Epoxy resin with super-hydrophobic surface and preparation method for epoxy resin

A technology of super-hydrophobic surface and epoxy resin, which is applied in the direction of coating, etc., can solve the problems of affecting the performance and reducing the mechanical strength, and achieve the effect of stable super-hydrophobic properties, good reproducibility and excellent self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

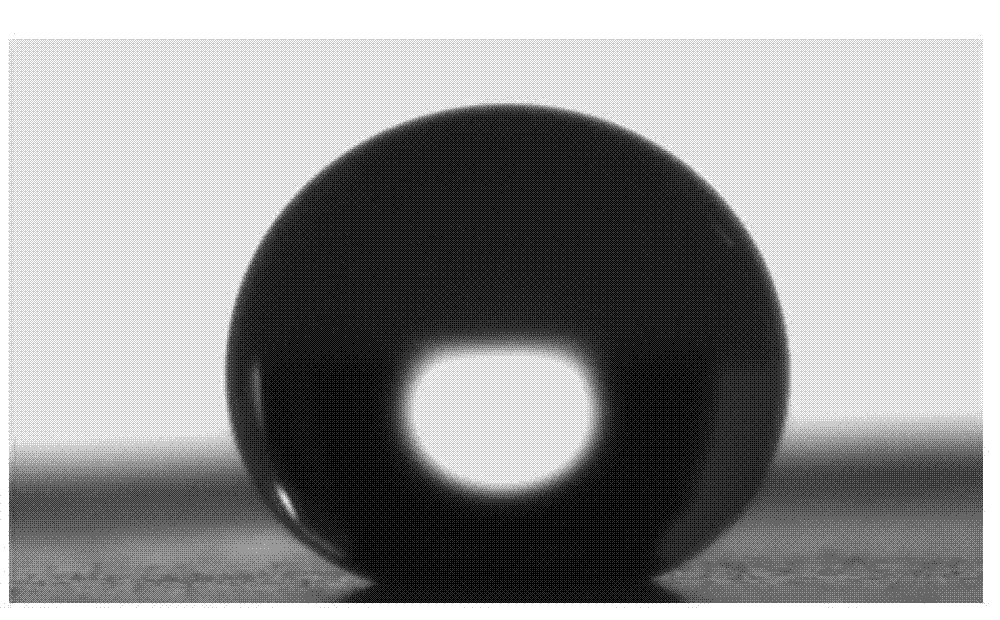

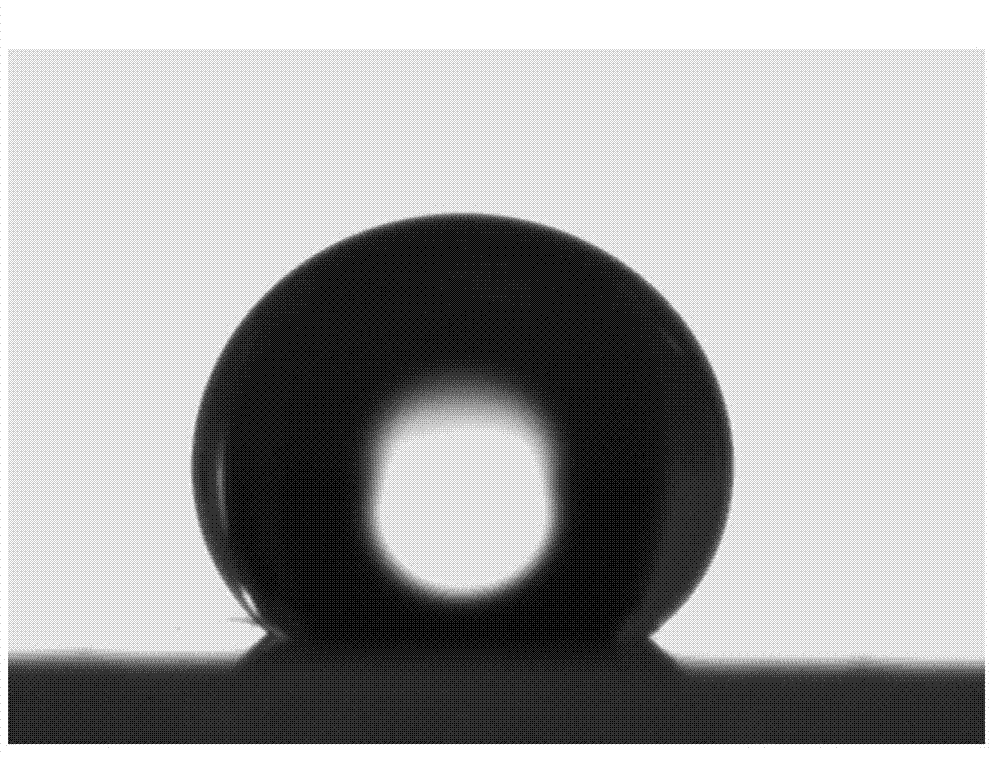

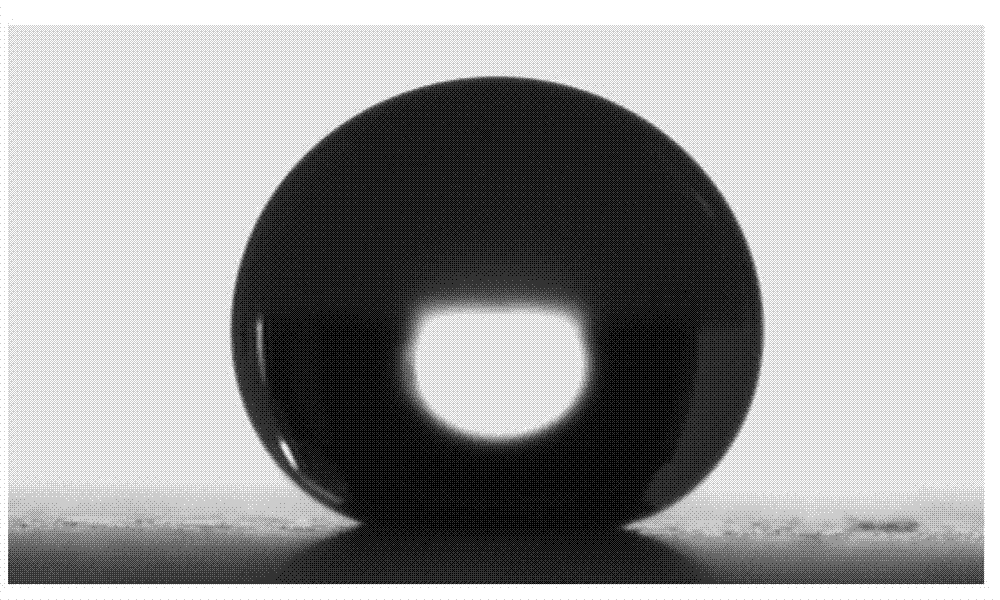

Image

Examples

Embodiment 1

[0031] First, sand the surface of the epoxy resin matrix to remove surface defects, then blow off the dust on the surface with a hair dryer, then clean it with tap water, and dry it naturally before use;

[0032] Weigh 20g of E-51 epoxy resin glue (purchased from Yueyang Baling Petrochemical Company) and add it to 100g of acetone for full dilution, then add 1.6g of diethylenetriamine, and mix well by stirring;

[0033] Apply the prepared epoxy resin glue evenly on the epoxy resin matrix with a brush;

[0034] Dissolve 1 gram of polyvinylpyrrolidone in 100ml of absolute ethanol, then slowly add 1 gram of spherical nano-zinc oxide powder with an average particle size of 10 nm into the absolute ethanol in which polyvinylpyrrolidone is dissolved and fully disperse with ultrasonic waves, The nano zinc oxide is uniformly dispersed in ethanol to form a uniform and stable suspension.

[0035] The epoxy resin matrix coated with glue was slowly taken out after dipping in the nano-zinc ...

Embodiment 2

[0039] First, sand the surface of the epoxy resin matrix to remove surface defects, then blow off the dust on the surface with a hair dryer, then clean it with tap water, and dry it naturally before use;

