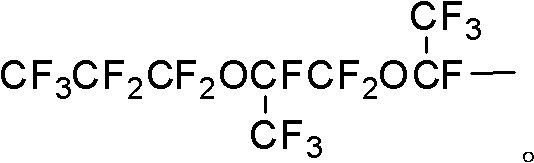

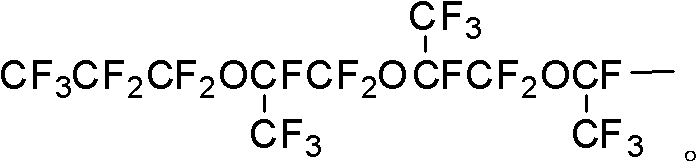

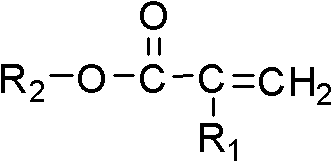

Fluorine-containing polyether acrylate polymer and preparation method thereof

A polyether acrylate and polymer technology, which is applied in plant fibers, textiles and papermaking, fiber processing and other directions, can solve problems such as respiratory system problems, refractory degradation, and neonatal death, and achieves low environmental pollution, simple preparation method, The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) In a 100mL single-necked flask, add 50mg emulsifier TO-5, 15mg SDS, 10mL water, 2mL acetone, heat up to 58°C, stir at high speed for 30min, then slowly add monomer: 0.4g methyl methacrylate , 0.5g butyl acrylate, 0.1g perfluoropolyether methacrylate, 0.01g N-methylolacrylamide, keep warm at 58°C, stir at high speed for 60min, and then sonicate for 20min to obtain the pre-emulsion.

[0033] (2) in N 2 Under protection, add 4mL of the above-mentioned pre-emulsion into a sealed three-necked flask equipped with a thermometer and a condenser tube, raise the temperature to 60°C, slowly add the aqueous solution of the initiator APS within 30 minutes, heat up to 70°C to polymerize, and the solution is blue. Finally, within 1.5 to 2.5 hours, add the remaining pre-emulsion to the three-necked flask at a constant speed, continue to react for 4 hours after the addition, and cool down to room temperature naturally.

[0034] The polymer obtained above was formulated into a solut...

Embodiment 2

[0036] (1) In a 100mL single-necked flask, add 50mg of emulsifier Pingping O, 15mg of SDS, 10mL of water, 2mL of acetone, raise the temperature to 100°C, stir at high speed for 30min, then slowly add monomer: 0.5g of methyl methacrylate, 0.5g butyl acrylate, 0.4g perfluoropolyether methacrylate, 0.01g N-methylolacrylamide, keep warm at 100°C, stir at high speed for 80min, and then sonicate for 20min to obtain the pre-emulsion.

[0037] (2) in N 2 Under protection, add 4mL of the above-mentioned pre-emulsion into a sealed three-necked flask equipped with a thermometer and a condenser tube, raise the temperature to 60°C, slowly add the aqueous solution of the initiator APS within 30 minutes, heat up to 70°C to polymerize, and the solution is blue. Finally, within 1.5 to 2.5 hours, add the remaining pre-emulsion to the three-necked flask at a constant speed, continue to react for 4 hours after the addition, and cool down to room temperature naturally.

[0038] The polymer obtain...

Embodiment 3

[0040] (1) In a 100mL single-necked flask, add 50mg emulsifier FM, 15mgSDS, 12mL water, heat up to 120°C, stir at high speed for 30min, then slowly add monomers: 0.5g methyl methacrylate, 0.5g butyl acrylate , 0.4g perfluoropolyether methacrylate, 0.01g N-methylolacrylamide, keep warm at 120°C, stir at high speed for 60min, and then sonicate for 20min to obtain the pre-emulsion.

[0041] (2) in N 2Under protection, add 4mL of the above-mentioned pre-emulsion into a sealed three-necked flask equipped with a thermometer and a condenser tube, raise the temperature to 60°C, slowly add the aqueous solution of the initiator APS within 30 minutes, raise the temperature to 75°C to polymerize, and the solution has blue light Finally, within 1.5 to 2.5 hours, add the remaining pre-emulsion to the three-necked flask at a constant speed, continue to react for 4 hours after the addition, and cool down to room temperature naturally.

[0042] The polymer obtained above was formulated into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com