Double-speed oil cylinder

A technology of oil cylinder and oil cylinder back cover, which is applied in the direction of fluid pressure actuating device, etc., which can solve the problems of low operating time of more than 30 seconds, no double-speed function, and unsatisfactory speed, so as to improve operating efficiency and reduce Effect of hydraulic loss and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

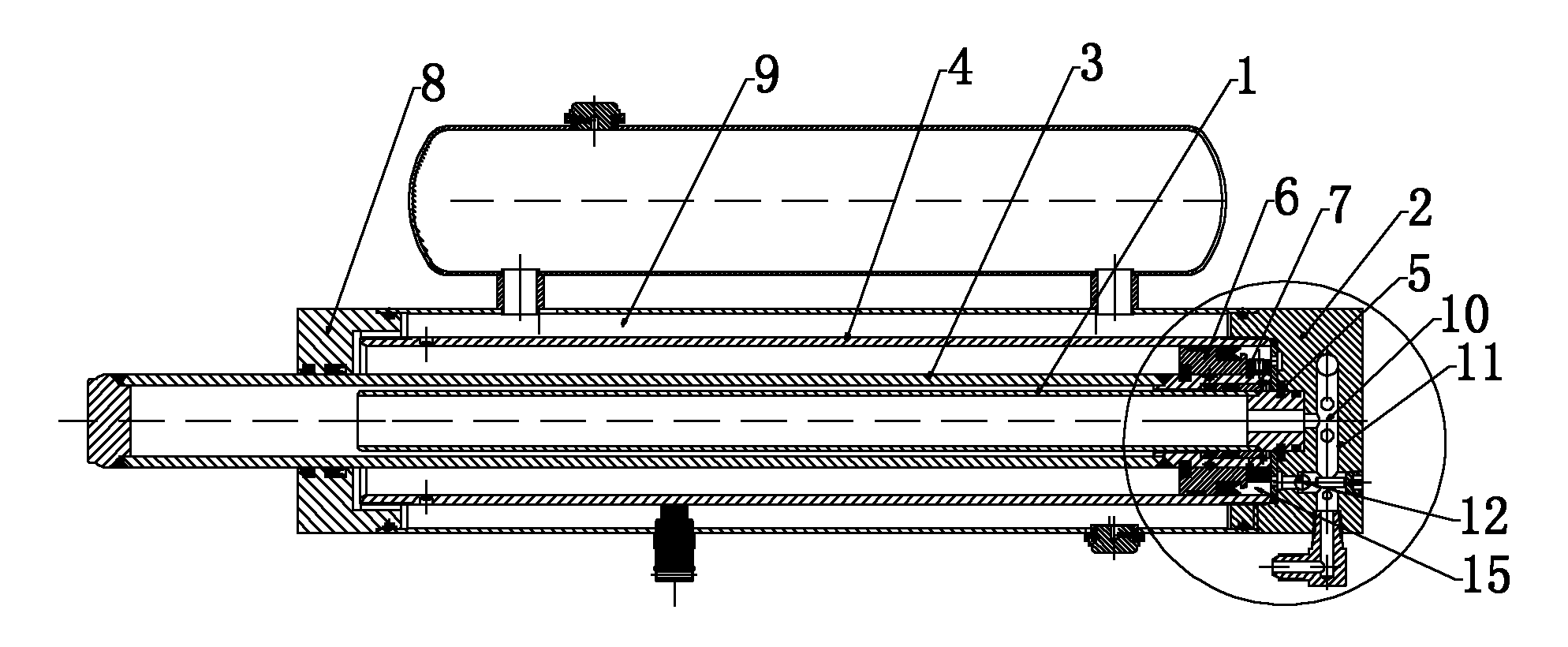

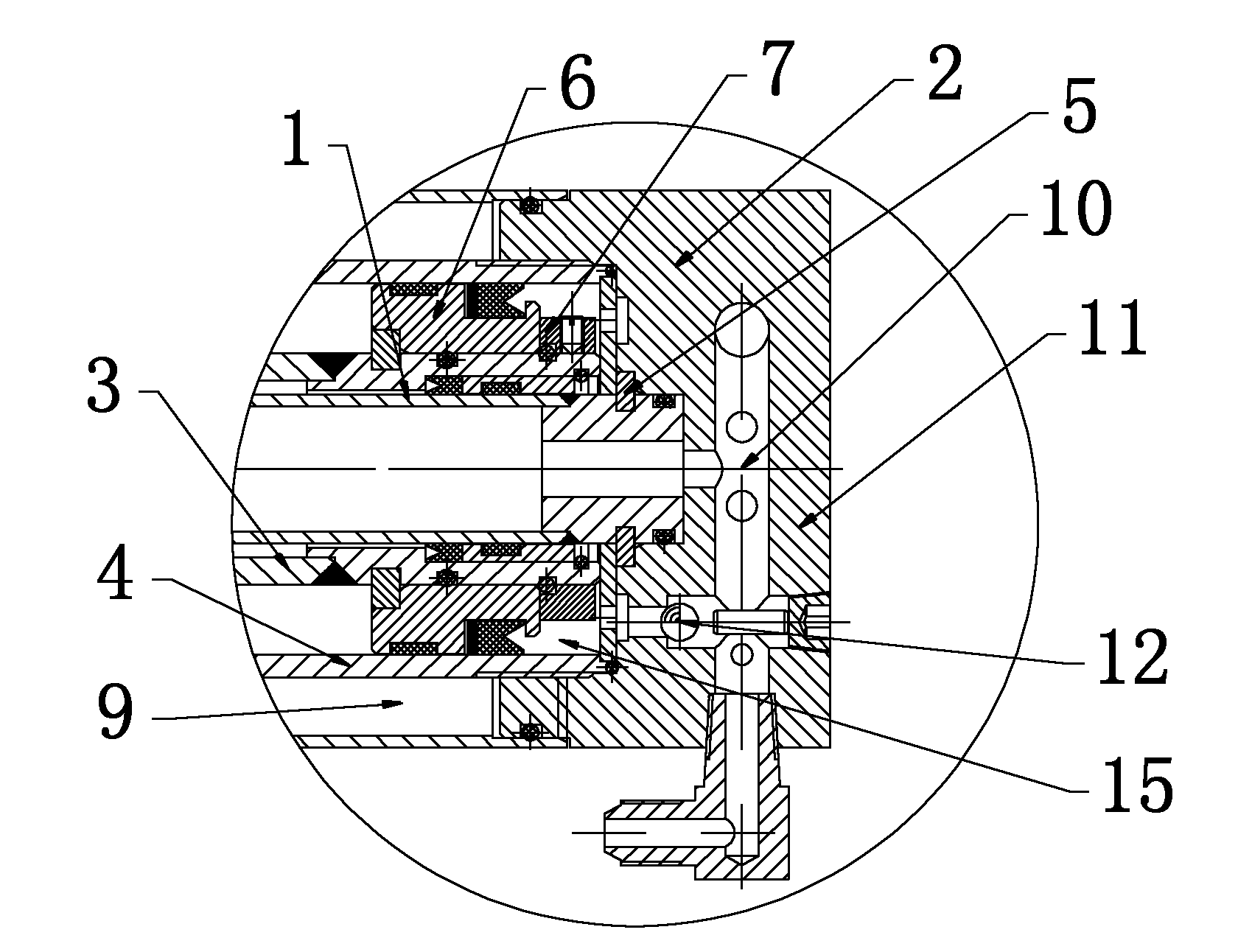

