Scrap steel preheating system

A technology for scrap steel and kiln, applied in the direction of preheating fee, lighting and heating equipment, furnace, etc., can solve the problems of reducing the utilization rate of heat energy, low preheating efficiency, water leakage, etc., to save the cooling problem and shorten the preheating cycle , to meet the effect of preheating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will be described in detail in conjunction with the accompanying drawings and specific embodiments.

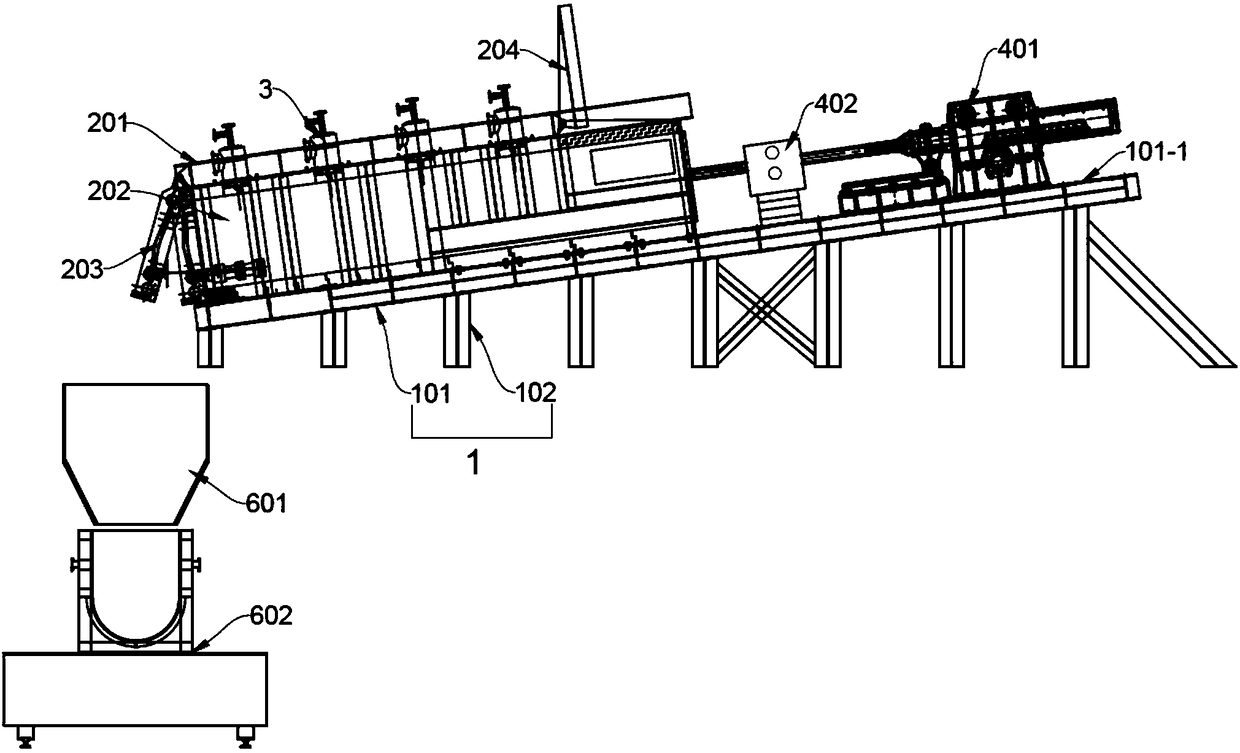

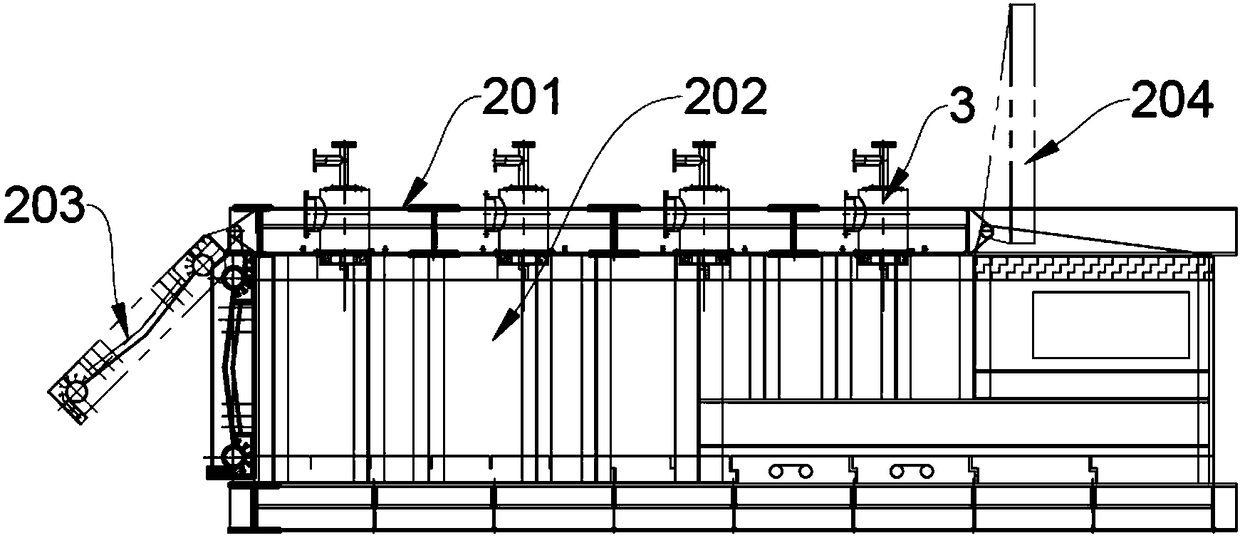

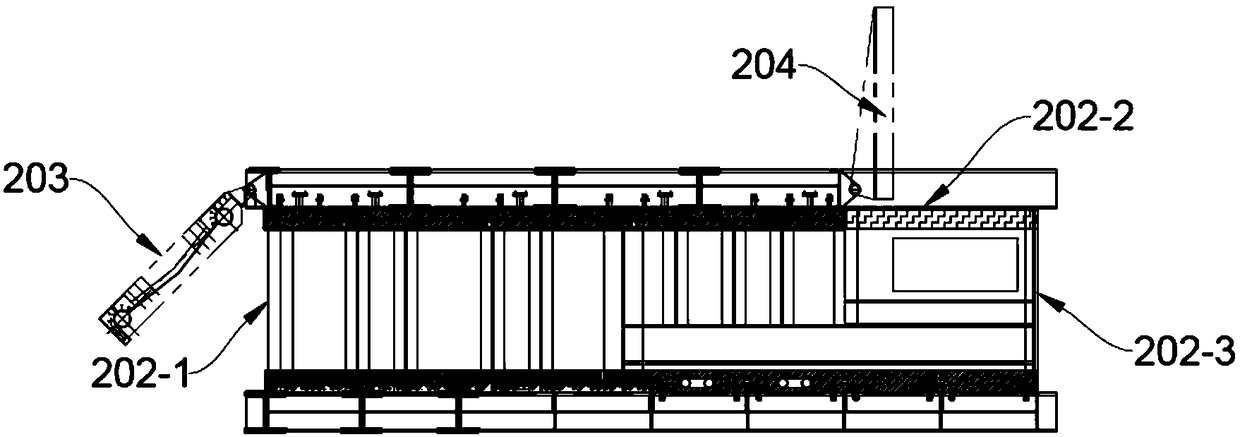

[0039] Such as figure 1 As shown, a steel scrap preheating system includes a kiln 2 , a conveying device, an installation frame 1 , a steel pushing mechanism 4 and a burner 3 . Among them, the kiln 2 is fixed on the mounting frame 1 by fasteners, and the burner 3 is installed on the kiln 2 for preheating scrap steel; the left end of the kiln 2 is a discharge port that can be opened and closed, and the right end is a The opening and closing of the steel pushing port is controlled by the steel pushing mechanism 4, and the side of the kiln 2 is provided with a feed port that can be opened and closed; the conveying device is used to put scrap steel into the kiln 2 from the feed port; The steel mechanism 4 is fixed on the mounting frame 1 and performs a reciprocating linear motion for pushing the preheated steel scrap out of the kiln 2 .

[0040] When scrap s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com