Process for preparing double component spunbonded nonwoven fabrics

A technology of non-woven fabrics and manufacturing methods, applied in non-woven fabrics, textiles and papermaking, fiber processing and other directions, can solve problems such as poor softness and water repellency, hard product feel, and monotonous product varieties, and achieve good water repellency, High tear strength and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

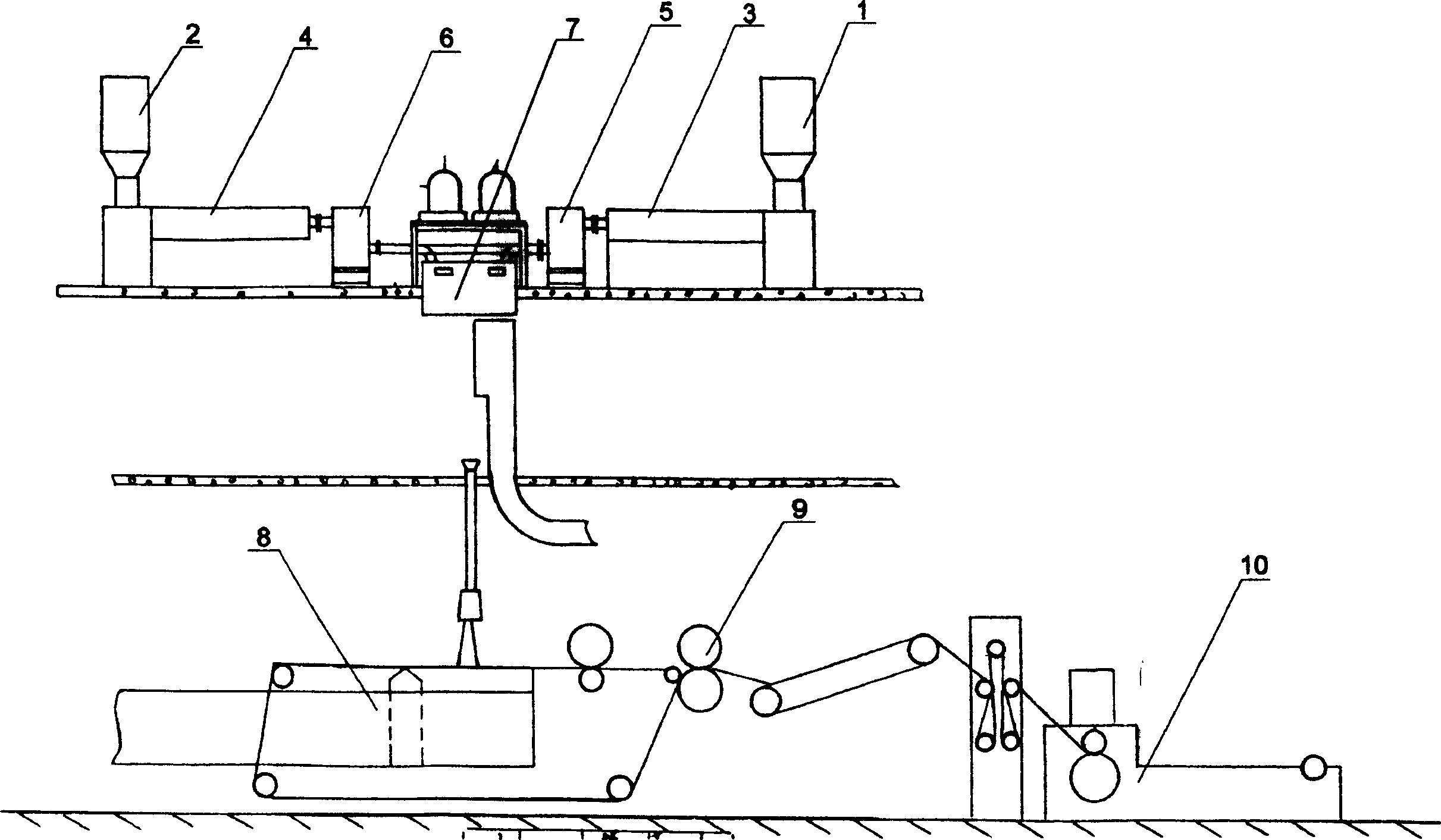

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0022] The manufacture of polyethylene / polypropylene bicomponent spunbond nonwovens is achieved through the following steps:

