Fluorinated graphene-containing waterproof and moisture-permeable composite fabric and preparation method thereof

A fluorinated graphene, waterproof and moisture-permeable technology, applied in chemical instruments and methods, single-component synthetic polymer rayon, protective clothing, etc., can solve the problem of difficult stability of equipment and raw materials, unstable product quality, and difficult composite process and other problems, to achieve the effect of improving mechanical properties and hydrophobic properties, good waterproof and moisture permeability, and good moisture permeability and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a waterproof and moisture-permeable composite fabric containing fluorinated graphene, comprising the following steps:

[0035] 1) Pour the weighed N,N-dimethylformamide and the fluorinated graphene solution whose solute accounts for 0.5% of the whole into a three-necked flask, and sonicate for 4 hours.

[0036] 2) Add polyurethane and aziridine isocyanate to the dispersion obtained in step 1) according to the ratio of polyurethane: aziridine isocyanate: fluorinated graphene of 10.0:5.85:0.0725, stir on an electric stirrer at room temperature for 3 hours, and make the mass fraction It is a 14.5% spinning solution containing fluorinated graphene.

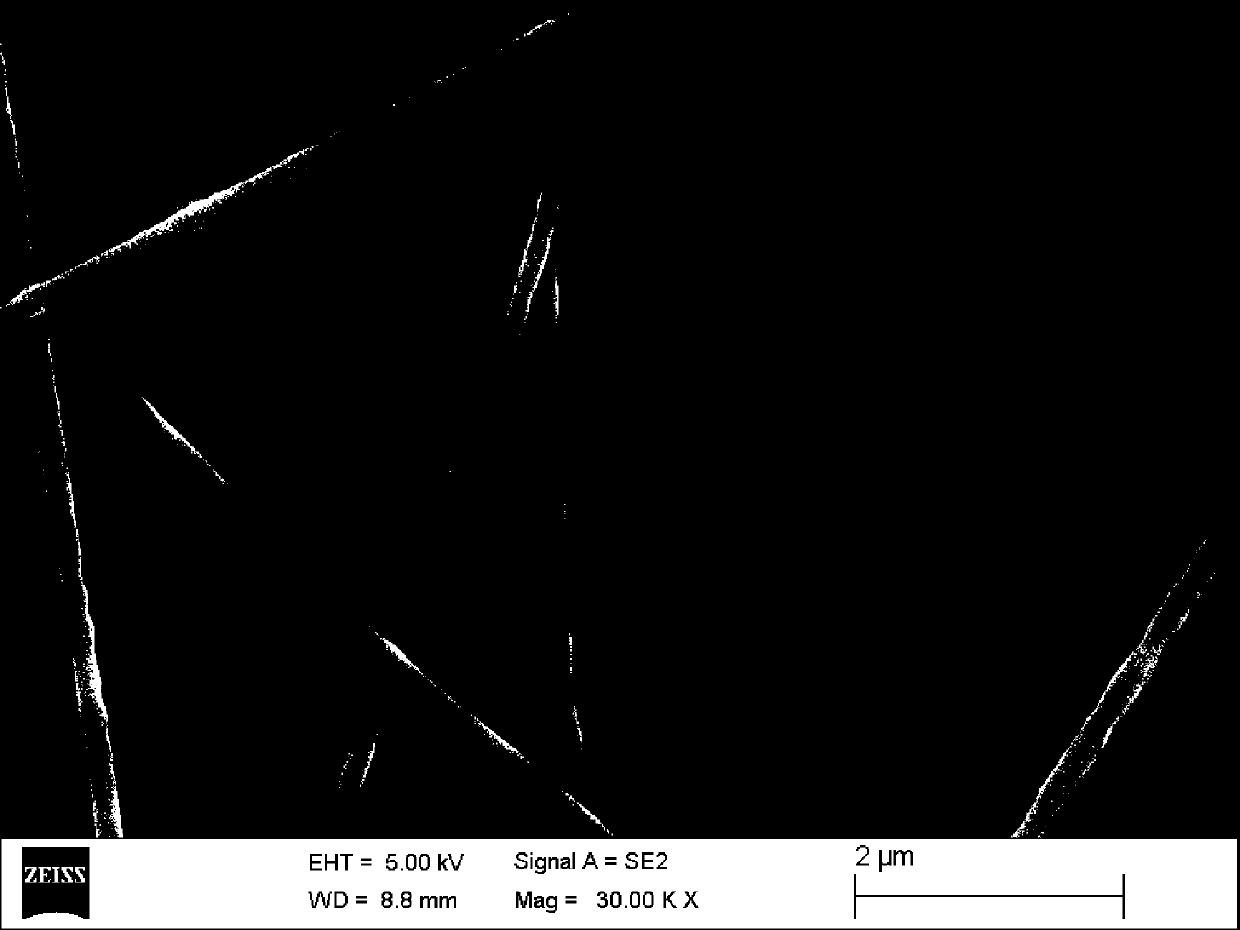

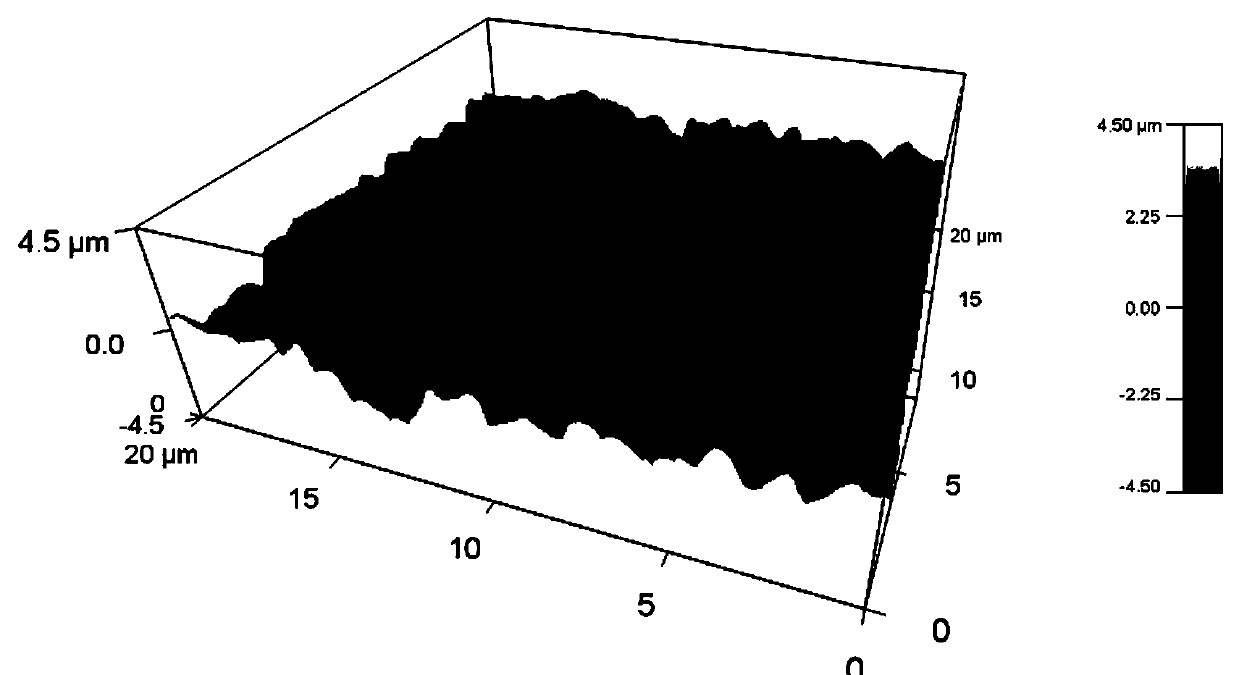

[0037]3) Use the solution obtained in step 2) to perform electrospinning. The electrospinning equipment mainly includes a liquid reservoir, a receiving device, a floor receiver and a high-voltage power transmission device. Among them, the voltage of the high-voltage generator is 35KV; the distance from ...

Embodiment 2

[0041] A preparation method of a waterproof and moisture-permeable composite fabric containing fluorinated graphene, comprising the following steps:

