Preparation method of super-elasticity graphene aerogel

A graphene aerogel, superelasticity technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as limiting production efficiency, increasing production costs, etc., achieving broad market prospects, reducing preparation costs, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

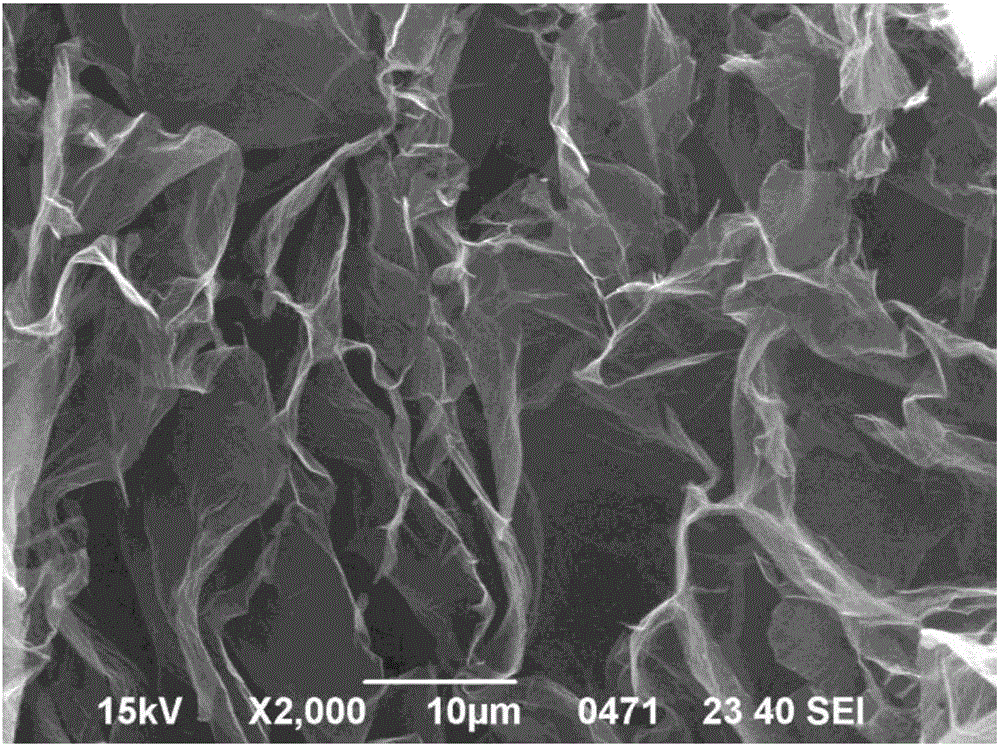

[0021] The preparation method of the superelastic graphene airgel that the present embodiment relates to, its concrete process step comprises:

[0022] (1) Add 5 mg of hydrazine hydrate as a reducing agent to a reaction vessel containing 10 ml of a graphene oxide solution with a concentration of 5 mg / ml, and stir in a water bath at 20° C. for 20 minutes so that the graphene oxide solution and hydrazine hydrate fully undergo an oxidation-reduction reaction, Prepare the mixed solution containing graphene for subsequent use;

[0023] (2), trim the polyurethane foam into the same shape as the graphene airgel that needs to be prepared with a trimming tool at room temperature, and the volume of the processed polyurethane foam block is 4.8-5.2cm 3 , put the polyurethane foam block into the mixed solution to absorb the mixed solution for 5-30 minutes, then place the reaction vessel in a 70°C oil bath and heat it for 20 hours to obtain a graphene-polyurethane hydrogel, remaining hydraz...

Embodiment 2

[0028] The preparation method of the superelastic graphene airgel that the present embodiment relates to, its concrete process step comprises:

[0029] (1), adding 150 mg of ascorbic acid as a reducing agent in a reaction dish containing 10 ml of a graphene oxide solution with a concentration of 7.5 mg / ml, stirred in a water bath at 10° C. for 60 minutes to make the graphene oxide solution and ascorbic acid fully undergo an oxidation-reduction reaction, and prepare Obtain the mixed solution containing graphene for subsequent use;

[0030] (2), trim the polypropylene foam block into the same shape as the graphene airgel that needs to be prepared with a trimming tool at room temperature, and the volume of the processed polypropylene foam block is 4.8-5.2cm 3 , put the polypropylene foam block into the mixed solution to absorb the mixed solution for 30 minutes, then place the reaction vessel in an oil bath at 100°C and heat it for 8 hours to obtain a graphene-polypropylene hydrog...

Embodiment 3

[0035] The preparation method of the superelastic graphene airgel that the present embodiment relates to, its concrete process step comprises:

[0036] (1) Add 150 mg of sodium borohydride as a reducing agent to a reaction vessel containing 10 ml of a graphene oxide solution with a concentration of 12 mg / ml, and stir in a water bath at 30° C. for 100 minutes so that the graphene oxide solution and sodium borohydride are fully oxidized and reduced Reaction, prepare the mixed solution containing graphene for subsequent use;

[0037] (2), trim the polyethylene terephthalate foam block into the same shape as the graphene airgel that needs to be prepared with a trimming tool at room temperature, and the processed polyethylene terephthalate foam The block has a volume of 5 cm 3 , put the polyethylene terephthalate foam block into the mixed solution to absorb the mixed solution for 30 minutes, then place the reaction vessel in an oil bath at 60°C and heat it for 24 hours to obtain g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Cell size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com