Lanxiang ultra black automobile refinishing coating and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

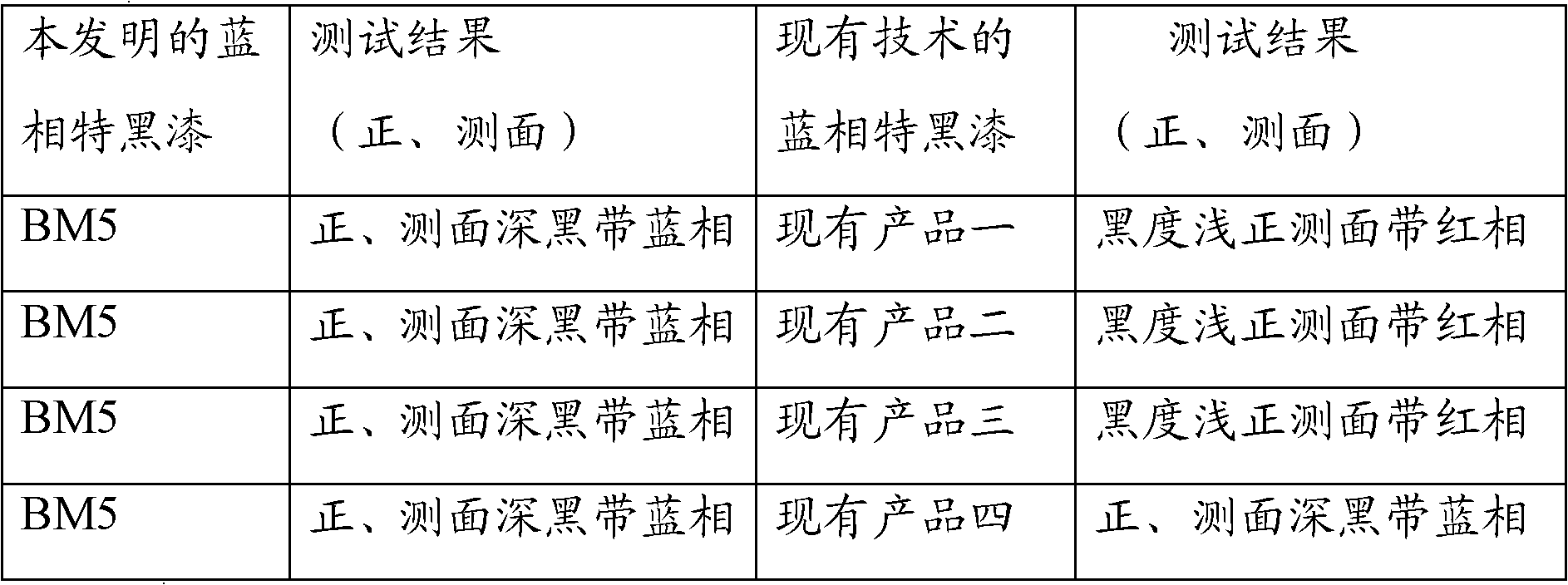

Image

Examples

Embodiment 1

[0023] 1. Prepare the following raw materials: 74.29 parts of acrylic resin, 2.4 parts of high-pigment carbon black powder, 1.9 parts of super dispersant, 0.95 parts of multiplier, 0.075 parts of high-pigment dye, 0.45 parts of nano-titanium dioxide, and 16.630 parts of mixed solvent;

[0024] Wherein, mixed solvent is the mixture of butyl acetate, ethyl acetate, xylene, ethylene glycol methyl ether acetate;

[0025] 2. Put the dispersing tank flat on the weighbridge, add 70% of the formula amount of acrylic resin into the dispersion tank, measure and add the formula amount of super dispersant into the dispersion tank, and measure and add the formula amount under manual stirring Carbon black powder, multiplier, dye powder, nano-titanium dioxide; add the remaining amount of acrylic resin, move the dispersing cylinder to the high-speed dispersing machine, move the dispersing shaft to the center of the dispersing cylinder, stabilize the dispersing cylinder, clamp Good static grou...

Embodiment 2

[0032] 1. Prepare the following raw materials: 76 parts of acrylic resin, 2.5 parts of high-pigment carbon black powder, 2.00 parts of super dispersant, 1 part of multiplier, 0.08 part of high-pigment dye, 0.5 part of nano-titanium dioxide, and 17.63 parts of mixed solvent;

[0033] Wherein, mixed solvent is the mixture of butyl acetate, ethyl acetate, xylene, ethylene glycol methyl ether acetate;

[0034] 2. Put the dispersing tank flat on the weighbridge, add 70% of the formula amount of acrylic resin into the dispersion tank, measure and add the formula amount of dispersant into the dispersion tank, measure and add the formula amount of charcoal under manual stirring Black powder, multiplier, dye powder, nano-titanium dioxide; add the remaining amount of acrylic resin, move the dispersing cylinder to the high-speed dispersing machine, move the dispersing shaft to the center of the dispersing cylinder, stabilize the dispersing cylinder, and clamp it well Static grounding wir...

Embodiment 3

[0041] 1. Prepare the following raw materials: 78.29 parts of acrylic resin, 2.6 parts of high-pigment carbon black powder, 2.1 parts of super dispersant, 1.05 parts of multiplier, 0.09 parts of high-pigment dye, 0.55 parts of nano-titanium dioxide, and 18.63 parts of mixed solvent;

[0042] 2. Put the dispersing tank flat on the weighbridge, add 70% of the formula amount of acrylic resin into the dispersion tank, measure and add the formula amount of dispersant into the dispersion tank, measure and add the formula amount of charcoal under manual stirring Black powder, multiplier, dye powder, nano-titanium dioxide; add the remaining amount of acrylic resin, move the dispersing cylinder to the high-speed dispersing machine, move the dispersing shaft to the center of the dispersing cylinder, stabilize the dispersing cylinder, and clamp it well Static grounding wire; put the mixed solvent after the acrylic resin is cast and before the powder is cast;

[0043] 3. Turn on the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photostability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com