Double-acting four-inlet four-outlet reciprocating pump

A four-in, four-out, reciprocating pump technology, used in pumps, piston pumps, pump components, etc., can solve the problem that it cannot meet the requirements of the normal reciprocating movement of the piston inside the working cylinder, cannot meet the pressure and temperature resistance requirements of the working cylinder, and cannot guarantee Inner wall weld smoothness and other issues, to achieve the effect of small footprint, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

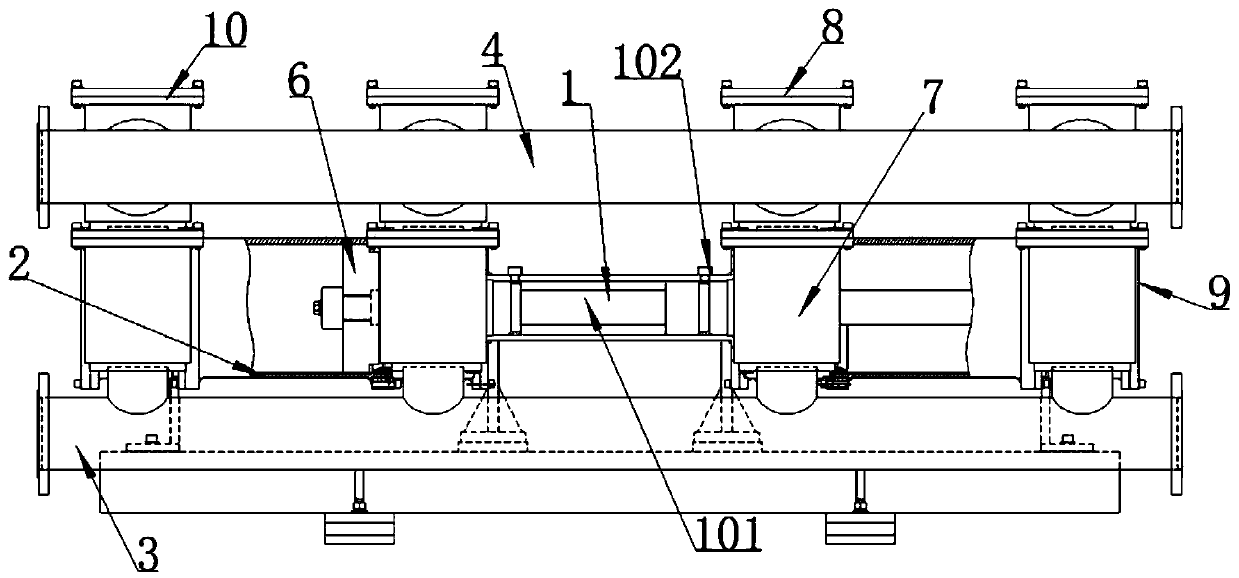

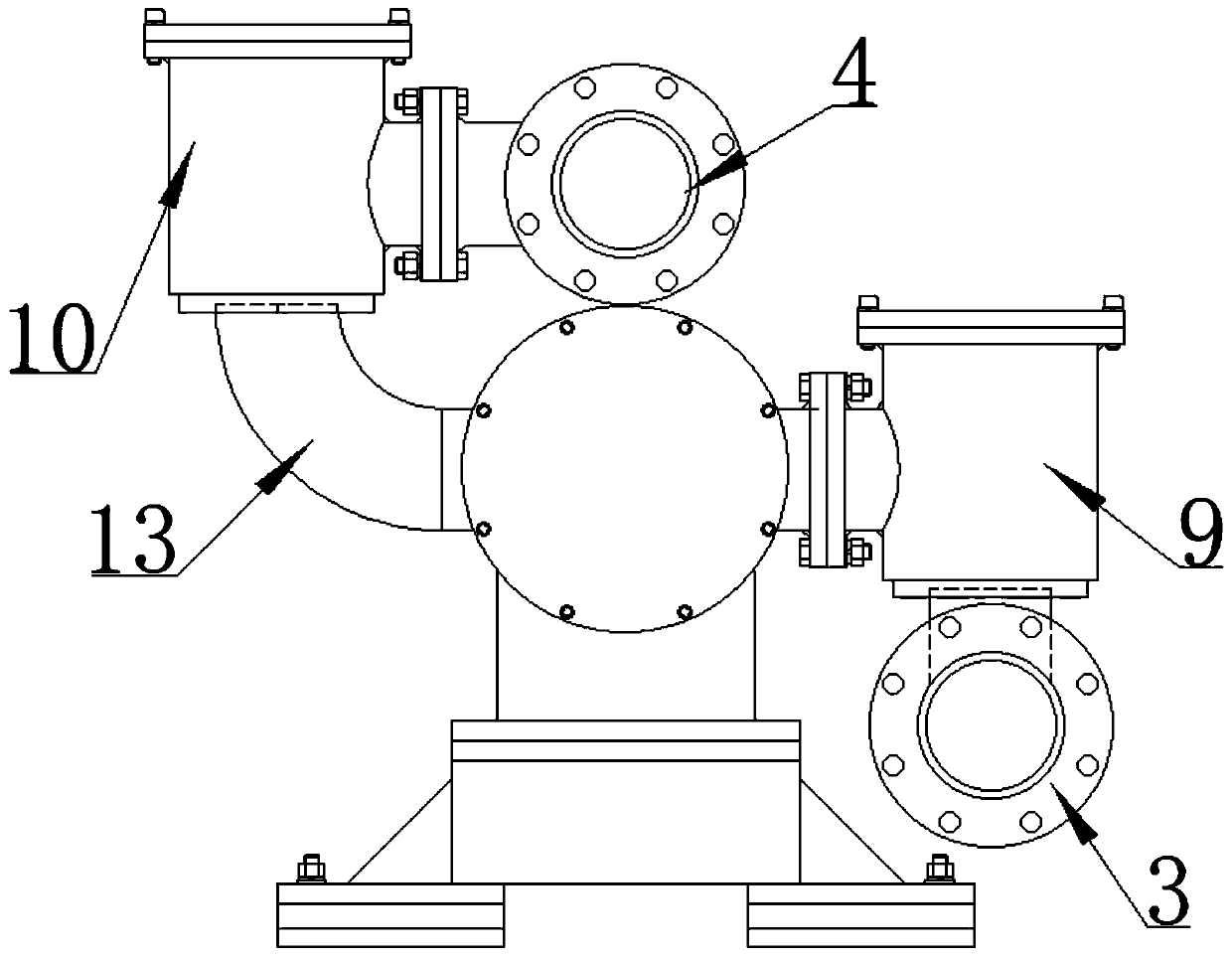

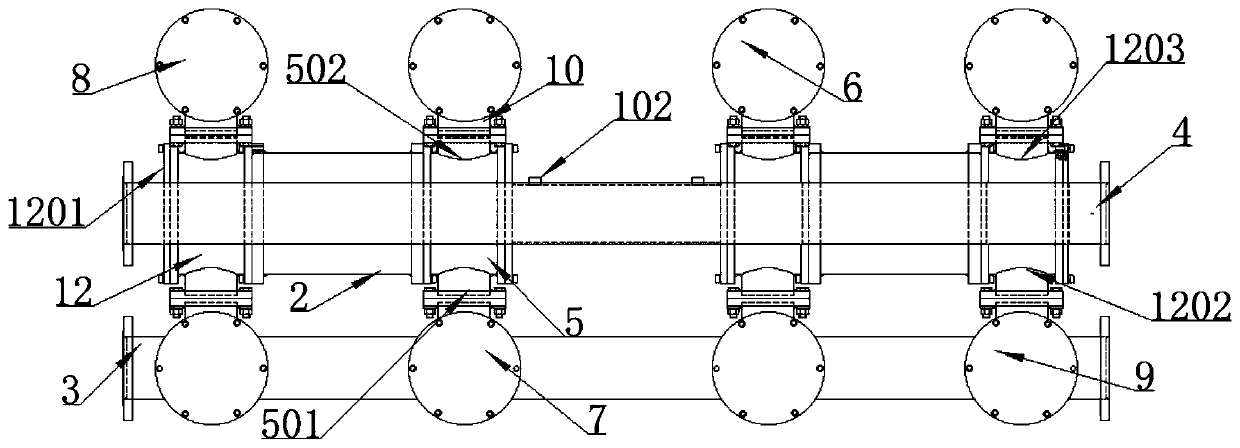

[0052] Such as Figure 1-3 As shown, a double-action four-inlet and four-outlet reciprocating pump provided in this embodiment includes a hydraulic cylinder block 1 , a main pump barrel 2 , a feed pipe 3 and a discharge pipe 4 .

[0053] The main pump barrel 2 is coaxially and symmetrically arranged on both sides of the hydraulic cylinder block 1, and the inner auxiliary pump barrel 5 is arranged axially between the main pump barrel 2 and the hydraulic cylinder block 1, and one end surface of the inner auxiliary pump barrel 5 passes through the flange It communicates with the port 2 of the main pump barrel, and the other end face is fixed to the end face of the hydraulic cylinder block 1 through the flange. .

[0054] A hydraulic drive rod 101 is provided inside the hydraulic cylinder block 1 along the axial direction. The two ends of the hydraulic drive rod 101 are respectively inserted into the main pump barrel 2 to fix the piston 6 . Oil port 102.

[0055] The annulus of...

Embodiment 2

[0069] Such as Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the port of the main pump barrel 2 away from the hydraulic cylinder block is provided with an elliptical head end cover 201, and the middle part of the elliptical head end cover 201 is provided with an opening , and the elliptical head end cover 201 communicates with the axial three-way pipe 11 through the opening, one port of the axial three-way pipe 11 communicates with the main pump barrel 2, and the other two ports are respectively connected to the second feed check valve 9 and The second discharge one-way valve 10; the second feed one-way valve 9 and the second discharge one-way valve 10 communicate with the feed pipeline 3 and the discharge pipeline 4 respectively.

[0070] The outer end of the main pump barrel 2 communicates with the axial three-way pipe 11 through the elliptical head end cover 201, thereby realizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com