High-specific-surface-area boron-doped diamond electrode and preparation method and application thereof

A diamond electrode, high specific surface area technology, applied in the direction of electrodes, chemical instruments and methods, electrolysis process, etc., can solve the problems of electrodes restricting the mass transfer efficiency of the electrode surface, etc., to improve sewage treatment efficiency, improve current efficiency, and increase conductivity and the effect of electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

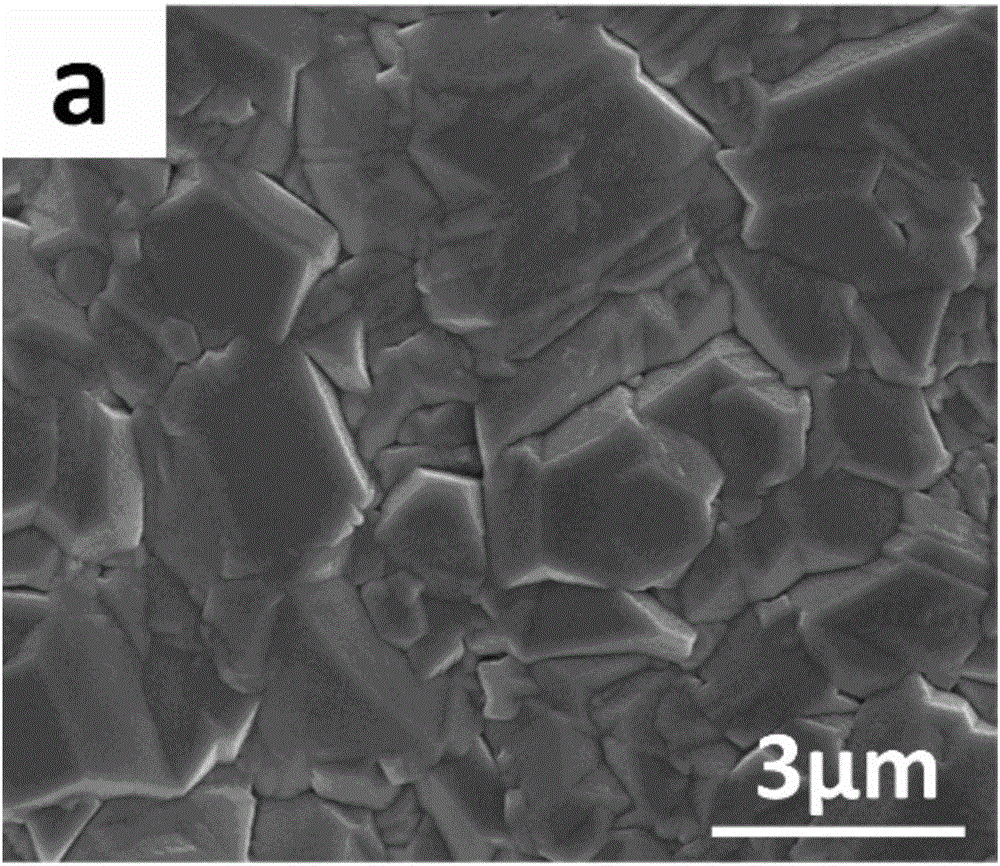

[0072] Embodiment 1: flat type (board)

[0073] (1) cleaning the flat niobium substrate;

[0074] (2) adopting the magnetron sputtering method to deposit a layer of metal chromium layer with a thickness of 500nm on the flat niobium surface;

[0075] (3) Place the chromium-modified flat niobium in the suspension of nanocrystalline and microcrystalline diamond mixed particles, vibrate in ultrasonic for 30 minutes, and disperse evenly to obtain a niobium matrix with nanocrystalline and microcrystalline diamond particles adsorbed on the surface .

[0076] (4) Boron-doped diamond film is deposited by hot wire CVD, deposition process parameters: hot wire distance 6mm, deposition temperature 700-750°C, hot wire temperature 2200°C, deposition pressure 3KPa, gas ratio (CH 4 :H 2 :B 2 h 6 ) (sccm) is 3:97:0.3, obtains diamond film thickness 20 μ m by controlling deposition time;

[0077] (5) The boron-doped diamond surface prepared in step (4) adopts the magnetron sputtering depos...