[0042] 1) Pour the weighed N,N-dimethylformamide and fluorinated graphene solution whose solute accounts for 1% of the whole into a three-necked flask, and sonicate for 4 hours.

[0043] 2) Add polyurethane and aziridine isocyanate to the dispersion obtained in step 1) according to the ratio of polyurethane: aziridine isocyanate: fluorinated graphene of 10.0:5.85:0145, stir on an electric stirrer at room temperature for 3 hours, and make the mass fraction It is a 14.5% spinning solution containing fluorinated graphene.

[0044] 3) Use the solution obtained in step 2) to perform electrospinning. The electrospinning equipment mainly includes a liquid reservoir, a receiving device, a floor receiver and a high-voltage power transmission device. Among them, in the electrospinning process: the voltage of the high-voltage generator is...

Embodiment 3

[0048] A preparation method of a waterproof and moisture-permeable composite fabric containing fluorinated graphene, comprising the following steps:

[0049] 1) Pour the weighed N,N-dimethylformamide and the fluorinated graphene solution whose solute accounts for 1.5% of the whole into a three-necked flask, and sonicate for 4 hours.

[0050] 2) Add polyurethane and aziridine isocyanate to the dispersion obtained in step 1) according to the ratio of polyurethane: aziridine isocyanate: fluorinated graphene of 10.0:5.85:0.2175, stir on an electric stirrer at room temperature for 3 hours, and make the mass fraction It is a 14.5% spinning solution containing fluorinated graphene.

[0051] 3) Use the solution obtained in step 2) to perform electrospinning. The electrospinning equipment mainly includes a liquid reservoir, a receiving device, a floor receiver and a high-voltage power transmission device. Among them, the voltage of the high-voltage generator is 35KV; the distance from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com