Non-return valve for plasticizing screw of injection molding machine

A technology of plasticizing screw and locker, which is applied in the field of backflow locker for plasticizing screw of injection molding machine, which can solve the problems of high pressure, large shear heat, affecting the quality of plastic melt and injection molded parts, and achieve self-improvement Cleans, improves pressure reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

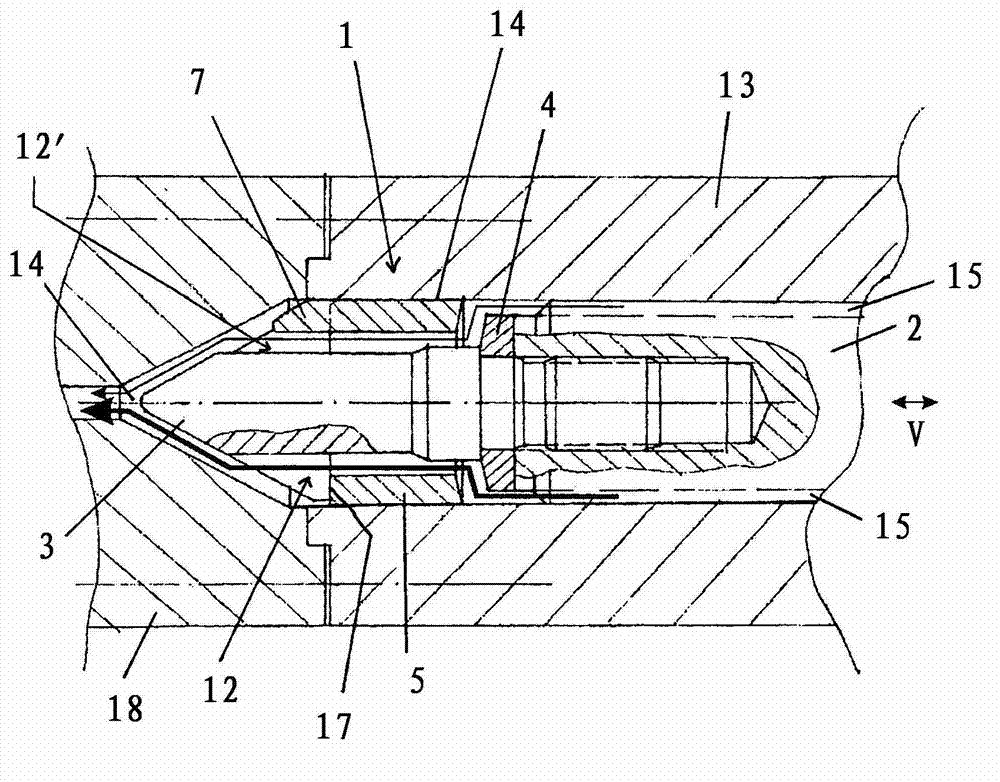

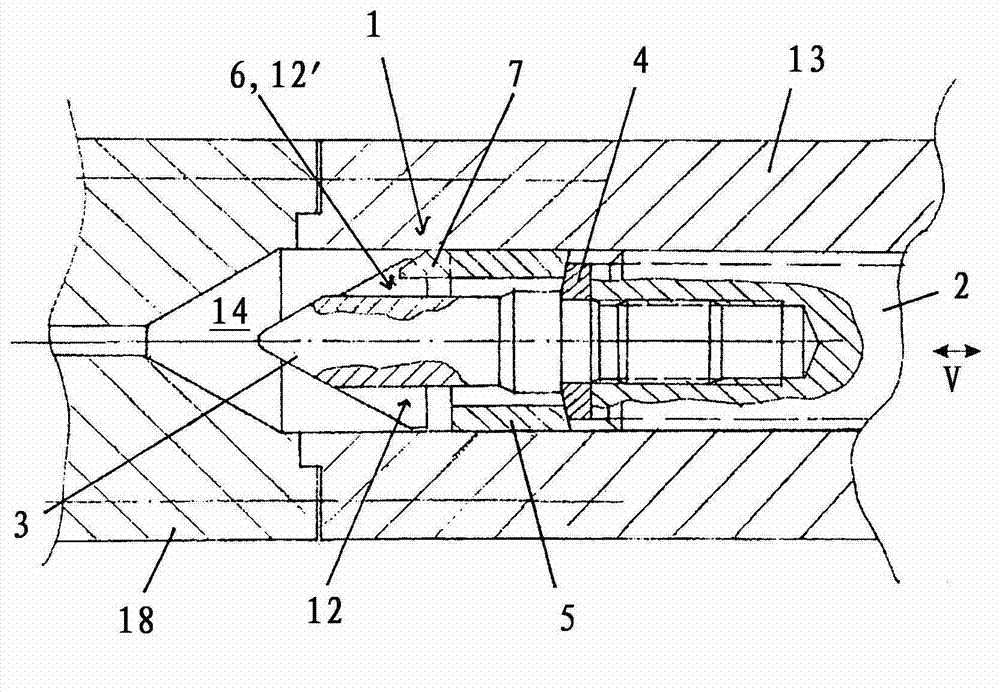

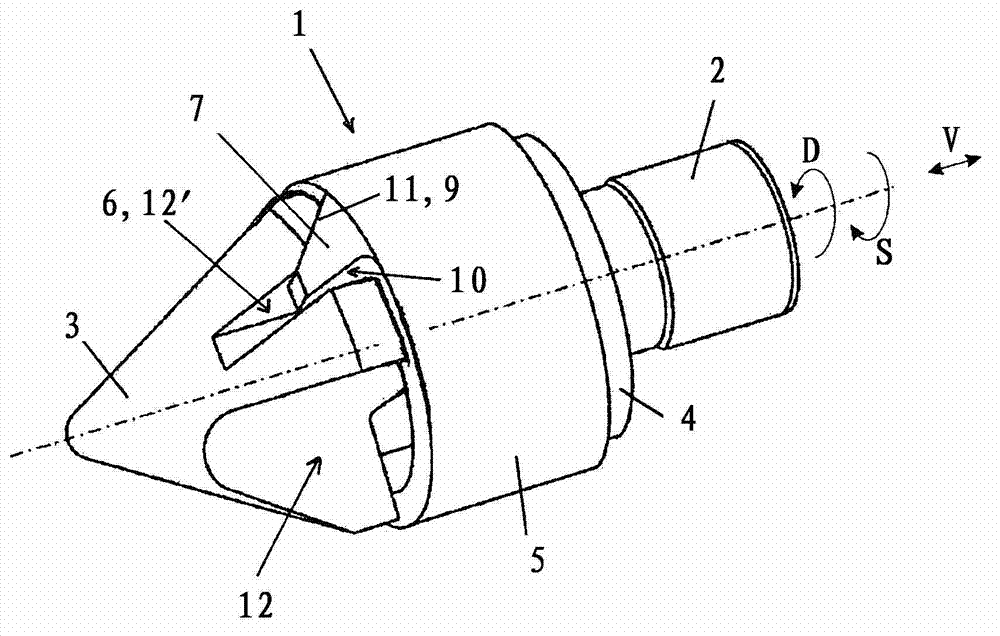

[0019] figure 1 The important parts of an injection molding machine for illustrating a first advantageous embodiment of the backflow lock 1 according to the invention are schematically shown in . Part of a plasticizing screw 2 can be seen, which is arranged rotatably and displaceably in a plasticizing cylinder 13 . Arranged on the tip 3 of the plasticizing screw 2 is a backflow lock 1 comprising a thrust ring 4 and a locking ring 5 arranged displaceably relative to the tip 3 and to the thrust ring 4 . The direction of movement of the locking ring 5 or of the plasticizing screw 2 is assigned the reference symbol V. The tip 3 has two guide rails 6 for the two carriers 7 arranged on the locking ring 5 and, in addition to the two guide rails 6 , four flow channels 12 and 12' for the plastic melt, wherein , only one of the two guide rails 6 and two of the four flow channels 12 and 12' can be seen in this figure. One of the visible flow channels, designated with the reference num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com