Broken soap recycling device

A soap and cylinder technology, applied in the field of household appliances, can solve the problems of high heating time control, time-consuming and laborious, complicated operation process, etc., achieve the effect of complete pressing process, solve resource waste, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better describe the technical solutions and advantages of the present invention, the technical solutions in the embodiments of the present invention are now clearly and completely described in conjunction with the accompanying drawings.

[0036] like Figure 1 to Figure 8 Shown is the accompanying drawing of the specific embodiment of the present invention.

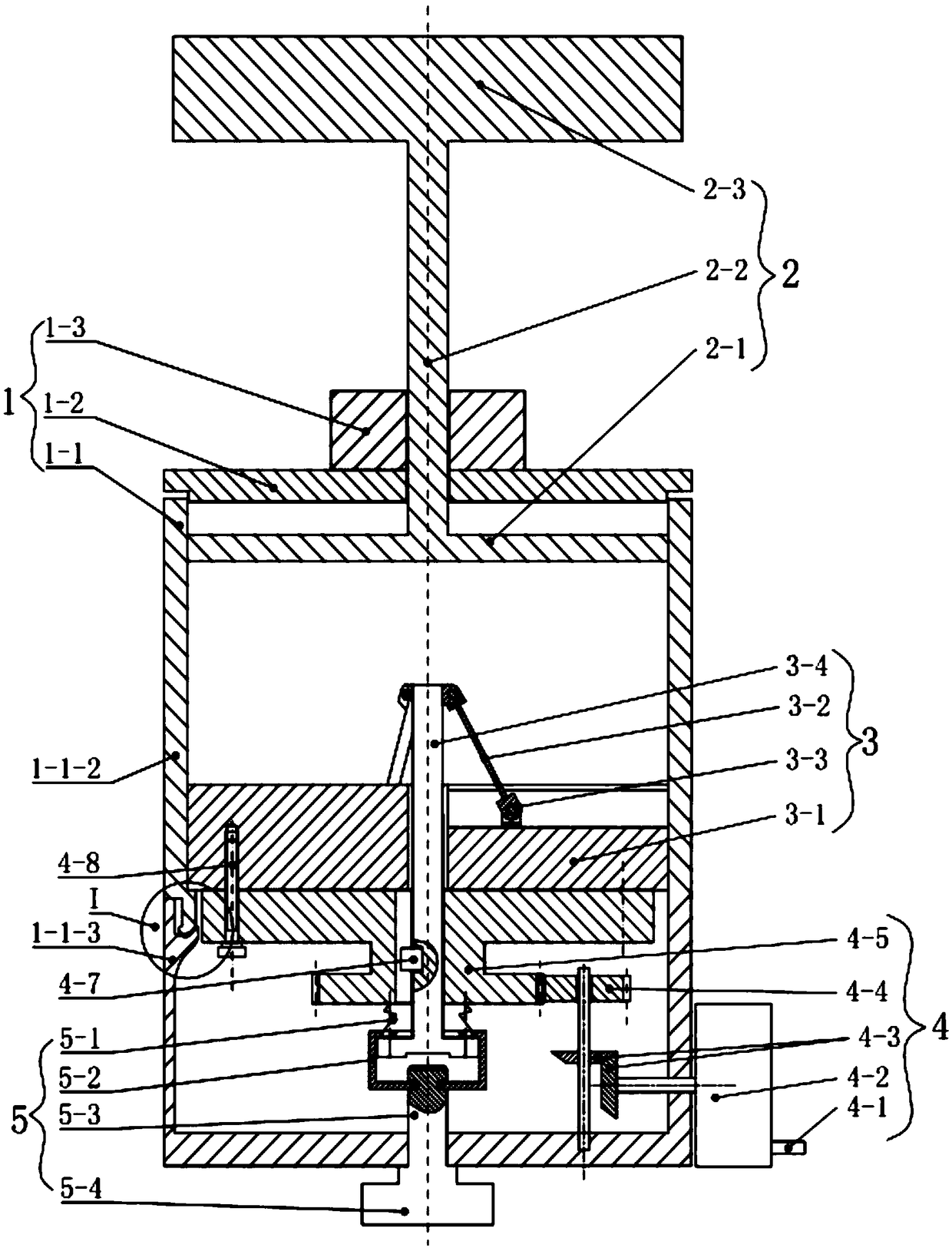

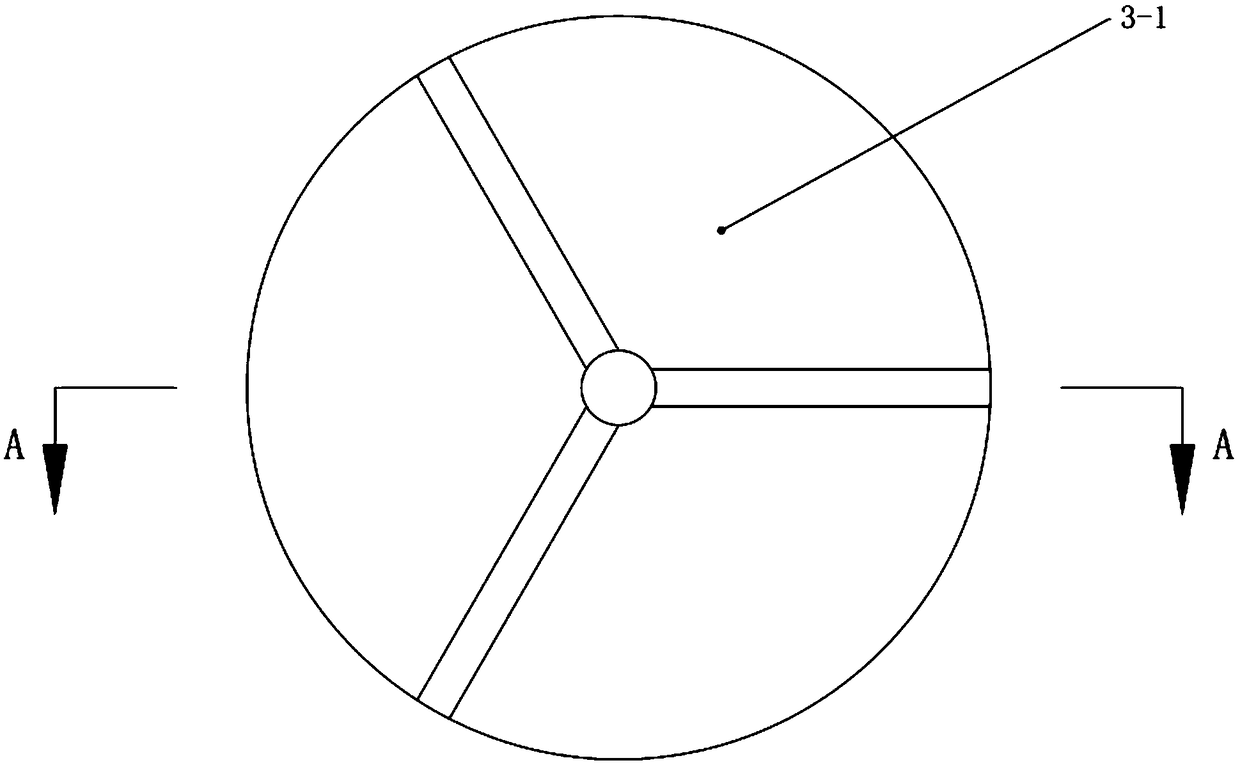

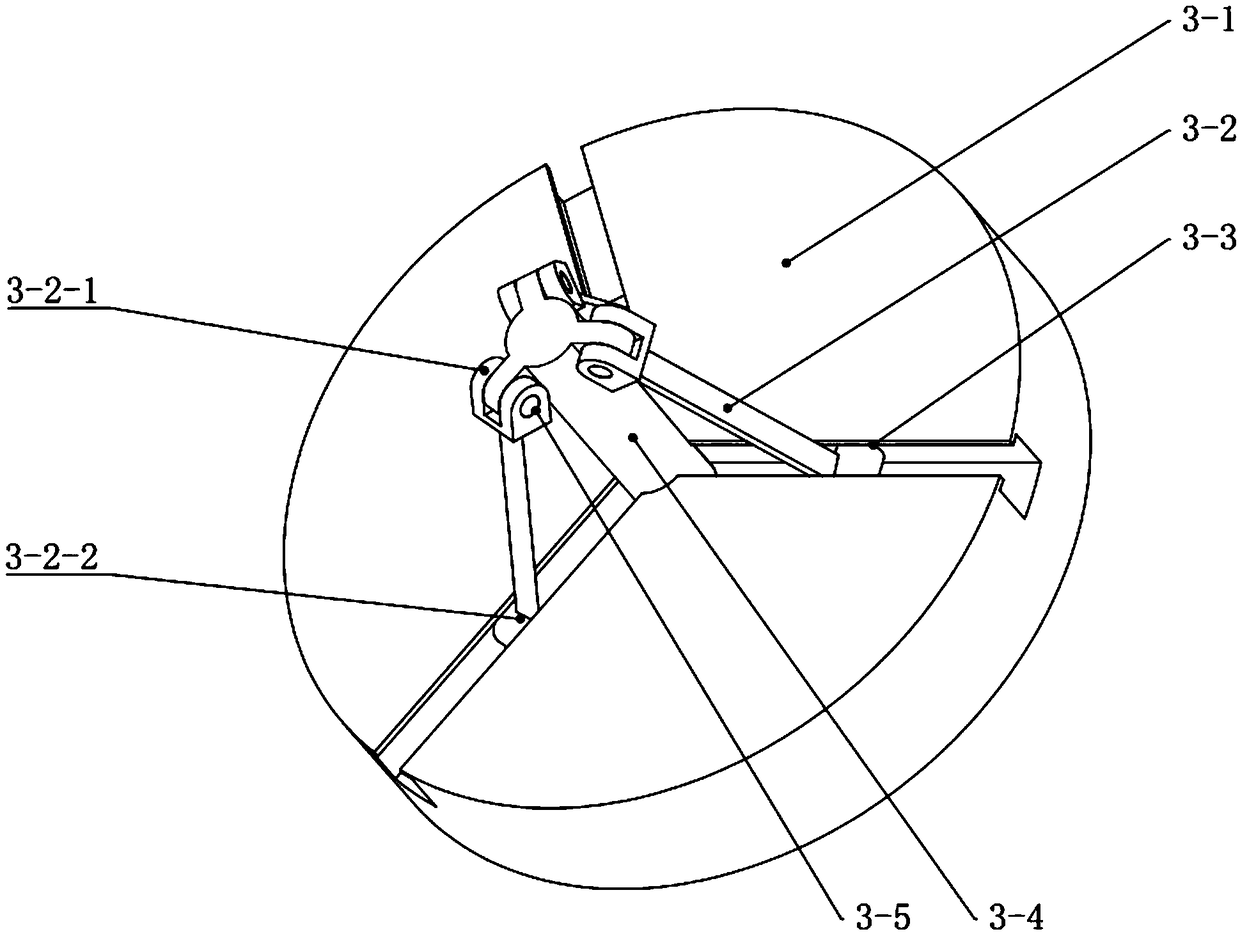

[0037] like Figure 1 to Figure 8 As shown, a crushed soap recycling device includes a bin body 1, a pressing mechanism 2, a cutting mechanism 3, a power mechanism 4, and a push rod reset mechanism 5, and is characterized in that:

[0038] The warehouse body 1 includes a shell cylinder 1-1 and a cylinder end cover 1-2, wherein: the shell cylinder 1-1 adopts a split structure, including an upper cylinder 1-1-2 and a lower cylinder seat 1-1-3 ; The upper cylinder body 1-1-2 and the lower cylinder base 1-1-3 pass as Figure 8 The shown elastic buckle structure (not numbered) is snapped together; the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com