A sand making device

A technology for manufacturing equipment and sand and gravel, which is applied in the field of sand and gravel manufacturing equipment, and can solve problems such as inability to apply processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

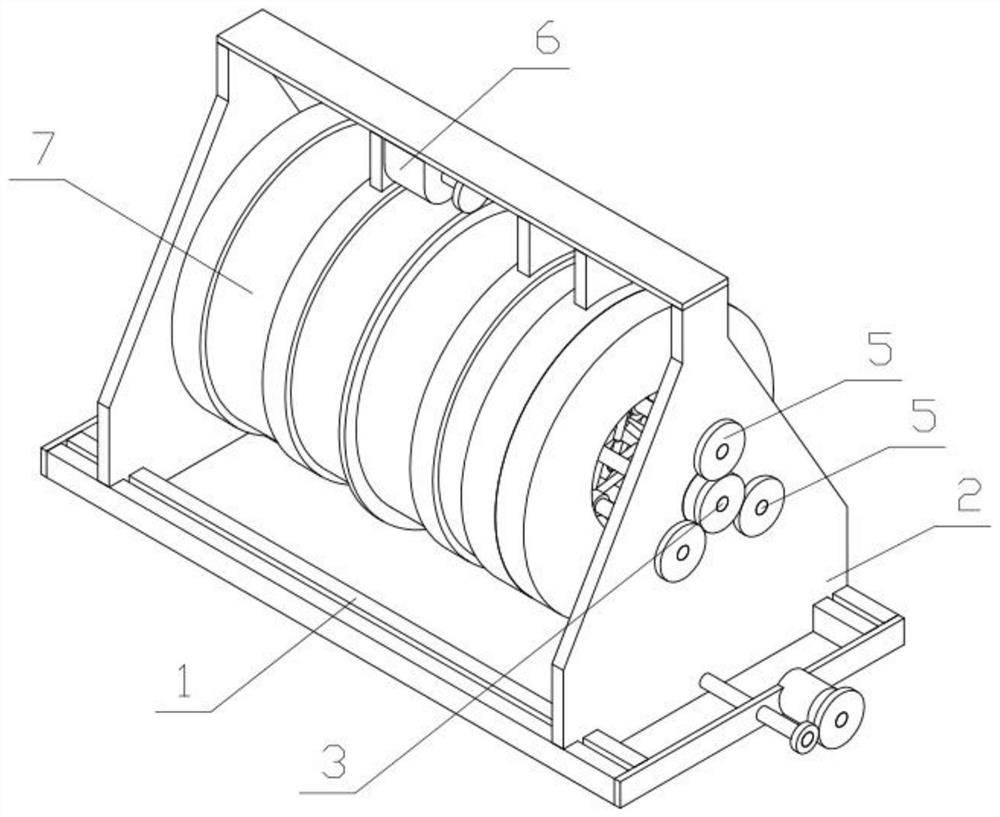

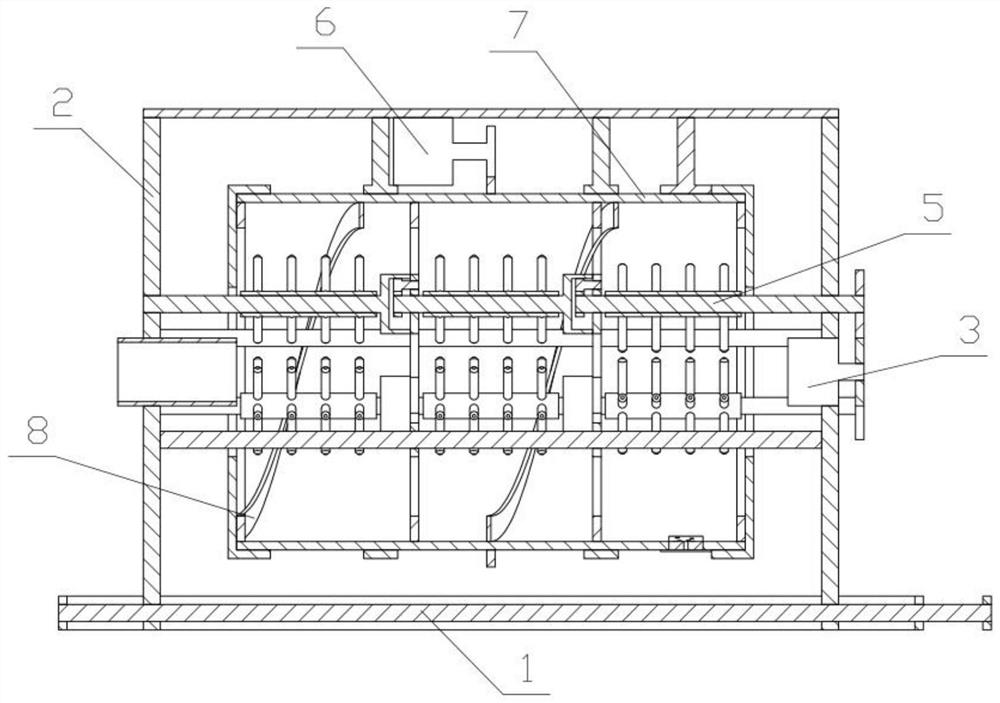

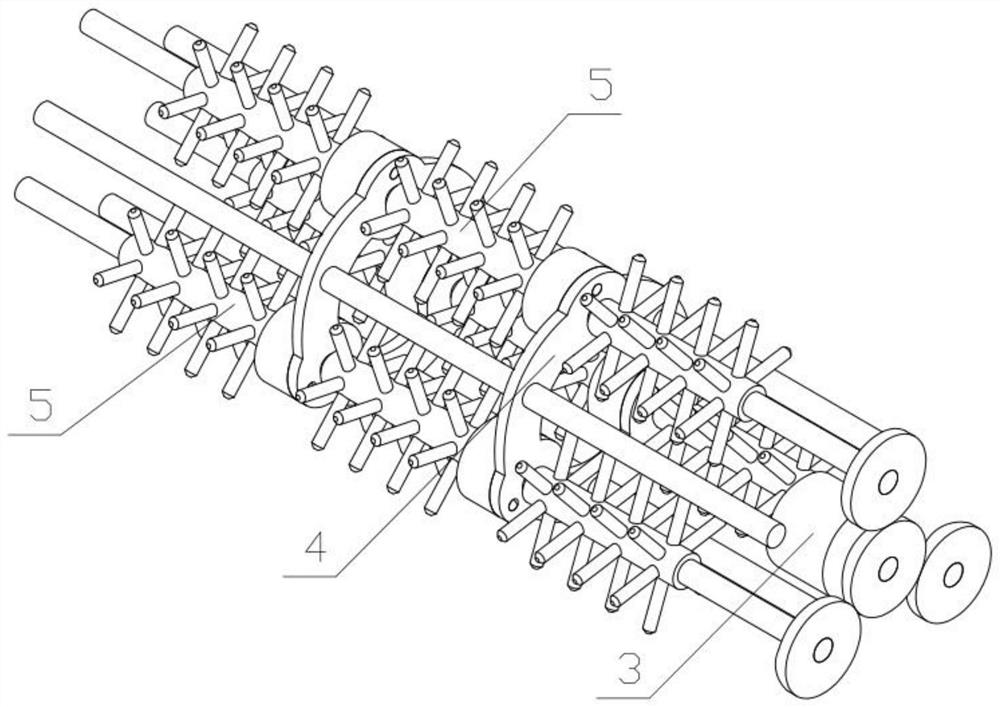

[0033] Combine below Figure 1-11Description of this embodiment, a gravel manufacturing device, including a sliding bracket 1, a device bracket 2, a power motor 3, a rotating bracket 4, a crushing mechanism 5, a rotating motor 6, a crushing cylinder 7 and a pushing mechanism 8, the sliding bracket 1 A device support 2 is connected on the device support 2, a power motor 3 is fixedly connected on the device support 2, a rotating support 4 is fixedly connected on the device support 2, and a plurality of crushing mechanisms 5 are connected in rotation on the device support 2, and a plurality of crushing mechanisms 5 are all connected with the power The motor 3 is meshed and driven, and a plurality of crushing mechanisms 5 are rotatably connected to the rotating bracket 4, the rotating motor 6 is fixedly connected to the device bracket 2, and the crushing cylinder 7 is rotatably connected to the device bracket 2, and the crushing cylinder 7 and the rotating motor 6 are meshed for tr...

specific Embodiment approach 2

