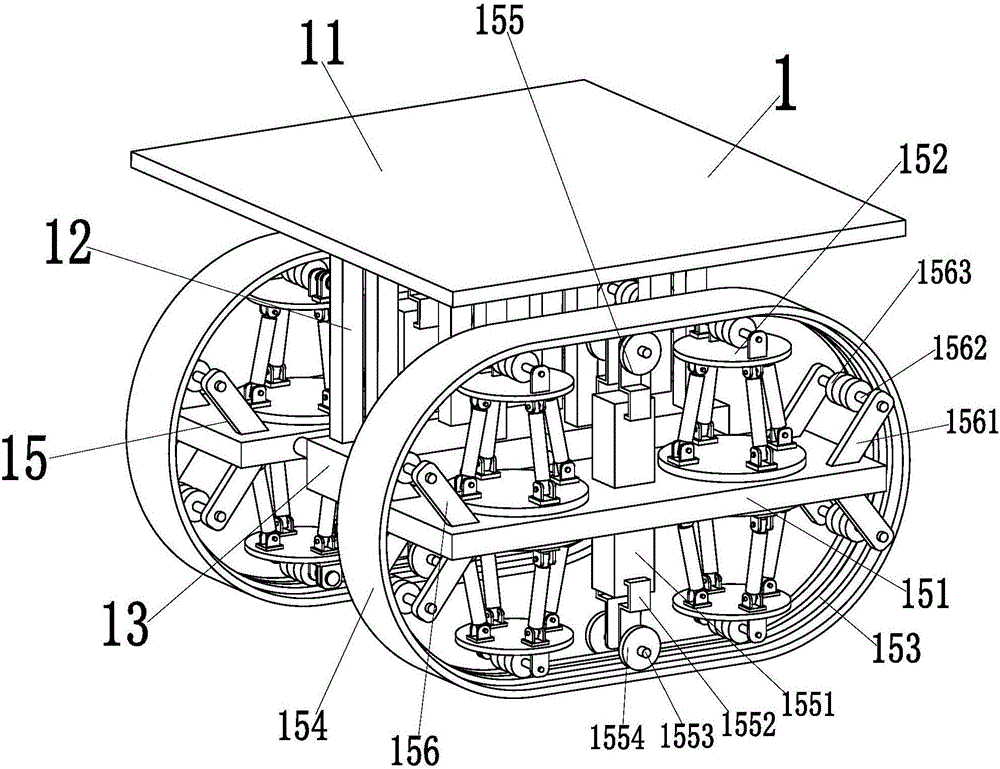

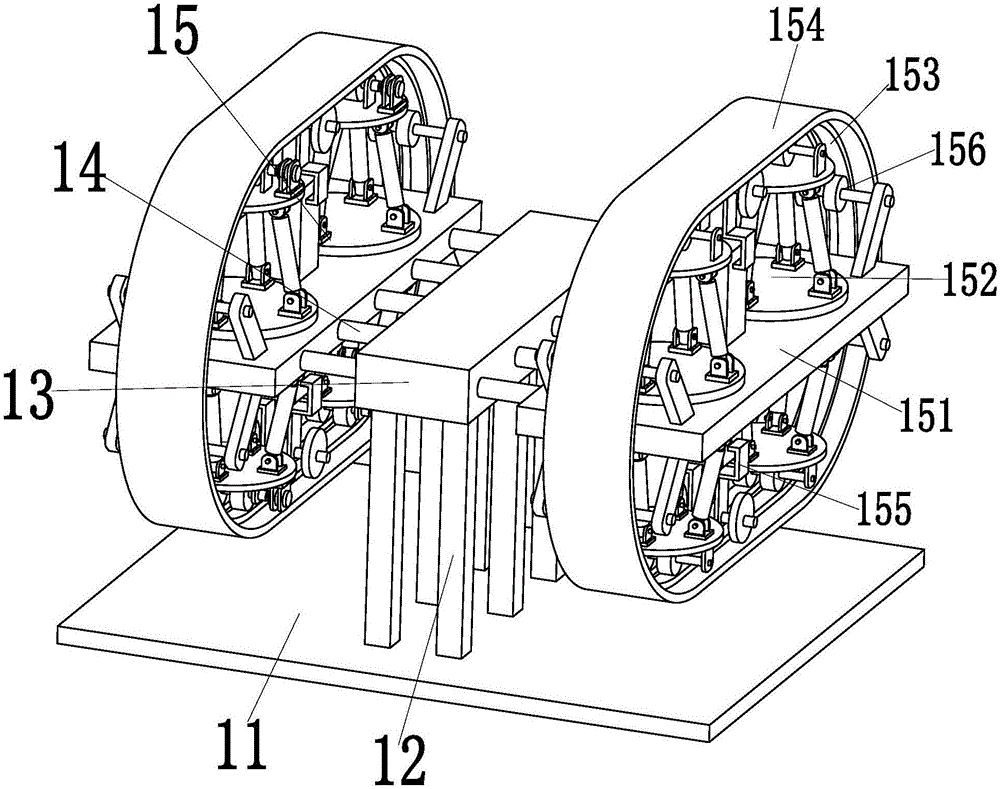

Track damping stone extruding and pushing machine with debris removal function

ActiveCN106368086ARealize automatic impurity removal functionRealize automatic pushing functionRailway tracksRailway cleaningEngineeringMechanical engineering

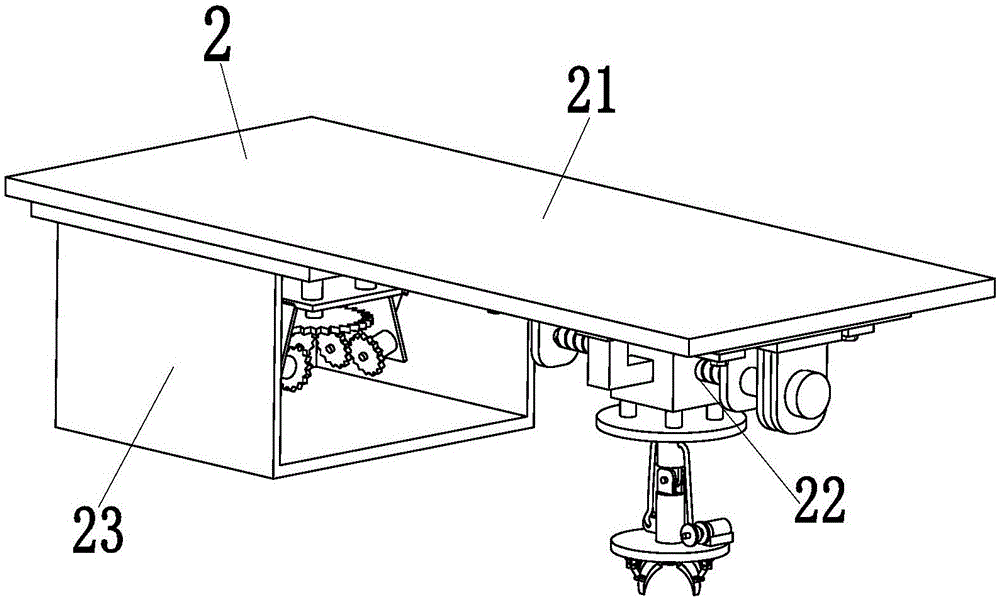

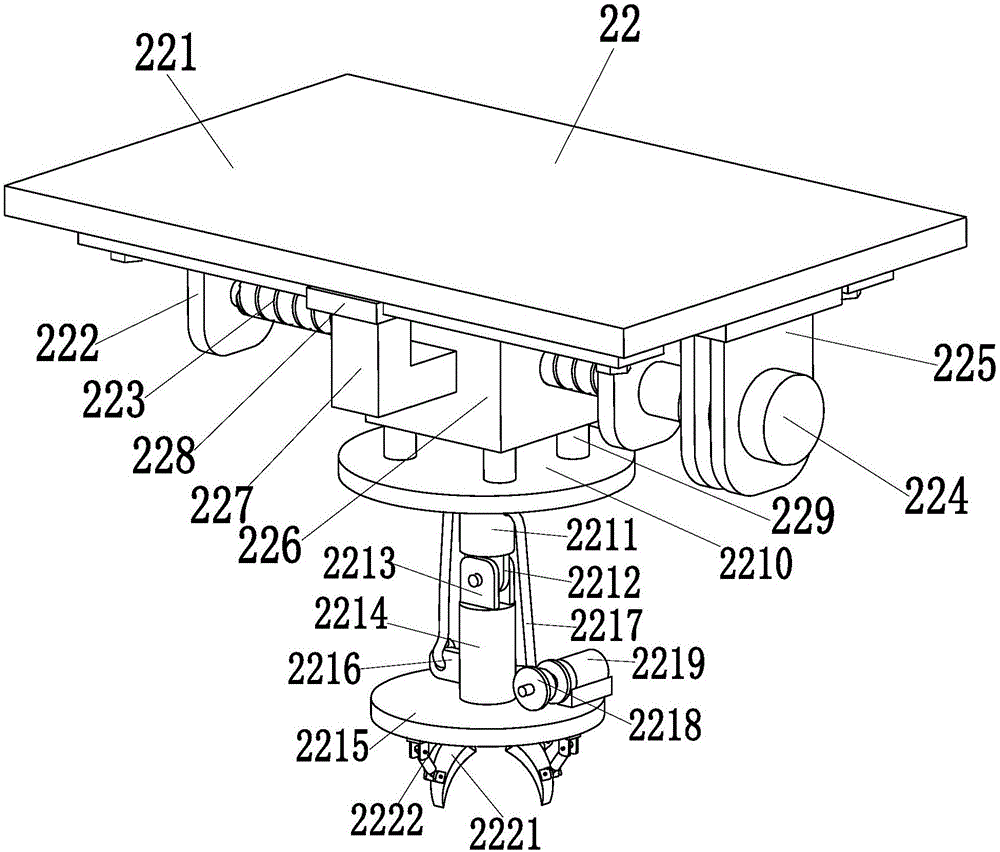

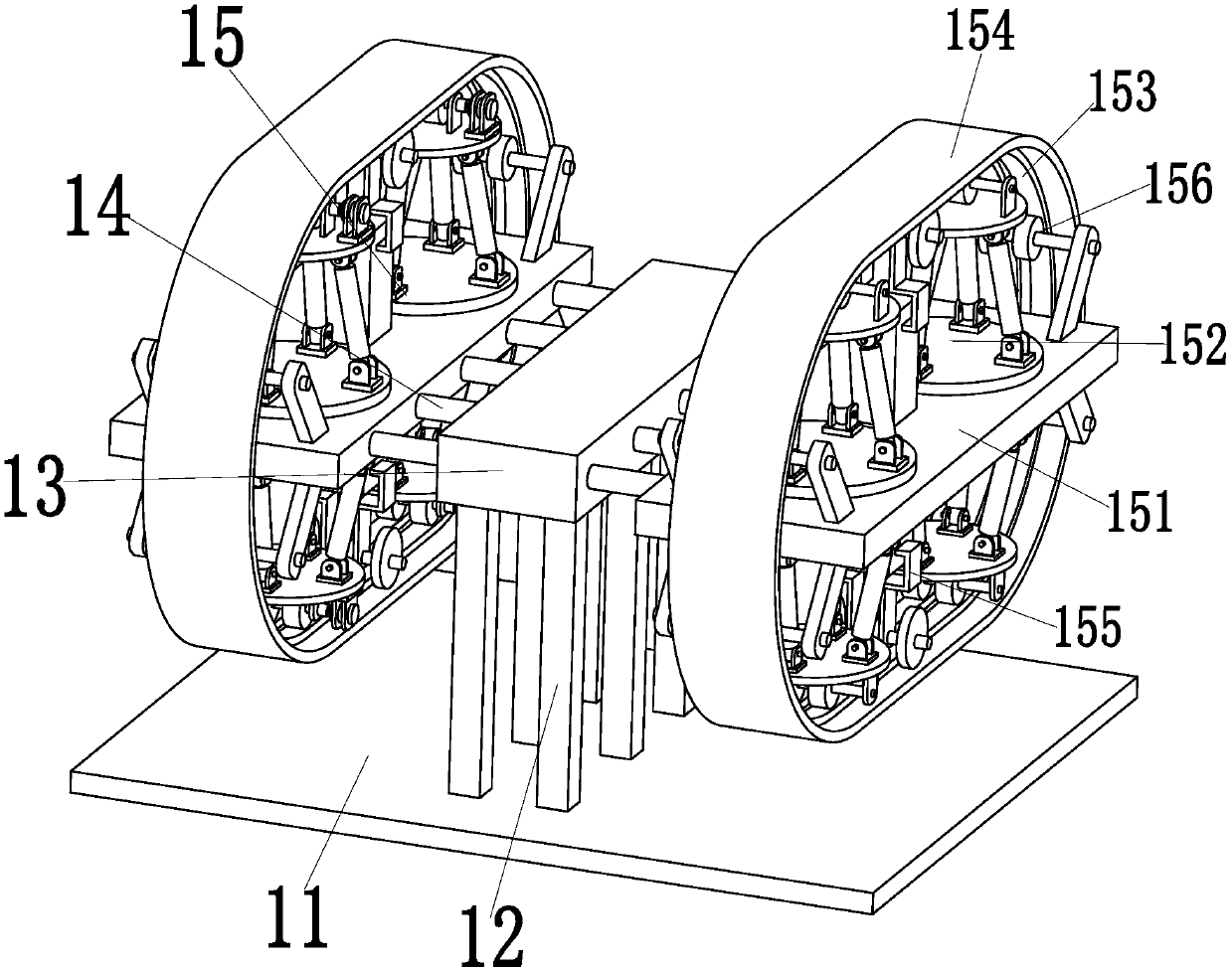

The invention relates to a track damping stone extruding and pushing machine with a debris removal function. The track damping stone extruding and pushing machine comprises a base plate; two rows of supporting columns are symmetrically arranged at the middle part at the lower end of the base plate; a track debris removal device is mounted at the lower ends of the two rows of supporting columns; the track debris removal device can realize the automatic debris removal function between rails; four supporting legs are symmetrically arranged at the lower end of the base plate, and a universal wheel is arranged at the lower end of each supporting leg; a track stone extruding and pushing device is mounted on the right side at the upper end surface of the base plate, and the track stone extruding and pushing device can realize the automatic extruding and pushing function of track damping stones; the track debris removal device comprises a debris removal supporting plate welded to the lower end surfaces of the two rows of supporting columns; a gripping and conveying mechanism is mounted on the right side at the lower end surface of the debris removal supporting plate; the gripping and conveying mechanism can realize the automatic gripping and conveying function to debris between the rails; and an adjustable crushing mechanism is mounted on the left side at the lower end surface of the debris removal supporting plate. Through the adoption of the track damping stone extruding and pushing machine disclosed by the invention, an automatic maintenance function integrating stone extruding and pushing as well as debris removal of the rails can be realized.