Embodiment 2

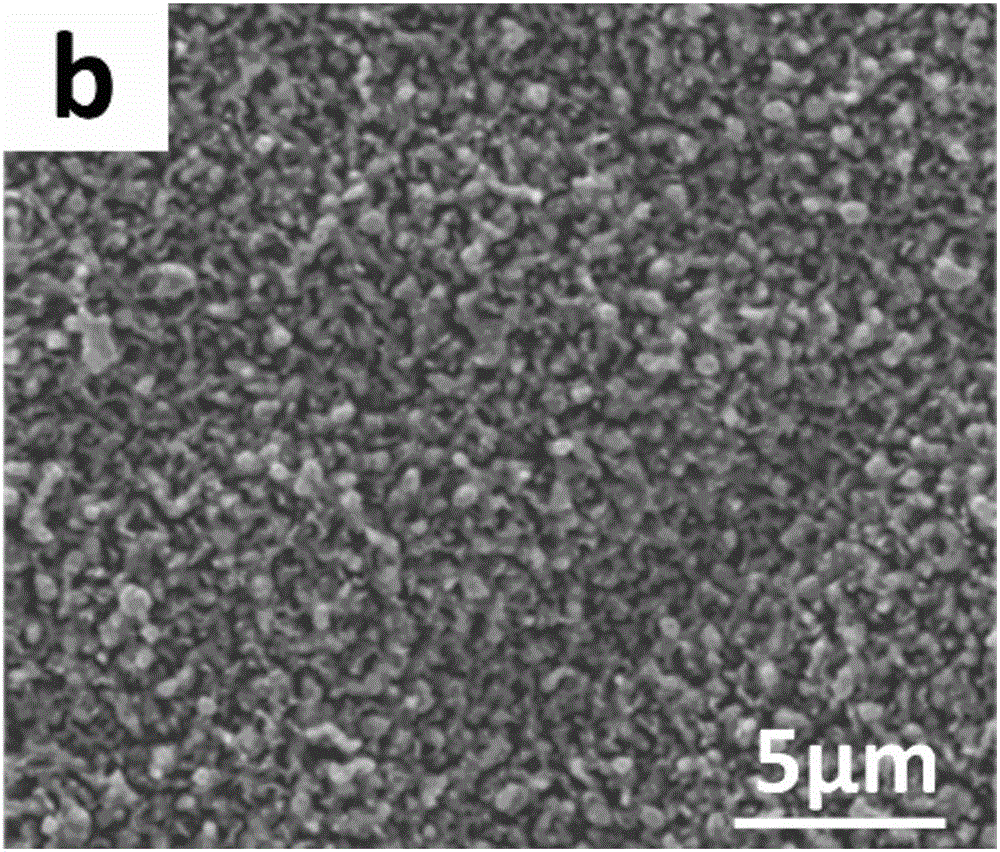

[0081] Embodiment 2: flat type (board)

[0082] (1) cleaning the tungsten sheet;

[0083] (2) Place the tungsten sheet in a suspension of mixed particles of nanocrystalline and microcrystalline diamond, oscillate in an ultrasonic wave for 30 minutes, and disperse evenly to obtain a niobium matrix with nanocrystalline and microcrystalline diamond particles adsorbed on the surface.

[0084] (3) Boron-doped diamond film was deposited by hot wire CVD, deposition process parameters: hot wire distance 6mm, deposition temperature 700-750°C, hot wire temperature 2200°C, deposition pressure 3KPa, gas ratio (CH 4 :H 2 :B 2 h 6 ) (sccm) is 3:97:0.3, obtains diamond film thickness 25 μ m by controlling deposition time;

[0085] (4) The boron-doped diamond surface prepared in step (3) adopts the magnetron sputtering deposition method to deposit a metal nickel layer, and the specific sputtering parameters are sputtering current 400mA, argon flow 10sccm, sputtering pressure 0.4Pa, sputte...

