Head washing machine

A hair washing machine and mixing faucet technology, which is applied in the field of hair washing machines and can solve the problems of easily damaged hoses and hose joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in detail through the following examples.

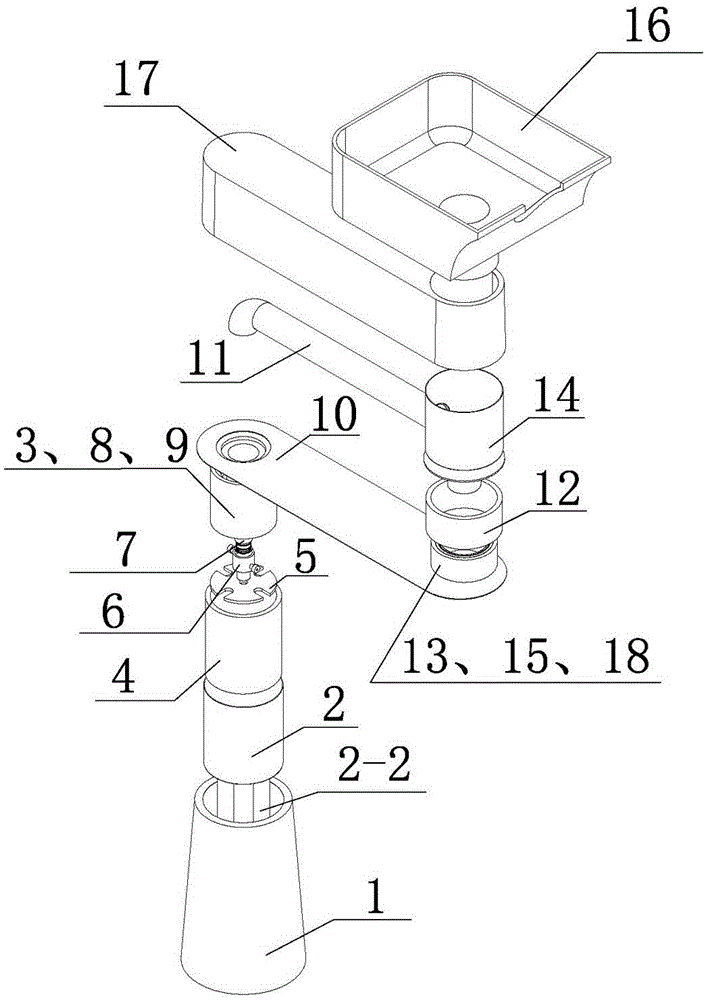

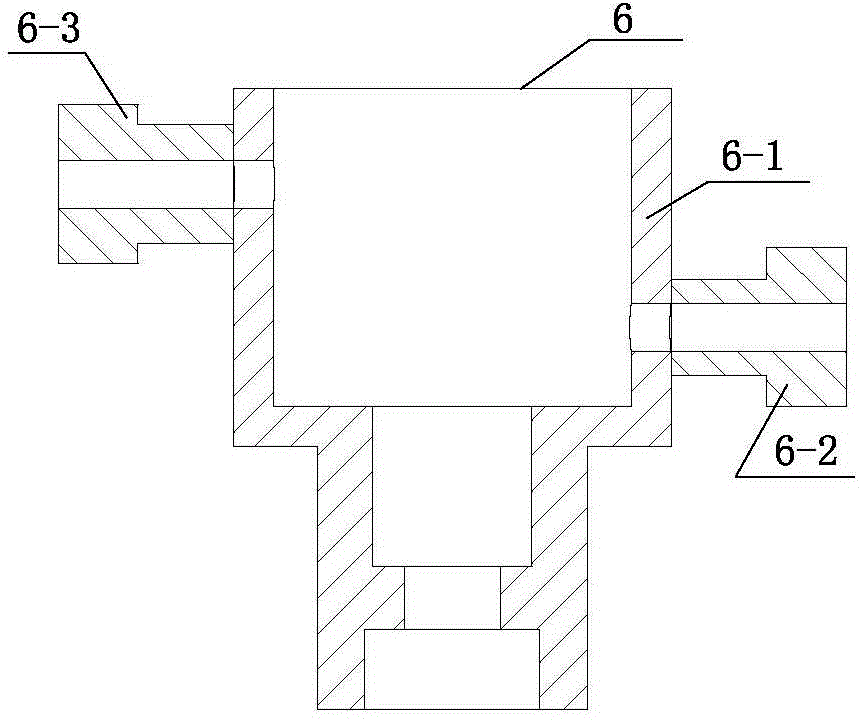

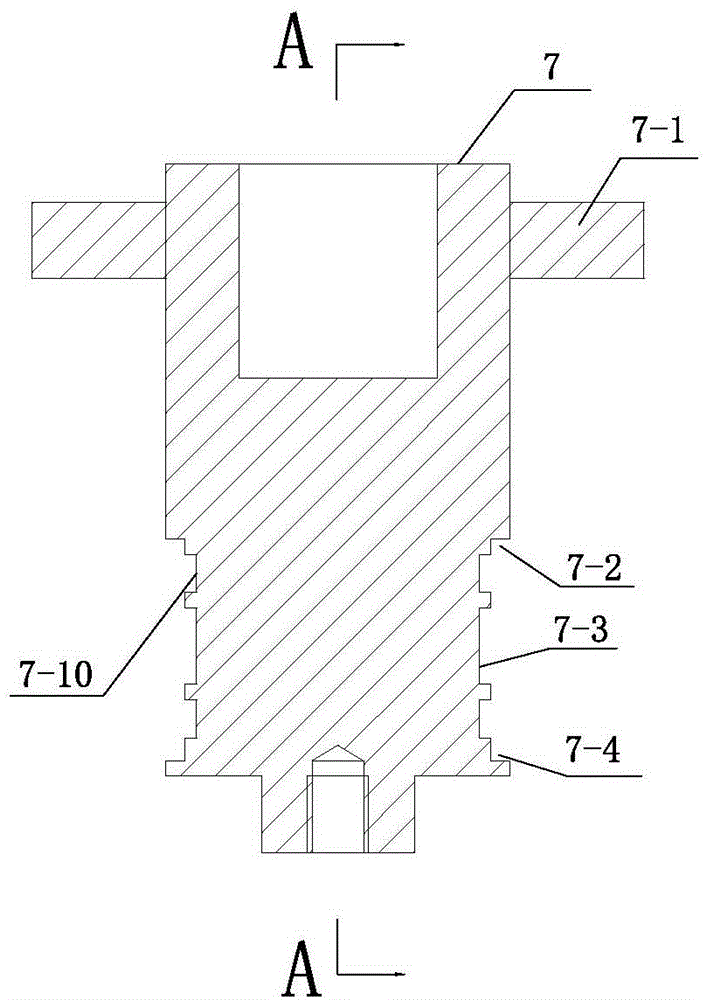

[0021] See Figure 1-Figure 11 As shown, a shampoo machine mainly consists of tank 16, second ball bearing 18, upper support 14, pipe 11, first ball bearing 8, rotating shaft 7, rotating sleeve 6, spacer 5, support 2, The cold and hot water mixing faucet is composed of cold and hot water hoses. The tank 16 is equipped with a cold and hot water mixing faucet. The bottom of the tank 16 is connected to one end of the horizontally arranged pipe 11 through the upper support 14, and the other end of the pipe 11 is connected to The cylinder 2-1 of the support 2 is connected, a support plate 10 is provided under the pipe 11, and a pipe cover 17 is installed on the support plate 10. The pipe 11 and the upper support 14 are hidden in the pipe cover 17 to become a horizontal arm, the support 2 The outer cover 1 is installed on the outside, and a water inlet hose 360° rotating splicing mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com