Environmentally-friendly durable water repellent fabric and processing method thereof

A processing method and environmentally friendly technology, which can be used in chemical instruments and methods, textiles and papermaking, synthetic resin layered products, etc., and can solve problems such as ecological environment threats and difficult biodegradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

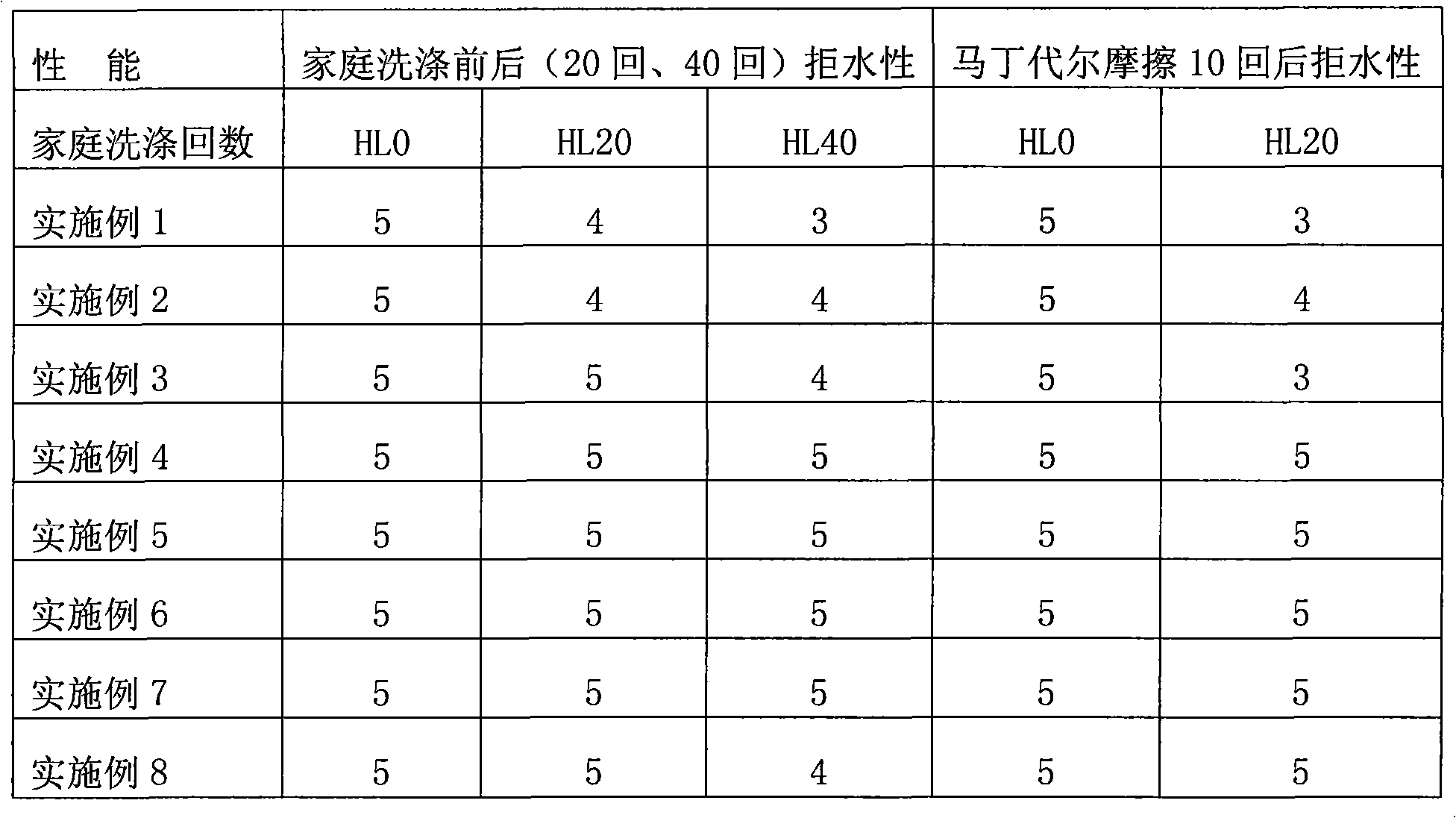

Examples

Embodiment 1

[0031] First, the PET100% fabric is subjected to the pretreatment of the padding process (I), then the padding process (II) is performed again, and finally the product is obtained by drying and setting. Its surface has a water-repellent layer containing polyurethane dendritic macromolecular structural units and melamine structural units.

[0032] The processing fluid components and parts by weight of the above-mentioned padding processing (I) and padding processing (II) are as follows:

[0033] Polyurethane dendrimer water-repellent resin 4 parts

[0034] Melamine bridging agent 1 part

[0035] Organic amine salt catalyst 1 part

[0036] 94 parts of water

[0037] The padding processing (I) is two dipping and two rolling, its drying temperature is 40°C, and the drying time is 2min; the padding processing (II) is two dipping and two rolling, its drying temperature is 130°C, drying time is 2min, and the setting temperature is 170°C , Setting time 0.75min.

Embodiment 2

[0039] The processing liquid component and parts by weight of padding processing (II) are as follows:

[0040] Polyurethane dendrimer water-repellent resin 4 parts

[0041] Aliphatic unblocked isocyanate bridging agent 1 part

[0042] 95 parts of water

[0043] All the other are with embodiment 1. The surface of the obtained product has a water-repellent layer containing polyurethane dendritic macromolecular structural units and isocyanate structural units.

Embodiment 3

[0045] The processing liquid component and parts by weight of padding processing (II) are as follows:

[0046] Aliphatic paraffin water-repellent resin 4 parts

[0047] Blocked isocyanate bridging agent 1 part

[0048] 95 parts of water

[0049] All the other are with embodiment 1. The surface of the obtained product has a water-repellent layer containing aliphatic paraffin wax structural units and isocyanate structural units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com