Flame-retardant power cable processing system and method

A processing system and power cable technology, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of inconvenient production and inefficient processing and production, and achieve the effect of efficient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

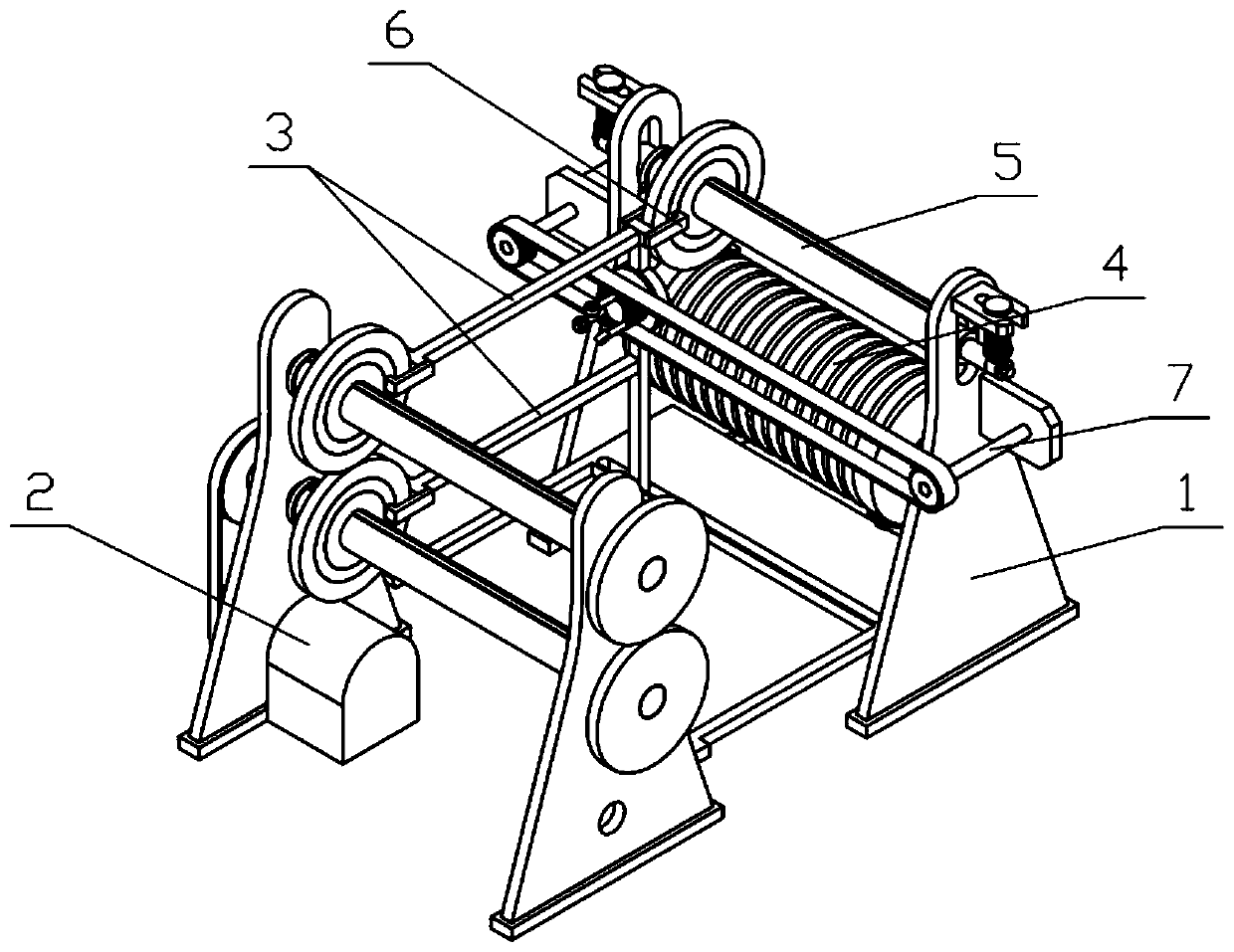

[0037] Combine below Figure 1-10 Describe this embodiment, a flame-retardant power cable processing system, including a processing bracket 1, a power mechanism 2, a connecting frame 3, a reel mechanism 4, a pressing mechanism 5, a winding frame 6 and a winding mechanism 7, the processing bracket 1 The upper is fixedly connected with a power mechanism 2, and the connecting frame 3 is provided with two, and one end of the two connecting frames 3 is all rotatably connected to the power mechanism 2, and the other ends of the two connecting frames 3 are all fixedly connected on the winding frame 6, and the winding The lower end of the frame 6 is slidably connected to the processing support 1, and the upper end of the winding frame 6 is rotatably connected to the pressing mechanism 5, and the pressing mechanism 5 is slidably connected to the processing support 1, and the pressing mechanism 5 and the processing support 1 are provided with The spring is compressed, and the reel mecha...

