Medical protective clothing fabric and preparation method thereof

A technology of protective clothing and fabrics, applied in the field of textile fabrics, can solve the problems of increasing patient treatment costs, environmental pollution, etc., and achieve the effects of reducing consumption costs, reducing infection risks, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the medical protective clothing fabric provided by the invention is energy-saving and environmentally friendly, and is simple and easy to operate, thereby reducing the preparation cost of the medical protective clothing fabric.

[0043] In a preferred embodiment of the present invention, cold pad stacking dyeing includes the following steps: padding the base fabric 101 with dye and lye at room temperature, then rolling and stacking and slowly rotating for 40-50 hours, and then draining the liquid and washed. In the present invention, room temperature refers to 25°C.

[0044] This preferred embodiment not only removes all the grease, impurities, dust, etc. contaminated on the base fabric 101 through the cold pad stack dyeing treatment, thereby improving the dyeing effect, but also makes the dyeing of medical protective clothing fabrics uniform and bright, improving the aesthetics of medical protective clothing fabrics At the same time, it can a...

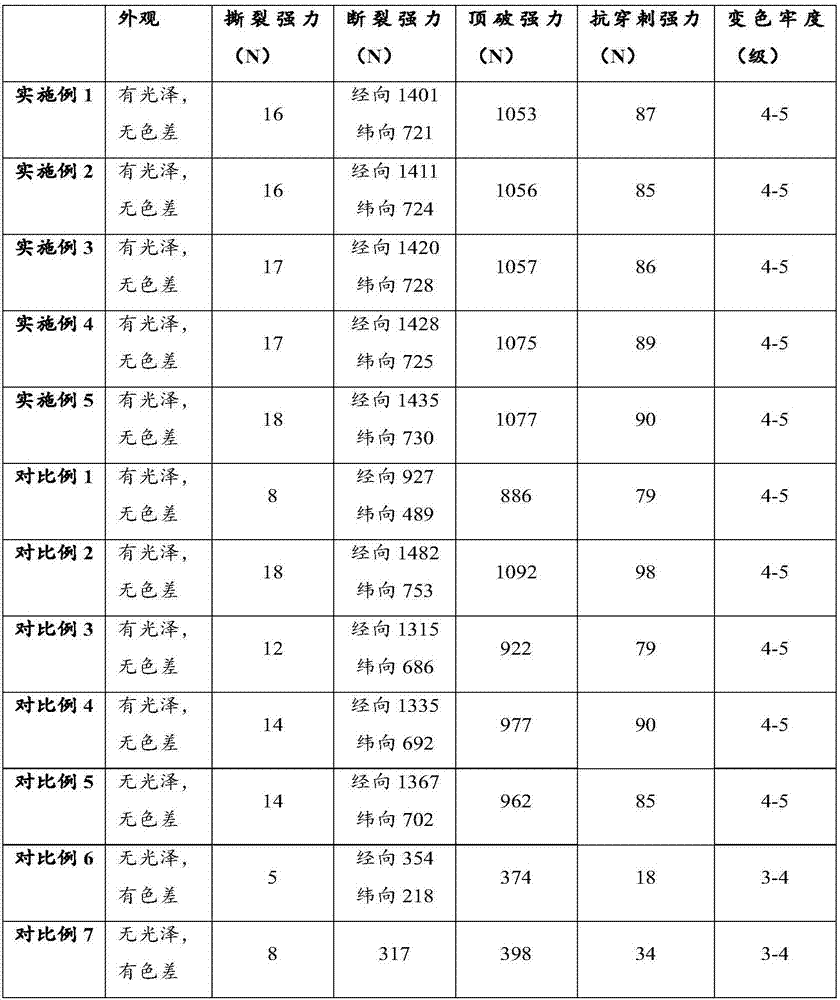

Embodiment 1

[0051] This embodiment provides a medical protective clothing fabric, including a base fabric, the outer surface of the base fabric is provided with a hydrophobic layer, the base fabric is woven by warp yarns and weft yarns, the warp density of the base fabric is 65 pieces / cm, and the base fabric The weft density is 32 pieces / cm, and the warp yarn is 70D / 38F polyester filament, and the weft yarn is 80D / 34F polyester filament.

[0052] The preparation method of the medical protective clothing fabric provided by the embodiment of the present invention comprises the following steps:

[0053] Step 1. Weaving the base fabric

[0054] Using 70D / 38F polyester filament as the warp yarn and 80D / 34F polyester filament as the weft yarn, weaving into a base fabric with a warp density of 65 pieces / cm and a weft density of 32 pieces / cm;

[0055] Step two, cold pad dyeing

[0056] At room temperature, the base fabric was soaked with pad dyeing solution and lye solution, then rolled and sta...

Embodiment 2

[0063] This embodiment provides a medical protective clothing fabric, including a base fabric, the outer surface of the base fabric is provided with a hydrophobic layer, the base fabric is woven from warp yarns and weft yarns, and the warp density of the base fabric is 75 pieces / cm. The weft density is 35 pieces / cm, and the warp yarn is 72D / 36F polyester filament, and the weft yarn is 78D / 36F polyester filament.

[0064] The difference between the preparation method of the medical protective clothing fabric provided in the embodiment of the present invention and the embodiment 1 is that:

[0065] In step 1, using 72D / 36F polyester filaments as warp yarns and 78D / 36F polyester filaments as weft yarns, weaving into a base fabric with a warp density of 75 pieces / cm and a weft density of 35 pieces / cm;

[0066] In step 2, the time for rolling and standing is 50 hours;

[0067] In step 3, the mass ratio of the water-repellent agent to the water-repellent synergist is 40:1; and in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com