Owner:湖州优研知识产权服务有限公司

Driving licence self-service making equipment

PendingCN109335139AFast certificationSensitive and accurate operationWrappingWrapper twisting/gatheringEngineeringMaterial supply

The invention discloses driving licence self-service making equipment. The driving licence self-service making equipment comprises a first material supplying mechanism used for supplying lamination film, a laminating system used for performing lamination sealing on original copy of a licence core, a second material supplying mechanism used for supplying the licence core, an image printing system used for printing an image portion of a licence, a text printing system used for printing an information portion of the licence core, a licence core cutting mechanism used for cutting and transportingthe licence core, a licence core pushing mechanism used for pushing and transferring the original copy and an ectype of the licence core, a conveying mechanism used for conveying the original copy andthe ectype of the licence core separately, a third material supplying mechanism used for supplying a leather sheath, and a lamination mechanism used for performing lamination.

Owner:武汉柏思睿电子科技有限公司

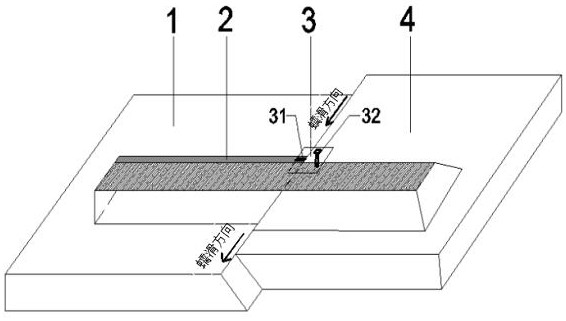

Cutting device for post processing of handmade soap

The invention discloses a cutting device for post processing of handmade soap. The cutting device comprises a cuboid workbench placed horizontally, wherein the workbench is connected with a supporting plate parallel to a side face using width and height as sides; the upper part of the supporting plate are connected with at least three cutting wires; the cutting wires are distributed in parallel at equal intervals along the width direction of the workbench; all the cutting wires are perpendicular to the supporting plate respectively; the upper ends of the cutting wires are respectively connected onto a fixed block; the lower ends of the cutting wires are respectively connected onto a sliding plate sliding along the width direction of the width direction; the sliding plate is connected with the supporting plate in a sliding manner; a pushing plate is arranged above the workbench; the pushing plate is positioned on the other side of the workbench and is opposite to the cutting wires; and a fixed device for fixing the handmade soap is arranged on the side face, facing the cutting wires, of the pushing plate. The handmade soap is pushed along the long side of the workbench, so that the handmade soap with long side is prevented from being collided or broken by manual operation, the cutting quality of the handmade soap is improved, and then the cutting efficiency of the handmade soap is improved.

Owner:橄享成都科技有限责任公司

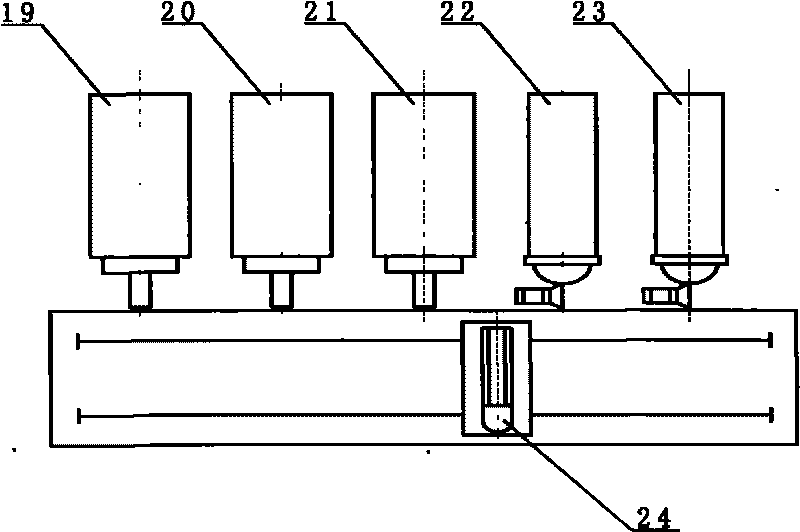

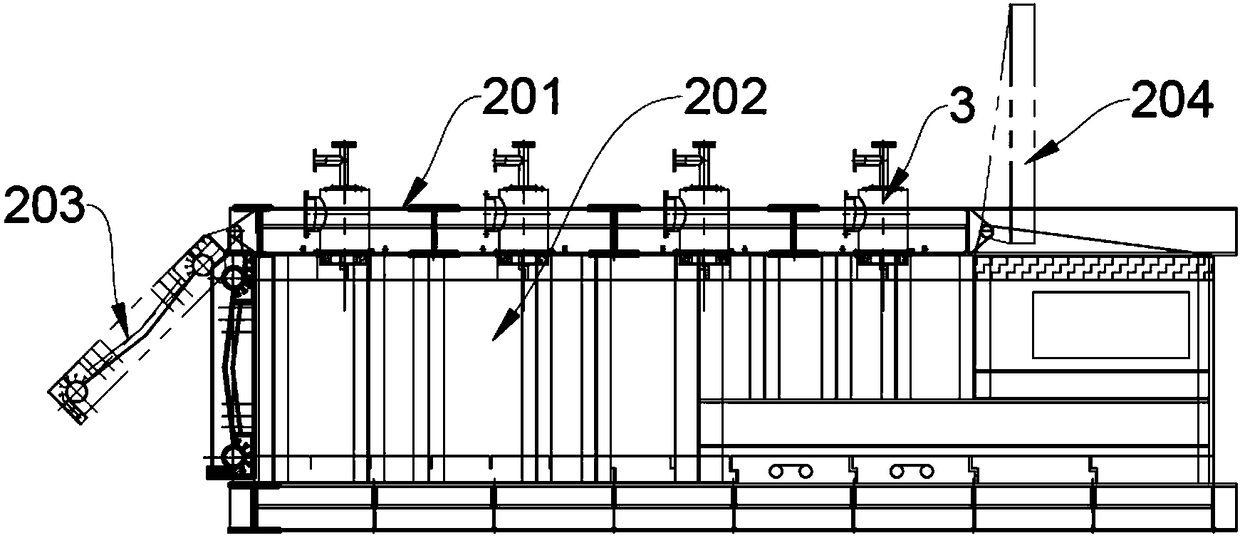

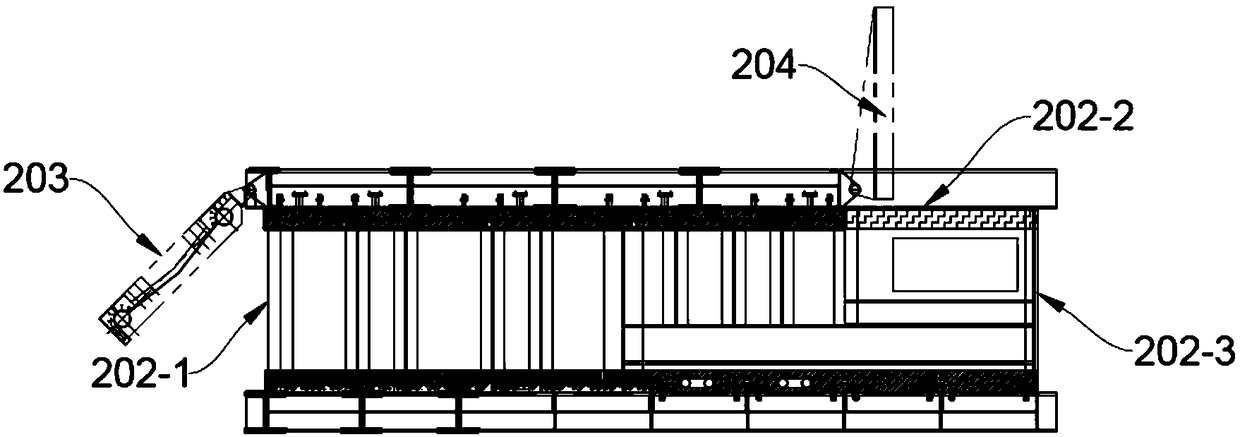

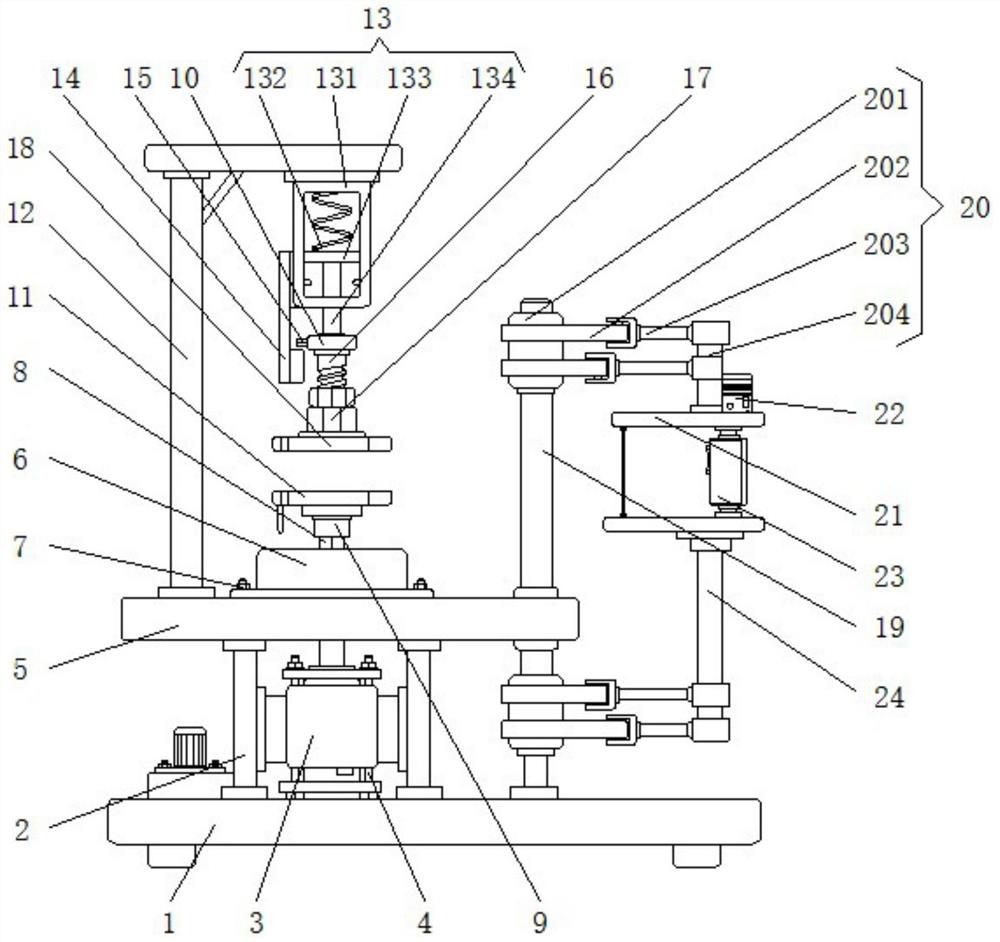

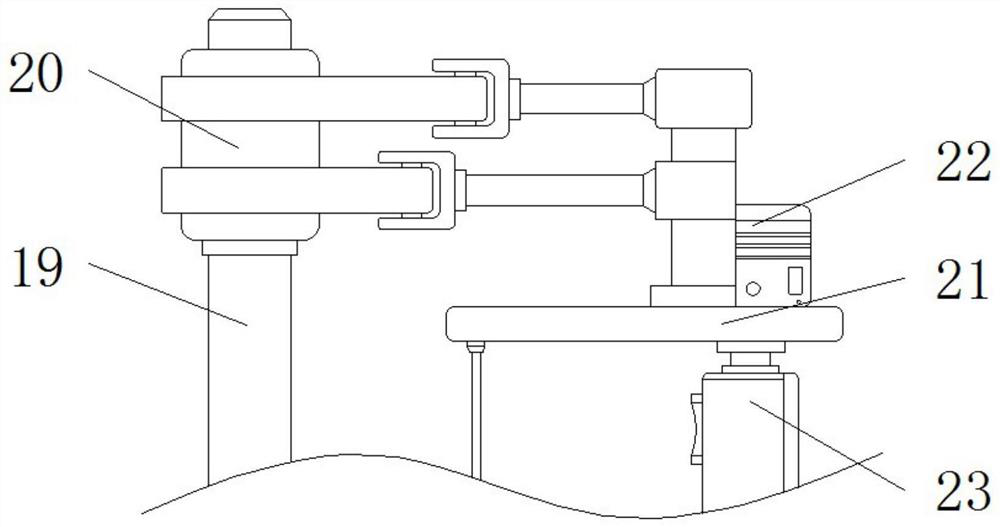

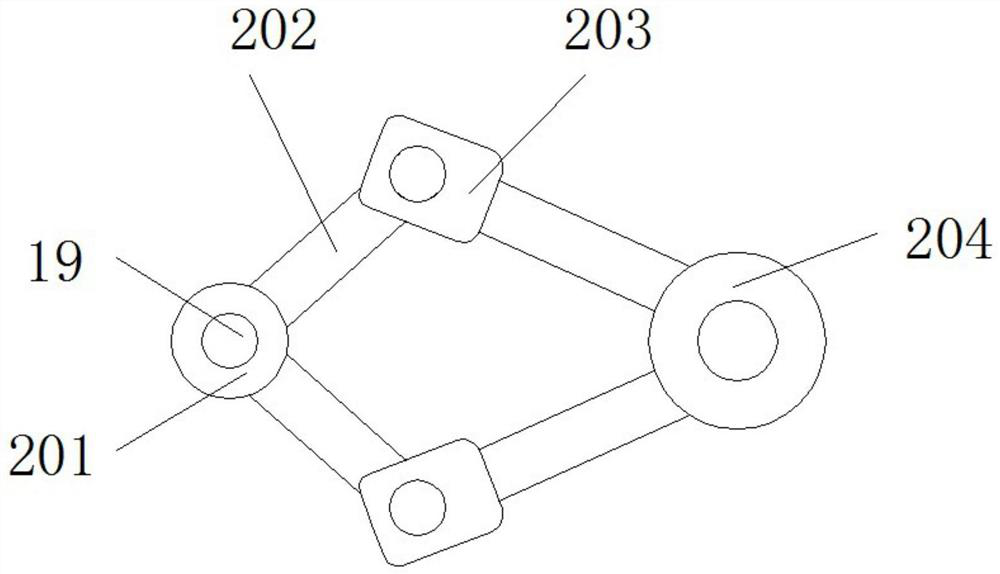

Scrap steel preheating system

The invention relates to a scrap steel preheating system. The scrap steel preheating system comprises a kiln, a conveying device, a mounting bracket, a steel pushing mechanism and a burner. The kiln is fixed on the mounting frame through fasteners, and the burner is installed on the kiln and used for preheating scrap steel. The left end of the kiln is an openable and closable discharging port, theright end of the kiln is a steel pushing port, the opening and closing of the steel pushing port is controlled by the steel pushing mechanism, and an openable and closable feeding port is formed in the side surface of the kiln. The conveying device is used for putting the scrap steel into the kiln from the feeding port. The steel pushing mechanism is fixed on the mounting bracket, does reciprocating linear motion and is used for pushing the preheated scrap steel out of the kiln. According to the scrap steel preheating system, the scrap steel is directly preheated by the kiln, the preheated scrap steel is pushed out by a steel pushing machine, the time in taking out the scrap steel from the kiln is shortened greatly by the adoption of the steel pushing machine, the time is counted in seconds, and thus continuous preheating of the scrap steel is realized.