[0040] Weigh 20g of E-51 epoxy resin glue and add it to 1000g of acetone for full dilution, then add 1.6g of diethylenetriamine, and mix evenly by stirring;

[0041] Apply the prepared epoxy resin glue evenly on the epoxy resin matrix with a brush;

[0042] Dissolve 0.5 gram of polyvinylpyrrolidone in 100ml of absolute ethanol, then slowly add 1.5 grams of spherical nano-zinc oxide powder with an average particle size of 30 nanometers into the absolute ethanol in which polyvinylpyrrolidone is dissolved and fully disperse with ultrasonic waves, The nano zinc oxide is uniformly dispersed in ethanol to form a uniform and stable suspension.

[0043] The epoxy resin matrix coated with glue was dipped in the nano-zinc oxide suspension for 1 minute, then slowly taken out, and then...

Embodiment 3

[0047] First, sand the surface of the epoxy resin matrix to remove surface defects, then blow off the dust on the surface with a hair dryer, then clean it with tap water, and dry it naturally before use;

[0048] Weigh 10g of E-51 epoxy resin glue and add it to 500g of acetone for full dilution, then add 0.8g of diethylenetriamine, and mix evenly by stirring;

[0049] Apply the prepared epoxy resin glue evenly on the epoxy resin matrix with a brush;

[0050] Dissolve 1 gram of polyvinylpyrrolidone in 1000ml of absolute ethanol, then slowly add 1 gram of spherical nano-zinc oxide powder with an average particle size of 50 nm into the absolute ethanol in which polyvinylpyrrolidone is dissolved and fully disperse it with ultrasonic waves. The nano zinc oxide is uniformly dispersed in ethanol to form a uniform and stable suspension.

[0051] The coated epoxy resin matrix was dipped in the nano-zinc oxide suspension for 1 minute, then slowly taken out, and then cured in a vacuum dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com