Simple soap cutting device

A cutting device, soap technology, applied in the direction of cutting soap, etc., can solve the problems of repeated cutting, large volume of cutting machine, complex structure, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

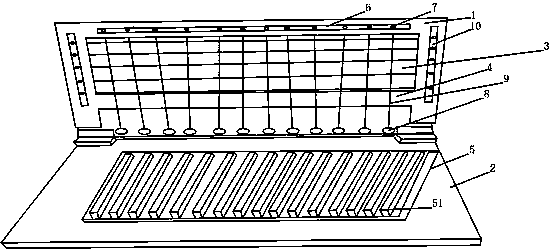

[0023] Such as figure 1 Shown, a kind of simple soap cutting device comprises upper box cover 1 and base plate 2, and described upper box cover 1 and base plate 2 are flexibly connected, and upper box cover 1 is provided with a cavity 3, and cavity 3 has suitable Depth, the upper part of the cavity 3 is provided with a groove a6 on the inner surface of the upper box cover 1, and a plurality of upper fasteners 7 are arranged in the groove a6, and the lower part of the cavity 3 is also provided with a concave surface on the inner surface of the upper box cover 1 , the concave surface is provided with a plurality of lower fasteners 8, a plurality of said upper fasteners 7 and a plurality of said lower fasteners 8 are located on a vertical line in a one-to-one correspondence, and the upper fastening A steel wire a9 is arranged between the piece 7 and the corresponding lower fastener 8;

[0024] A placement frame 5 is provided on the base plate 2, and the placement frame 5 include...

Embodiment 2

[0027] Such as figure 1 As shown, similar to embodiment 1, the difference is:

[0028] It also includes a horizontal cutting part arranged on the inner surface of the upper cover 1 , the horizontal cutting part includes a groove b10 arranged on both sides of the cavity 3 and a cutter arranged between the grooves b10 on both sides of the cavity 3 .

[0029] The cutter is a plurality of steel wires b parallel to the horizontal direction fixed between the grooves.

[0030] Further, the placement frame 5 is also provided with a plurality of horizontal strips arranged on the base, cutting gaps are formed between the plurality of horizontal strips, and the cutting gaps and steel wires b are set in one-to-one correspondence, and each of the steel wires b can Press fit in the corresponding cutting gap. The setting of the horizontal cutting part further cuts the soap into smaller pieces, which can speed up the cutting efficiency of the soap, and in actual sales, it is more in line wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com