Owner:上海轩鼎冶金科技集团有限公司

Cutting equipment for textile clothing

ActiveCN111851046AEasy to push and compress quicklyPush fastSevering textilesHydraulic cylinderTextile production

The invention relates to the technical field of textile production and processing equipment, and discloses cutting equipment for textile clothing. The cutting equipment comprises a supporting frame, wherein the middle of the top end of the supporting frame is correspondingly and fixedly connected with the bottom ends of two fixing rods I, the inner sides of the two fixing rods I are correspondingly and fixedly connected with the two sides of a fixing frame I, and one end of a hydraulic cylinder penetrates through the inner part of the top end of a worktable and extends to the top of a mold cavity, and is fixedly connected with the bottom end of a diamond joint. According to the cutting equipment for textile clothing, through the matching of the hydraulic cylinder, the mold cavity, the diamond joint and an upper mold plate, textile fabrics in the inner cavity of the mold cavity are conveniently and quickly pushed and pressed upwards, multiple layers of fabrics can be simultaneously cut,meanwhile the problem that in the cutting process of multiple layers of the fabrics, some fabrics generates relative sliding, resulting in poor cutting accuracy or quality, and the textile fabrics are wasted is avoided, and the cutting efficiency of the cutting device and the accuracy and quality during fabric cutting are effectively improved.

