Solar battery with structure of oxide-metal multilayer film/silicon substrate

A technology for solar cells and oxide films, applied in the field of solar cells, can solve the problems of expensive equipment, high-risk chemicals in raw materials, etc., and achieve the effects of fewer manufacturing processes, reduction of Auger recombination and dead layers, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

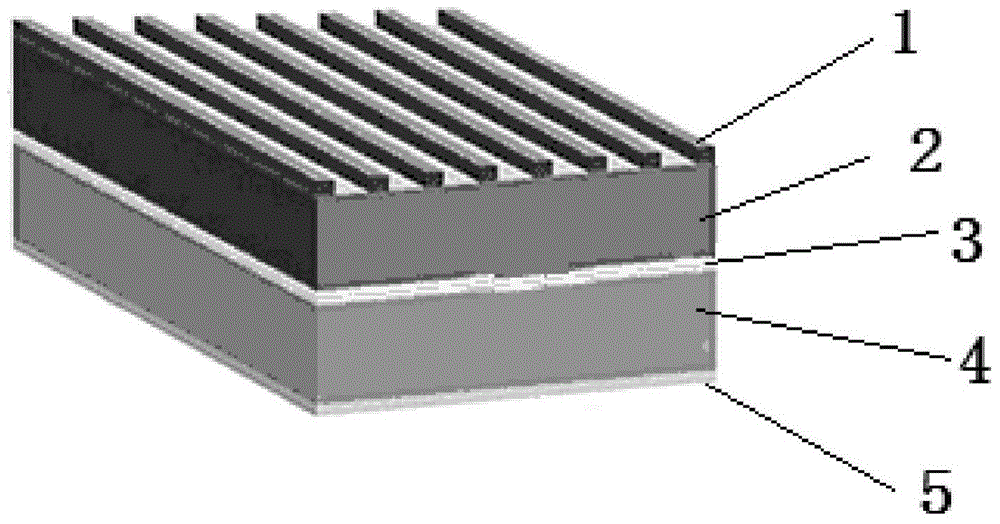

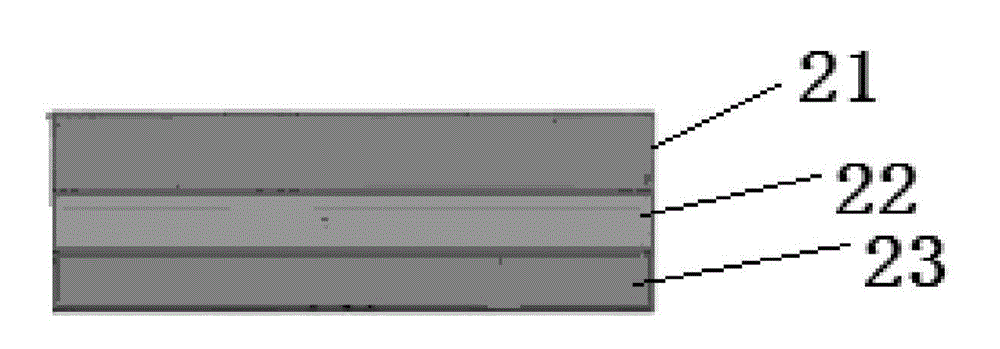

[0038] Such as figure 1As shown in , the structure provided in this embodiment is an oxide-metal multilayer film / silicon-based solar cell, and the structure of the solar cell includes from top to bottom: silver electrode 1, oxide-metal multilayer film 2, passivation layer 3, a silicon substrate 4 and an all-aluminum back electrode 5, the oxide-metal multilayer film 2 is composed of a first oxide film 21, a metal film 22 and a second oxide film 23, wherein the first oxide film 21 and the second oxide film 23 is MoO 3 film, the metal film 22 is an Ag film, and the passivation layer 3 is SiO 2 passivation layer.

[0039] Wherein the thickness of the first oxide film is 10-20 nm, the thickness of the metal film is 2-15 nm, and the thickness of the second oxide film is 30-50 nm.

[0040] The above structure is an oxide-metal multilayer film / silicon-based solar cell, which is prepared by the following method:

[0041] (1) Clean the n-type or p-type single crystal silicon wafer w...

Embodiment 2

[0048] The structure provided in this embodiment is an oxide-metal multilayer film / silicon-based solar cell. The difference from Embodiment 1 is that the passivation layer 3 is Al 2 o 3 passivation layer.

[0049] The above structure is an oxide-metal multilayer film / silicon-based solar cell, which is prepared by the following method:

[0050] (1) Clean the n-type or p-type single crystal silicon wafer with the RCA process, and then use atomic layer deposition (ALD) technology to deposit a layer of Al on the surface of the silicon wafer 2 o 3 Passivation layer, set the deposition temperature to 200°C, Al(TMA), N 2 、H 2 The pulse time of O is: 0.1s, 10s and 0.1s respectively, the flow rate is respectively: 150sccm, 150sccm and 200sccm, and 10-30 cycles are performed to deposit 1-3nm aluminum oxide on the surface of the silicon wafer;

[0051] (2) Then MoO is prepared on the surface of the passivation layer by a resistive thermal evaporation coating machine 3 Thin film, va...

Embodiment 3

[0056] The structure provided in this embodiment is an oxide-metal multilayer film / silicon-based solar cell. The difference from Embodiment 1 is that the passivation layer 3 is TiO 2 passivation layer.

[0057] The above structure is an oxide-metal multilayer film / silicon-based solar cell, which is prepared by the following method:

[0058] (1) Clean the n-type or p-type single crystal silicon wafer with the RCA process, and then use atomic layer deposition (ALD) technology to deposit a layer of TiO on the surface of the silicon wafer 2 Passivation layer, set the deposition temperature to 200-300°C, TiCl 4 , N 2 、H 2 The pulse time of O is: 1s, 3s and 1s respectively, the flow rate is respectively: 150sccm, 150sccm and 200sccm, carry out 10-30 cycles, and deposit 1-3nm titanium dioxide on the surface of the silicon wafer;

[0059] (2) Then MoO is prepared on the surface of the passivation layer by a resistive thermal evaporation coating machine 3 Thin film, vacuum degree ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com