Split type constant magnetic thermal circulation pit furnace

A split-type and well-type furnace technology, which is applied in the direction of vertical furnace, furnace, electric furnace heating, etc., can solve the problems of long production and processing time, inconsistent furnace core temperature, small heating surface, etc., to prevent material oxidation and high-efficiency processing The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

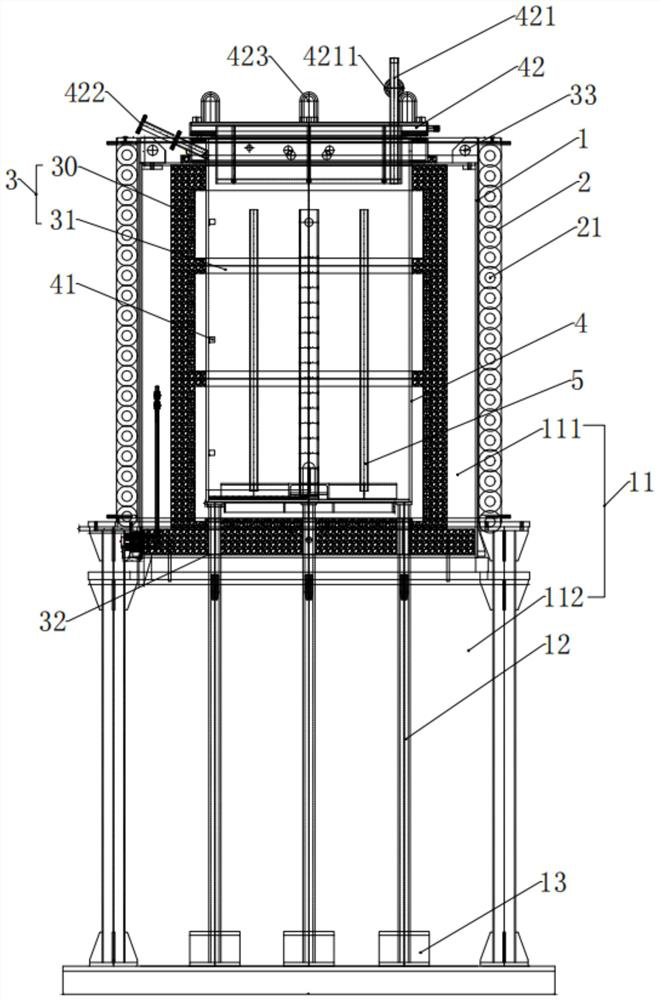

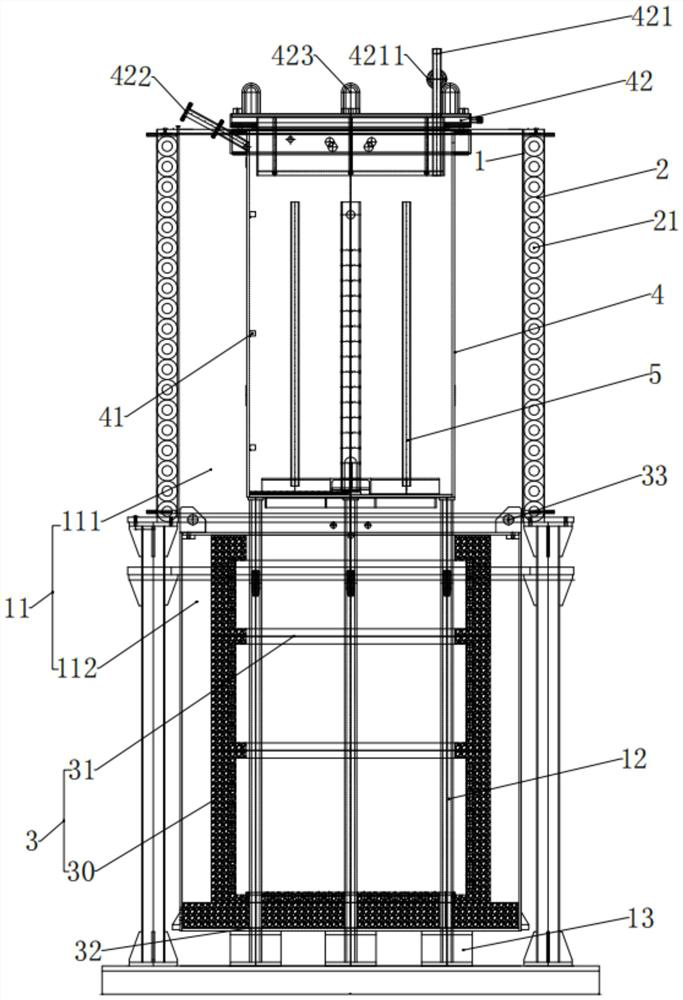

[0025] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0026] A kind of split-type constant magnetic heat circulation well-type furnace according to this specific embodiment, comprising:

[0027] A furnace body 1 with an inner chamber 11, the inner chamber 11 includes a heating chamber 111 located at the upper section of the inner chamber 11, and a cooling chamber 112 located at the lower section of the inner chamber 11, the heating chamber 111 is provided with a furnace 4, and the outer side of the furnace body 1 corresponds to the heating chamber 111 The position is provided with a magnet. Based on practical applications, the cooling chamber 112 is equipped with a cooling liquid. The cooling liquid can be water or other liquids with a large specific heat capacity. Here, water is used as the cooling liquid; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com