Clamping-nail fixing structure for lamp cap

A fixed structure and staple technology, applied in discharge lamps, discharge tubes, electrical components, etc., can solve problems such as hidden safety hazards, complex processes, and poor spot welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

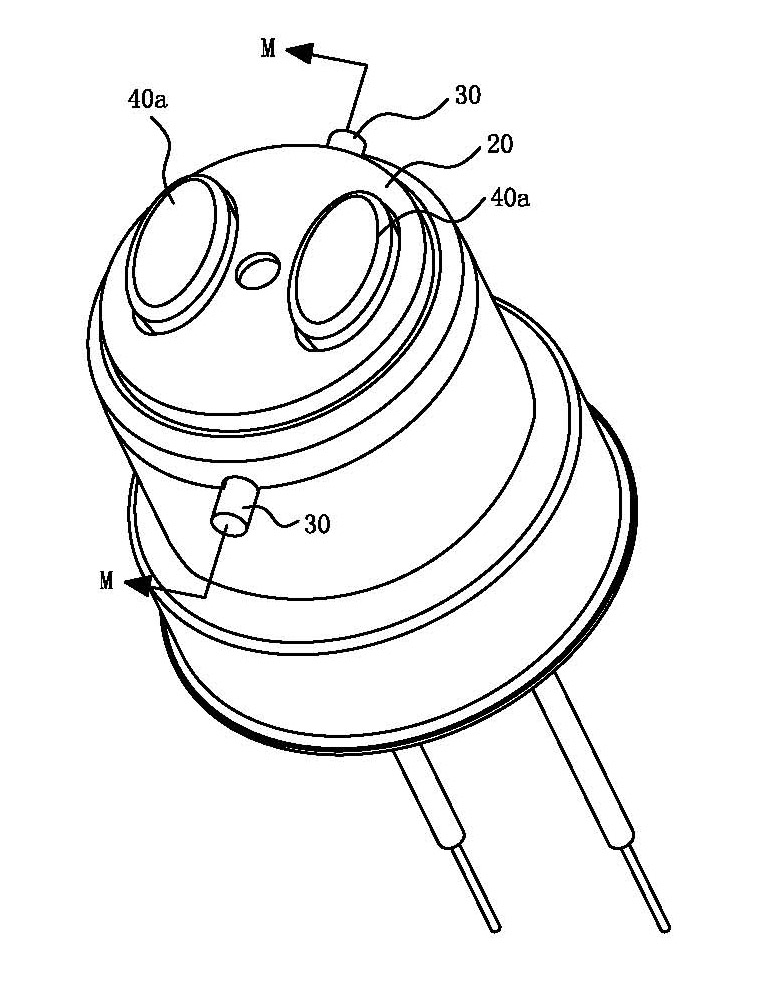

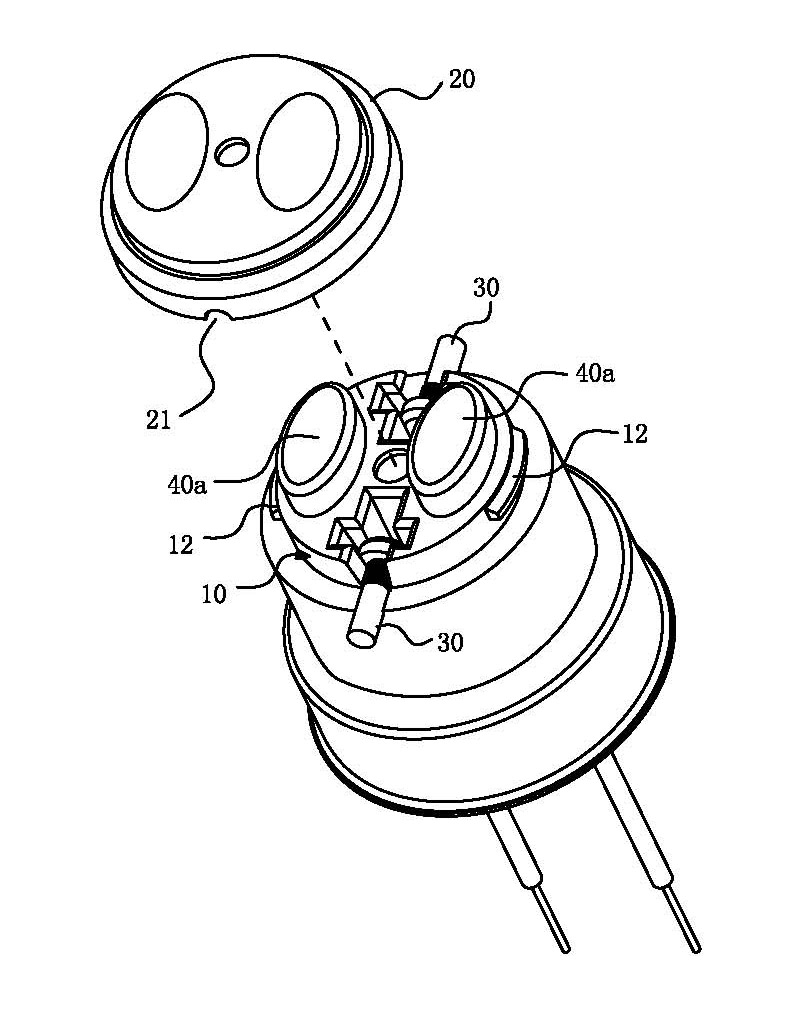

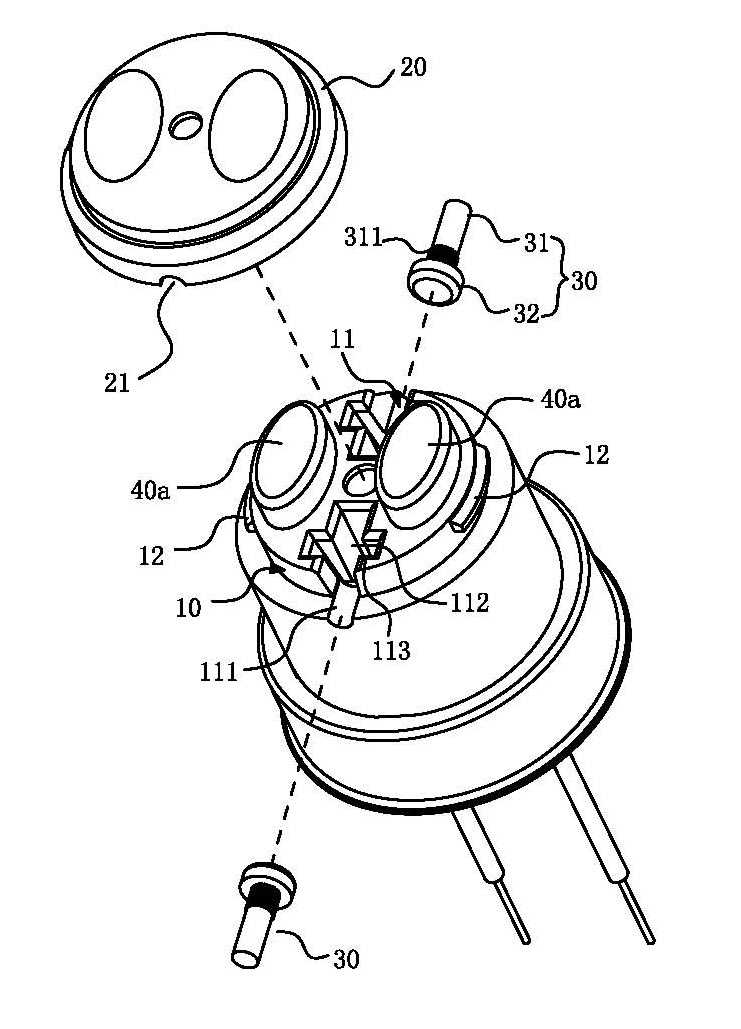

[0043] See Figure 1 to Figure 5 As shown, it shows the specific structure of the first embodiment of the present invention, including a fixed joint case 10 , an insulating cover 20 and a staple 30 .

[0044] Wherein, the number of the staples 30 is two, and each staple 30 includes a clamping part 31 and a limiting part 32 integrally connected, and a plurality of clamping parts are arranged on the outer surface of the clamping part 31 near the limiting part 32. The tooth-shaped convex strip 311, of course, can also be other structural designs such as convex points that can make the surface friction force large enough to prevent the staple 30 from rotating, and is not limited thereto; generally speaking, in this embodiment, , the aforementioned clip 30 is in the shape of a rivet, the aforementioned clamping portion 31 is in the shape of a rivet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com