Owner:汕头市潮南区达锋制衣有限公司

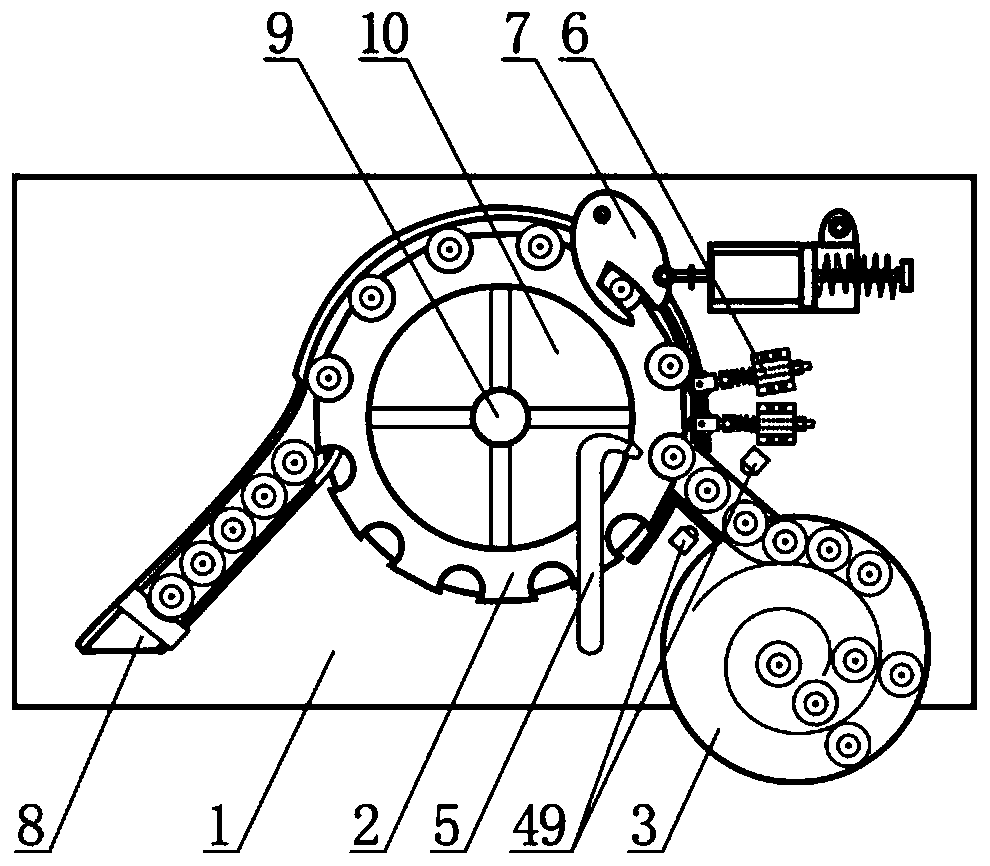

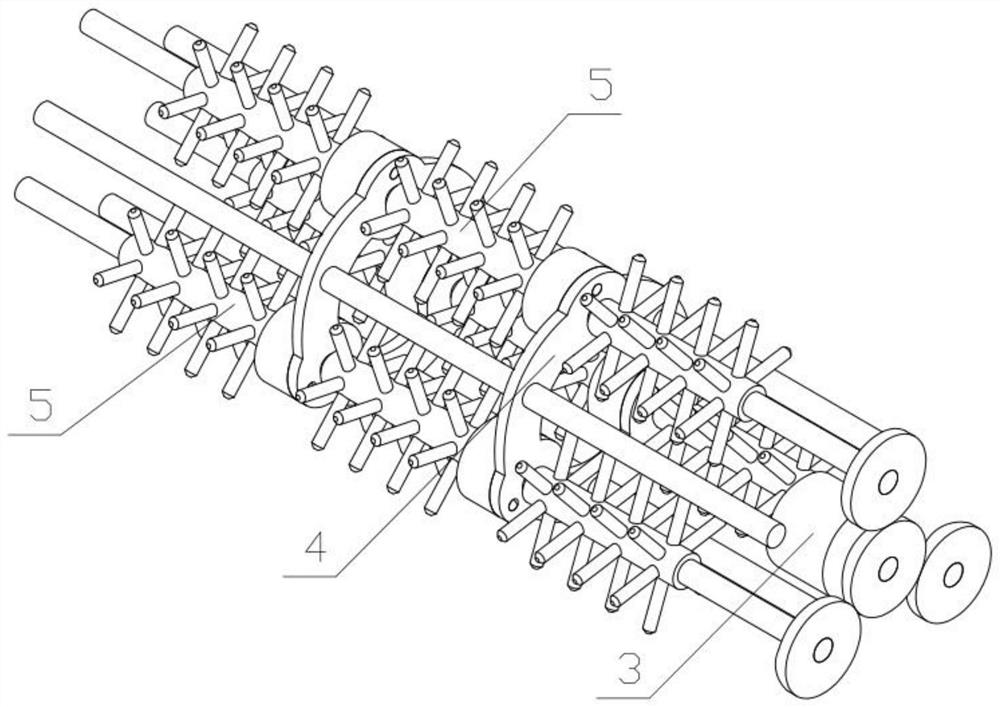

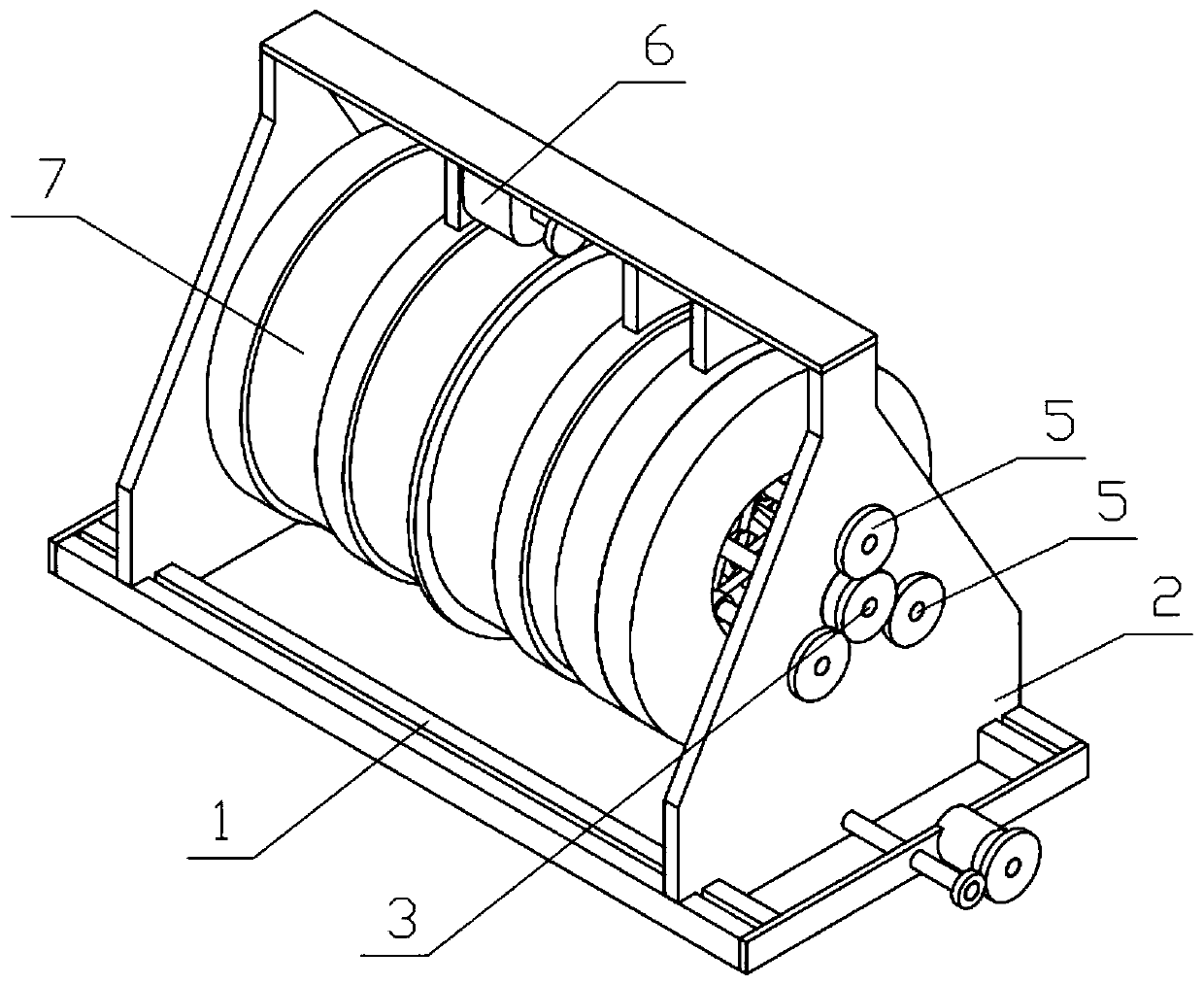

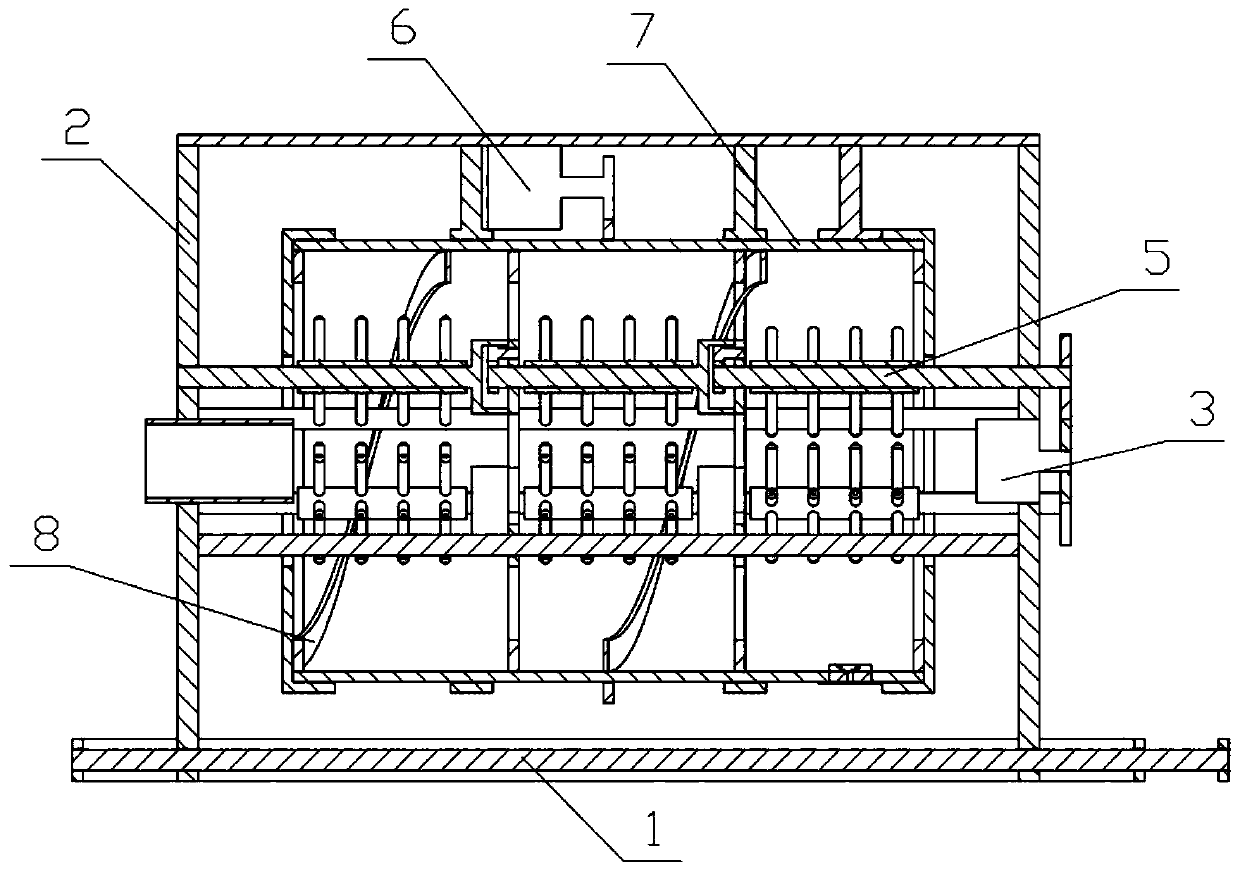

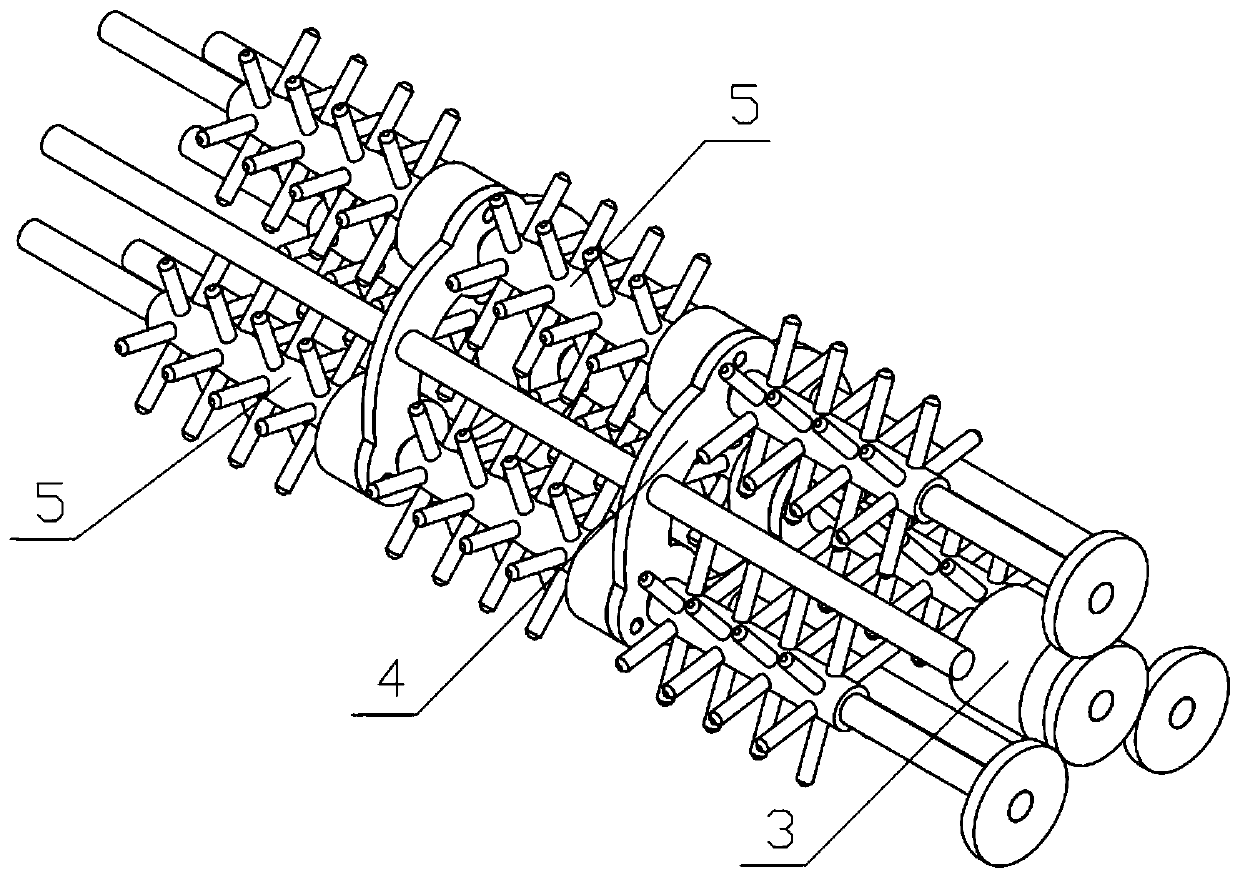

A sand making device

ActiveCN110871125BGuaranteed processing speedPush fastGrain treatmentsMining engineeringElectric machine

The invention relates to a manufacturing device, more specifically a sand and gravel manufacturing device, including a sliding bracket, a device bracket, a power motor, a rotating bracket, a crushing mechanism, a rotating motor, a crushing cylinder and a pushing mechanism, which can drive multiple The crushing mechanism rotates, and multiple crushing mechanisms crush the stones in the crushing barrel. There are multiple pushing areas on the pushing mechanism. The pushing speed of each pushing area is different. The crushing mechanism is equipped with multiple crushing areas. Each crushing area The torque is different, and the multiple pushing areas correspond to the multiple crushing areas. The stone first passes through the crushing area with a large torque and the slow pushing area to ensure that large stones can be completely crushed, ensuring the crushing effect, and the torque in the crushing area. Decrease in turn, and the pushing speed in the pushing area will increase in turn to ensure the processing speed of the stone.

Owner:HARBIN UNIV

Cutting equipment for textile clothes

ActiveCN111851046BEasy to push and compress quicklyPush fastSevering textilesHydraulic cylinderTextile production

The invention relates to the technical field of textile production and processing equipment, and discloses a tailoring equipment for textile clothes, including a support frame, the middle part of the top of the support frame is respectively fixedly connected with the bottom ends of two fixed rods I, and the inner sides of the two fixed rods I They are respectively fixedly connected to both sides of the fixed frame I, and one end of the hydraulic cylinder runs through the interior of the top of the workbench and extends to the top of the mold cavity and is fixedly connected to the bottom of the rhombus joint. The cutting equipment for textile clothes, through the cooperation of the hydraulic cylinder, the mold cavity, the diamond joint and the upper template, is convenient to quickly push and compress the textile fabric in the inner cavity of the mold cavity, and can cut multiple layers of fabric at the same time. In the process of cutting multi-layer fabrics, some fabrics will slide relative to each other, resulting in poor cutting accuracy or quality, and then causing the waste of textile fabrics, effectively improving the cutting efficiency of the cutting device and the accuracy and accuracy of cutting fabrics. quality.

Owner:汕头市潮南区达锋制衣有限公司

Assembling process of double oil cylinder pushing mechanism for injection molding machine

The assembly process of the double oil cylinder pushing mechanism for injection molding machine disclosed in the present invention, S1, inserting the first plunger into the first flow cavity in the cylinder body; S2, contacting the side wall of the annular protrusion on the second piston One end surface is coated with abrasive, and then the second piston coated with abrasive is placed into the second flow chamber through the second flow chamber port in the cylinder; S3, the side with abrasive on the second piston and The side wall of the annular protrusion is in close contact with and rotates after applying pressure to the second piston at the same time. The side wall of the annular protrusion and the side with abrasive on the second piston are ground mutually so that the side wall of the annular protrusion and the second piston Sealing is achieved between one side of the piston; S4. Use the third end cover and the sealing ring to close the port of the second flow chamber, and insert the pressurized plunger on the third end cover through the perforation of the second piston In the pressurized chamber at the end of the first plunger. It improves the driving efficiency, and the end surface of the piston has a high tightness with the surface in contact with it.

Owner:余姚市鹰图机械设备有限公司

Sandstone manufacturing device

The invention relates to a manufacturing device, in particular to a sandstone manufacturing device. The sandstone manufacturing device comprises a sliding bracket, a device bracket, a power motor, a rotating bracket, crushing mechanisms, a rotating motor, a crushing cylinder and a pushing mechanism, a plurality of crushing mechanisms can be driven to perform rotation through the power motor, the plurality of crushing mechanisms can crush stones in the crushing cylinder, a plurality of pushing areas are arranged on the pushing mechanism, the pushing speed of each pushing area is different, thecrushing mechanism is provided with a plurality of crushing areas, the torque of each crushing area is different, and the plurality of pushing areas correspond to the plurality of crushing areas respectively. According to the sandstone manufacturing device, the stones first passes through the crushing areas with large torque and the pushing areas with slow driving, so that it can be ensured that the large stones can be completely crushed, the crushing effect is ensured; and the torque in the crushing areas is reduced sequentially, and the pushing speed in the pushing areas is accelerated sequentially, so that the processing speed of the stones is ensured.

