Completely transparent microfluidic acoustic body wave chip and preparation method thereof

A microfluidic and acoustic technology, applied in the field of micro-total analysis system, can solve problems such as unfavorable observation and optical analysis and identification, increase the cost of preparation, limit the scope of application, etc., to achieve improved optical performance, improved visibility, and expanded applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

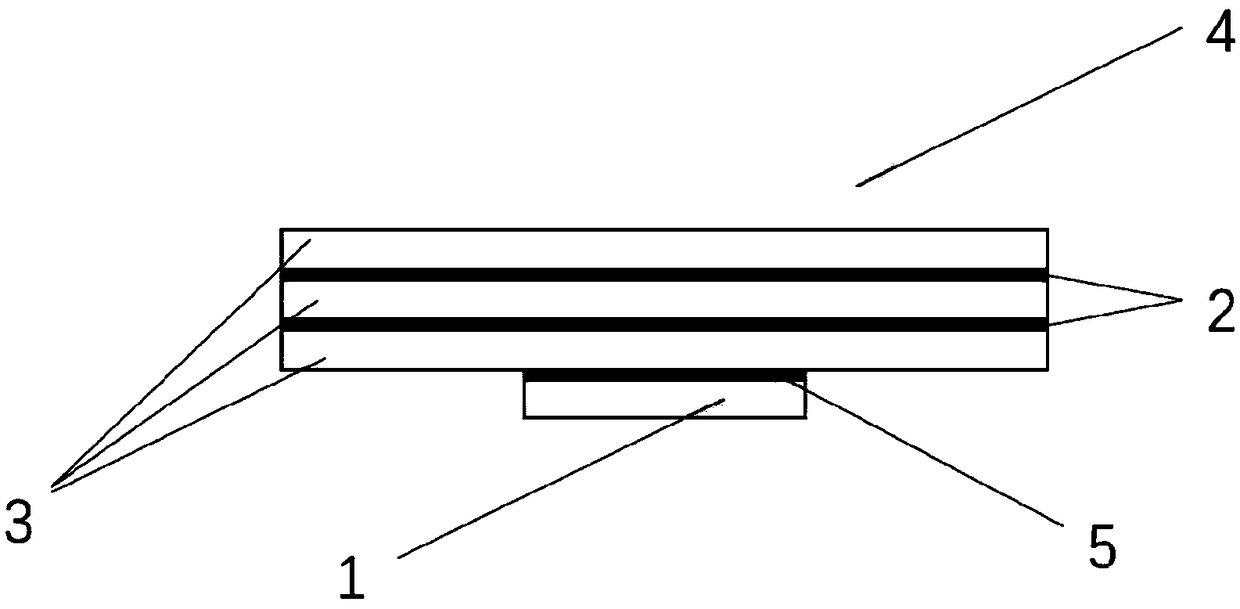

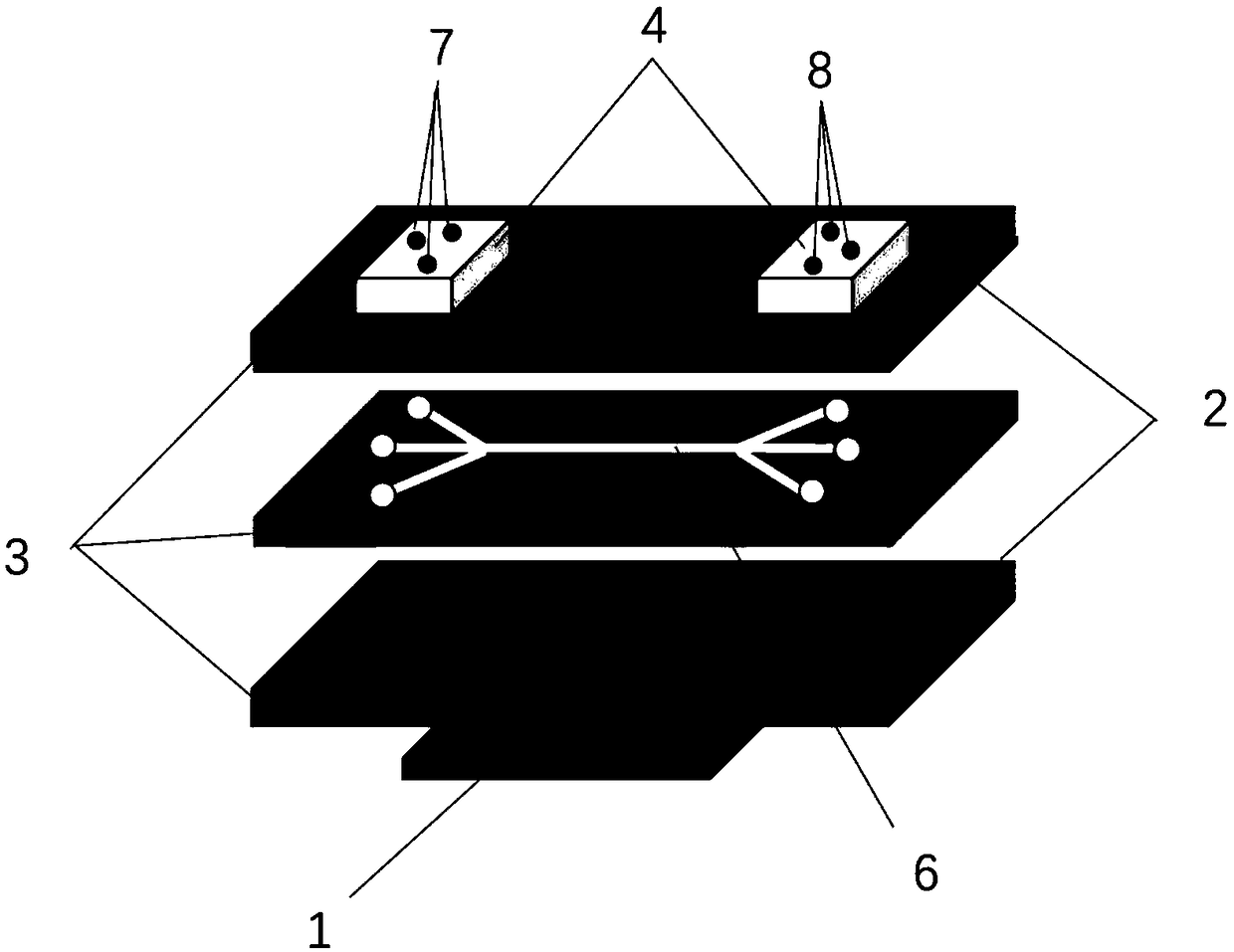

[0041] Fabrication of fully transparent microfluidic volume wave chip

[0042] The preparation steps are as follows:

[0043] 1) Cutting three glass sheets 3 with the same size and a thickness of 300-500 microns, the upper glass sheet is opened with a sample inlet 7 and a sample outlet 8 for fluid inlet and outlet, and the number of inlet and outlet samples is 3; The middle glass sheet is cut with a micron-level channel 6 through the glass cut by laser, and the three sample inlets 7 are converged to the central channel and then divided into three sample outlets 8; the lower glass sheet is complete glass for packaging chamber;

[0044] 2) Evenly spin-coat the UV-curable epoxy resin layer 2 on the uppermost and lowermost glass surfaces through a glue leveler, and then paste them on the two sides of the middle glass respectively to ensure that the hole positions of the inlet and outlet of the upper glass and the middle glass are aligned , bonded by ultraviolet light irradiation...

Embodiment 2

[0050] The application effect contrast of embodiment 1 and comparative example 1

[0051] attached image 3 It is the application effect diagram of Comparative Example 1. Depend on image 3 It can be seen that the 15 μm polystyrene microspheres are obviously gathered into two lines in the channel, which can achieve the effect of particle aggregation and manipulation.

[0052] attached Figure 4It is the application effect diagram of embodiment 1. In the figure, the 15 μm silica microspheres are brought together in the channel to the two parallel lines in the middle area under the action of the sound field.

[0053] From attached image 3 And attached Figure 4 It can be seen that the chip prepared by the present invention has the same effect as the prior art product in actual use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com