A pepper soap cutting device

A technology of soap and pepper, applied in the direction of cutting soap, solid separation, chemical instruments and methods, etc., can solve the problems of soap block accumulation, leftover material adhesion, affecting the appearance and quality of soap block, etc., to reduce equipment cost and energy consumption cost , reducing the effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

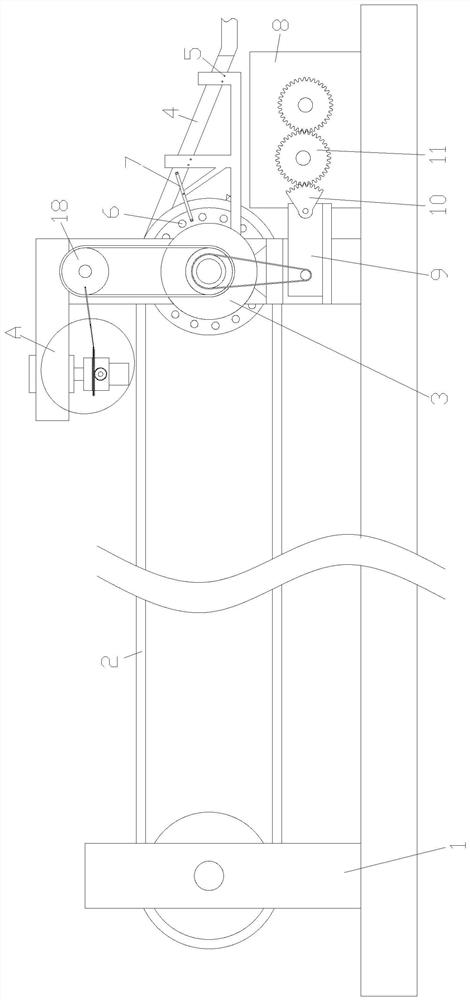

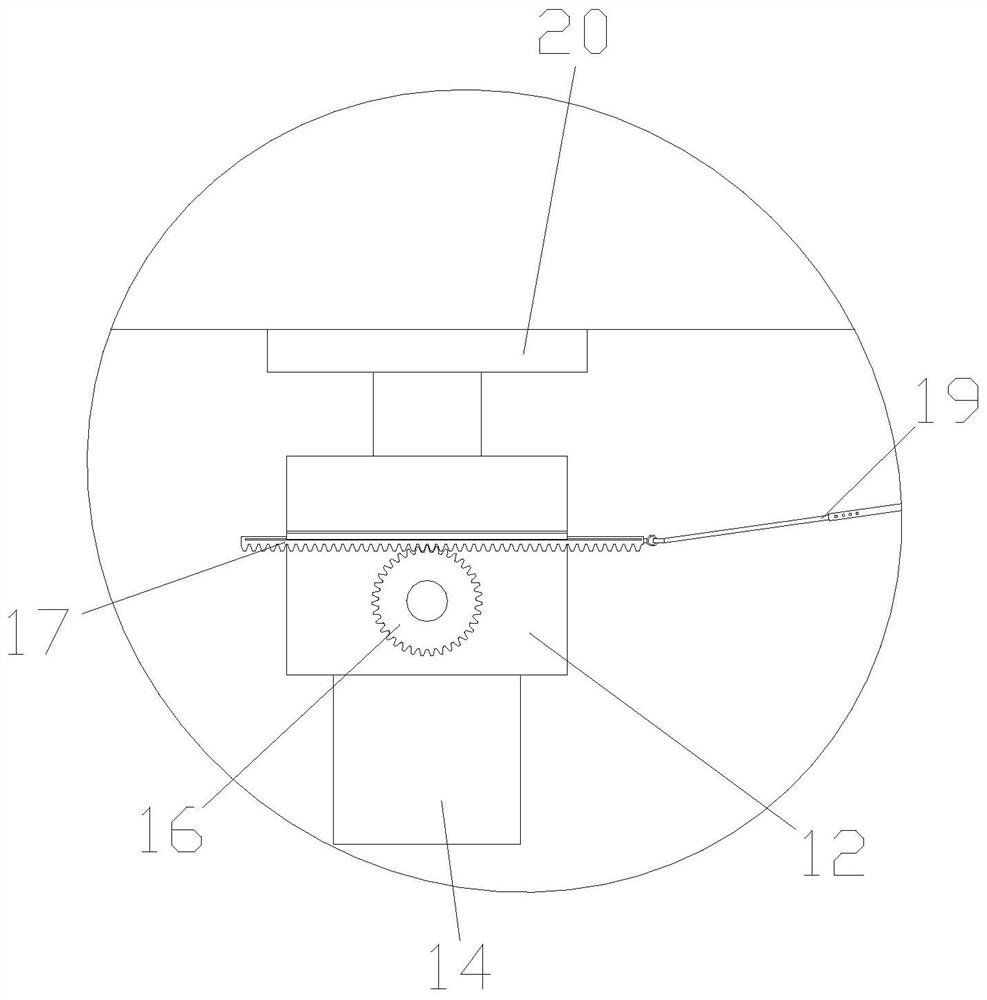

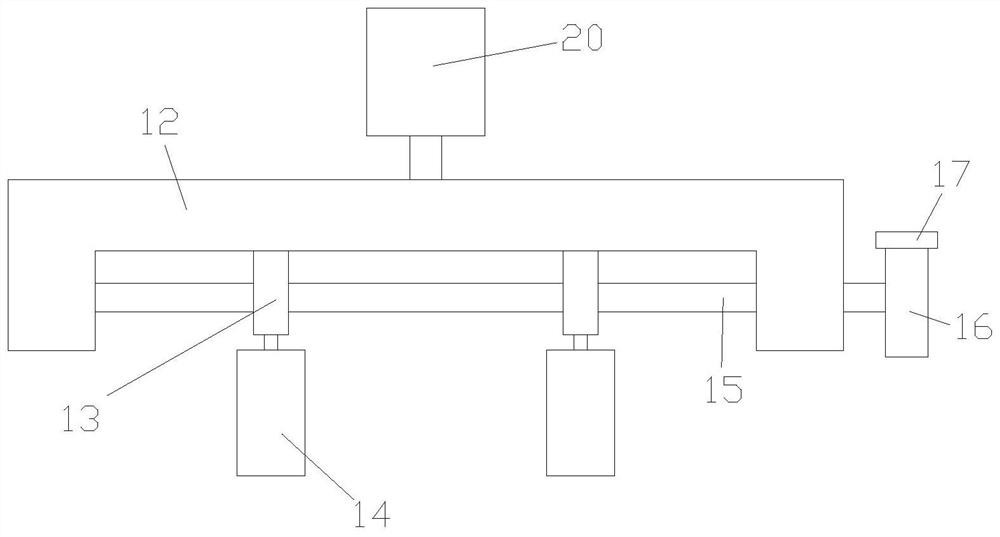

[0023] refer to Figure 1~Figure 3 Shown: a kind of prickly ash soap slitting device comprises frame 1, and the conveyor belt 2 that is used for transporting soap is arranged on the frame 1 rotation, and conveyor belt 2 is existing structure, and conveyor belt 2 is driven by the motor 3 that is installed on frame 1 Power is provided, and the top of the conveyor belt 2 is provided with a slitting mechanism. In this embodiment, the slitting mechanism is positioned at the discharge end of the conveyor belt 2, and the discharge end of the conveyor belt 2 is provided with a scraper block positioned at the slitting mechanism; The end is obliquely provided with a guide screen 4 for screening the cut soap pieces and leftovers. The guide screen 4 uses the power of the conveyor belt 2 to reciprocate along the plane where the screening surface is located through the reciprocating swing mechanism. Shaking; the guide screen 4 is connected to the frame 1 through a plurality of support rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com