Owner:HARBIN UNIV

An automatic maintenance vehicle for subway tracks

ActiveCN106120499BRealize automatic impurity removal functionRealize the automatic pruning functionRailway cleaningTrack maintainenceEngineeringAuto maintenance

Owner:临沂恒元城市建设运营有限公司

A track damping stone pusher with impurity removal function

ActiveCN106368086BRealize automatic impurity removal functionRealize automatic pushing functionRailway tracksRailway cleaningEngineeringMechanical engineering

The invention relates to a track damping stone extruding and pushing machine with a debris removal function. The track damping stone extruding and pushing machine comprises a base plate; two rows of supporting columns are symmetrically arranged at the middle part at the lower end of the base plate; a track debris removal device is mounted at the lower ends of the two rows of supporting columns; the track debris removal device can realize the automatic debris removal function between rails; four supporting legs are symmetrically arranged at the lower end of the base plate, and a universal wheel is arranged at the lower end of each supporting leg; a track stone extruding and pushing device is mounted on the right side at the upper end surface of the base plate, and the track stone extruding and pushing device can realize the automatic extruding and pushing function of track damping stones; the track debris removal device comprises a debris removal supporting plate welded to the lower end surfaces of the two rows of supporting columns; a gripping and conveying mechanism is mounted on the right side at the lower end surface of the debris removal supporting plate; the gripping and conveying mechanism can realize the automatic gripping and conveying function to debris between the rails; and an adjustable crushing mechanism is mounted on the left side at the lower end surface of the debris removal supporting plate. Through the adoption of the track damping stone extruding and pushing machine disclosed by the invention, an automatic maintenance function integrating stone extruding and pushing as well as debris removal of the rails can be realized.

Owner:湖州优研知识产权服务有限公司

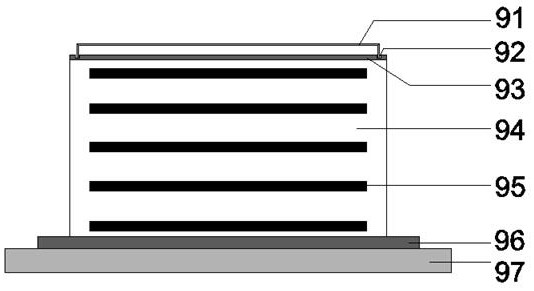

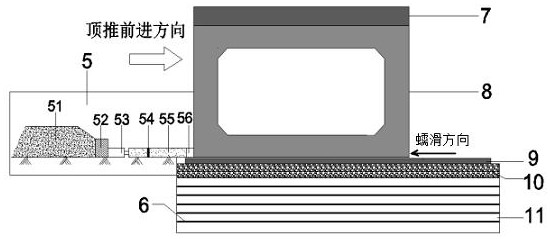

A subgrade structure spanning active faults

InactiveCN110804919BReduce adverse effectsIncrease structural flexibilityGround-workRoadwaysArchitectural engineeringMonitoring system

The invention discloses a roadbed structure spanning an active fault, the roadbed structure includes a roadbed foundation, a displacement monitoring system and a homing and pushing system; the roadbed foundation is divided into a left disk area and a right disk area in the horizontal direction, and the The side of the creeping direction of the left disc area is provided with a homing and pushing system, and the displacement monitoring system is set at the boundary between the left disc area and the right disc area. When the displacement monitoring system detects that the horizontal creep displacement of the subgrade reaches the threshold , activate the homing and pushing system to push the box culvert and surface layer to the initial position. The roadbed structure of the present invention avoids the problems of line growth and passenger and cargo transportation time caused by the line avoiding active faults, greatly saves economic costs, and the roadbed construction and maintenance are simple, high in safety and reliability, and can be used in creeping active fault areas. widely used.

Owner:LANZHOU JIAOTONG UNIV

Guide rail mechanism for bidirectional power head of brick making machine

The invention discloses a guide rail mechanism for a bidirectional power head of a brick making machine. A bidirectional grooved cam and a bidirectional guide rail are mounted on a bidirectional power head body, the bidirectional grooved cam is hinged to a speed reducer through the bidirectional guide rail and a rotary silicone pad, and the speed reducer is connected with a driving motor through a double screw. The whole bidirectional power head mechanism has the advantages of integrated structure, high push speed and high accuracy by the aid of the mechanism mode of the bidirectional power head, the bidirectional guide rail, the double screw and the bidirectional grooved cam.