Embodiment 3

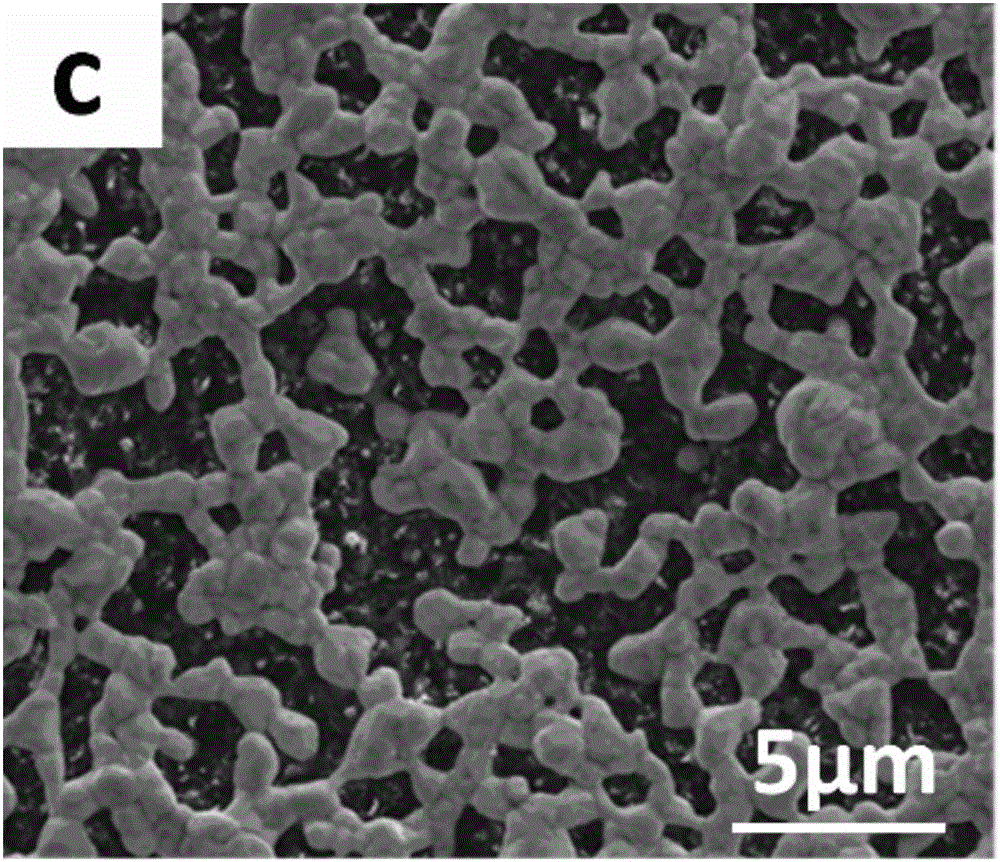

[0089] Embodiment 3: flat type (board)

[0090] (1) silicon wafer is cleaned;

[0091] (2) Place the silicon chip in a suspension of mixed particles of nanocrystalline and microcrystalline diamond, vibrate in an ultrasonic wave for 30 minutes, and disperse evenly to obtain a niobium substrate with nanocrystalline and microcrystalline diamond particles adsorbed on the surface.

[0092] (3) Boron-doped diamond film was deposited by hot wire CVD, deposition process parameters: hot wire distance 6mm, deposition temperature 700-750°C, hot wire temperature 2200°C, deposition pressure 3KPa, gas ratio (CH 4 :H 2 :B 2 h 6 )(sccm) is 3:97:0.3, deposition time 4h;

[0093] (4) The boron-doped diamond surface prepared in step (3) adopts the magnetron sputtering deposition method to deposit a metal nickel layer, and the specific sputtering parameters are sputtering current 400mA, argon flow 10sccm, sputtering pressure 0.4Pa, sputtering Time 60s;

[0094] (5) Put the sample obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com