[0035] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the sliding bracket 1 includes a sliding track 1-1, a connecting plate I1-2, a reciprocating screw rod 1-3 and a reciprocating motor 1-4, the sliding track 1- 1 There are two, the front and rear ends of the two slide rails 1-1 are fixedly connected with connecting plates I1-2, and the two connecting plates I1-2 are connected with reciprocating screw rods 1-3 in rotation, one side A reciprocating motor 1-4 is fixedly connected to the connecting plate I1-2, and the reciprocating motor 1-4 and the reciprocating screw mandrel 1-3 are transmission connected.

specific Embodiment approach 3

[0037] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the device bracket 2 includes a support plate I2-1, a connecting plate II2-2, a support plate II2-3, a feeding cylinder 2-4, and an installation ring I2 -5. Blocking the arc plate 2-6 and the arc hole 2-7, there are two supporting plates I2-1, and the upper ends of the two supporting plates I2-1 are fixedly connected with the connecting plate II2-2, the connecting plate The lower end of II2-2 is fixedly connected with the installation ring I2-5, the front side of the lower end of the connection plate II2-2 is fixedly connected with the blocking arc plate 2-6, and the lower end of the blocking arc plate 2-6 is provided with an arc hole 2- 7. The feeding cylinder 2-4 is fixedly connected to the support plate Ⅱ2-3 on the rear side, and the left and right sides of the two support plates Ⅰ2-1 are respectively slidably connected to the two sliding rails 1-1. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com