Owner:XUZHOU KAILONG MINING SCI & TECH DEV

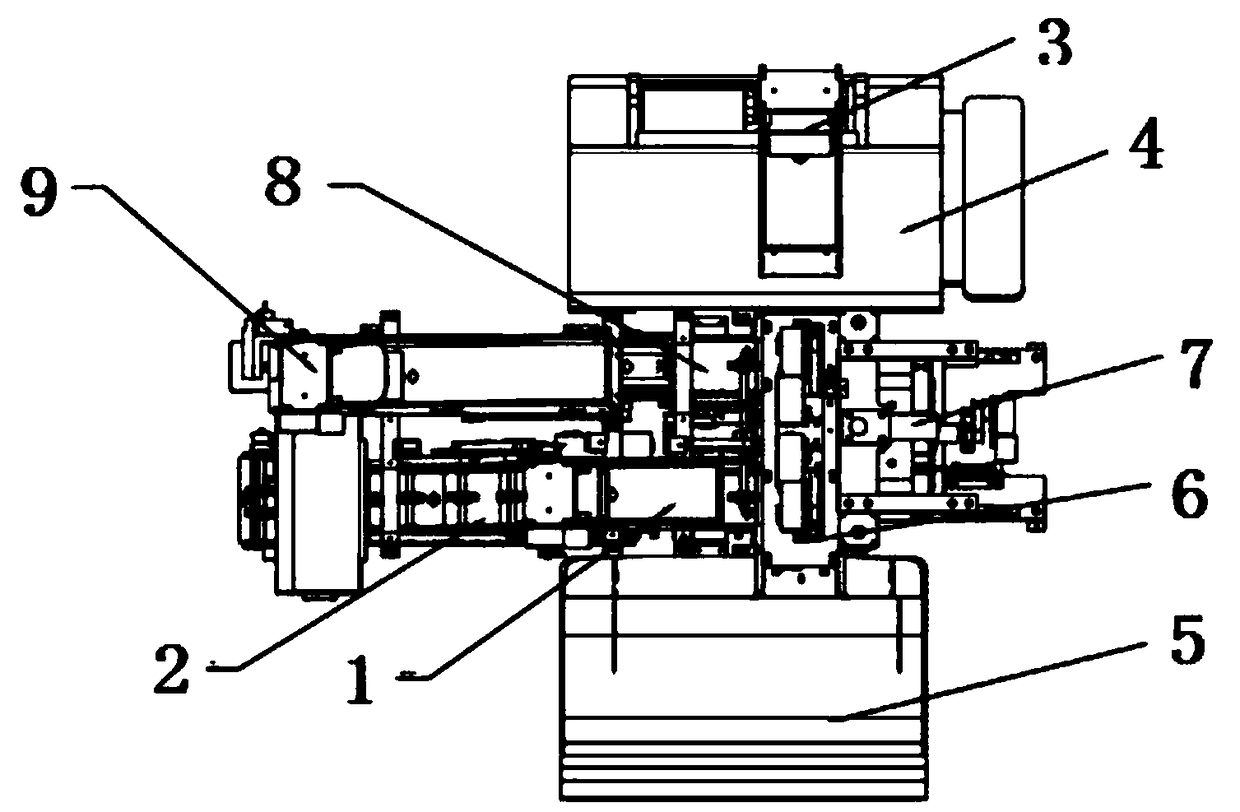

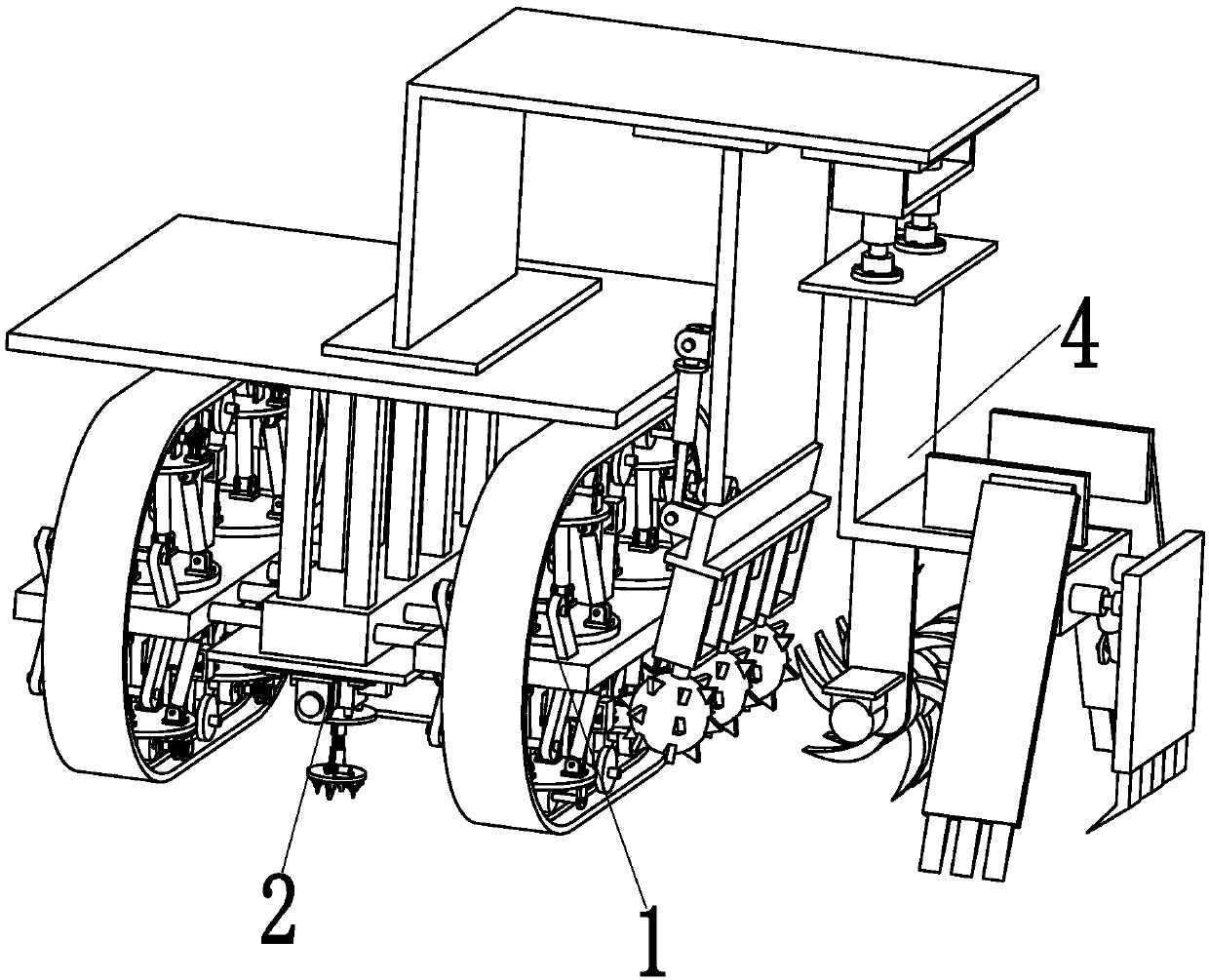

A kind of automatic processing equipment for train track

ActiveCN106337327BRealize automatic motion detection functionUniform rigid self-steady walking functionBallastwayTrack superstructureAbutmentEngineering

The invention relates to automatic treatment equipment for a power train rail. The automatic treatment equipment comprises a rail moving base, wherein the rail moving base can realize an automatic moving detection function for the rail; a rail debris removal device is mounted at the middle part of the lower end surface of the rail moving base, and can realize an automatic debris removal function between the rails; a rail stone extruding and pushing device is mounted on the upper end surface of the rail moving base, and can realize an automatic extruding and pushing function for rail shock absorption stones; the rail debris removal device comprises a debris removal supporting plate welded on the lower end surface of a moving abutment; a grabbing and conveying mechanism is mounted on the right side of the lower end surface of the debris removal supporting plate, and can realize an automatic grabbing and conveying function for debris between the rails; an adjustable smashing mechanism is mounted on the left side of the lower end surface of the debris removal supporting plate. The automatic treatment equipment can realize a road condition detection, stone extruding and pushing and debris removal all-in-one automatic maintenance function for the rails.

Owner:常熟紫金知识产权服务有限公司

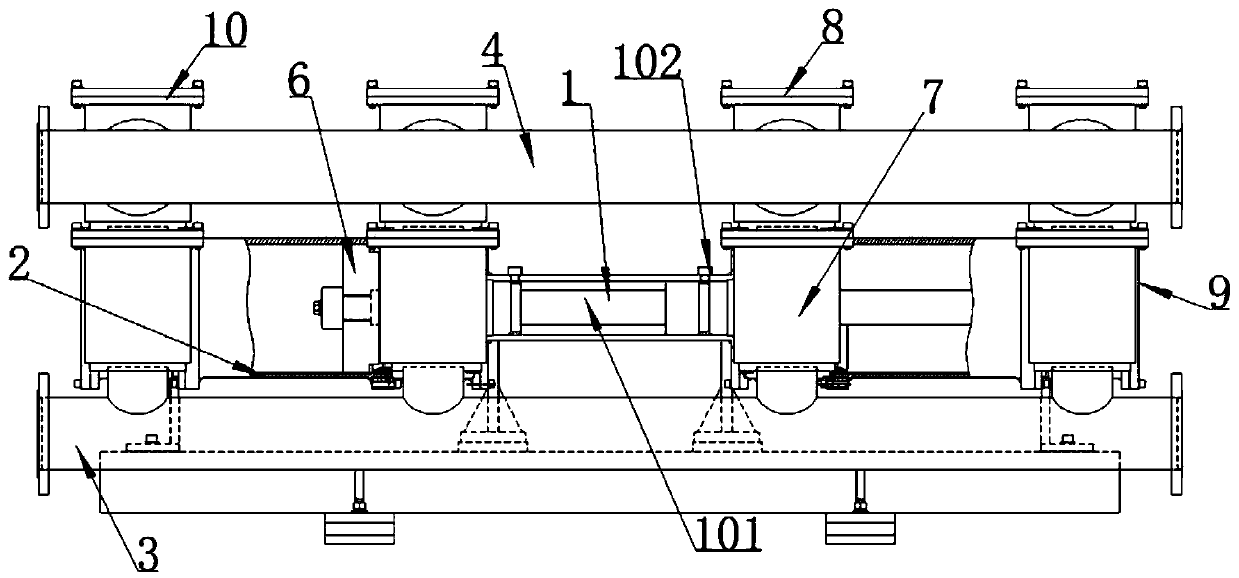

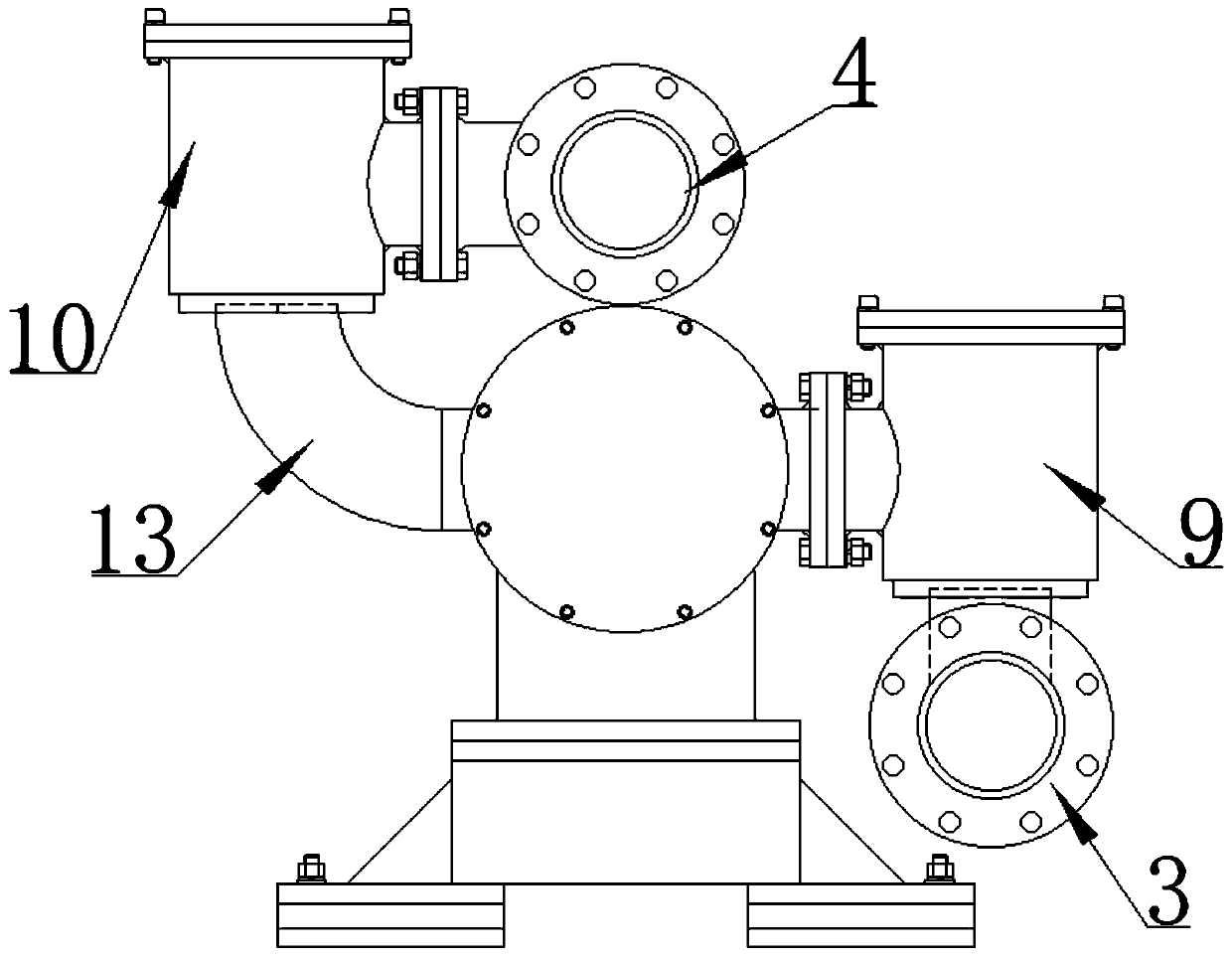

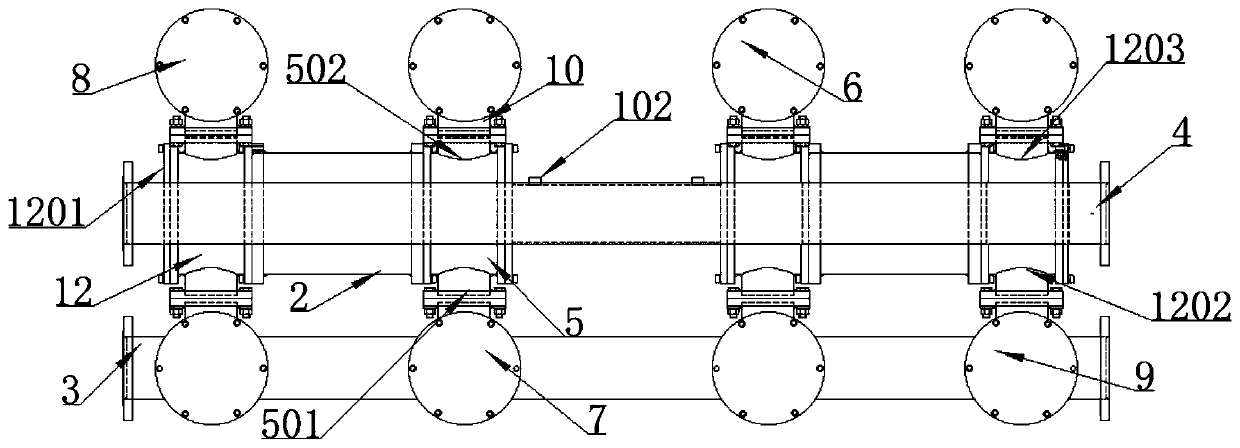

Double-acting four-inlet four-outlet reciprocating pump

PendingCN110345036AIncrease temperatureReduce power lossPositive displacement pump componentsPiston pumpsHydraulic cylinderEngineering

The invention discloses a double-acting four-inlet four-outlet reciprocating pump. The reciprocating pump comprises a hydraulic cylinder body, main pump barrels, a feeding pipeline and a discharging pipeline, the main pump barrels are coaxially and symmetrically arranged on two sides of the hydraulic cylinder body, and inner auxiliary pump barrels are arranged between the main pump barrels and thehydraulic cylinder body. One end face of each inner auxiliary pump barrel communicates with a port of the corresponding main pump barrel, and the other end face of each inner auxiliary pump barrel isfixed to the end face of the hydraulic cylinder body. A hydraulic driving rod is arranged in the hydraulic cylinder body, the two ends of the hydraulic driving rod are inserted into the main pump barrels and fixedly provided with pistons, and oil openings are formed in the circumferential surface of the hydraulic cylinder body. An inner feeding opening and an inner discharging opening are formedin the annular surface of each inner auxiliary pump barrel, wherein any angle is formed between the inner feeding opening and the inner discharging opening, and the inner feeding opening and the innerdischarging opening communicate with the feeding pipeline and the discharging pipeline through one-way valves. Ports, away from the inner auxiliary pump barrels, of the main pump barrels communicatewith the feeding pipeline and the discharging pipeline through one-way valves. The reciprocating pump is simple in structure, small in occupied area, low in manufacturing, maintenance and site cost and small in fluid resistance, the output flow under the same power is remarkably increased, and the power can be effectively reduced.

