Guide rail mechanism for bidirectional power head of brick making machine

A power head and brick making machine technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of slow driving speed, low precision, complex structure, etc., and achieve the effect of fast driving speed, high precision and overcoming complex structure

Inactive Publication Date: 2013-12-18

XUZHOU KAILONG MINING SCI & TECH DEV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Beneficial effects: because the present invention adopts the mechanism mode of bidirectional power head, bidirectional guide rail, double screw rod and bidirectional grooved cam, the whole bidirectional power head mechanism has the advantages of structural integration, fast driving speed and high precision, and achieves the advantages of the present invention. The purpose of effectively overcoming the defects of complex structure, slow driving speed and low precision existing in the existing power head guide rail mechanism

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

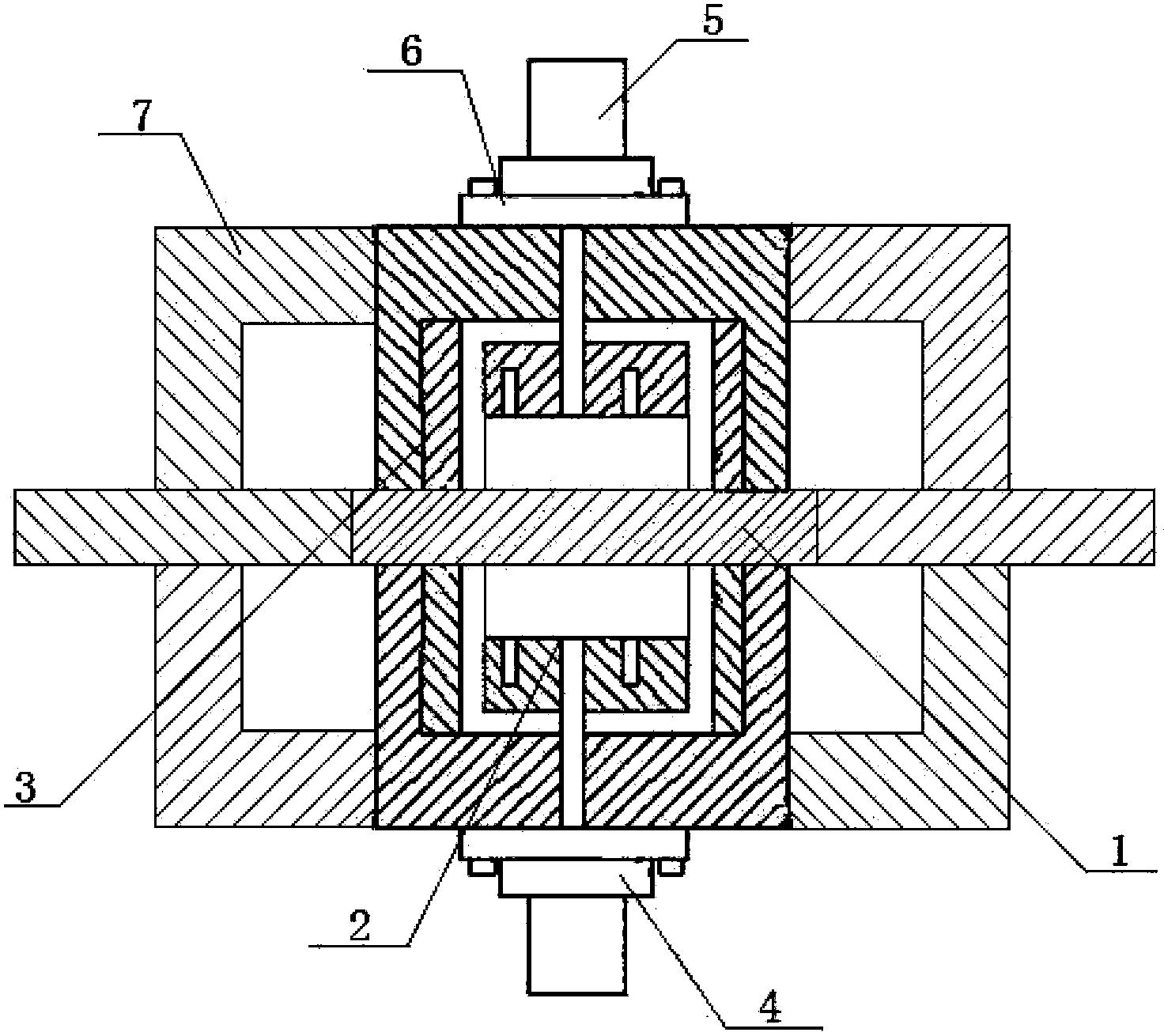

[0009] The two-way power head guide rail mechanism has a two-way power head body (1), and a two-way grooved cam (2) and a two-way guide rail (3) are installed on the top of the two-way power head body (1), and the two-way grooved cam (2) passes through the two-way guide rail (3), the rotary silicone pad (7) is hinged to the reducer (4), and the reducer (4) is connected to the drive motor (5) through a double screw (6).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a guide rail mechanism for a bidirectional power head of a brick making machine. A bidirectional grooved cam and a bidirectional guide rail are mounted on a bidirectional power head body, the bidirectional grooved cam is hinged to a speed reducer through the bidirectional guide rail and a rotary silicone pad, and the speed reducer is connected with a driving motor through a double screw. The whole bidirectional power head mechanism has the advantages of integrated structure, high push speed and high accuracy by the aid of the mechanism mode of the bidirectional power head, the bidirectional guide rail, the double screw and the bidirectional grooved cam.

Description

technical field [0001] The invention relates to a bidirectional power head guide rail mechanism, in particular to a bidirectional power head guide rail mechanism for a brick making machine, which belongs to the technical field of brick making machinery. Background technique [0002] The guide rail mechanism of the power head is an important component of the brick making machine. At present, the guide rail mechanism of the power head used in the brick making machine is a single independent structure. Only the head guide rail mechanism can achieve the driving effect, so the current power head guide rail structure used on the brick making machine has the defects of complex structure, slow driving speed and low precision. Contents of the invention [0003] The object of the present invention is to provide a bidirectional power head guide rail mechanism for brick making machines with integrated structure, fast driving speed and high precision, so as to overcome the above-me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28B3/00

Inventor 张胜凯

Owner XUZHOU KAILONG MINING SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com