[0023] (1) Feeding and melting: the raw material slices of the two components of sliced polypropylene and sliced polyethylene are respectively added to feed bins 1 and 2, and are respectively heated and melted in screw extruders 3 and 4 and extruded out of the screw extruder. After entering the respective melt filter devices 5 and 6 to filter and remove impurities, they become polyethylene and polypropylene spinning melts;

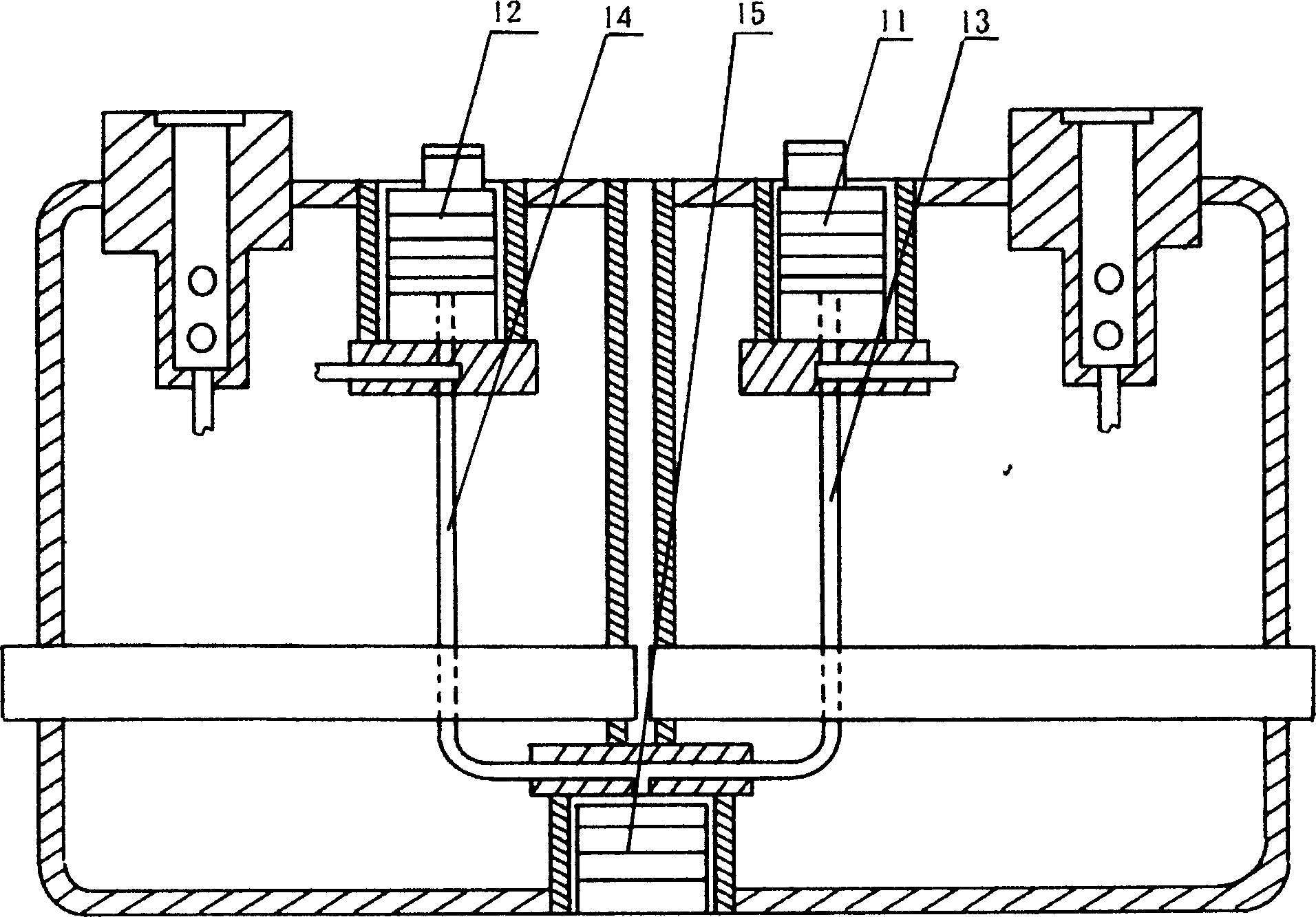

[0024] (2) Composite spinning: polyethylene, polypropylene spinning melt enters composite spinning box 7 through pipeline respectively, two metering pumps 11,12, then pass through two melt pipelines 13,14 of equal length, respectively Converged on the spinneret 15 to form a composite filament tow, two spinne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com