Owner:江苏艾迪环境科技有限公司

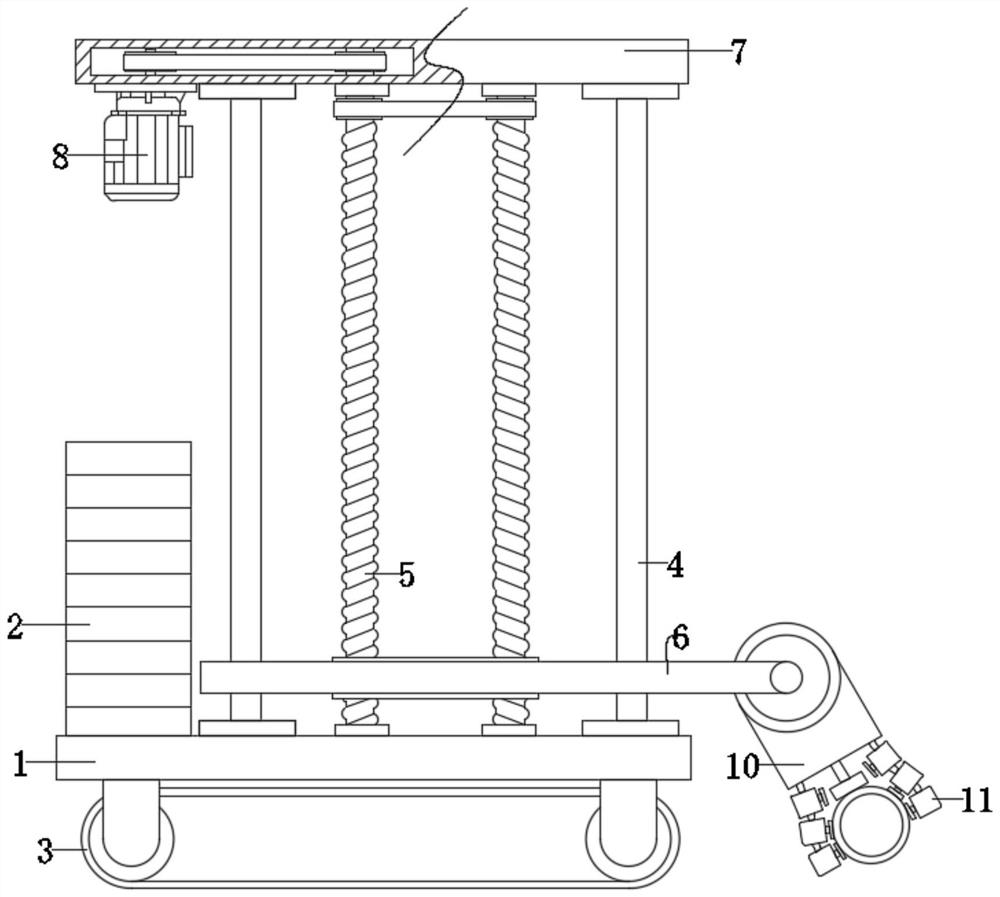

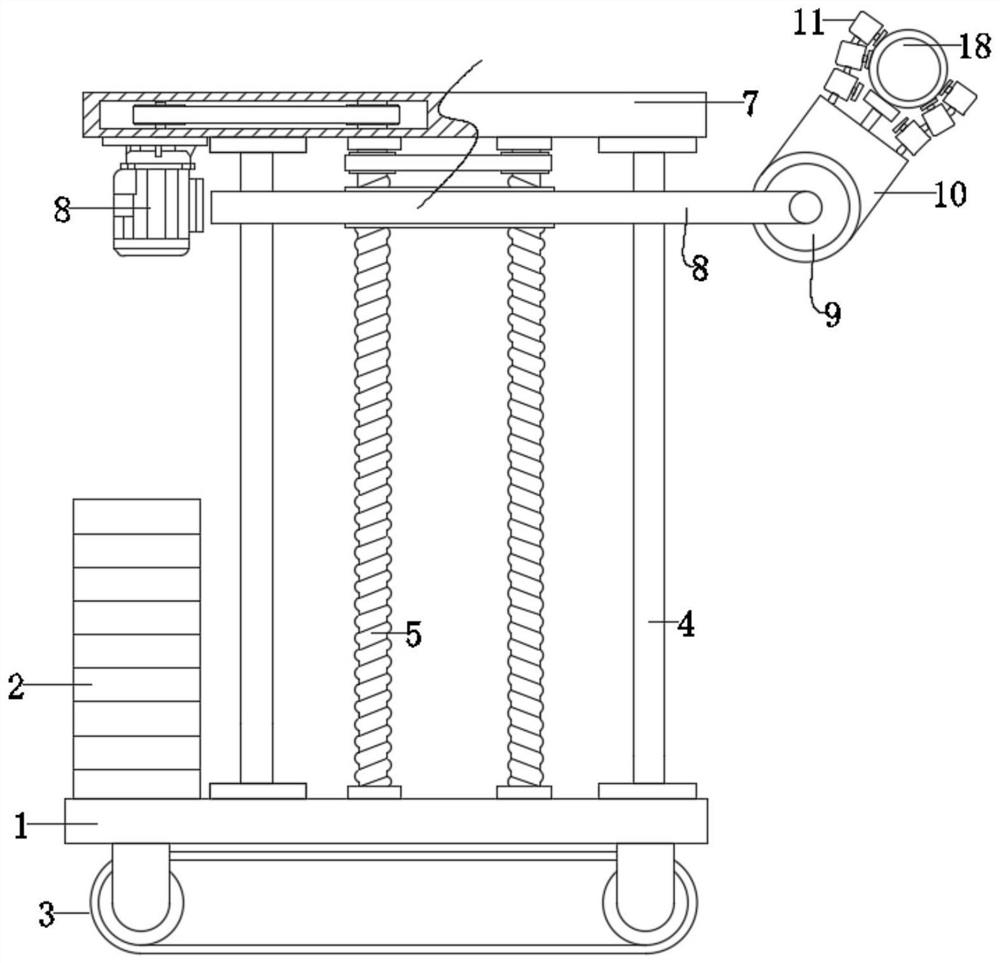

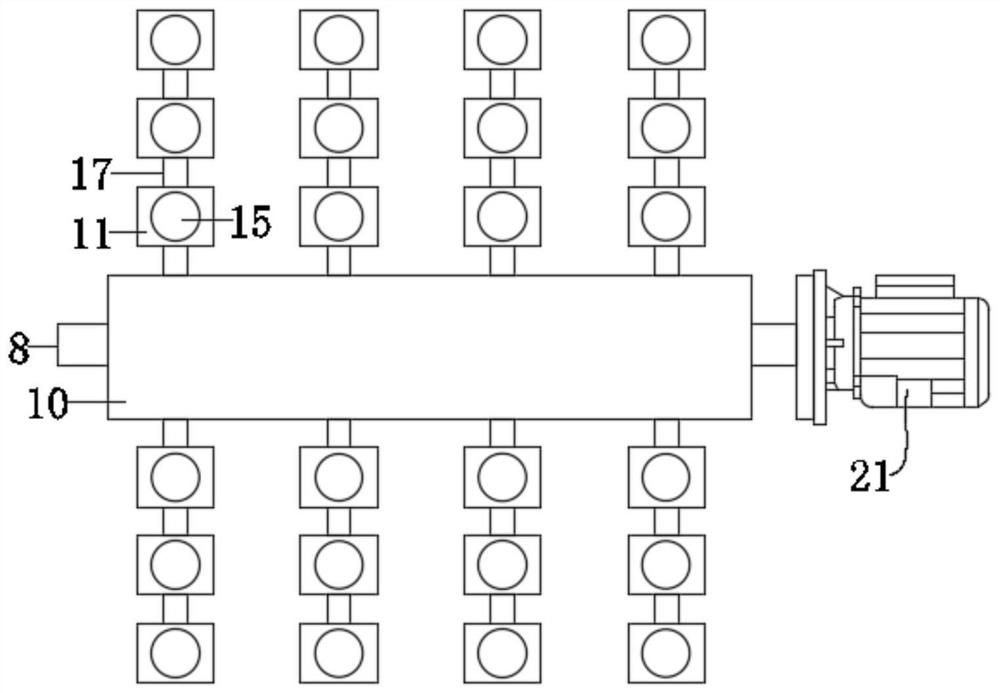

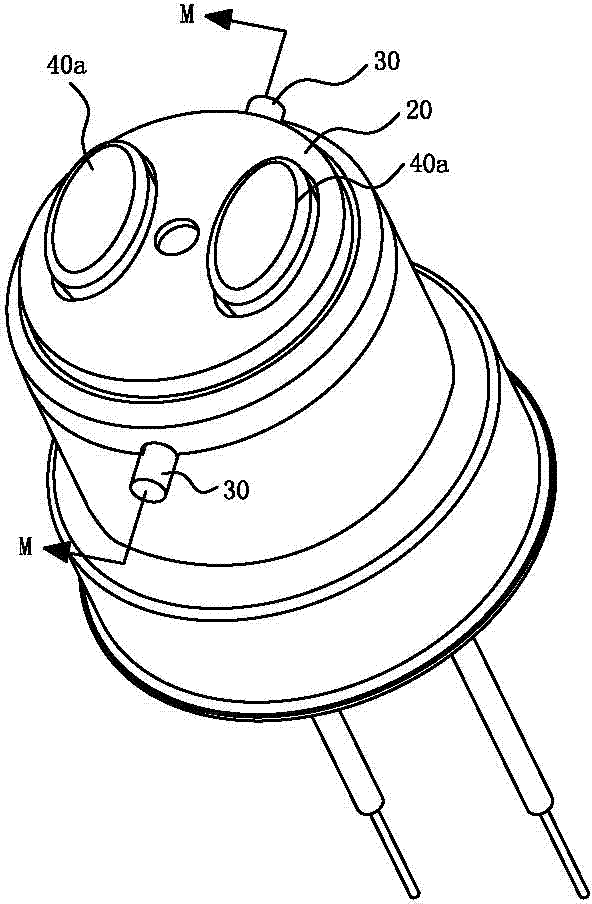

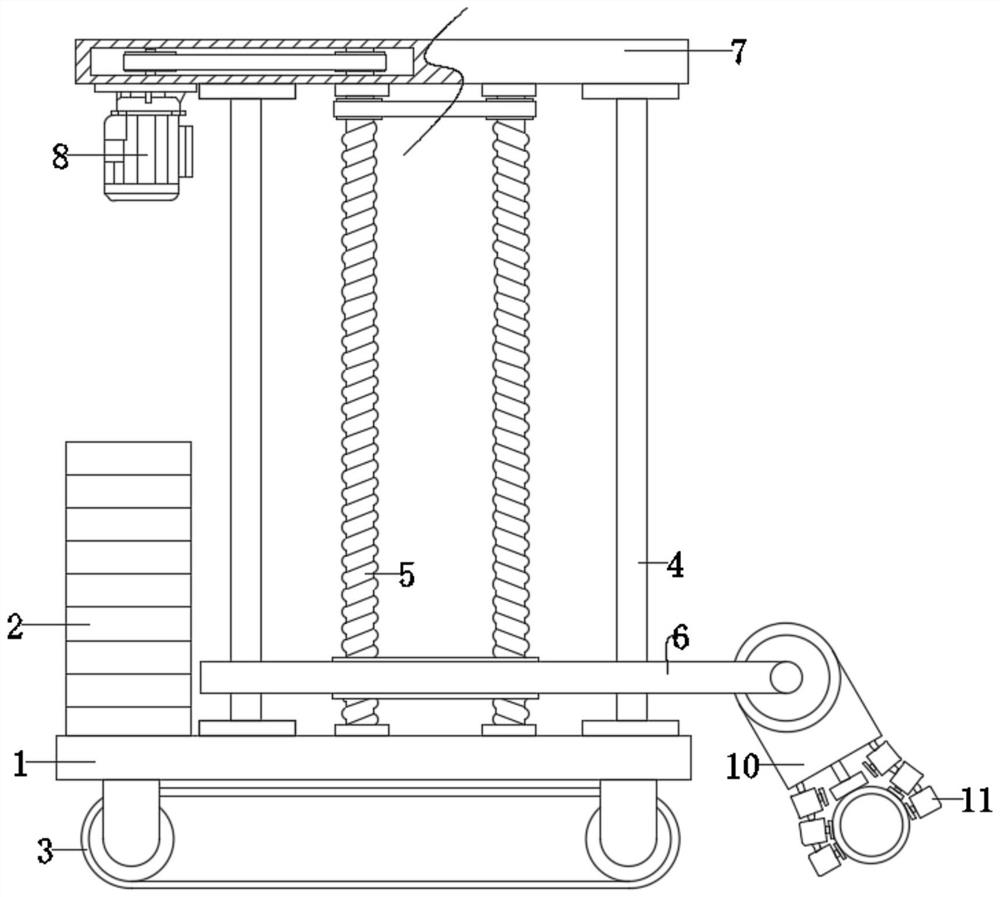

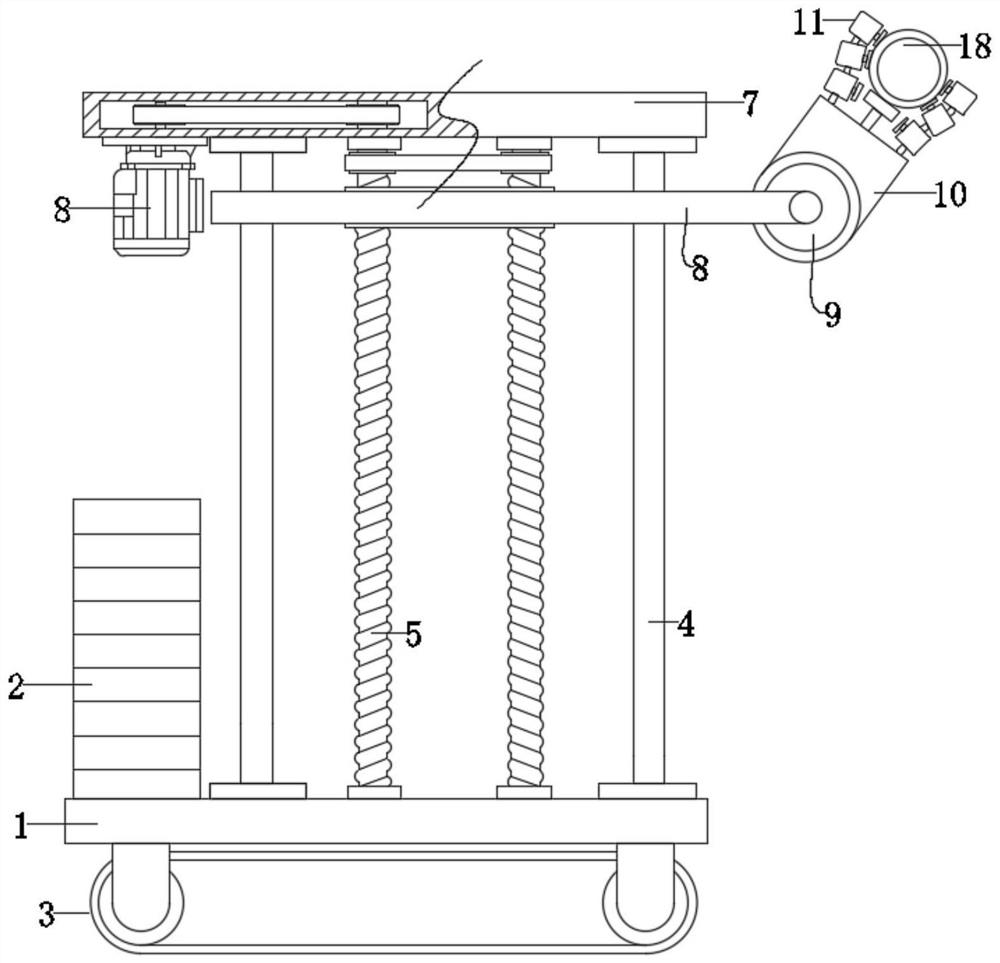

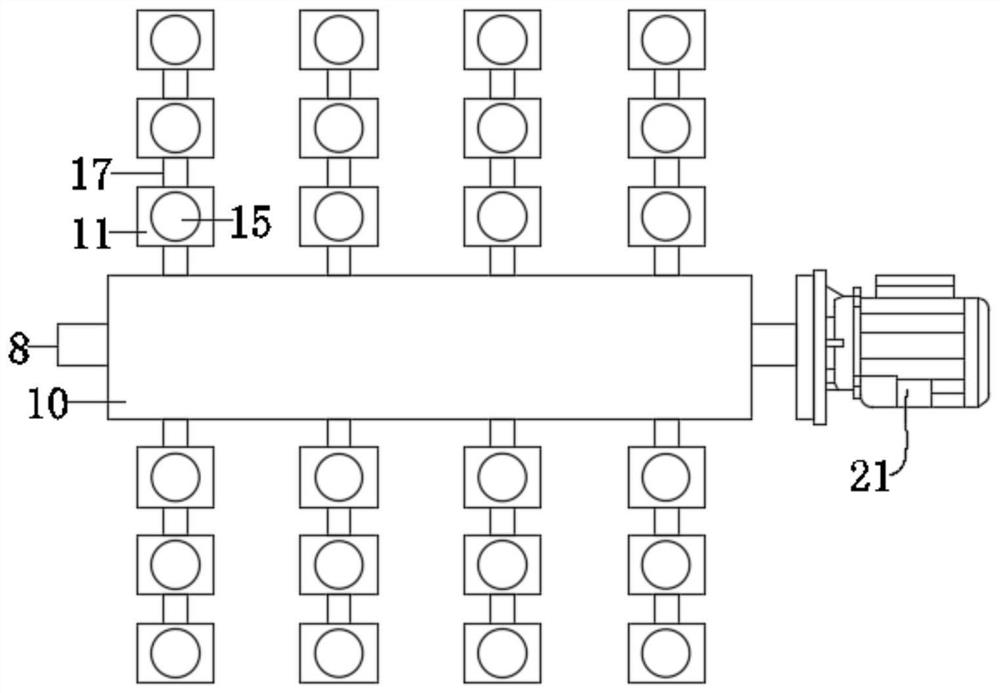

A shield machine steel pipe installation lifting device

The invention discloses a lifting device for installing a steel pipe of a shield machine, which comprises a bottom plate, an upper plate and a lifting assembly, the lifting assembly is arranged and installed between the bottom plate and the upper plate, and a clamping assembly is connected and installed on the lifting assembly, and the clamping assembly The upper clamps the steel pipe; the clamping component includes a clamping seat, a clamping block and an adsorption component, the adsorption component is arranged on the clamping block, and the clamping block is arranged and installed on the clamping seat. Because the adjacent clamping blocks of this device are hinged by connecting rods, a single set of clamping blocks has certain flexibility and can adapt to steel pipes of different diameters; The piston rod is in contact with the steel pipe, which improves the stability during the clamping process; at the same time, when the device lifts the steel pipe to the corresponding position, the adsorption components on both sides are contacted and adsorbed, and the steel pipe is quickly pushed to the The corresponding position, improve the actual use effect.

