Electrode for a welding torch for tungsten gas-shielded welding and welding torch having such an electrode

A technology of gas shielded welding and tungsten inert gas, which is applied in the fields of ion welding torch, electrode of ion welding torch, high current welding, and electrode of tungsten gas shielded welding torch, which can solve anode damage, High current density, increased self-amplification effect, etc., to avoid electrode damage and increase capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

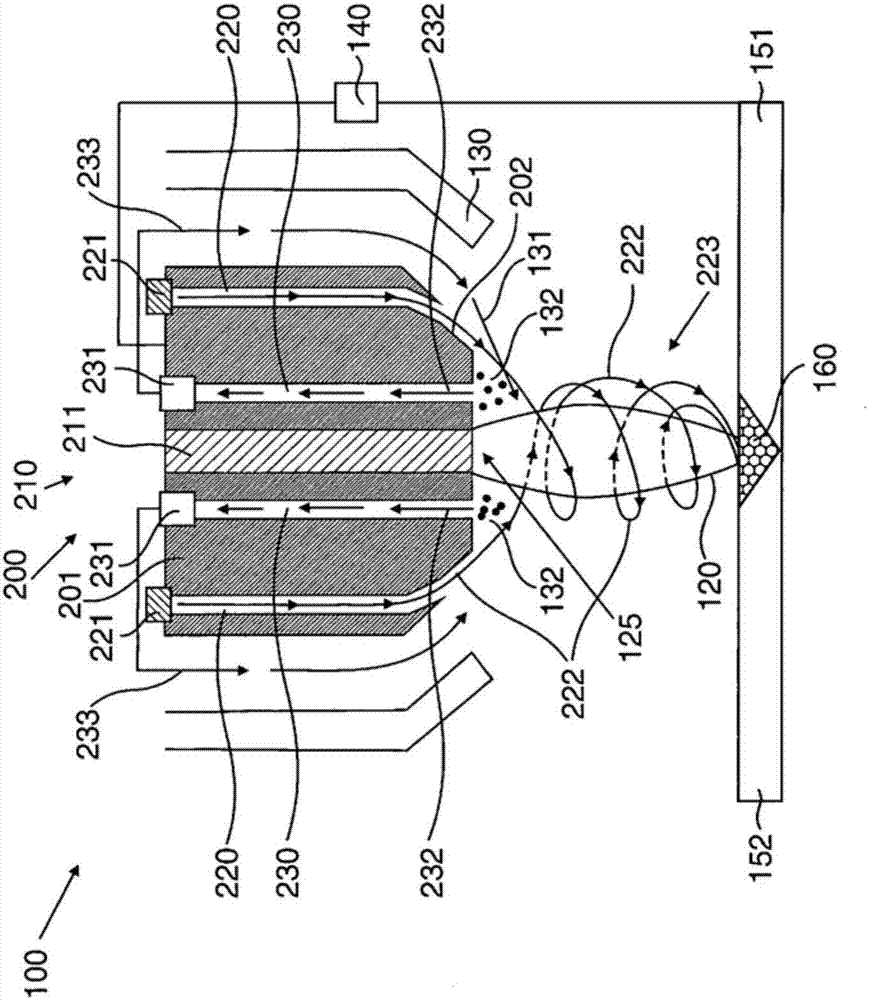

[0066] figure 1 A preferred embodiment of a welding torch referenced 100 for gas tungsten arc welding according to the invention is schematically depicted. In this example, the welding torch 100 is designed as a welding torch for gas tungsten arc welding. The welding torch 100 is used to weld the first workpiece 151 and the second workpiece 152 in a joining process.

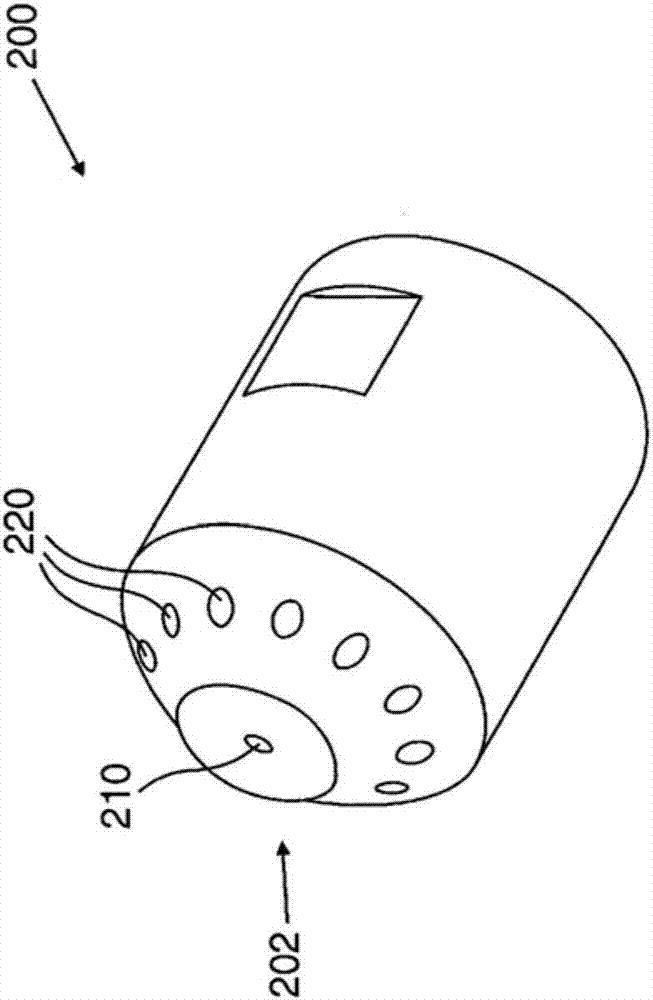

[0067] The welding torch 100 has an electrode 200 according to a preferred embodiment of the invention. The workpieces 151 , 152 and the electrode 200 are electrically connected to the welding power source 140 . Therefore, the electrode 200 is supplied with welding current. Electrode 200 is used here as an anode, and workpieces 151 and 152 are used as cathodes. The arc 120 burns between the electrode 200 and the workpieces 151 , 152 . The arc 120 at least partially melts the first and second workpieces 151 , 152 to create a weld puddle 160 .

[0068] The welding torch 100 performs high current welding, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com