Plastic particle feeding device of plastic extruding machine for cable processing

A technology of plastic granules and feeding equipment, which is applied in the field of plastic processing and feeding equipment, can solve problems such as increased load, equipment jamming, equipment blockage, etc., and achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

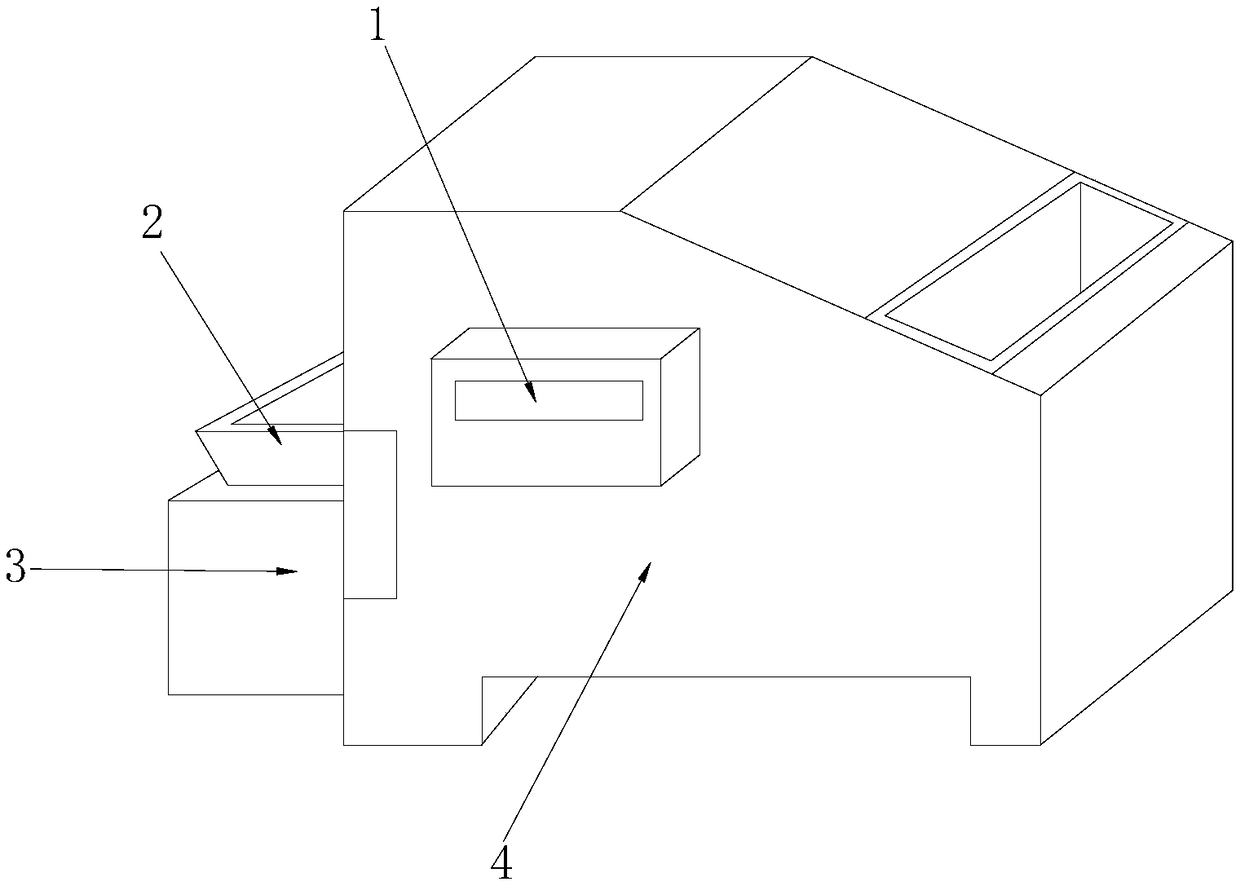

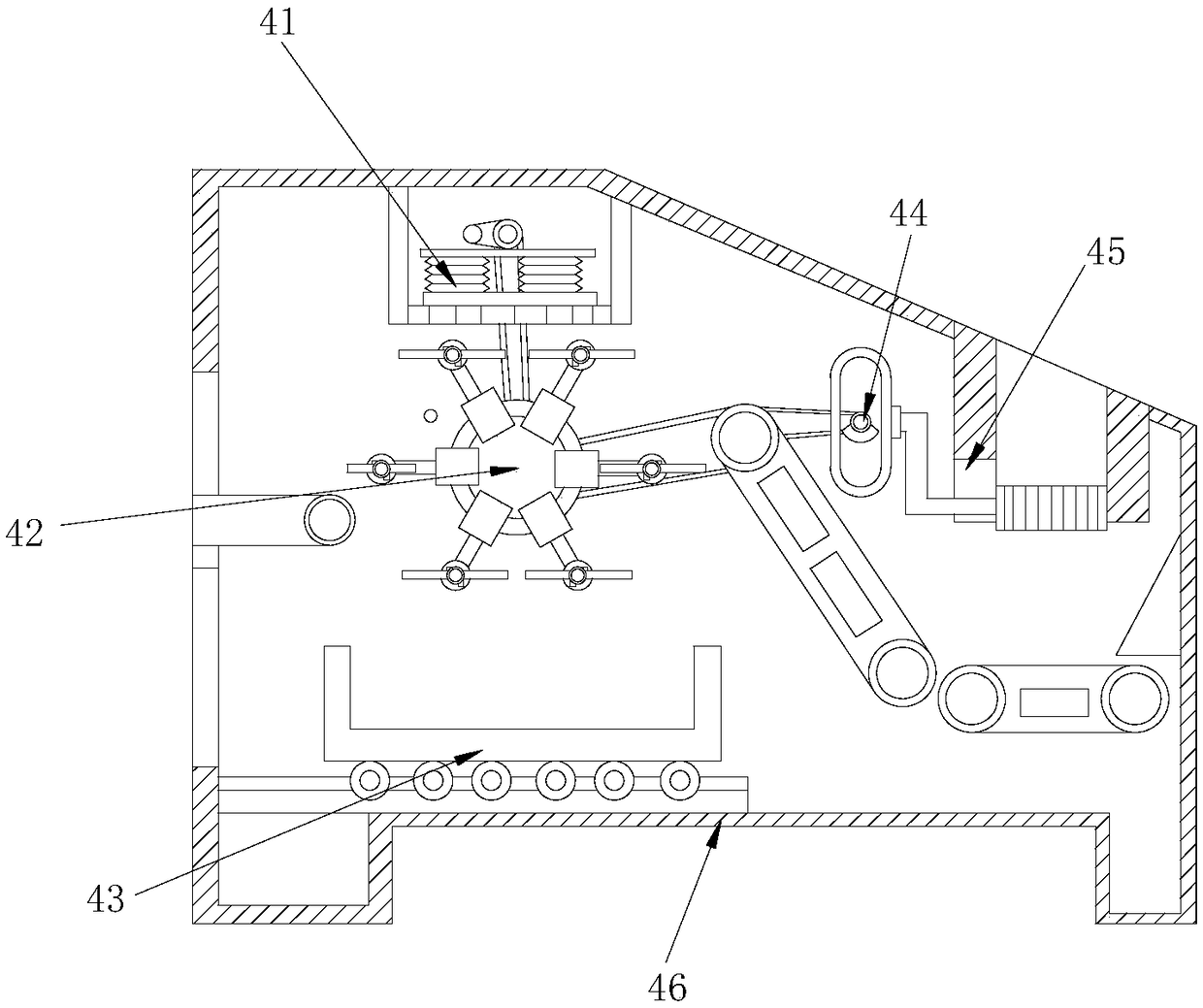

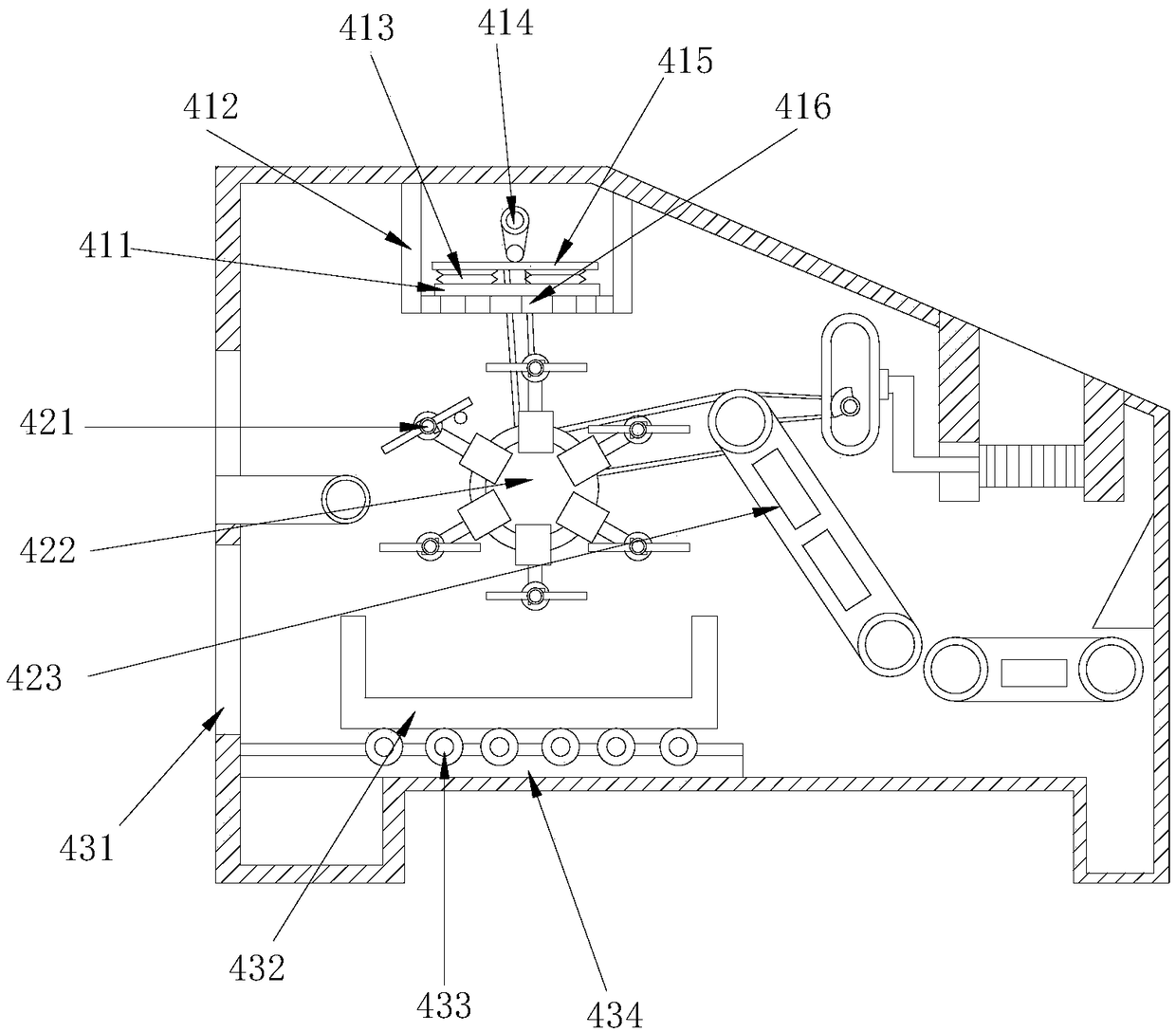

[0024] see Figure 1-Figure 4, the present invention provides plastic particle feeding equipment for extruders used in cable processing, its structure includes a controller 1, a feed hopper 2, an extruder 3, a body 4, the rear end of the controller 1 is connected to the body The front end of 4 is welded, and the bottom end of described feeding hopper 2 is arranged on the top of extruder 3, and both are integral structures, and described feeding hopper 2 is positioned at the left side of machine body 4, and described extruder The right end of 3 is welded with the left end of body 4, and described body 4 comprises dehumidification mechanism 41, intermittent feeding mechanism 42, water storage mechanism 43, screening driving mechanism 44, screening mechanism 45, shell 46, and the top of described dehumidification mechanism 41 Welded with the top of the casing 46, the water storage mechanism 43 is positioned directly below the intermittent feeding mechanism 42, the intermittent fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com