Owner:CHINA RAILWAY 19TH BUREAU GRP RAIL TRANSIT ENG +1

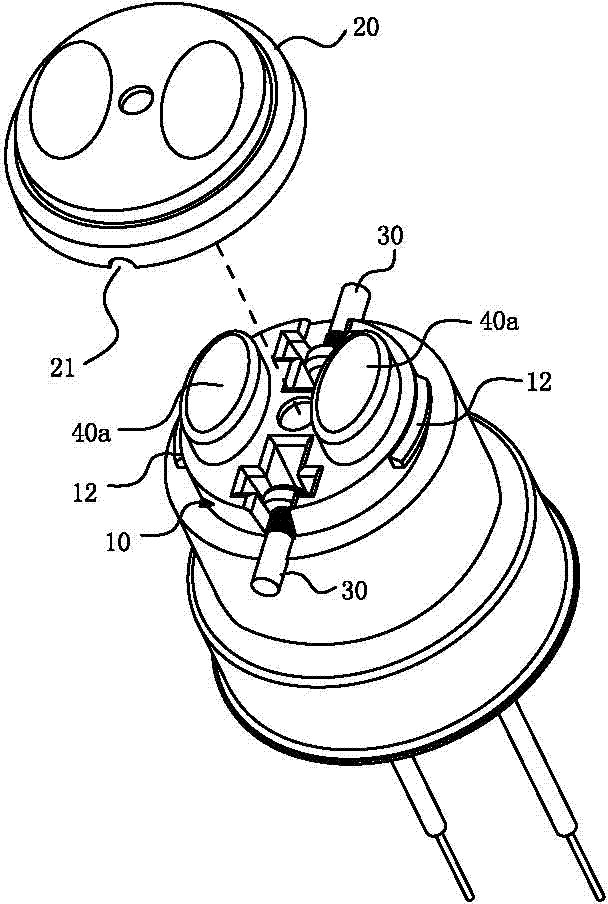

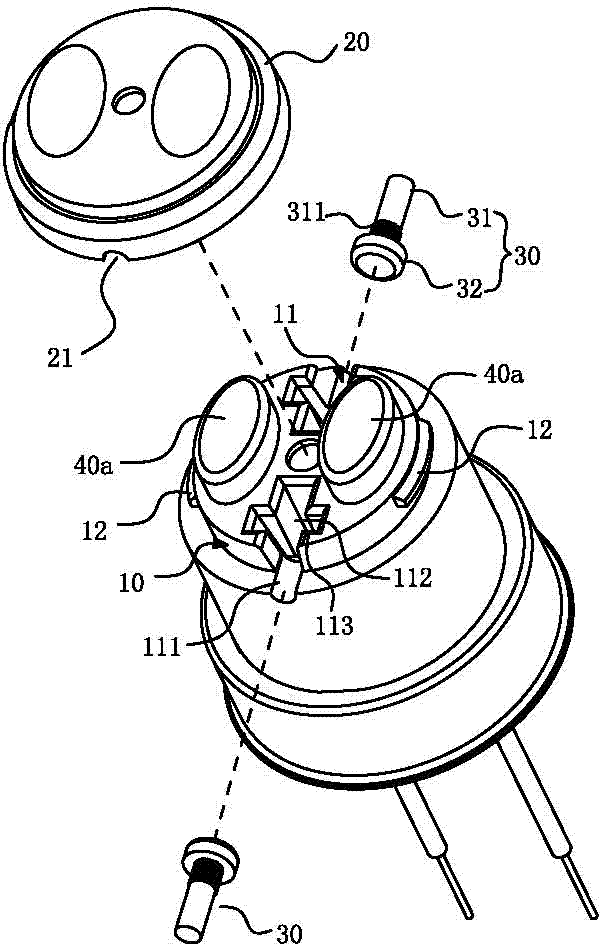

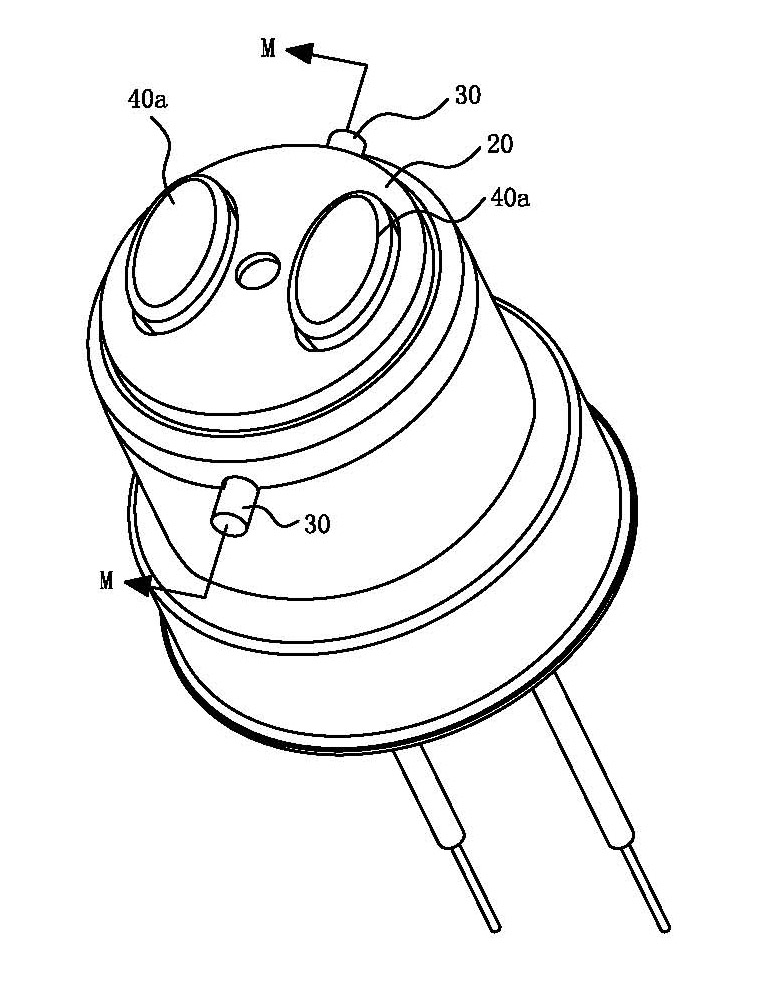

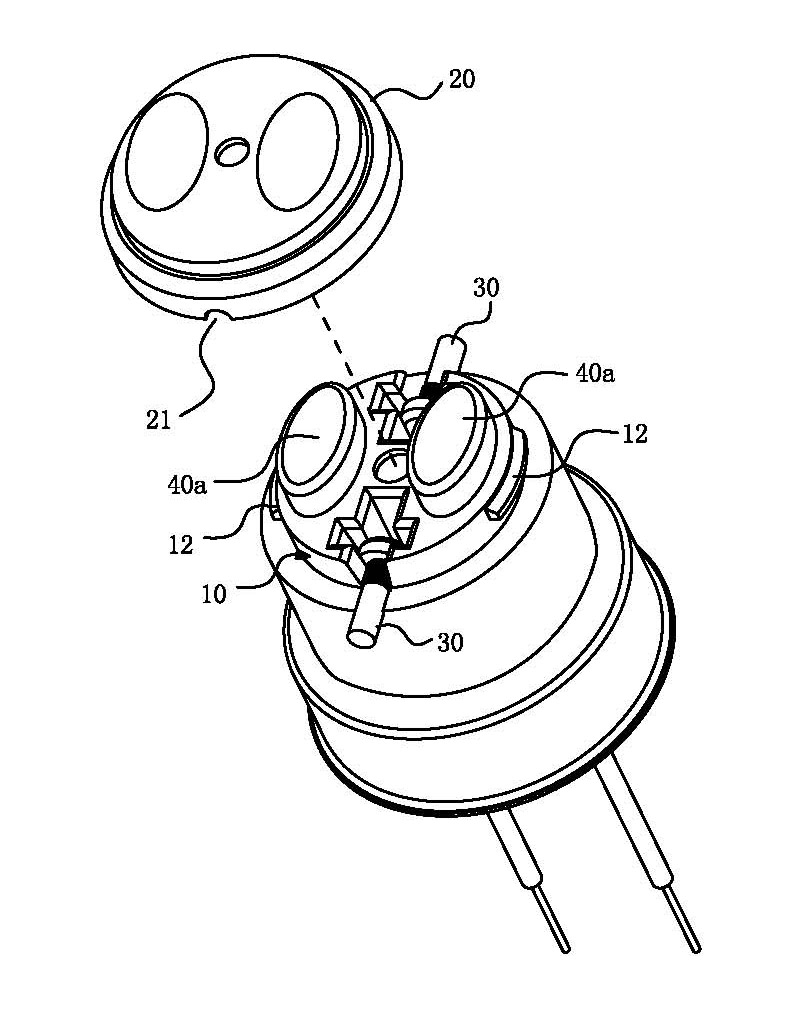

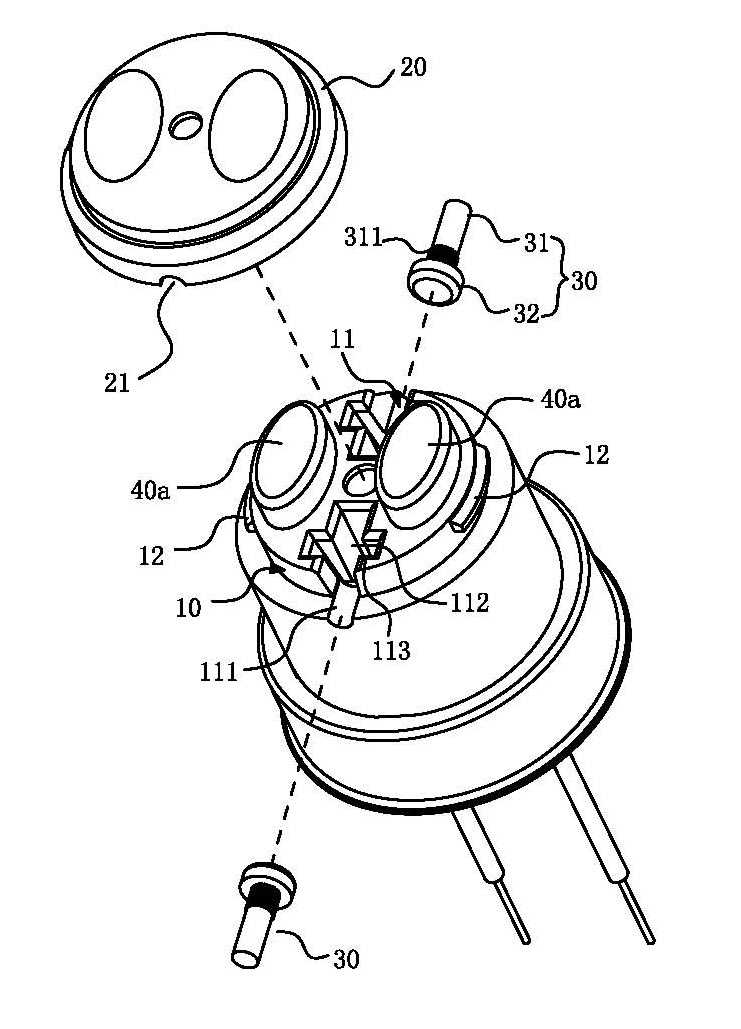

Clamping-nail fixing structure for lamp cap

InactiveCN102074432BEasy to installEasy to assembleElectric discharge tubesElectric discharge lampsBiomedical engineering

Owner:DONGGUAN CASUN LAMPBASE IND CO LTD

Clamping-nail fixing structure for lamp cap

InactiveCN102074432AEasy to installEasy to assembleElectric discharge tubesElectric discharge lampsBiomedical engineering

Owner:DONGGUAN CASUN LAMPBASE IND CO LTD

Automatic treatment equipment for power train rail

ActiveCN106337327ARealize automatic motion detection functionUniform rigid self-steady walking functionBallastwayTrack superstructureAbutmentEngineering

The invention relates to automatic treatment equipment for a power train rail. The automatic treatment equipment comprises a rail moving base, wherein the rail moving base can realize an automatic moving detection function for the rail; a rail debris removal device is mounted at the middle part of the lower end surface of the rail moving base, and can realize an automatic debris removal function between the rails; a rail stone extruding and pushing device is mounted on the upper end surface of the rail moving base, and can realize an automatic extruding and pushing function for rail shock absorption stones; the rail debris removal device comprises a debris removal supporting plate welded on the lower end surface of a moving abutment; a grabbing and conveying mechanism is mounted on the right side of the lower end surface of the debris removal supporting plate, and can realize an automatic grabbing and conveying function for debris between the rails; an adjustable smashing mechanism is mounted on the left side of the lower end surface of the debris removal supporting plate. The automatic treatment equipment can realize a road condition detection, stone extruding and pushing and debris removal all-in-one automatic maintenance function for the rails.

Owner:常熟紫金知识产权服务有限公司

Shield tunneling machine steel pipe mounting and lifting device

The invention discloses a shield tunneling machine steel pipe installing and lifting device which comprises a bottom plate, an upper plate and a lifting assembly, wherein the lifting assembly is arranged and installed between the bottom plate and the upper plate, a clamping assembly is connected and installed on the lifting assembly, and a steel pipe is clamped on the clamping assembly; and the clamping assembly comprises a clamping base, clamping blocks and adsorption assemblies, the adsorption assemblies are arranged on the clamping block, and the clamping blocks are installed on the clamping base. According to the device, the adjacent clamping blocks are hinged through connecting rods, so that a single group of clamping blocks has certain flexibility and can adapt to steel pipes with different diameters; when the adsorption assemblies on the clamping blocks are adsorbed on the steel pipes, a piston rod of a telescopic rod abuts against the steel pipe, and the stability in the clamping process is improved; and meanwhile, when the device lifts the steel pipe to the corresponding position, the adsorption assemblies on the two sides make contact with each other for adsorption, the steel pipe is quickly pushed and lifted to the corresponding position through the pushing and lifting effect of the telescopic rod, and the actual using effect is improved.

Owner:CHINA RAILWAY 19TH BUREAU GRP RAIL TRANSIT ENG +1

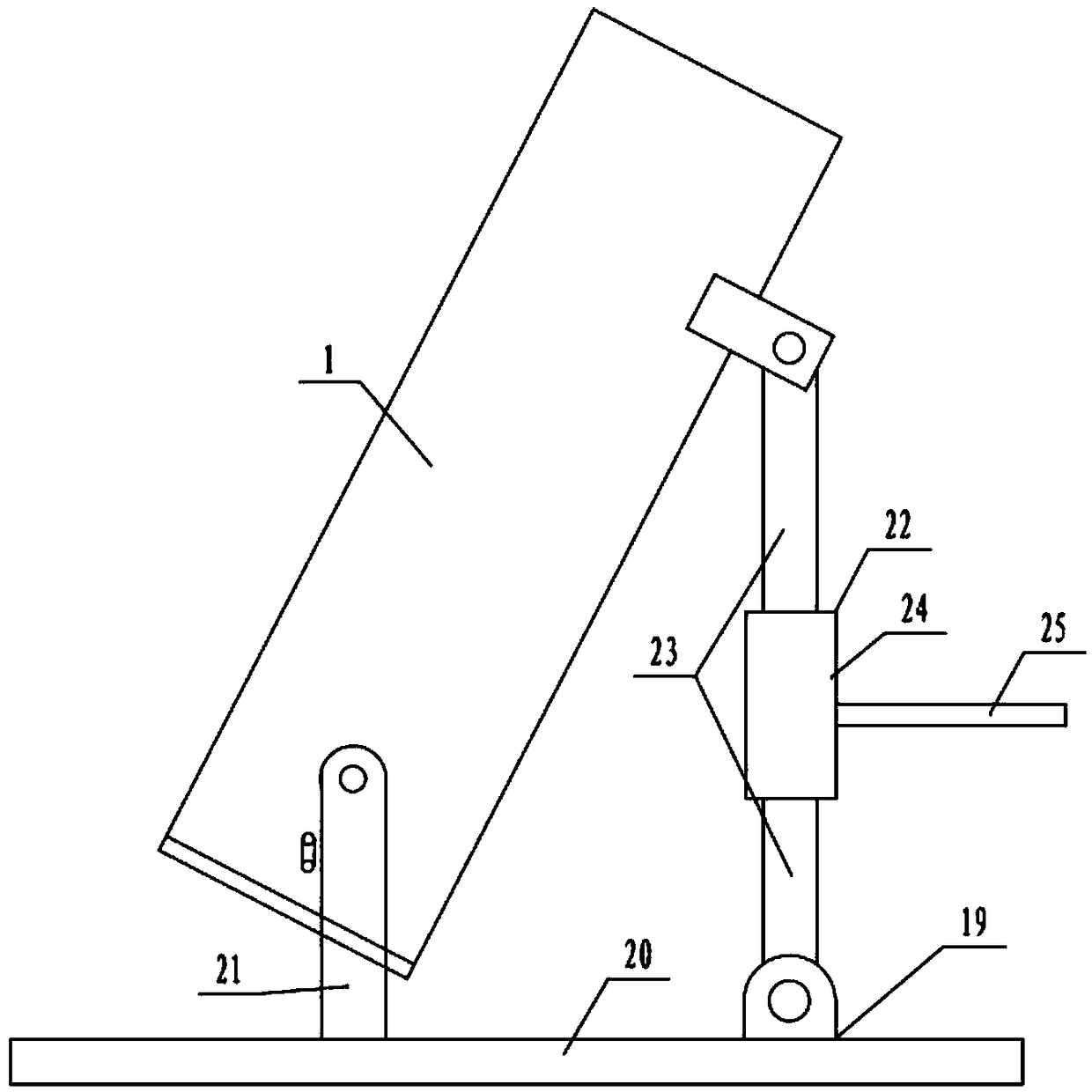

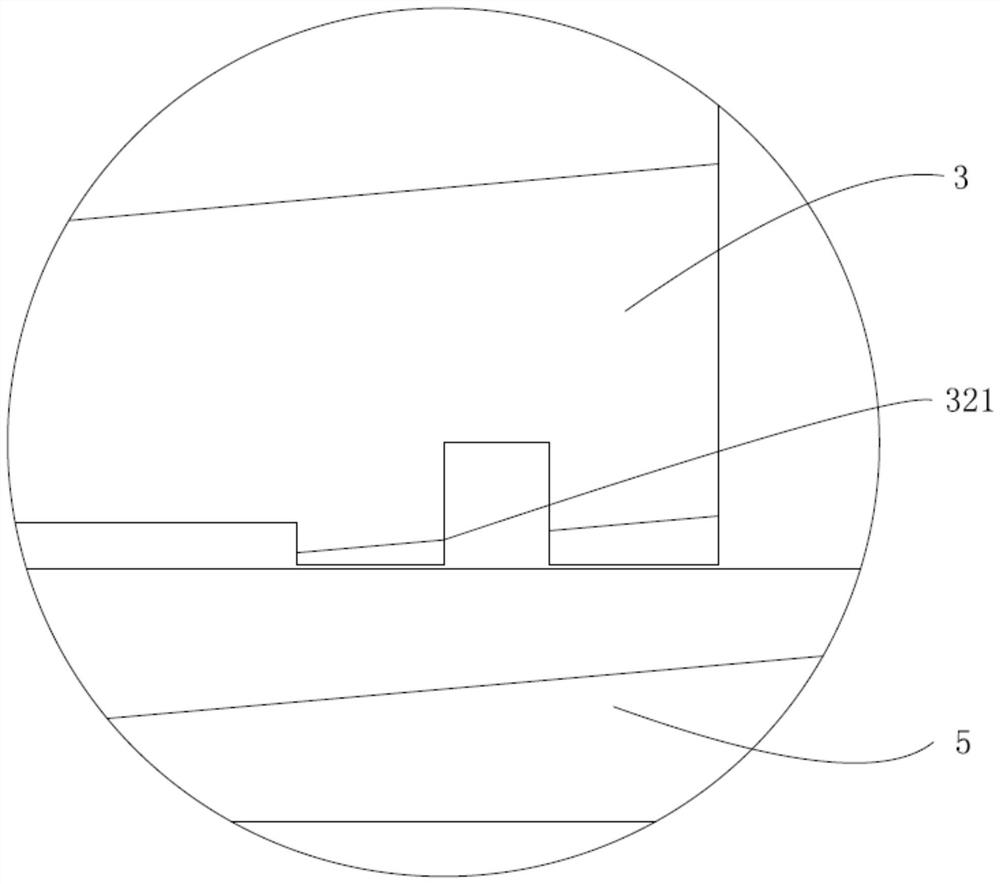

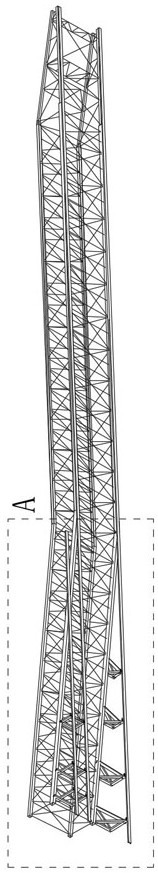

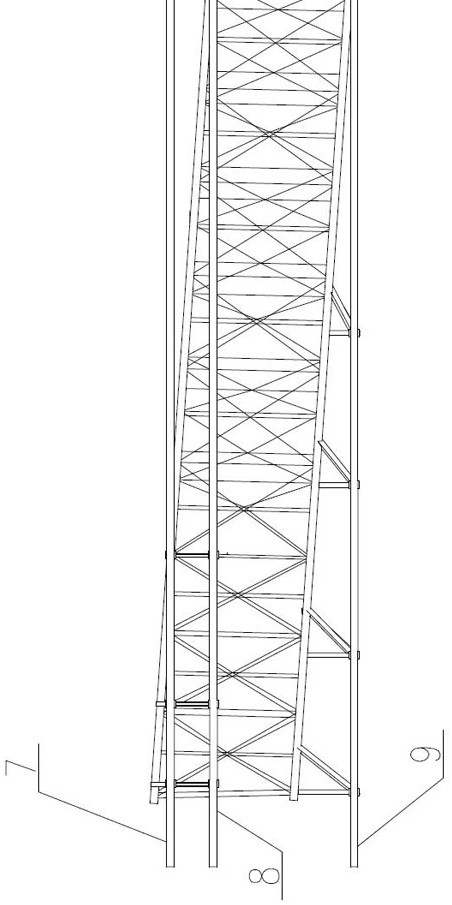

Supporting system for rapid pushing of spatial double-fold-line steel truss girder

PendingCN114717971ASolving push issuesEasy to pushTruss-type bridgeBridge erection/assemblySupporting systemThird rail

The invention relates to a supporting system for rapid pushing of a spatial double-fold-line steel truss girder, and belongs to the technical field of bridge pushing construction. The spatial double-fold-line steel truss girder comprises a straight line section and a bidirectional bent section, a plurality of portal supports and a plurality of ox horn supports are arranged on a front bottom beam and a rear bottom beam of the bent section at intervals respectively, and sliding shoes are arranged on the two sides of the lower end of each portal support respectively. The sliding shoes on the two sides of the door frame type supports are slidably connected to the first linear track beam and the second linear track beam respectively, the track beam at the front bottom beam of the linear section coincides with the second track beam, the sliding shoes are arranged at the lower ends of the ox horn supports, and the sliding shoes of the ox horn supports are jointly slidably connected to the third linear track beam. The track beam at the rear bottom beam of the straight line section is overlapped with the third track beam; the problems that in the pushing process of an existing double-fold-line bridge, construction deviation is likely to be caused, and main structure components are likely to be damaged are solved.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com