Paint for preventing covering ice for insulator and its preparation method

An insulator, anti-icing technology, applied in the direction of coating, can solve problems such as line outage, and achieve the effects of reducing harm, excellent hydrophobicity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

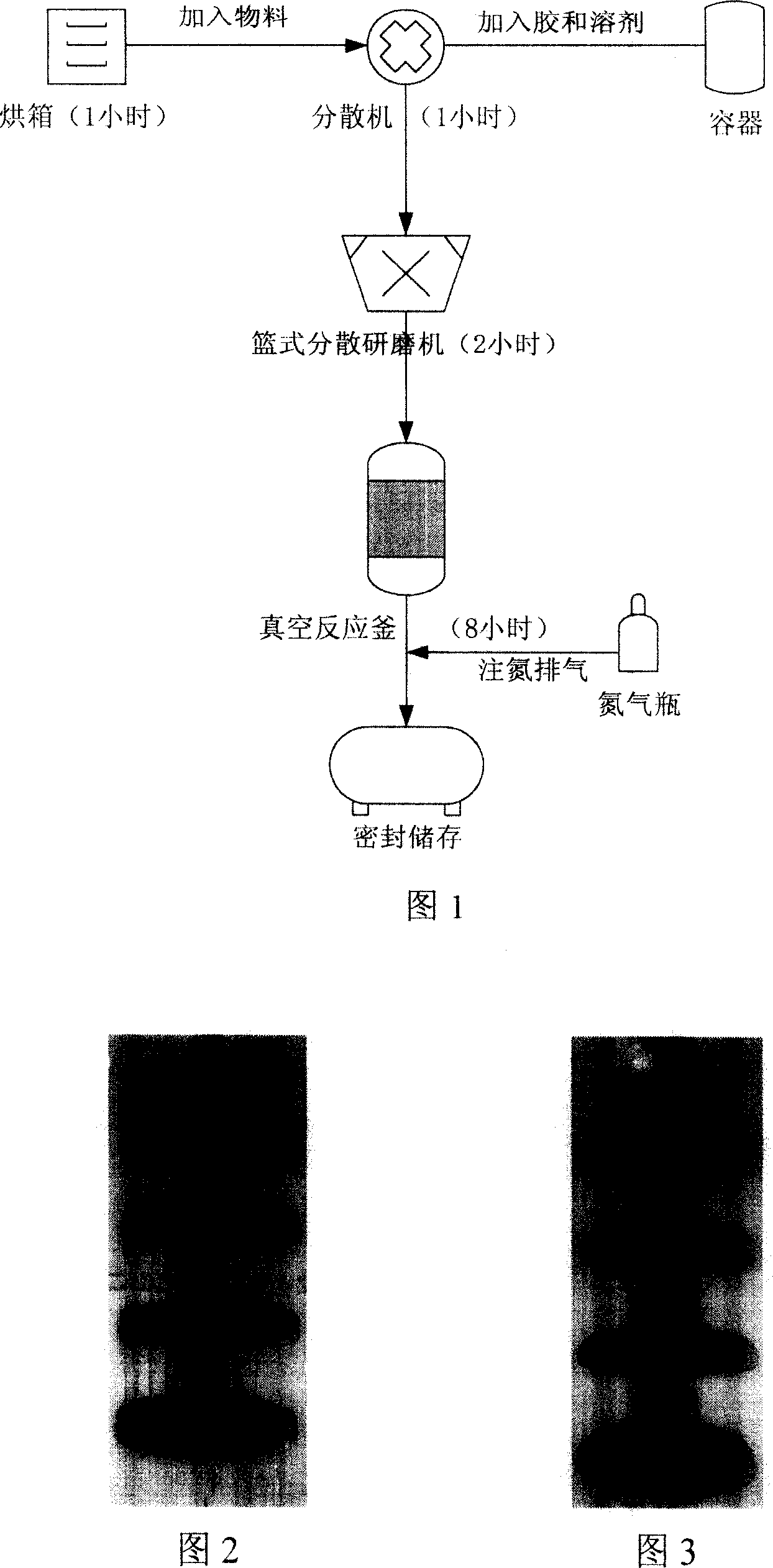

Method used

Image

Examples

Embodiment 1

[0034]Embodiment 1 Anti-icing coating for insulators contains by weight: 100 parts of 107 base glue (polydimethylsiloxane, viscosity 10000 Pa S), 150 parts of petroleum ether (or solvent gasoline), 15 parts of carbon black, 10 parts of carbon fiber powder, 15 parts of aluminum hydroxide, 3 parts of silicon dioxide, 3 parts of zinc oxide and 7 parts of silane coupling agent.

[0035] Polydimethylsiloxane, commonly known as base rubber, is the base rubber of room temperature vulcanized silicone rubber, with a molecular weight of 10,000-80,000. Cross-linking reaction to form linear polysiloxane.

[0036] The carbon black is special conductive carbon black, and the nitrogen adsorption specific surface area is 300m 2 / g.

[0037] Carbon fiber powder is made of polyacrylonitrile-based carbon fiber continuous filaments, which are cut into several millimeters long short fibers and ground by special cutting equipment.

[0038] The role of aluminum hydroxide is to improve the flame r...

Embodiment 2

[0060] Embodiment 2 Anti-icing paint for insulators contains by weight: 100 parts of 107 base glue (polydimethylsiloxane, viscosity 5000Pa·S), 100 parts of petroleum ether (or solvent gasoline), 12 parts of carbon black, 10 parts of carbon fiber powder, 30 parts of aluminum hydroxide, 3 parts of silicon dioxide, 3 parts of zinc oxide and 7 parts of silane coupling agent.

[0061] The paint is suitable for areas with relatively heavy pollution and relatively large salt density. Coatings formulated with this formula have better arc ablation resistance and hydrophobic migration properties under harsh environmental conditions. The preparation method of the coating described in embodiment 2 is the same as that of embodiment 1.

[0062] See Table 3 for the basic performance test results of the anti-icing coating on insulators in Example 2.

[0063] table 3

[0064] Test items

Remark

Hydrophobic

Class 1, 100°-110°

Water spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nitrogen adsorption specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com