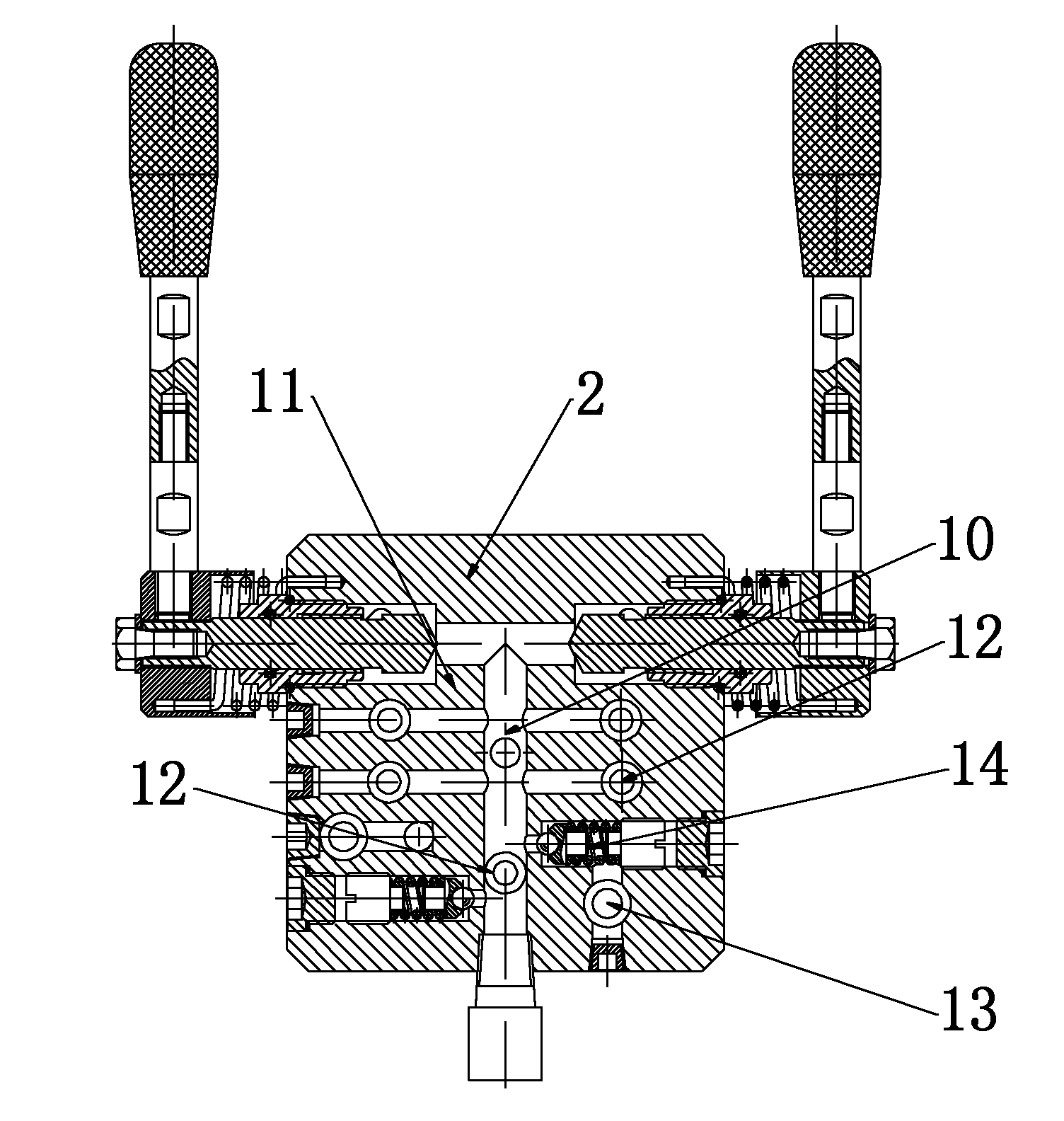

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the two-speed oil cylinder described in this embodiment mainly includes a cylinder block 4, an oil cylinder front cover 8, an oil cylinder rear cover 2, a large piston 6, a fixed piston rod 1 and a moving piston rod 3, and one end of the cylinder body 4 passes through the back of the oil cylinder. The cover 2 is closed, and the other end of the cylinder body 4 forms a sealed space through the front cover 8 of the oil cylinder and the moving piston rod 3. The large piston 6 is arranged at one end of the moving piston rod 3. There is a fixed piston rod 1, the fixed piston rod 1 is a hollow structure with both ends connected, one end of the fixed piston rod 1 is connected with the oil cylinder rear cover 2, and the end of the movable piston rod 3 in the cylinder body 4 is connected to the fixed piston rod 1 through the large piston 6 The outer wall is closed, and the large piston 6 is slidably connected on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com