Zinc-air battery pack employing vertical circulation of electrolyte

A battery pack and electrolyte technology, applied in the field of electrolyte vertical circulation zinc-air battery pack, can solve problems such as insufficient current intensity, achieve easy replacement and disassembly, improve the effect of insufficient current intensity, and improve electrolyte dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

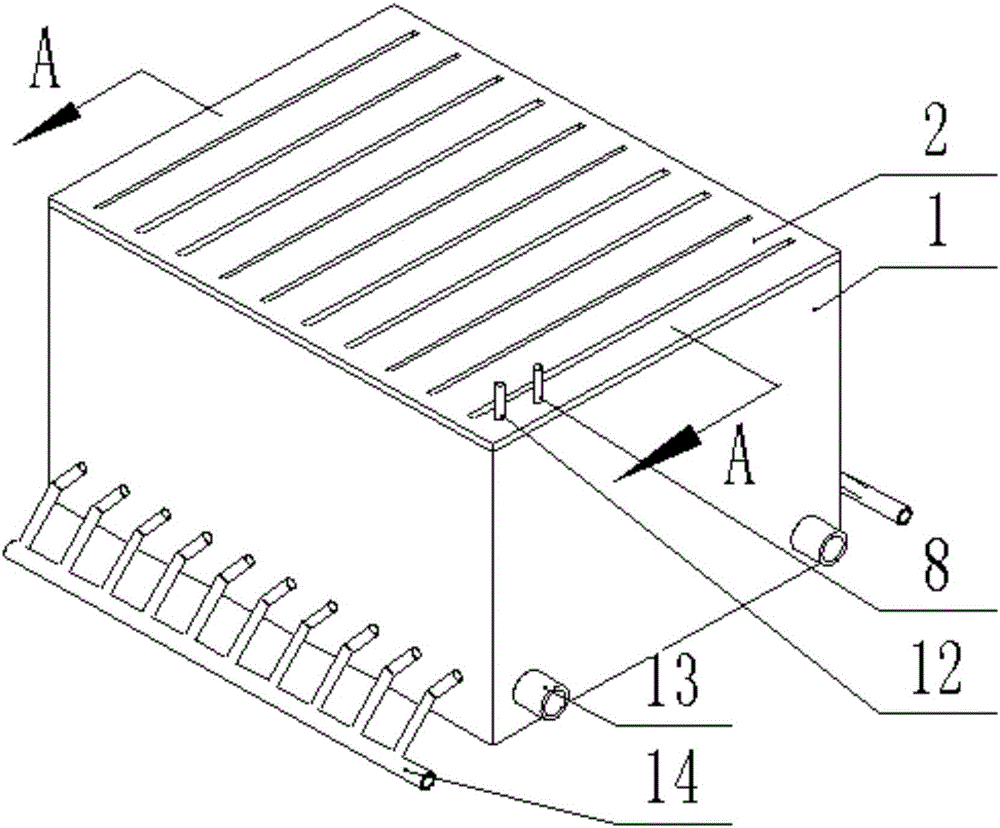

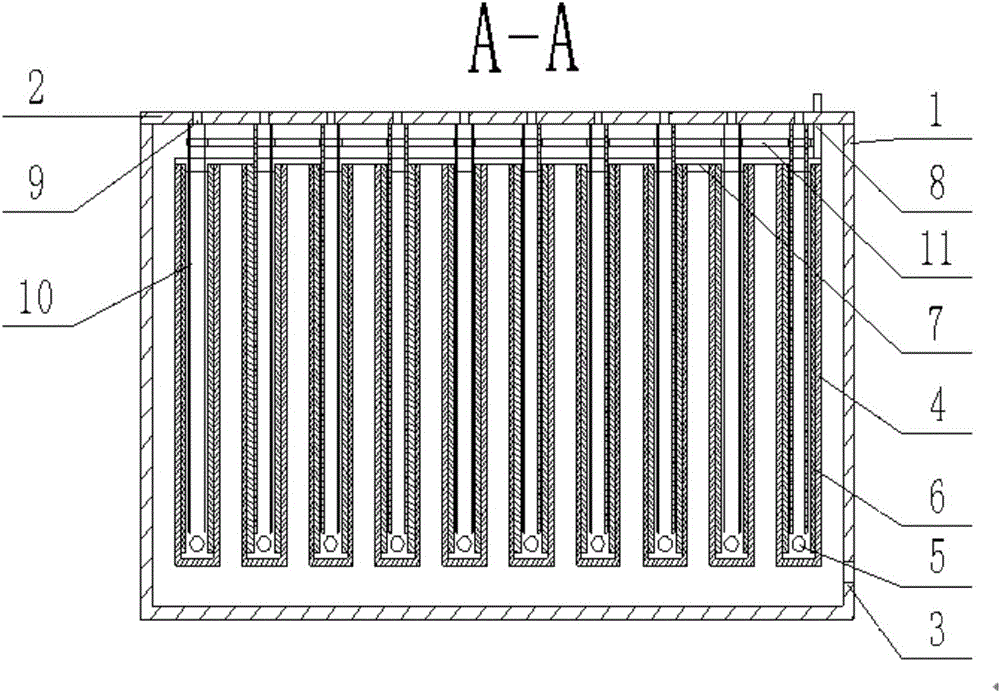

[0020] A kind of electrolytic solution vertical circulation zinc-air battery pack (see Figure 1-7 , referred to as the battery pack), including box 1, top plate 2, zinc pole support frame 4, zinc anode plate 6, zinc pole conductive sheet 7, anode terminal 8, air cathode plate 10, air electrode conductive sheet 11 and cathode terminal 12;

