Formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride)

A technology of waste oil and epoxy is applied in the research field of plasticized polyvinyl chloride formulation, which can solve the problems of inability to realize industrialized production, high cost, complicated operation, etc., and achieve the effect of low cost, simple process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 Get 1000g of processed waste oil and 90g of formic acid and place them in a reactor, feed circulating hot water, slowly add 670g of concentrated sulfuric acid hydrogen peroxide dropwise at about 40°C (hydrogen peroxide: concentrated sulfuric acid=200: 1), drop After the addition, the temperature was rapidly raised to 70°C, and the reaction was carried out at constant temperature for 6 hours. The sample was placed in the still for 2 hours, the lower layer was separated, and the remaining oil layer was washed with 5% sodium bicarbonate solution until slightly alkaline (PH ≈ 8), and then washed with distilled water (PH ≈ 7). Distillation and dehydration under reduced pressure gave a clear and transparent light yellow oily product.

Embodiment 2

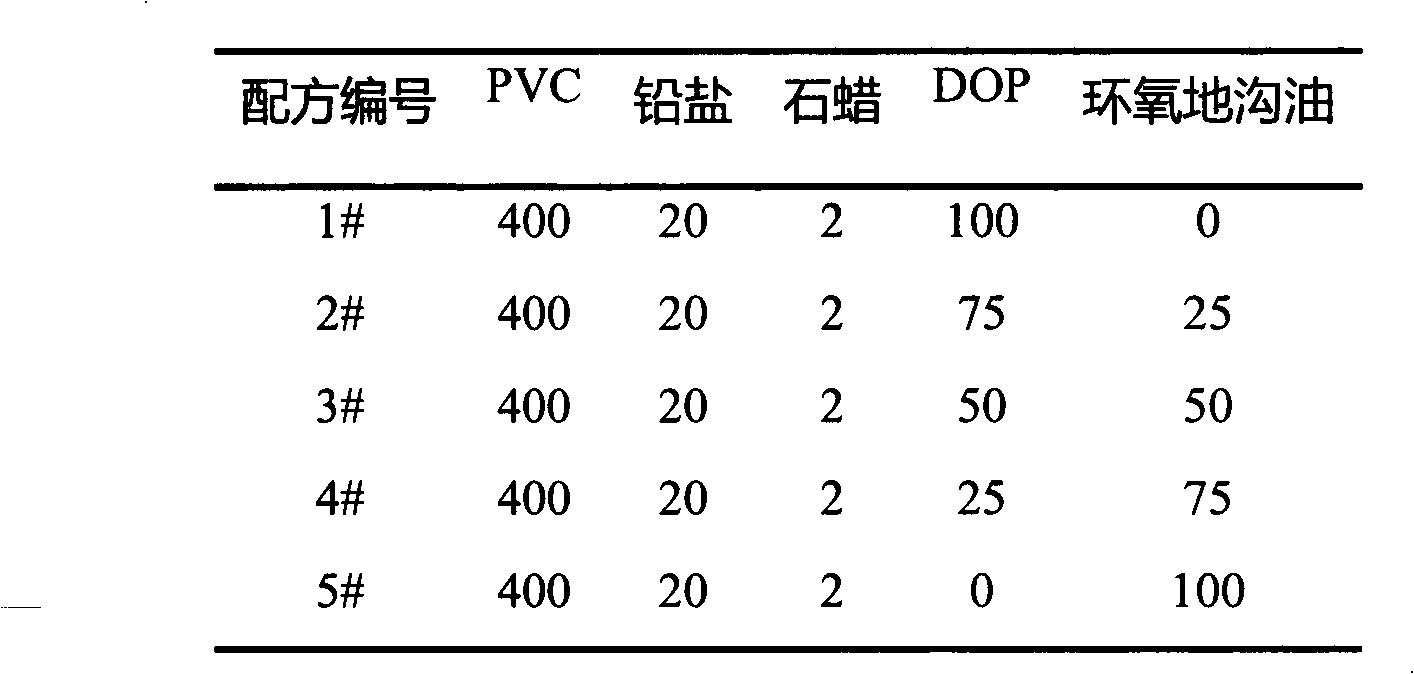

[0018] Example 2 Weigh 400g of PVC, 20g of lead salt, 2g of paraffin, 50g of dioctyl phthalate, and 50g of epoxidized waste oil, and mix them uniformly; place the mixed sample at a roller temperature of about 165°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com