Efficient water-cooling argon arc welding gun

A argon arc welding torch, water cooling technology, applied in arc welding equipment, electrode characteristics, welding equipment and other directions, can solve the problems of slow speed, low working current, low welding temperature, etc., to reduce the cost of use, improve the current intensity, improve welding effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

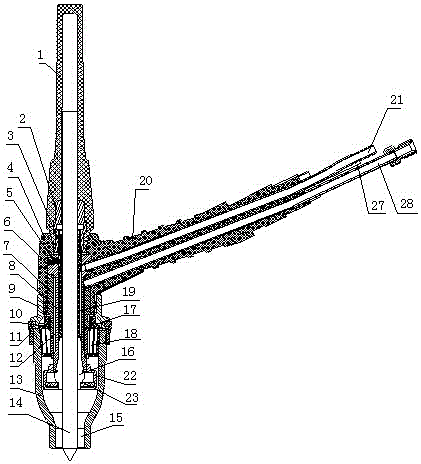

[0031] The method of use is as follows:

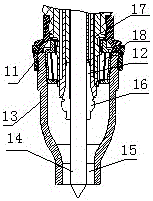

[0032] 1) First fix the tungsten pole clamp in the center hole of the gun head body with the positioning bolt, and then put the inner heat insulation sleeve on the outer edge of the ring groove on the outer circle of the gun head

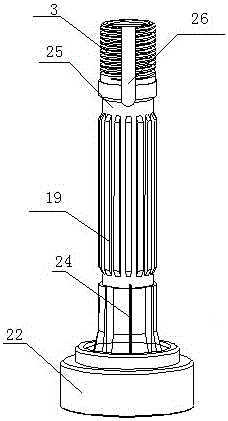

[0033] 2) Put the welding torch head assembly into the torch head body sheath from bottom to top, and the upper end of the tungsten pole clip is exposed from the top of the torch head body, and is fixed with the nut at the bottom of the back cap and the external thread on the top of the tungsten pole clip ;

[0034] 3) Screw the outer connecting sleeve to the lower end of the gun head body sheath, and the inner convex ring on the inner circle of the outer connecting sleeve presses and fixes the outer convex ring on the outer circle of the inner heat insulation sleeve in the gun head body;

[0035] 4) Fix the outer heat insulation sleeve on the outer circle of the inner heat insulation sleeve through threads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com