[0021] The box body 1 and the top plate 2 are sealed and connected to form the main part of the battery pack; the zinc pole support frame 4 is a U-shaped structure with an open upper end, a closed lower end, and vertically placed side plates; the outer side of the zinc pole support frame 4 The wall is sealed and connected to the inner side wall of the box body 1, and there are gaps between the bottom and top of the zinc pole support frame 4 and the box body 1; there is no contact between each zinc pole support frame 4; the bottom of the side wall of the box body 1 is open There is an electrolyte return hole 5, the hole is located inside th...

Embodiment 2

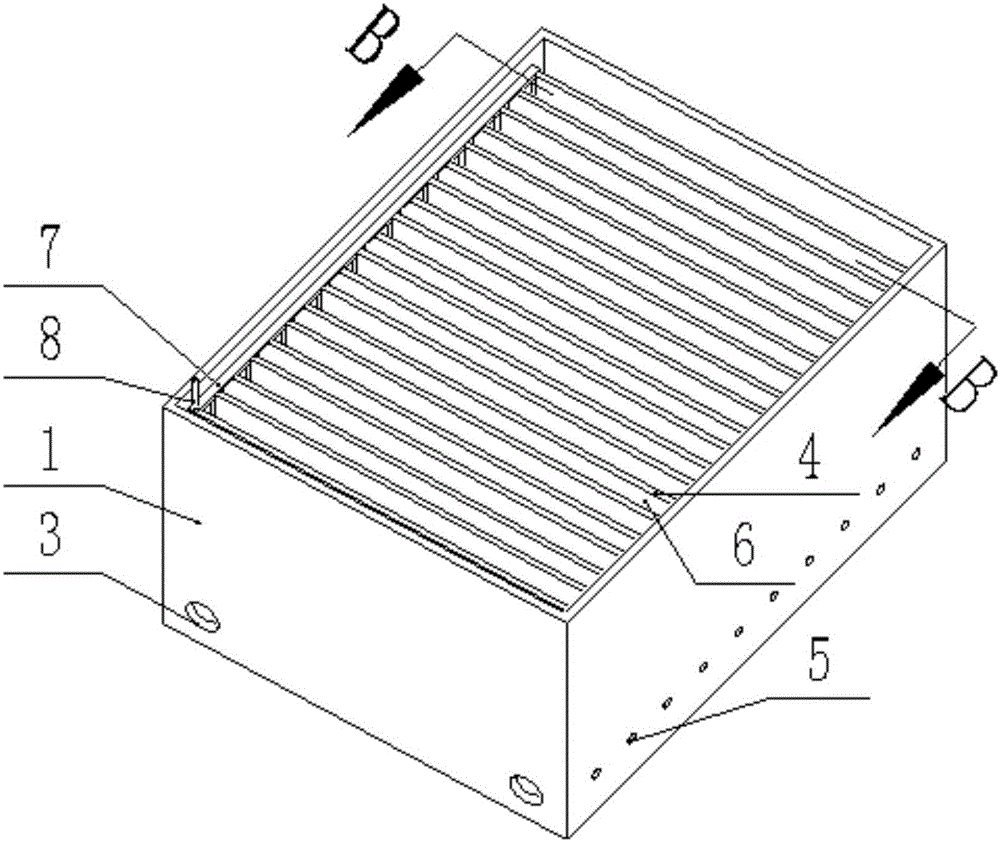

[0024] An electrolyte vertical circulation zinc-air battery pack (battery pack for short), comprising a box body 1, a top plate 2, a zinc pole support frame 4, a zinc anode plate 6, a zinc pole conductive sheet 7, an anode terminal 8, and an air cathode plate 10. Air electrode conductive sheet 11 and cathode terminal 12;

[0025] The box 1 and the top plate 2 are sealed and connected to form the main part of the battery pack; the zinc pole support frame 4 is a V-shaped structure with an open upper end and a closed lower end, and the two side plates form an angle of 45° with the horizontal plane; the zinc pole support The outer wall of the frame 4 is sealed and connected with the inner wall of the box body 1, and there are gaps between the bottom and top of the zinc pole support frame 4 and the box body 1; there is no contact between each zinc pole support frame 4; the box body 1 There is an electrolyte return hole 5 at the bottom of the side wall, and the opening position is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com