Coating device and coating method for graphene lithium battery pole piece

A coating device and battery pole piece technology, applied in the field of coating, can solve the problems of uneven coating, falling and low coating quality, and achieve the effects of uniform coating, increasing current intensity and improving coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

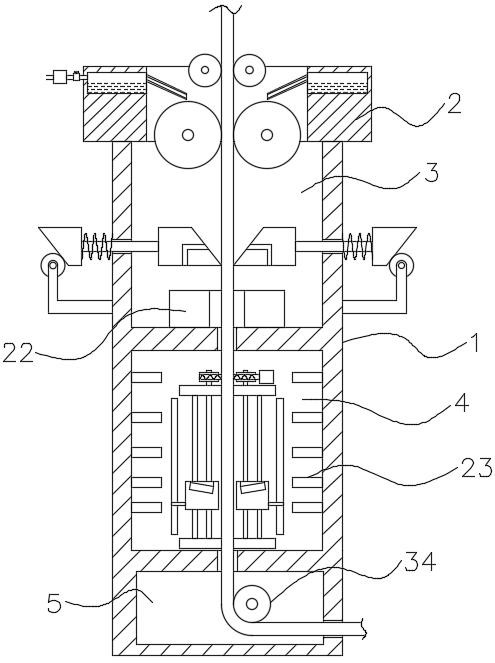

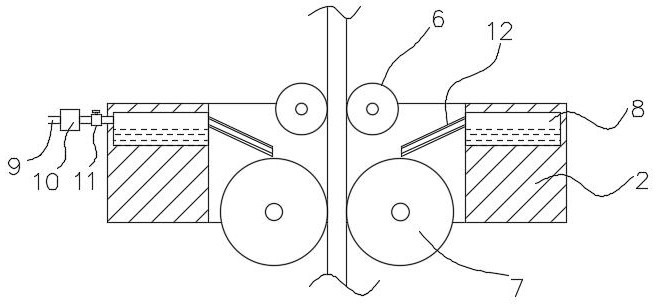

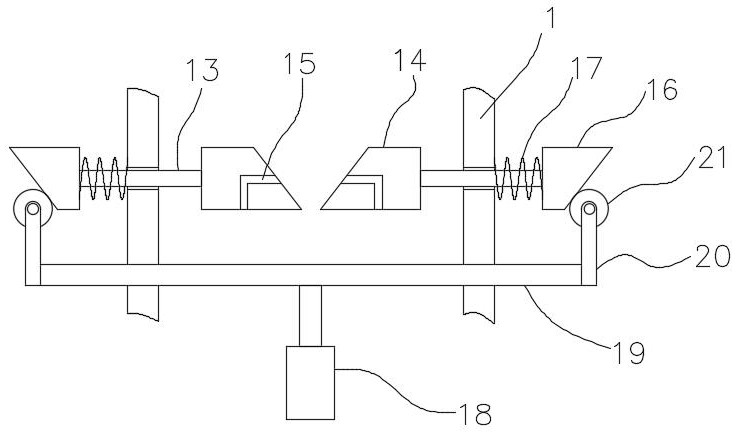

[0030] refer to Figure 1-4 , a coating device for a graphene lithium battery pole piece, comprising a coating device body 1, a coating chamber 3, a drying chamber 4 and a transfer chamber 5 are provided in the coating device body 1 from top to bottom, and the coating chamber 3 The upper side of the upper side is open and the top plate 2 is fixedly connected to the opening. A coating port is opened in the top plate 2. A pair of guide rollers 6 and a pair of coating rollers 7 are installed on the inner walls of both sides of the coating port from top to bottom. Both coating rollers 7 are connected with the first motor, and telescopic air cylinders are installed on the side where the two first motors are far away from each other. It should be noted that the first motor and the coating roller 7 can move in the horizontal direction, and the coating The roller 7 includes a roller shaft inserted on the axis, the two ends of the roller shaft are connected with the bearing seat, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com