specific Embodiment approach 2

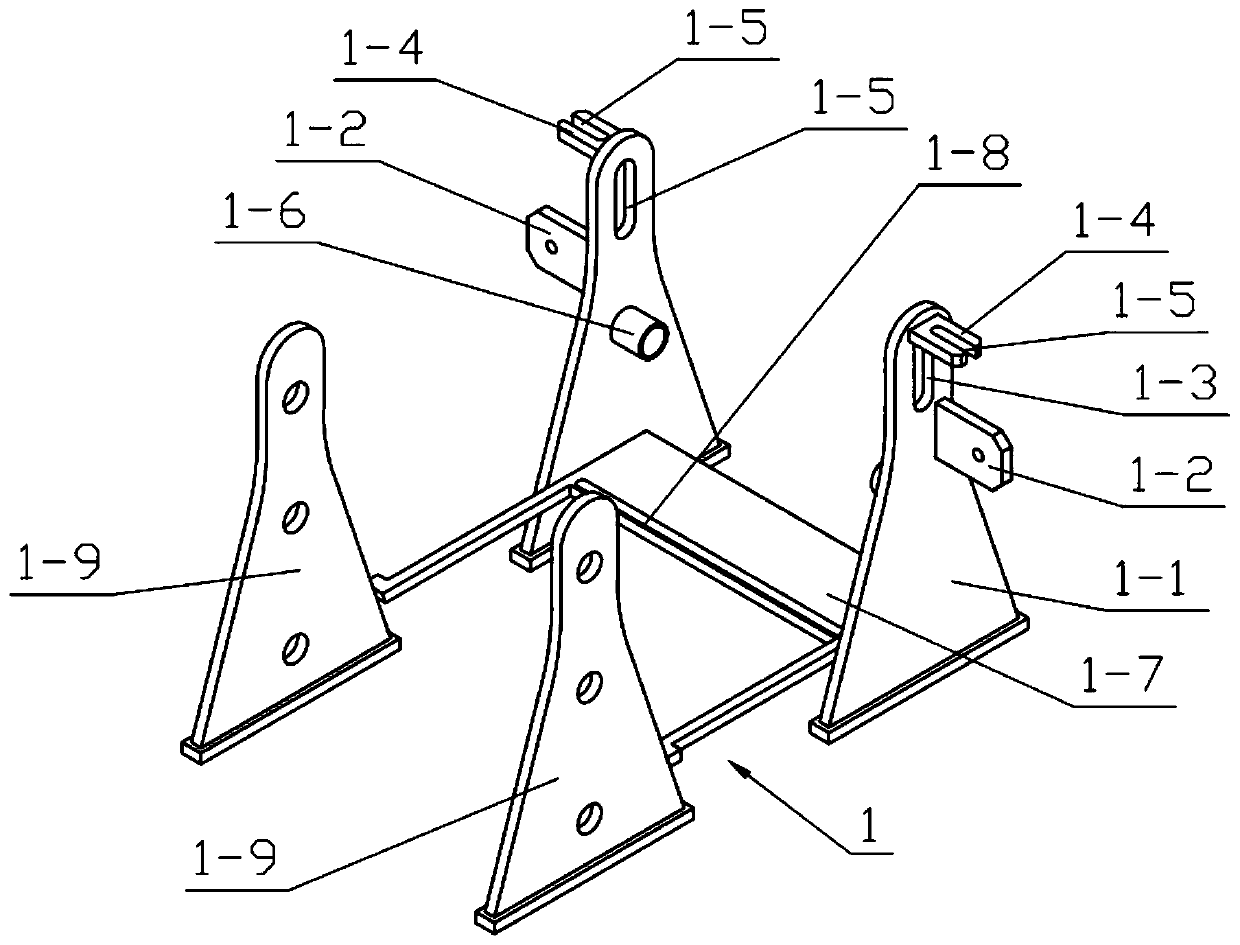

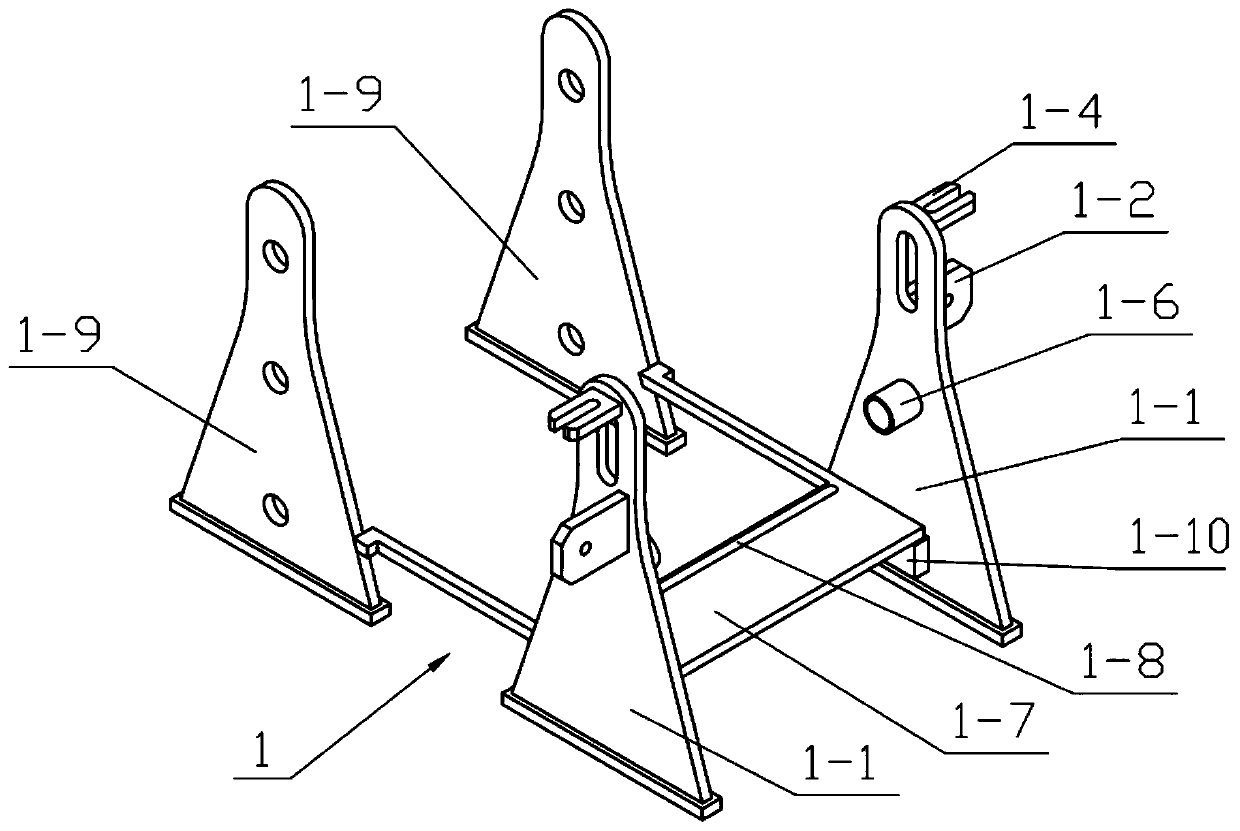

[0039] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain Embodiment 1, the processing bracket 1 includes a support plate I1-1, a support plate II1-2, a vertical waist hole 1-3, a connecting plate 1-4, and a sliding hole 1 -5. Connecting sleeve 1-6, inserting plate I1-7, sliding waist hole 1-8, supporting plate III1-9 and inserting plate II1-10, two supporting plates I1-1 are provided, two supporting plates I1 The outer sides of -1 are fixedly connected with supporting plates II1-2, the two supporting plates I1-1 are provided with vertical waist holes 1-3, and the outer sides of the upper ends of the two supporting plates I1-1 are fixedly connected with connecting plates 1 -4, the two connecting plates 1-4 are provided with sliding holes 1-5, the inner sides of the two supporting plates I1-1 are fixedly connected with connecting sleeves 1-6, the inner sides of the lower ends of the two supporting plates I1-1 Both sides are fixedly connec...

specific Embodiment approach 3

[0041] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the power mechanism 2 includes a motor 2-1, a power pulley I2-2, a power shaft 2-3, a power gear I2-4, and a power pulley II2 -5, connection key I2-6, extrusion molding wheel I2-7, rotating groove I2-8, transmission shaft 2-9, power gear II2-10, connection key II2-11, extrusion molding wheel II2-12 and rotation Slot II 2-13, the motor 2-1 is fixedly connected to the support plate III 1-9 on one side, the two ends of the power shaft 2-3 are respectively connected to the two support plates III 1-9 in rotation, and the two ends of the drive shaft 2-9 The ends are respectively connected to the two support plates III1-9, the output shaft of the motor 2-1 is fixedly connected to the power pulley I2-2, and the two ends of the power shaft 2-3 are respectively fixedly connected to the power gear I2-4 and The power pulley Ⅱ2-5, the power pulley Ⅱ2-5 and the power pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com